Page 1

Installation Instructions

Residential Reverse Osmosis System

Model FMRO5-MT-AG

Page 2

Installation Instructions

Residential Reverse Osmosis

Drinking Water System

Your Reverse Osmosis System has been tested to

ensure it will operate correctly. The following

periodic maintenance is recommended so your

system will provide years of trouble-free service:

Replacement parts Replacement

Pre-filter (sediment) Every 6 mos.

Pre-filters (activated carbon) Every 6 mos.

R/O membrane Every 2-3 years

Post filter (carbon) Every 6 mos.

Components

Thefollowing components make up your Reverse

Osmosis DrinkingWaterSystem:

Pre-filter (sediment) removes larger particles such

as sand, silt, rust and scale.

Pre-filters (activated carbon) remove chlorine in the

feed water to protect the reverse osmosis

membrane.

Reverse Osmosis Membrane reduces dissolved

minerals, metals and salts. During the process,

harmful compounds are separated by the

membrane and the reject water goes to waste

(drain).

Filter housings and R/O module hold pre-filters

and membranes. A bracket is provided so they

maybemounted, typically below sink.

Storage tank holds filtered water, ready for use.

Automatic shut-off valve senses when the

storage tank is full and closes the water supply to

conserve water.

The dedicated faucet is used to dispense RO

produced water when needed.

Feed water saddle valve is connected to the cold

water line to supply water to the R/O system.

Waste water saddle valve is connected to the

drain to remove reject water from the R/O system.

Tubing supplies feed and reject water.

Fittings are used for necessary hose connections.

Tools

The following tools may be necessary, depending

on each particular installation:

Center punch and hammer

Concrete drill bits

Phillips head and flat blade screwdrivers

Adjustable wrench

Crescent wrench

Teflon tape

Plastic tube cutter

Air pressure gauge (low pressure)

Air pump (hand)

System location

Your R/O system may be installed under a sink, in a

basement or other location, depending on available

space. Do not install unit where temperatures fall

below freezing; otherwise, damage will result.

Connection to an icemaker should also be

considered for optimum performance.

Guidelines for component placement are as follows:

Faucet should be placed near the sink where

drinking / cooking

water is normally required. A 2"

flat surface is required to mount the faucet if an

existing hole for a second faucet is not available.

The thickness of the mounting thickness should not

exceed 1-1/4".

Storage tank may be placed where it is convenient,

within ten feet of the faucet. Under the sink or in a

nearby cabinet are excellent choices. If tank is

located further than 10 feet from the faucet, use 1/2"

tubing to reduce pressure drop. Full tanks may

weight more than thirty pounds, so a sturdy shelf is

required.

R/O unit may be mounted on either side of the sink,

in a cabinet or heated basement, with nearby

access to a potable, cold water line.

Feed water connection is accomplished with a

self-piercing feed water saddle valve. Locate this

assembly as close to the R/O unit as possible.

Connect to a potable, cold water supply line only.

Note: Softened water is preferred since it will

extend the life of your R/O membrane.

Drain connection is accomplished using a waste

water saddle valve which is designed to fit around a

standard 1-

1/2" OD drain pipe. The drain saddle

valve should always be installed above (before) the

tap and on the vertical or horizontal tailpiece.

An activated carbon post-filter is provided for a

final "polish" and to remove foul tastes, odors and to

provide great tasting drinking water.

3/8" variable speed electric drill, 1/8" & 1/2" bits

1-1/4" porcelain hole cutter (if hole for second

faucet is not provided

1-1/4" wood bit

Page 3

Page 4

3

Procedures:

A. Center punch small indent for hole.

B. Drill the required pilot hole.

C. Set-up the chassis punch per instructions and

tighten nut to cut the desired hole size.

D. Clean up sharp edges with file.

2. Mounting the faucet

Disassemble hardware from the threaded nipple,

except for chrome base plates and rubber washers.

(Rubber washers may be replaced with bead of

plumber's putty for neater appearance.)

Feed the threaded nipple through sink or counter

mounting hole and orient the faucet. From below

sink or counter, assemble the white spacer flat

washer and hex nut on threaded nipple and tighten

by hand. (Open end up; open side toward air gap).

After checking faucet orientation, tighten with a

wrench until secure.

3. Feed water valve and tubing installation

Thesaddle tapping valve which is supplied is

designed for use with 3/8" to 1/2" OD soft copper

supply tubing (plain or chromed) and rigid metal

pipe. Do not use with flexible ribbed supply tubing

which is too thin and requires special hardware.

Self-tapping feed water saddle valve installation

Installation procedures using soft copper tubing:

1. Turn off cold water valve from under sink or

main water line valve for whole house.

2. Before installing saddle tapping valve, make

sure piercing lance does not protrude beyond

rubber gasket.

3. Assemble saddle valve on copper tubing.

4. Turn handle clockwise to pierce soft copper

tube until valve is firmly seated. (Valve is

closed in this position.)

5. Turn on water supply to pressure cold water

line.

6. Snug nut/seal with wrench around valve stem.

7. Connect tubing to feed water valve using brass

compression nut,insert and plastic sleeve.

Saddle valve installations with metal pipe:

1. Turn off cold water supply.

2. Drill 3/16" hole at desired location.

3. At this point, make sure piercing lance does not

protrude beyond rubber gasket.

4. Assemble saddle on to pipe, aligning with hole.

5. Turn saddle valve handle clockwise to close

valve.

6. Tighten nut/seal around valve stem with

wrench.

7. Connect tubing to feed water valve using brass

compression nut,insert and plastic sleeve.

8. Turn on cold water supply.

9. To open valve, turn handle counterclockwise

and check for leaks.

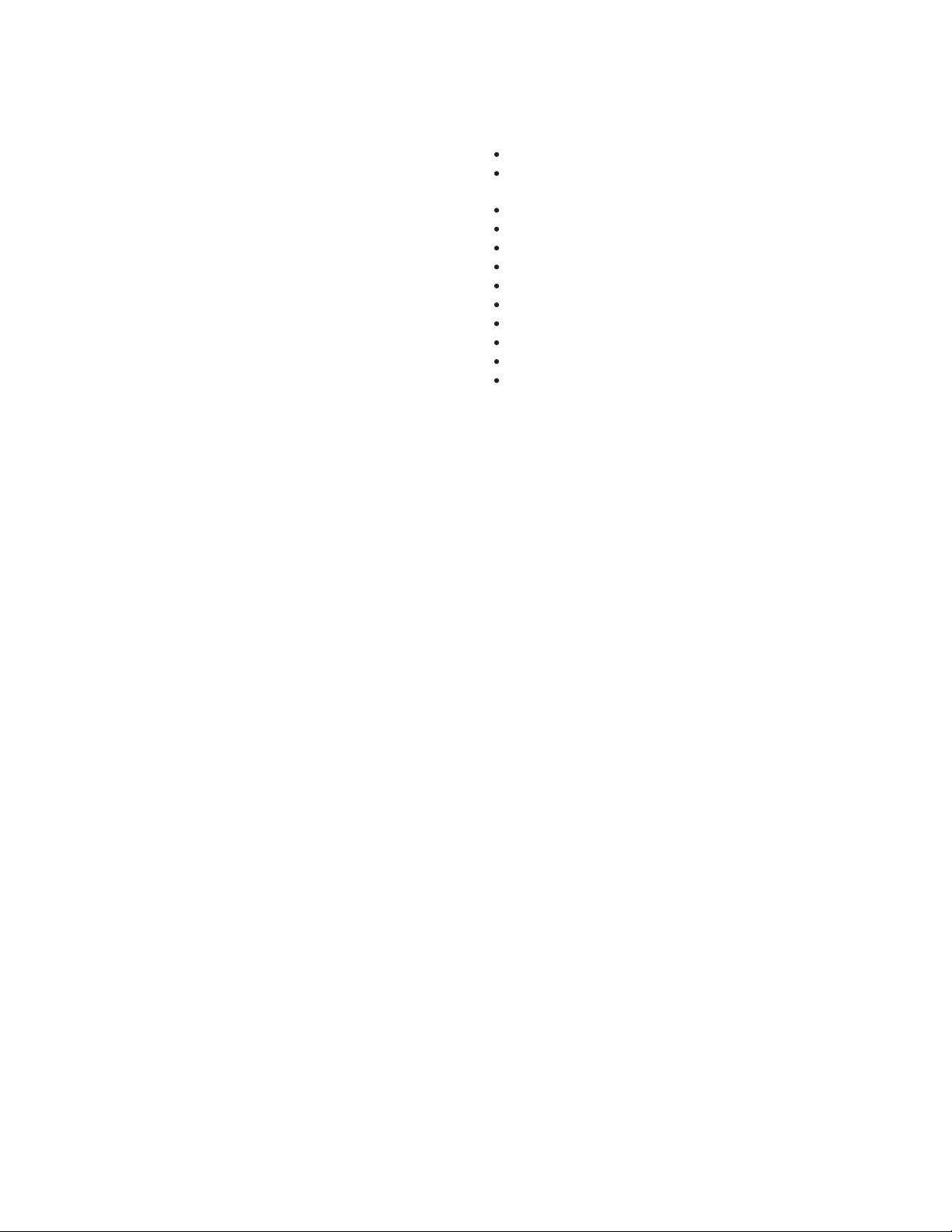

4. Drain saddle valve installation

Prior to proceeding it is important to inspect the

condition of drain pipes to make sure they are not

thin and frail.

Drain saddle valves are designed to be installed on

standard 1-1/2" OD drain pipe. Install drain saddle

valve above (and before) the trap and on the

vertical or horizontal tailpiece. Never install a drain

saddle valve close to the outlet of a garbage

disposal or plugging of the RO drain line may result.

Drain saddle valve installation

Procedures

1. Position threaded half of drain saddle valve at

selected location and mark for the opening.

2. Drill 1/4" hole at mark through one side of pipe.

3. Position both halves of drain saddle on drain

pipe so threaded opening lines with hole.

4. Secure drain saddle clamp on valve with bolts

and nuts provided. (Do not over tighten and

make sure there isequal space between saddle

halves on each side.)

Valve handle

Reversible

backplate

Tightening

screw

Tubing to

RO inlet

Compression

nut

Brass

insert

Plastic ferrule

Brass

insert

1/4" Screw 1/4" Nut

Drain pipe

1/4" Drilled hole

Drain clamp

front plate

Page 5

4

5. Initial tubing connections

Forconvenience on under counter installations it

maybeadvisable to complete under counter hose

connections at this time.

6. RO component installation

Install RO membrane, carbon pre filer and sediment

pre filter in modules of RO unit. (Refer to RO

installation diagram.)

7. RO unit installation

The RO unit is normally mounted to the right or left

sink cabinet sidewall, depending on where supply

tank is to be located. Generally the unit is installed

at the front of the cabinet and the tank at the rear.

To mount the unit, elevate it at least 2" off the floor,

level it and mark the location of mounting holes

needed. Drill holes for mounting screws and install

screws, allowing the mounting bracket slots to slip

over them.

Note: If the cabinet sidewalls are not solid, unit

maysit on the floor with screws to keep it against

the cabinet in a vertical position.

8. Pre-fill, sanitizing and supply tank placement

Prefilling the storage tank is always recommended

so there is sufficient pressure to check for leaks and

sufficient water to flush the carbon post filter.

It is important to use a sanitizer (such as Clorox) so

tubing, fittings, tank and the faucet will be safe to

use upon start-up.

To pre-fill storage tank follow these directions:

1. Connect storage tank to feed water line.

2. Open feed water valve and valve on tank.

3. Allow to fill for approximately three minutes.

4. Turn off feed water valve and tank valve.

5. Do not flush tank for approximately 15 minutes.

Thesupply tank should be placed under the counter

or within 10 feet of the RO unit.

Note: Tanks are pre-pressurized at 7 psi. Prior to

installation, check, add or release as required.

9. Final tubingconnections

With all components in place, complete final tubing

connections using these guidelines:

Tubing should follow contour of the cabinets.

Cut tubing to desired length using square cuts

and proper cutting devise.

Make no sharp bends.

Keep tubing from the RO unit to the tank and

faucet as short as practical for good flow.

Under sink installations following installation

diagram and the following procedures:

1. Connect tubing from faucet to RO unit.

2. Connect tubing from tank to RO unit.

3. Connect tubing from supply valve to RO unit.

4. Connect tubing from drain valve to RO unit.

Icemaker hookup (optional)

The RO drinking water device can be connected to

any standard refrigerator ice maker or ice maker /

water dispenser. (Do not connect to a commercial

type bar ice maker.)

To complete this operation, connect a tee with shutoff valve into the faucet tubing and route tubing to

the refrigerator. (Hooking up to an existing copper

line is not recommended unless it is new

installation.) Shut off ice maker by lifting lever prior

to turning off the existing tap water supply line to

the refrigerator. Turn on ice maker after the RO

system has been drained several times and the

tank has a full supply of water.

Note: Before any service is preformed on the RO

system, turn off ice maker valve and ice maker unit.

Turn back only after RO tank is full.

System start-up

Prior to start-up

1. Check all connections be sure they are secure.

2. Turn on feed water valve and check for leaks.

(Turn off and correct leaks if leaks occur.)

3. Open valve on storage tank and open faucet

until a steady stream of water flows.

4. Close faucet and wait five minutes to see if

leaks result.

Note: When the system is first turned on, water

may intermittently"spurt" from the air gap opening

on the side of air gap faucets. This is common and

should correct itself after an initial period of time.

Flushing system and checking operation

To make sure RO system is operating correctly,

following these simple procedures:

1. Open faucet handle and allow tank to

completely drain of sanitizing solution.

Do not use this water.

Page 6

5

Note: When tank is empty, faucet will steadily

drip. This is the rate the RO system processes

water.

2. With faucet handle in "open" position, measure

the rate of the steady drip from spout. Use a

graduated cylinder and watch with a second

hand to calculate approximate production in

gallons per day.

Note:

Milliliters per minute X 0.38 = GPD.

Ounces per minute X 11.2 = GPD

3. Proceed to check reject flow rate by

disconnecting tubing at drain connection and

measure flow as described above.

Note: Proper ratio should be 3 reject water to

1 part of product water, on average.

4. Close faucet and re-inspect system for leaks.

5. Allow system to process water for

approximately four hours, at which point tank

will be practically full.

6. Open faucet again and allow tank to empty for a

second time.

Do not use this water.

7. Wait another four hours to allow tank to re-fill.

Note: If no objectionable tastes are noticed after

second tank draining, RO processed water is ready

for use. Otherwise, drain tank and re-fill for a third

time.

8. At this point supply line to ice maker connection

(optional) may be opened.

Maintenance

Your RO system contains filters and membranes

which must be replaced periodically for proper

operation. (Please see page 1 for general changeout recommendations.)

Note: Change-out procedures may be amended,

depending on source water conditions.

To change filters and membranes follow these

procedures:

1. Close feed water valve by turning it clockwise.

2. Open faucet to allow holding tank to drain.

3. Loosen and remove filter housings using

wrench provided and discard cartridges and or

membrane.

4. Wash the inside of the housings using mild

detergent and soft cloth. Thoroughly rinse all

soap before reassembly.

5. Replace filter cartridges and membrane before

sanitizing system.

Note: The system should besanitized before

installing the activated carbon post filter cartridge.

Sanitizing instructions

To sanitize system follow these procedures with the

feed watervalveclosed:

1. Remove pre-filters and membrane from

housings.

2. Use 5-1/4% unscented bleach such as Clorox.

3. Add one cap full (2 tsp or 10 ml) of bleach to

each pre-filter housing and membrane module.

4. Carefully refill housings with tap water and

temporarily replace without carbon cartridge,

sediment cartridge or membrane installed.

5. Slowly open the feed water line at faucet.

6. Close faucet as soon as water begins to drip

out of spout.

7. Let system stand for approximately 15 minutes.

8. After fifteen minutes do the following in order:

Close feed water valve.

Close holding tank valve while faucet is

open to release pressure.

9. Remove housings and empty them.

10. Remove any protective wrap from pre-filters

and membrane and install them in the

appropriate filter housings. Tighten with wrench.

11. Replace post carbon filter if necessary.

Note:

Be sure to check o-rings are in place when

installing cartridges in filter housings.

12. Disconnect product water tubing from the

holding tank and put 50 drops of bleach into the

tubing. Reconnect tubing.

13. Slowly open feed water saddle valve. When

water begins to drip from faucet, close faucet

and open holding tank valve.

14. Do not open faucet for at least eight (8) hours.

15. Discard the first two tanks of water produced,

as they contain chlorine. Do not use this

water.

16. When faucet is first opened, air and black

carbon powder may be noticed. This is normal.

Page 7

6

Water quality

Water quality from an RO system is normally

determined with a TDS Meter,

which measures total

dissolved solids in water, measuring conductivity.

The results are normally m eas ured in parts per

million or milligrams per liter. Fewer dissolved

solids results in higher quality water.

RO membranes are rated by the amount of

dissolved solids they reject, expressed as "rejection"

percentage". For example if feed water contains

100 ppm of dissolved solids and the product water

after th e membrane has 10 ppm

of dissolved solids

the rejection r ate is 90%. The formula is as f ollows:

Perc ent rejecti o n =

Feed water TDS– Product water TDS X 100%

Feed water TDS

Water production

Product water rate

Usable water producti on f rom an RO syste m is

designated product water rate, produced on a daily

basis. The rate is normally described in gallons per

day (gpd) or milliliters per minute (ml/min.).

Reject water rate

The flow of water to drain is designated as reject

water rate, as measured in gallons per day (gpd) or

milliliters per minute (ml/min.).

Using a graduated cylinder the formulas are:

Milliliters per minute X 0.38 = gallons per day

Ounces per minute X 11.2 =gallonsper day

Reject ratio

The reject ratio is the amount of water produced

compared to th e amount of water flowing to drain.

The form ula is as f ollows:

Rejec t rate

Rejec t rati o =

Pro duct rate

Percent recovery

The percent recovery is another way to m eas ure

the amount of water produced c ompared to the

amount of water which is actually used.

Theformula to determined percent recovery is as

follows:

Product water r ate X 100%

Perc ent recovery =

Feed water r ate

Note: Produc t water rate is th e sum of the f eed

water flow rate and reject water flow rate.

Exam ple:

Pro duct water rate =10 gpd

Rejec t water rate = 40 gpd

Feed water = 10 gp d + 40 gpdor50gpd

Perc ent recovery = 20%

Water pressure and temperature

Pro duct water quality and production of RO

systems is dependent on pressure and

tem peratu r e. Typically, RO mem branes are treated

at standard conditions of 77˚ F (25˚ C) and 60 ps i

(4 bar) discharging to atmosphere. In general, th e

higher the pressure differential and temperature,

increased quality and quantity of water is produced.

These facto rs sho uld be cons idered when sizing

RO systems for a particular application.

John Guest

®

brand fittings

Many RO systems utilize John Guest b rand fitt ings.

These user - friendly fittings provide superior

performance and may be provided with this system.

Pro per use of

these push-in fittings is shown below

Along with these fittings, all tubing selected must be

of high quality and must be cut with a plastic tube

cutter or sharp razor with a clean, square cut.

Should a leak occ ur at a fitting, the cause is

generally defective tubing. T

o fix a leak, relieve

pressure, release tubing, cut off at least 1/4" from

the end (square cut), reattach the tubing and

confirm the connection is leak free. Each time a

new connection is made, it is advisable to cut off

1/4" from th e end of th e tu bin g

using these fittings.

Conventional compression fittings

If John Guest f itt ings are not used, it is essential to

install inserts at th e ends of all tube connections

when conventional fittings are used.

To attach Tubing

Cut the tube square and push into the tube stop. For

metal tube, remove burrs and chamfer tube end to

prevent the "O" ring seal from being damaged. For soft

or thin walled plastic tubing we recommend the use

of a tube insert.

Pull the tube to check that it is secure. It is good

pratice to check the system before use.

Page 8

Loading...

Loading...