Page 1

For Residential and Commercial Applications

ES-FBV-4

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

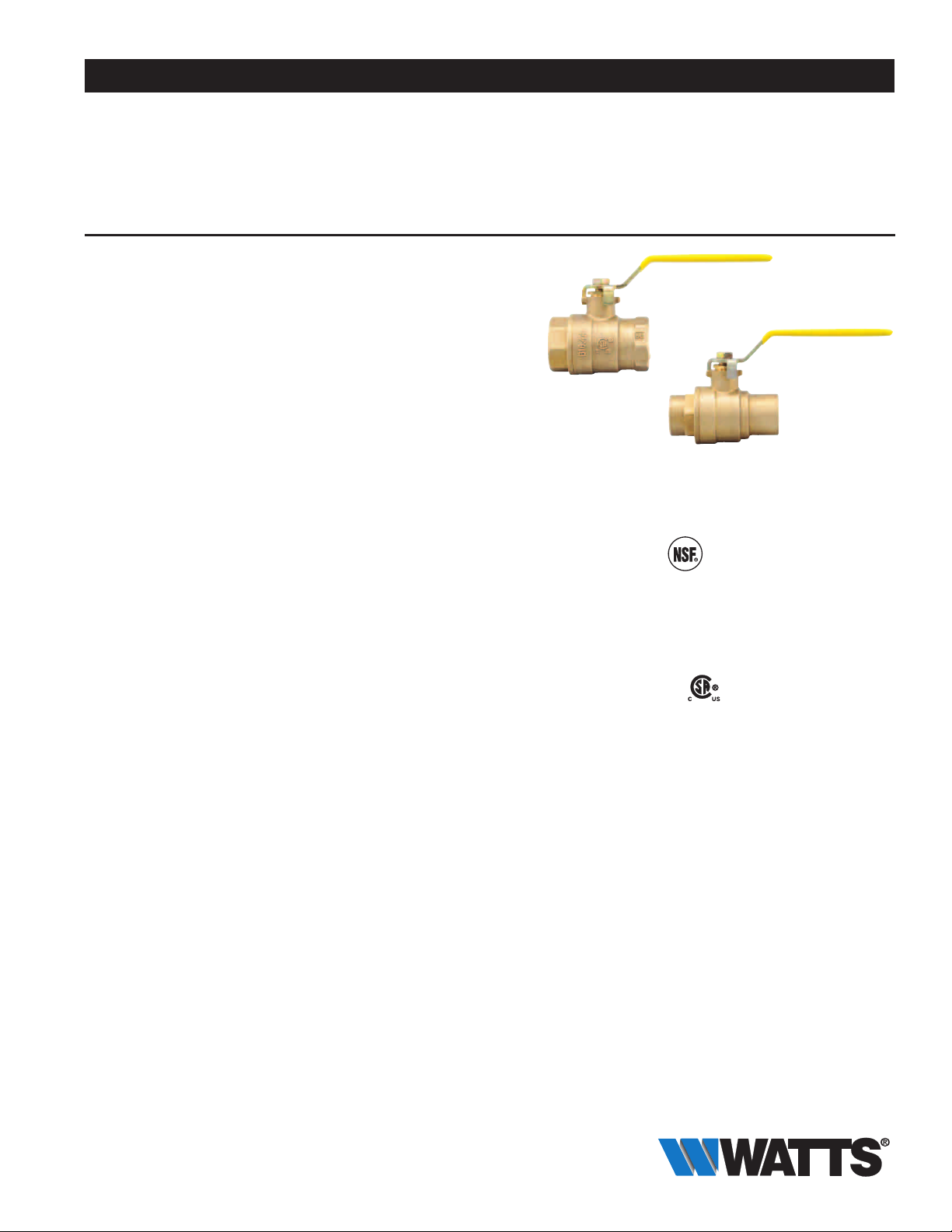

Series FBV-4, FBVS-4

2-Piece, Full Port,

Brass Ball Valves

Sizes: 1⁄4" – 3" (8 – 80mm)

Series FBV-4, FBVS-4 2-Piece, Full Port, Brass Ball Valves are

suitable for a full range of liquids and gases in residential and

commercial applications.

These valves feature an adjustable packing for longer service life,

a bottom loaded blow-out proof stem for safety, a fluorocarbon

elastomer stem O-ring to prevent stem leaking at installation,

and are rated to 600psi WOG/150psi WSP

and 400psi WOG/125psi WSP 2

1

⁄2"– 3" (65–80mm).

Features

• CSA approved threaded valves only ¼" – 3"

• Certified to NSF/ANSI Standard 61/8

• Metal-to-metal adapter body seal to eliminate adapter leaks

after soldering

• Fluorocarbon elastomer stem O-ring prevents stem leaks

• Adjustable stem packing gland provides longer service life

• Bottom loaded blowout proof stem

• PTFE stem packing seal and seats

• Machined chrome-plated brass ball

• Complies with MSS-SP-110

1

⁄4"– 2" (8 – 50mm)

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

FBV-4

Approvals

¼" – 3" FBV-4

½" – 3" FBVS-4

Certified to NSF/ANSI Standard 61/8

Domestic cold water at 73°F

Gas Approvals (Threaded Valves Only)

¼" – 3"

CSA

½ psig, 5 psig

@ -40°F to 125°F

FBVS-4*

Models

FBV-4 1⁄4" – 3" (8 – 80mm) threaded end connections

FBVS-4

1

⁄2" – 3" (15 – 80mm) solder end connections*

Specifications

Approved valves shall be 2-piece full port design constructed of

a forged brass body and end adapter. Seats and stem pack-

ing shall be PTFE. Stem to be bottom-loaded, blowout proof

design with a fluorocarbon elastomer O-ring to prevent stem

leakage.

Valves required to have an adjustable packing gland and

chrome-plated brass ball. Threaded valves ½" – 3" shall be

CSA approved to ½ psig and 5 psig and certified to NSF/ANSI

Standard 61/8 by NSF. Solder valves also required to be certified by NSF to NSF/ANSI Standard 61/8. Valve sizes ¼" – 2"

pressure rated to 600 psi WOG and 150 psi WSP. Valve sizes

2 ½" – 3" pressure rated to 400 psi WOG and 125 WSP.

Valves specified are Watts Series FBV-4 or FBVS-4.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Pressure — Temperature

Temperature Range: -40ºF to 400ºF (-40ºC to 204ºC)

Pressure Rating:

2

1

⁄4"– 2" (8 – 50mm)

600psi (41.4 bar) WOG non-shock

150psi (10.3 bar) WSP

1

⁄2"– 3" (65 – 80mm)

400psi (27.6 bar) WOG non-shock

125psi (8.6 bar) WSP

Installation Information

Apply heat with the flame directed AWAY from the center of the

valve body. Excessive heat can harm the seats. After soldering,

the packing nut may have to be tightened.

*This valve is designed to be soft soldered into lines without disassembly, using a low temperature solder to 420°F (216°C). Higher

temperature solders may damage the seat material.

Page 2

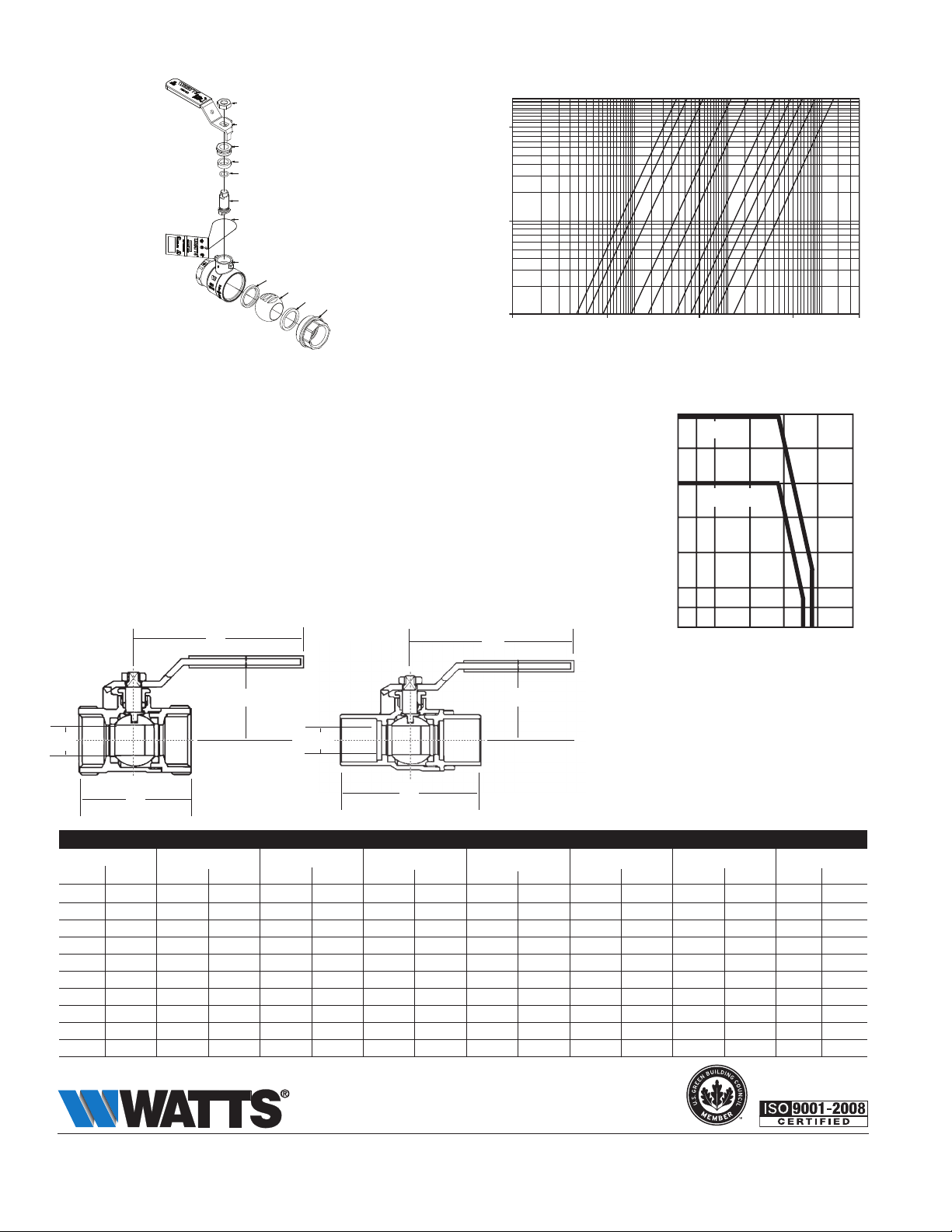

Materials

Flow Curves

1

A

A

B

B

C

C

D

D

E

E

G

G

H

H

I

I

J

J

K

K

J

J

L

L

20

10

1

Differential Pressure (psig)

.1

2 2 4 5 6 7 8 9 20 30 50 80 200 400 600 800 2000

1 10 100 1000 5000

⁄4” 3⁄8” 1⁄2” 3⁄4” 1” 11⁄4” 11⁄2 “ 2” 21⁄2” 3”

Flow (gpm)

A. Handle Nut Zinc plated carbon steel

B. Handle Assembly Zinc plated carbon steel

with vinyl insulator

C. Packing Nut Brass

D. Stem Packing Virgin PTFE

E. O-Ring Fluorocarbon elastomer (FKM)

G. Stem Machined Brass

H. Tag Cardboard, Mylar coated both

sides

I. Body Forged brass

J. Seats Virgin PTFE

K. Ball Chrome plated brass

L. Adaptor Forged brass

Dimensions-Weights

H

C

I

L

FBV-4

I

L1

Valve Seat Rating

H

C

FBVS-4

bar psi

41.3 600

34.5 500

27.6 400

20.7 300

Pressure

13.8 200

6.9 100

3.4 50

0 0

1

⁄4” – 2”

21⁄2” – 3”

50 100 200 300 400 500 °F

10 38 93 149 204 260 °C

Temperature

SIZE (DN) DIMENSIONS WEIGHT

C H

in. mm in. mm in. mm in. mm in. mm in. mm lbs. kg. lbs. kg..

1

⁄4 8 113⁄16 46 37⁄16 87 7⁄16 11 13⁄4 45 — — 0.4 0.16 — —

3

⁄8 10 113⁄16 46 37⁄16 87 1⁄2 13 13⁄4 44.7 — — 0.4 0.17 — —

1

⁄2 15 113⁄16 46 37⁄16 87 1⁄2 13 2 50 21⁄16 53 0.4 0.18 0.4 0.16

3

⁄4 20 21⁄16 53 315⁄16 101 11⁄16 18 21⁄4 57 25⁄8 67 0.6 0.27 0.5 0.24

1 25 2

1

1

⁄4 32 21⁄2 64 41⁄4 108 13⁄16 31 31⁄8 80 311⁄16 93 1.5 0.68 1.4 0.64

1

1

⁄2 40 3 76 55⁄16 135 17⁄16 37 37⁄16 88 43⁄16 107 2.3 1.06 2.1 0.95

2 50 3

1

2

⁄2 65 41⁄16 104 73⁄8 188 21⁄2 64 55⁄16 134 63⁄16 158 7.9 3.57 7.2 3.27

3 80 4

7

⁄16 62 41⁄4 108 15⁄16 24 213⁄16 71 34⁄16 83 1.1 0.49 1.0 0.44

1

⁄2 89 6 153 2 51 41⁄8 105 55⁄16 135 3.7 1.69 3.8 1.74

1

⁄2 114 73⁄4 197 3 76 61⁄8 155 71⁄4 184 11.8 5.37 11.0 4.99

A Watts Water Technologies Company

I

L L1 FBV-4 FBVS-4

USA: No. Andover, MA • Tel. (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Burlington, ON • (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

ES-FBV-4 1140 © 2011 Watts

Loading...

Loading...