Page 1

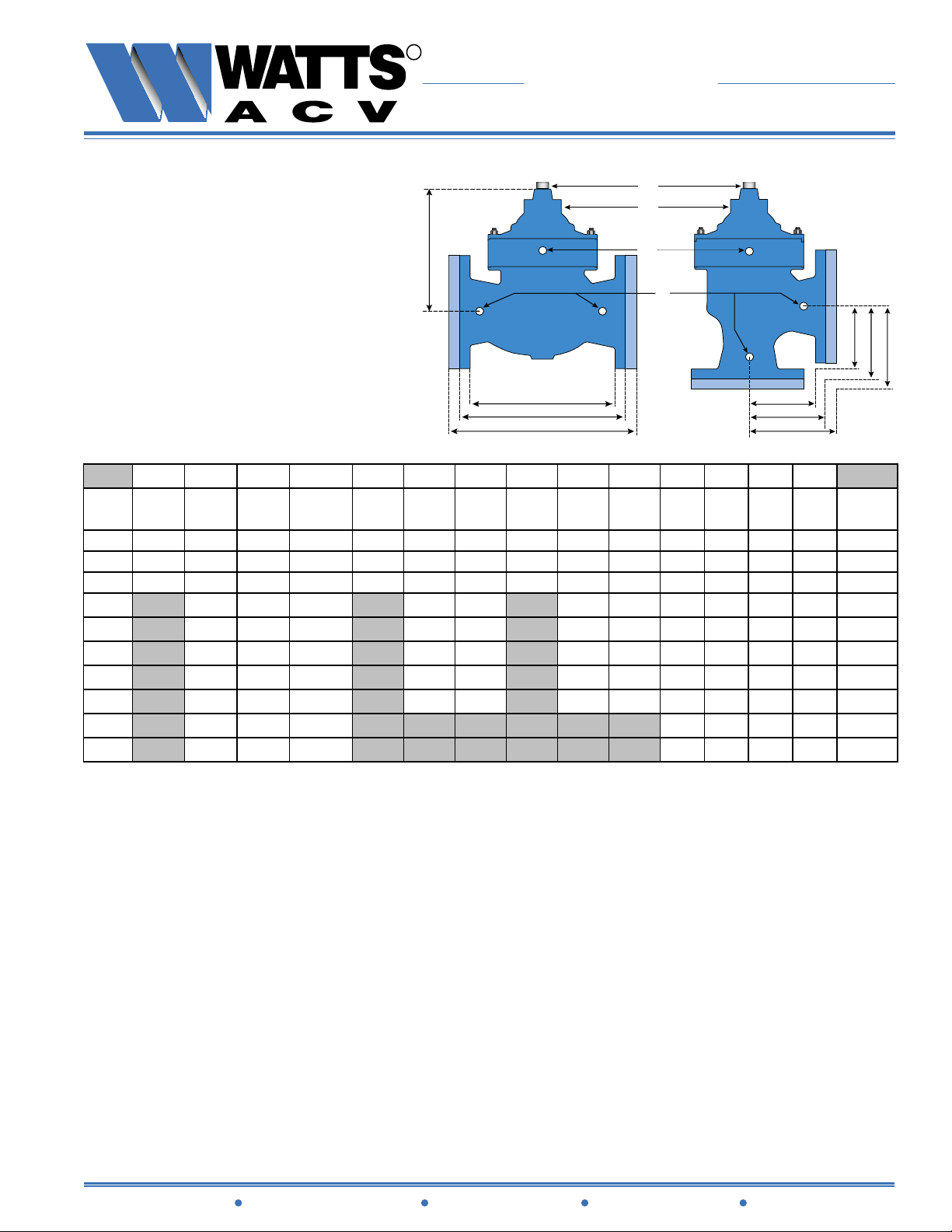

R

Classic Series

K

E

F

G

H

I

J

B

C

G

H

I

J

D

L

M

F500 (Globe)

F1500 (Angle)

1/05

Standard Materials

Standard Materials

Globe Angle

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion

Bonded Epoxy Lined

and Coated

Trim: 316 Stainless Steel (1-1/4” – 8”)

ASTM B62 Bronze (10” – 24”)

(Stainless Steel Optional)

Elastomers: Buna-N (standard)

EPDM (optional)

Viton (optional)

Stem, Nut & Stainless Steel

Spring:

Dimensions

A B C D E F G H I J K L M N

VALVE

Description

Description

GLOBE

SIZE

THRD.

2 9-3/8 9-3/8 10 6-3/8 4 4 4-1/4 4 4 4-1/4 1/2 1/2 1/4 1/4 40

2-1/2 11 11 11-5/8 8-1/2 5-1/2 5-1/2 5-13/16 4 4 4-5/16 1/2 1/2 3/8 1/4 70

3 10-1/2 12 13-1/4 8-3/4 5-1/4 5-3/4 6-1/8 5-1/4 5-3/4 6-1/8 1/2 1/2 3/8 1/4 105

4 15 15-5/8 10-1/4 6-3/4 7-1/8 6-3/4 7-1/8 1/2 1/2 3/8 1/4 230

6 20 21 14 8-1/2 8-7/8 8-1/2 8-7/8 1/2 1/2 1/2 1/2 375

8 25-3/8 26-3/8 19-1/2 11 11-1/2 11 11-1/2 1/2 1 1/2 3/4 800

10 29-3/4 31-1/8 22-1/2 14-7/8 15-5/8 14-7/8 15-5/8 1 1 1 3/4 1100

12 34 35-1/2 24-3/4 17 17-3/4 17 17-3/4 1 1 1 1 1720

14 39 40-1/2 26 1 1 1 1 2600

16 41-3/8 43-1/2 30-1/2 1 1 1 1 3300

GLOBE

150#

GLOBE

300#

COVER TO

CENTER

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

PORT

SIZE

PORT

SIZE

PORT

SIZE

PORT

SIZE

*Estimated in lbs.

SHIPPING

WEIGHTS*

The WATTS ACV Models F500 and F1500 are full port, dual chamber basic valves that incorporate a one-piece disc

and diaphragm assembly. This assembly is the only moving part within the valve, allowing it to open or close as

commanded by the pilot control system.

When pressure is applied to the upper diaphragm chamber and released from the lower diaphragm chamber, the valve

travels to a closed position. When pressure is applied to the lower diaphragm chamber and released from the upper

diaphragm chamber the valve travels to a full open position. When pressure is balanced between the upper and lower

diaphragm chambers, the valve will hold an intermediate position until commanded to modulate open or closed by the

pilot control system.

Model F500: Globe Pattern Dual Chamber Basic Valve

Model F1500: Angle Pattern Dual Chamber Basic Valve

Operating Pressure

Operating Pressure

Threaded = 400 psi / 150 Flanged=250 psi / 300 Flanged = 400 psi

Operating Temperature

Operating Temperature

Buna-N: 160°F Maximum

EPDM: 300°F Maximum

Viton: 250°F Maximum

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.wattsacv.com

Page 2

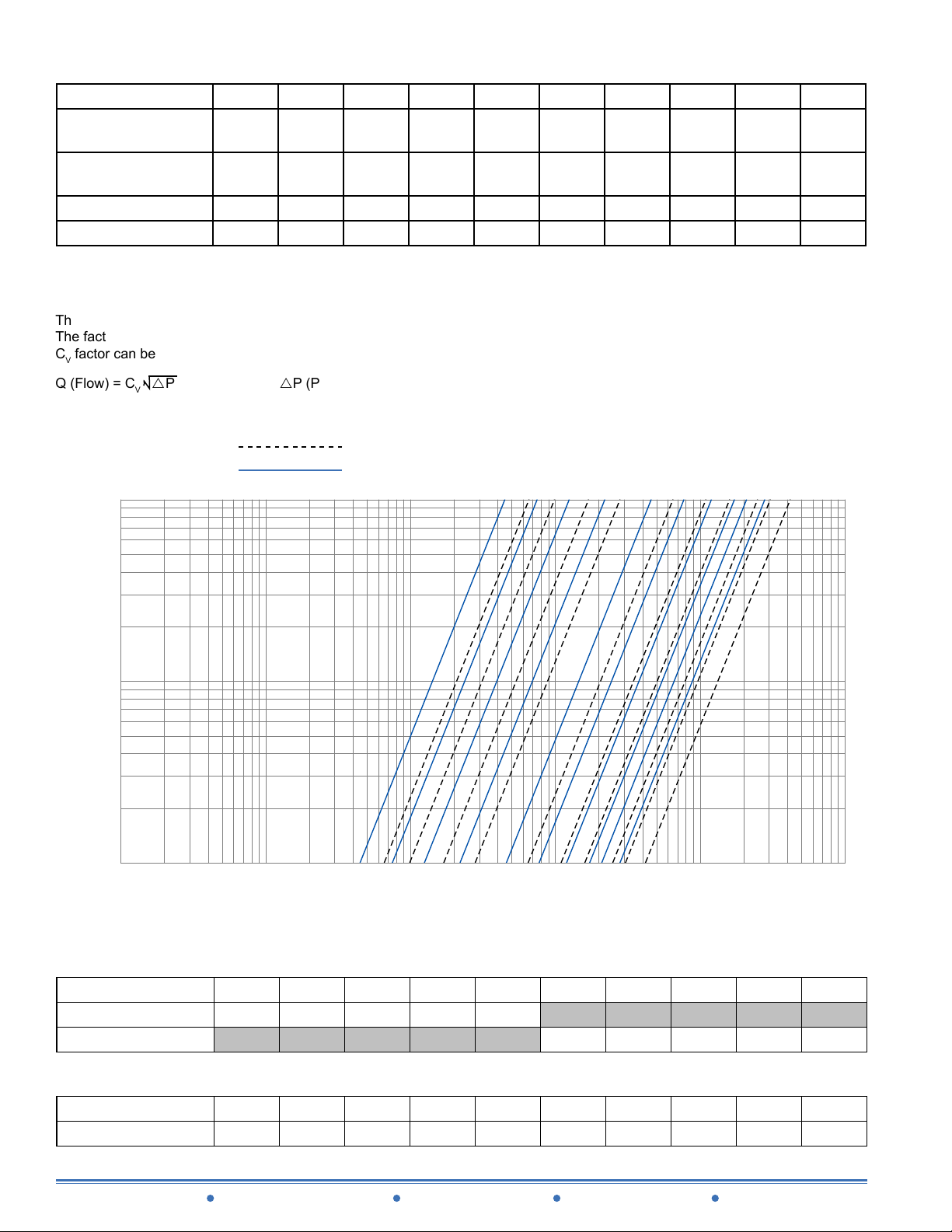

Maximum continuous flow based on velocity of 20 ft. per second.

Maximum intermittent flow based on velocity of 25 ft. per second.

The CV factor of a valve is the flow rate in US GPM at 60° F that will cause a 1 psi drop in pressure.

The factors stated are based upon a fully open valve.

CV factor can be used in the following equations to determine Flow (Q) and Pressure Drop (r P):

Q (Flow) = CV r P rP (Pressure Drop) = (Q/CV)

2

Flow Data - ACV F500 (Globe) / F1500 (Angle)

Valve Size - Inches 2 2-1/2 3 4 6 8 10 12 14 16

Maximum Continuous

Flow Rate Gpm (Water)

Maximum Intermittent

Flow Rate Gpm (Water)

208 300 460 800 1800 3100 4900 7000 8500 11000

260 370 570 1000 2300 3900 6000 8600 10500 14000

CV Factor GPM (Globe) 55 75 125 220 460 775 1200 1730 2100 2800

CV Factor GPM (Angle) 66 99 170 280 650 1100 1600 2500 3060 4210

Estimated

Headloss

100

80

60

Angle

Globe

2-1/2

2

2-1/2

2

3

4

3

4

6

8

6

8

10

12

10

14

12

16

14

16

40

30

20

10

8

6

Pressure Drop (p.s.i.)

4

3

2

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000

100,000

Flow Rate - Gallons per minute (Water)

Valve Cover Chamber Capacity

Valve Size (in) 2 2-1/2 3 4 6 8 10 12 14 16

fl.oz. 4 10 10 22 70

U.S. Gal 1-1/4 2-1/2 4 6-1/2 9-1/2

Valve Travel

Valve Size (in) 2 2-1/2 3 4 6 8 10 12 14 16

Travel (in) 1/2 5/8 3/4 1 1-1/2 2 2-1/2 3 3-1/2 4

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.wattsacv.com

Loading...

Loading...