Page 1

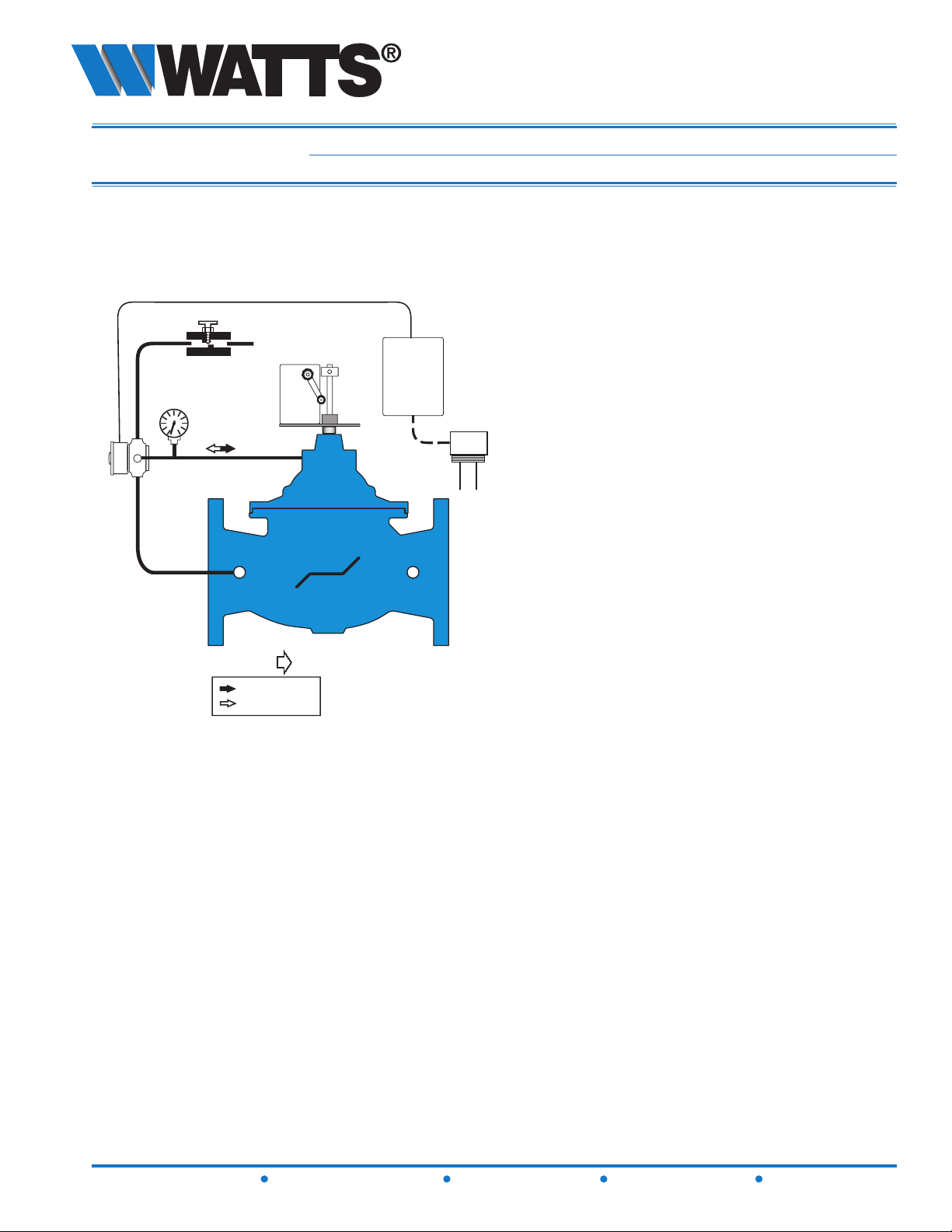

To Atmosphere

FLOOD PROTECTION SHUT DOWN VALVE

(3” and smaller)

01/10

ClassiC series

3

6

2

X

FC

FLOW

CLOSES VALVE

OPENS VALVE

To Floor

Drain

L

X

X

JB113

1

4

FS99

F113-12RFP (Globe)

F1113-12RFP (Angle)

• Installed upstream of Reduced Pressure Zone

Backow Preventer.

• Normally Open Valve - Closes when discharge from

RPZ Relief Valve is sensed or by engaging Solenoid

Manual Operator.

• Limit Switch provides local visual and remote

electrical indication of valve closure.

• Valve must be manually reset. Pressure gauge

(provided) indicates valve reset for automatic service

• Anti-Scale Coated Main Valve Stem for added

5

protection.

• Fail Safe operation - Valve closes upon Main Valve

or Pilot Diaphragm failure.

Standard Components

1 - Main Valve (Single Chamber)

2 - 3-Way Solenoid

3 - Manual Reset Ball Valve

Port 1 - Valve Cover

Port 2 - Pressure

Port 3 - Atmosphere

4 - JB113 Junction Box

5 - FS99 Flow Sensor

6 - Pressure Gauge

L - Limit Switch

X - Isolation Cocks

FC - Flo-Clean Strainer

Operations

The Watts Flood Protection Shutdown Valve system

prevents catastrophic property damage that can occur due to Relief Valve discharge and/or a blocked or

overwhelmed oor drain during normal relief valve operation. Typical conditions which can cause continuous

relief valve discharge are:

• Fouled First Check Seat due to dirt, debris or rocks

• Failed First Check Spring

• Clogged or blocked Relief Valve Sensing Line

• Relief Valve Diaphragm failure

The Watts 113-12RFP Flood Protection Shutdown

Valve is a normally open valve designed to be installed

upstream of a Reduced Pressure Zone (RPZ) Backow

Prevention device. It is normally open and closes driptight when continuous relief valve discharge through the

drain pipe is sensed by the FS99 Flow Sensor, energiz-

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

ing the Solenoid Pilot. The Solenoid Pilot is equipped

with a Manual Operator which simulates power when

manually engaged. The valve mounted JB113 Junction

Box is equipped with an adjustable time delay to avoid

valve closure due to intermittent or nuisance relief valve

discharge. The Limit Switch provides local visual and

remote electrical indication of valve closure. The valve

remains closed and cannot re-open if ow stops or electrical service is interrupted, and must be manually reset

after the RPZ is diagnosed and/or repaired.

The valve comes complete with the valve mounted JB113

Junction Box with adjustable time delay, pre-wired Solenoid Valve, Manual Reset with Pressure Gauge, Limit

Switch and FS99 Flow Sensor (eld installed). Fail-safe

operation is assured by closing valve upon Main Valve

or Pilot Diaphragm failure and a specially coated Main

Valve Stem for added protection.

Page 2

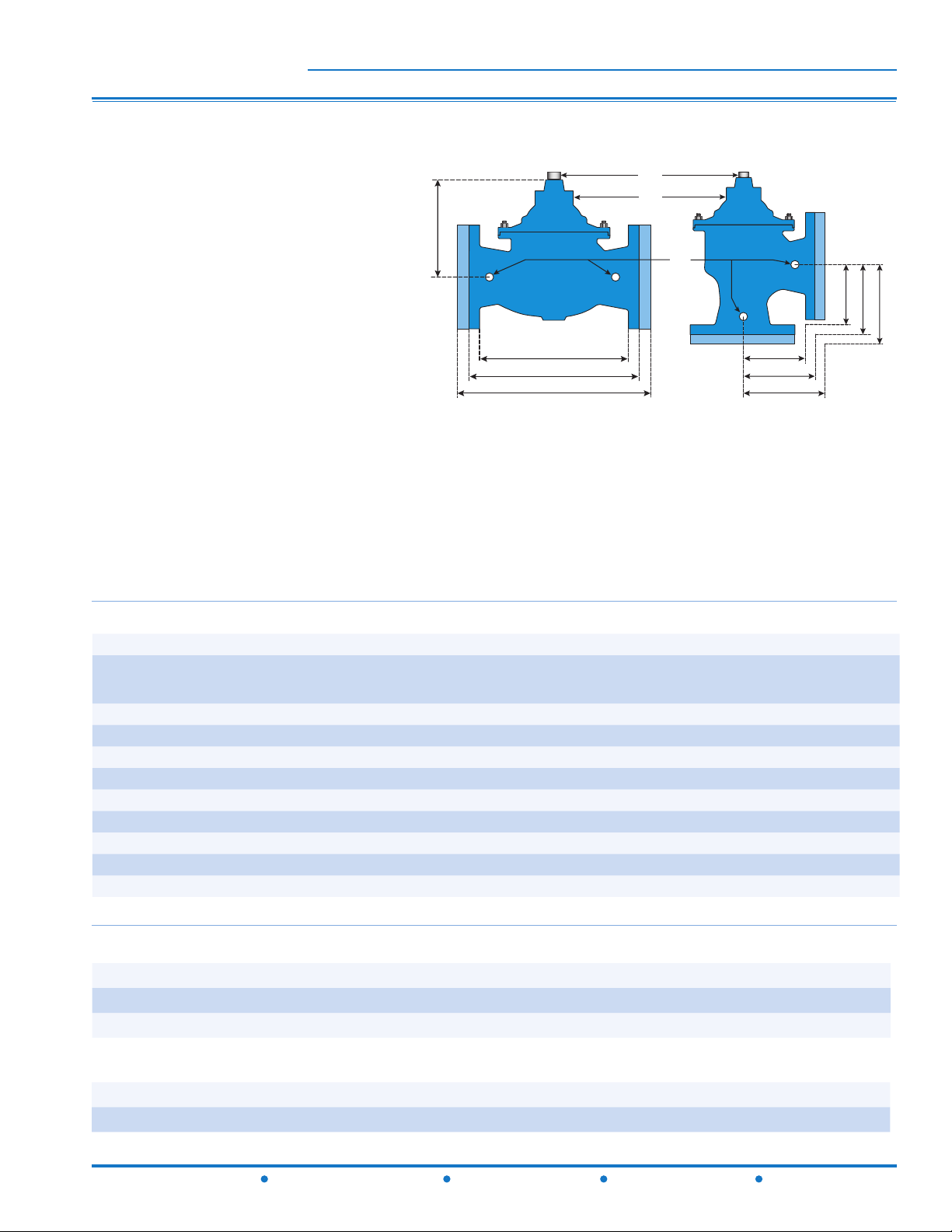

ClassiC series

F113-12RFP (Globe)

F1113-12RFP (Angle)

Materials

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion

D

Globe

Angle

L

M

Bonded Epoxy Lined

and Coated

Trim: 316 Stainless Steel

Elastomers: Buna-N (standard)

K

I

J

H

EPDM (optional)

Stem, Nut &

Spring:

Viton (optional)

Stainless Steel

A

B

C

E

F

G

Operating Pressure Operating Temperature Pilot System Tubing & Fittings

Threaded = 400 psi

150 Flanged = 250 psi

300 Flanged = 400 psi

Buna-N: 160°F Maximum

EPDM: 300°F Maximum

Viton: 250°F Maximum

NEMA 4 General Purpose

Solenoid

Brass

110-VAC

Copper / Brass (Standard)

Stainless Steel (Optional)

Dimensions

A B C D E F G H I J K L M

VALVE

GLOBE

SIZE

THRD.

1-1/4 7-1/4 - - 3-1/2 3-1/4 - - 1-7/8 - - 1/4 1/2 1/8 15

1-1/2 7-1/4 8-1/2 9 3-1/2 3-1/4 4 - 1-7/8 4 - 1/4 1/2 1/8 15

2 9-3/8 9-3/8 10 4-15/16 4 4 4-1/4 4 4 4-1/4 1/2 1/2 1/4 35

2-1/2 11 11 11-5/8 7 5-1/2 5-1/2 5-13/16 4 4 4-5/16 1/2 1/2 3/8 65

3 10-1/2 12 13-1/4 7 5-1/4 5-3/4 6-1/8 5-1/4 5-3/4 6-1/8 1/2 1/2 3/8 95

4 - 15 15-5/8 8-5/8 - 6-3/4 7-1/8 - 6-3/4 7-1/8 1/2 1/2 3/8 190

6

8 - 25-3/8 26-3/8 15-3/4 - 11 11-1/2 - 11 11-1/2 1/2 1 1/2 650

10 - 29-3/4 31-1/8 18-3/4 - 14-7/8 15-5/8 - 14-7/8 15-5/8 1 1 1 940

GLOBE

- 20 21 11-3/4 - 8-1/2 8-7/8 - 8-1/2 8-7/8 1/2 1/2 1/2 320

150#

GLOBE

300#

COVER TO

CENTER

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

PORT

SIZE

PORT

SIZE

PORT

SIZE

SHIPPING

WEIGHTS*

For larger sizes consult factory

Valve Cover Chamber Capacity

Valve Size (in) 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

.oz. 4 4 4 10 10 22 70

U.S. Gal - - - - - - -

- -

1-1/4 2-1/2

Valve Travel

Valve Size (in) 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

Travel (in) 3/8 3/8 1/2 5/8 3/4 1 1-1/2 2 2-1/2

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 3

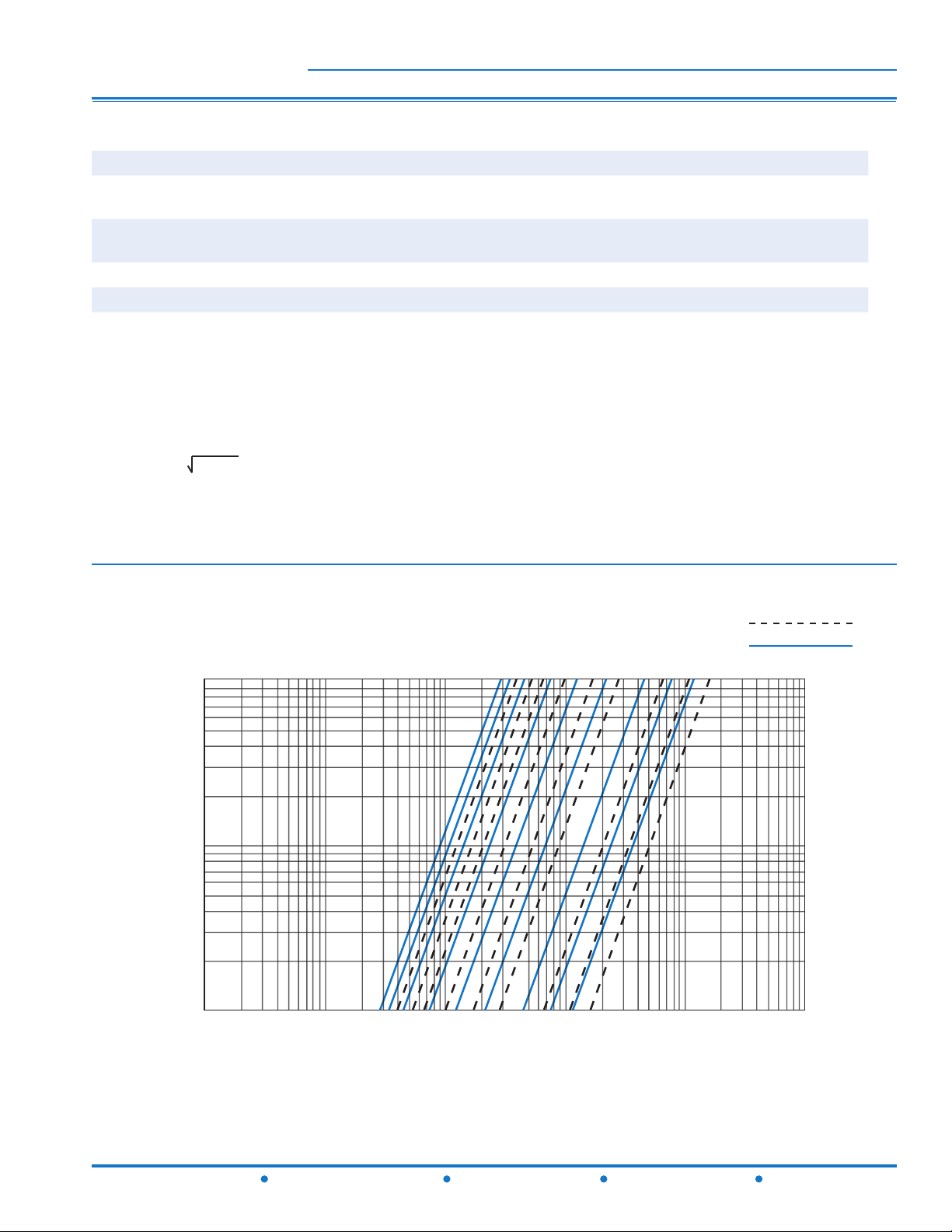

ClassiC series

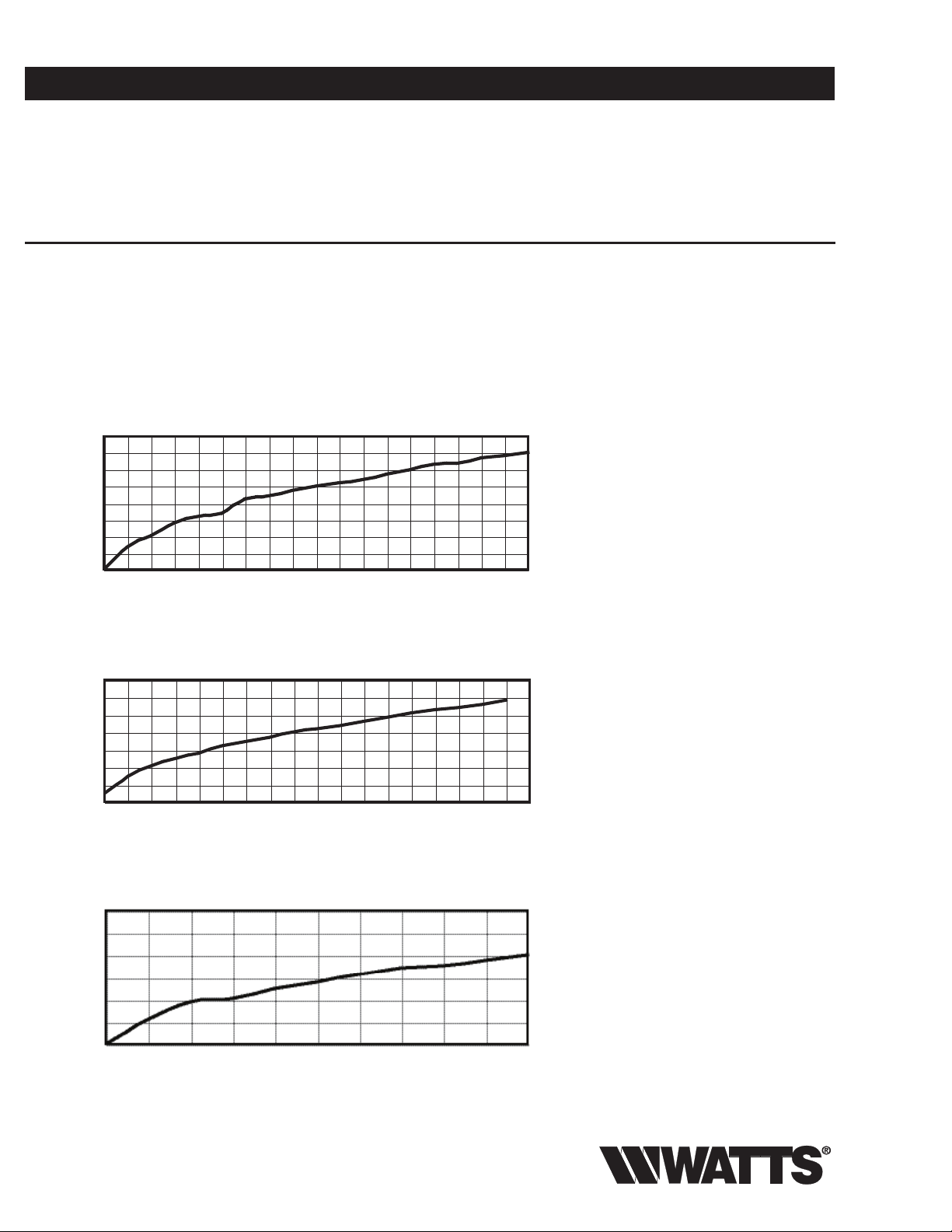

Flow Data

Valve Size - Inches 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

Maximum Continuous Flow Rate Gpm

(Water)

F113-12RFP (Globe)

F1113-12RFP (Angle)

93 125 208 300 460 800 1800 3100 4900

Maximum Intermittent Flow Rate Gpm

(Water)

115 158 260 370 570 1000 2300 3900 6000

CV Factor GPM (Globe) 29 34 55 75 125 220 460 775 1200

CV Factor GPM (Angle) 39 53 66 99 170 280 650 1100 1600

Maximum continuous flow based on velocity of 20 ft. per second.

Maximum intermittent flow based on velocity of 25 ft. per second.

The Cv Factor of a value is the flow rate in US GPM at 60° F that will cause a 1 psi drop in pressure.

The factors stated are based upon a fully open valve.

Cv factor can be used in the following equations to determine Flow (Q) and Pressure Drop (∆ P):

Q (Flow) = Cv ∆ P

Headloss

100

∆ P (Pressure Drop) = (Q/CV)2

1/4

1

1/221/2

1/4

1

1

1/2

1/2

2

1

2

3

2

3

4

6

4

6

8

10

8

10

Angle

Globe

50

10

5

Pressure Difference psi

1

1

10000020000100005000100050010050105

Flow Rate - Gallons per minute (Water)

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 4

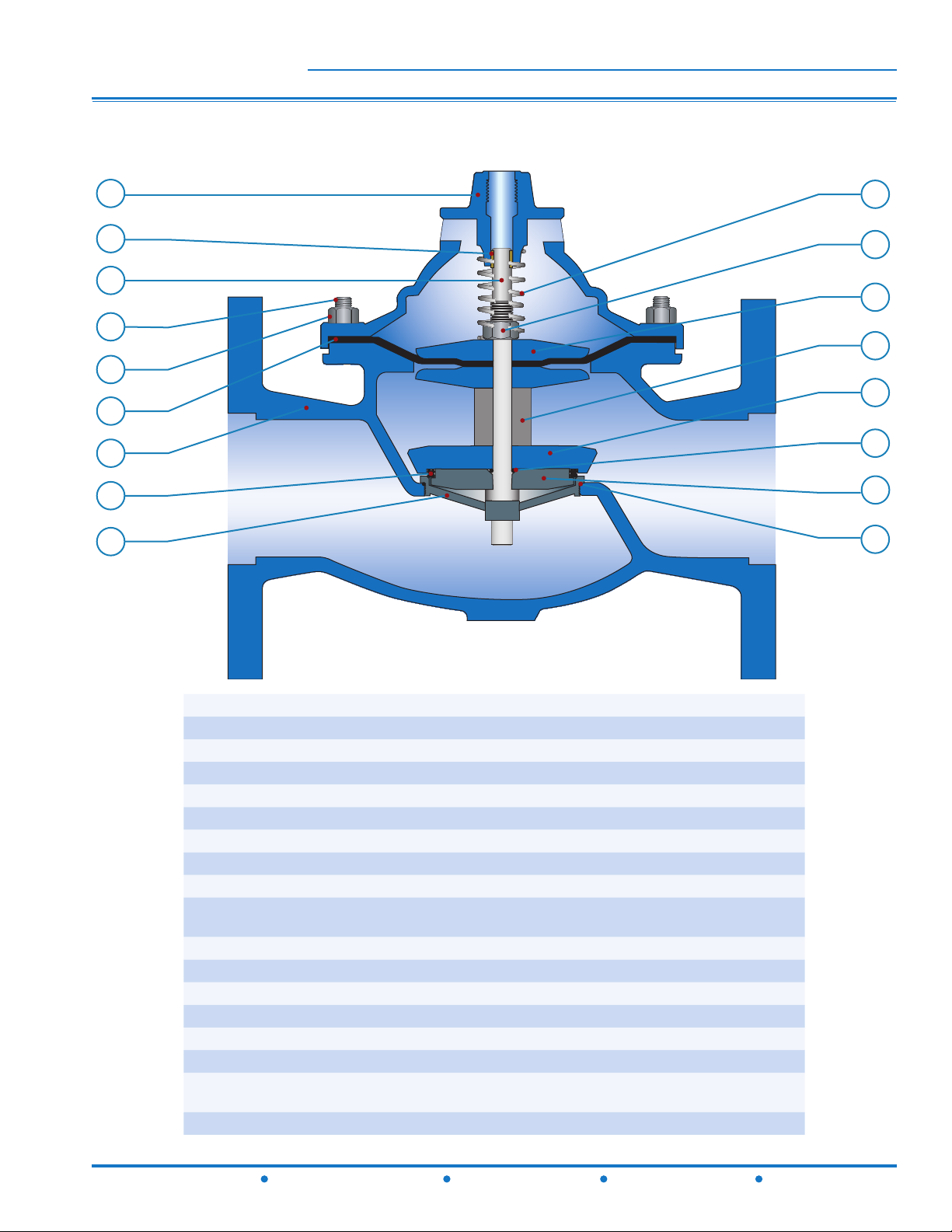

ClassiC series

Main Valve

F113-12RFP (Globe)

F1113-12RFP (Angle)

1

2

10

11

3

12

4

13

5

14

6

7

8

9

15

16

17

ITEM DESCRIPTION MATERIAL

1 Cover ASTM A536 65-45-12 Epoxy Coated Ductile Iron

2 Cover Bearing SAE 841 Bronze

3 Shaft / Stem ASTM A276 304 Stainless Steel

4 Stud ASTM A570 Gr.33 Zinc Plated Steel

5 Cover Nut ASTM A570 Gr.33 Zinc Plated Steel

6 Diaphragm* Buna-N (Nitrile)

7 Body ASTM A536 65-45-12 Epoxy Coated Ductile Iron

8 Quad Seal* Buna-N (Nitrile)

9 Seat Ring ASTM A743 CF8M (316) Stainless Steel (8” and Smaller)

ASTM B62 Bronze (10” and Larger)

10 Spring ASTM A276 302 Stainless Steel

11 Stem Nut ASTM A276 304 Stainless Steel

12 Diaphragm Washer ASTM A536 65-45-12 Epoxy Coated Ductile Iron

13 Spacer ASTM A276 304 Stainless Steel

14 Quad Seal Retainer ASTM A536 65-45-12 Epoxy Coated Ductile Iron

15 O-Ring* Buna-N (Nitrile)

16 Quad Seal Plate ASTM A743 CF8M (316) Stainless Steel (8” and Smaller)

ASTM B62 Bronze (10” and Larger)

17 Seat Gasket* Buna-N (Nitrile)

* Contained in Main Valve Repair Kit

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 5

ClassiC series

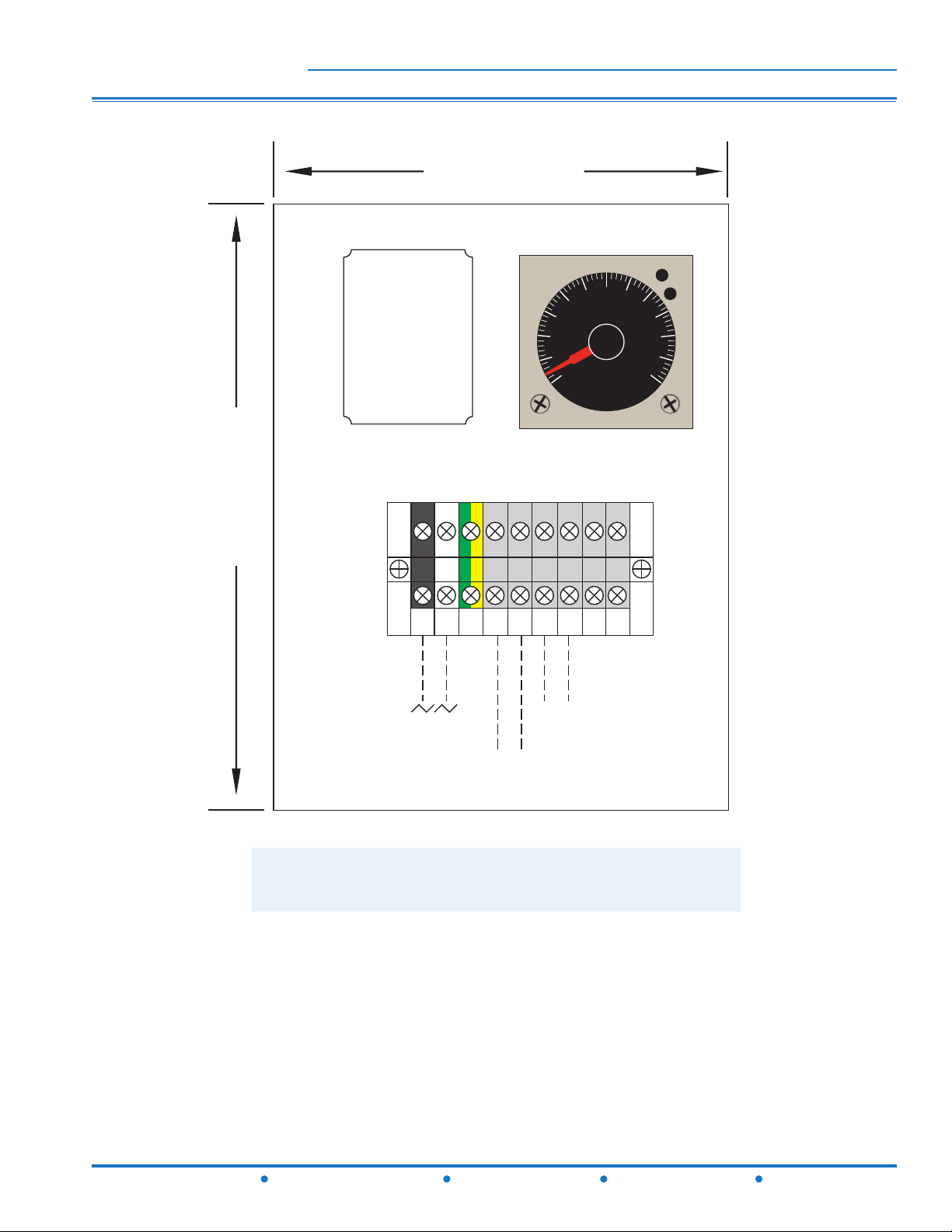

JB113 Junction Box

F113-12RFP (Globe)

F1113-12RFP (Angle)

6.00

Power

8.00

Relay with

Red LED

Indicator

L N G 1 2 3 4 5 6

Incoming Power

120V, 1 PH

(Field Terminated)

Flow Sensor

(Field Terminated)

Solenoid

( by factory)

FS-99

15

10 20

5 25

0 30

SEC

UP

3/4 “ Conduit Connections (x 3)

CERTIFIED ELECTRICIAN TO CONNECT MAIN POWER

AND FS99 FLOW SENSOR TO JB113 JUNCTION BOX

The valve mounted JB113 Junction Box is a lockable NEMA 4 enclosure equipped with an adjustable time delay,

electrical relay and terminal strip. There are three 3/4 inch conduit connections. The valve solenoid is prewired.

The valve is normally open and closes drip-tight when continuous relief valve discharge through the drain pipe is

sensed by the FS99 Flow Sensor.

The valve mounted JB113 Junction Box is equipped with an adjustable time delay to avoid valve closure due to

intermittent or nuisance relief valve discharge. The time delay is adjusable from 0-30 seconds.

Adjusting the dial clockwise increases the time delay for valve closure. Adjusting the dial counterclockwise decreases the time delay for valve closure.

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 6

ClassiC series

FS-99 Flow Sensor

F113-12RFP (Globe)

F1113-12RFP (Angle)

The FS99 Flow Sensor is eld installed in the

discharge piping from the RPZ Relief Valve.

The FS99 senses water in the discharge piping signaling the JB113 Junction Box to close

the valve.

From RPZ

Relief Valve

(with Air Gap)

Sensor Probes installed

1/4 inch above pipe

To Floor Drain

NOTE TO INSTALLING CONTRACTOR

• Client/Contractor to provide installation Tee for Flow Sensor.

• Install Flow Sensor in RPZ discharge line in HORIZONTAL position as shown.

• Sensor Probes should be cut to length and installed 1/4 inch above pipe bottom.

• ENSURE SENSOR PROBES DO NOT CONTACT PIPE BOTTOM OR SIDES.

• CERTIFIED ELECTRICIAN TO CONNECT MAIN POWER AND FS99 FLOW

SENSOR TO JB113 JUNCTION BOX

bottom

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 7

ClassiC series

B

A

A

F113-12RFP (Globe)

F1113-12RFP (Angle)

The valve Solenoid is prewired to the JB113 Junction Box and is equipped with a Manual Operator. Turning Manual Operator in (clockwise) approximatly 5-6 turns simulates electricity to the

Solenoid. Turning Manual Operator out (counterclockwise) returns the valve to electrical stand-by

service. Manual operator must be disengaged for

normal valve operation.

Disengaged

A B C

Male Pipe Female Pipe Length

Thread (in) Thread (in) Thread (in)

1/4 1/8 11/16

3/8 1/4 7/8

1/2 3/8 7/8

Engaged

A

B

The valve pilot circuit is equipped with a Model 60

Flo-Clean Strainer which is used to lter the uid

passing through the control pilot circuit, and provide protection to pilot circuit speed controls and

pilots. It is installed in the inlet body port of the

main valve, exposing the strainer element to main

line ow. The currents and ow across the screen

create a self-scouring effect, cleaning the lter element.

The Model 51 Single Limit Switch provides local

visual and remote electrical indication of valve

position. The adjustable collar is set to contact the

trip arm when the main valve is closed. The collar

can be positioned on the stem by loosening the

set-screw to actuate the switch upon valve closure.

The single pole double throw Micro-Switch can be

connected to the building monitoring system to

indicate valve closure.

Single Pole Double Throw Switch

Common Lug

Normally Open

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Normally Closed

Page 8

ClassiC series

F113-12RFP (Globe)

F1113-12RFP (Angle)

1

3

4

6

8

9

10

11

12

13

2

5

7

14

15

1 Limit Switch

2 Bracket

3 Stem

4 Trip collar

5 Set Screw

6 Cap

7 Wiper Ring*

8 O-Ring*

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

9 Guide

10 O-Ring*

11 Polypak*

12 Locknut

13 Body

14 Pin

15 Coupling

Page 9

F113-12RFP (Globe)

ClassiC series

Installation

Control Valve

• Fully read all technical information provided.

• Prior to installation ush line to remove debris.

• Install valve upstream of the RPZ Backow Assembly.

• For ease of valve service and electrical connections do not install valve vertically. Install

valve horizontally “in line” (valve cover facing UP), so ow arrow matches ow through the

line. Consult factory prior to ordering if installation requirements are other than described.

• Vertical installation of valves larger than 6” is not recommended and may result in poor valve

performance and increased maintenance requirements.

• Install inlet and outlet isolation valves. NOTE: When using buttery valves, insure disc does

not contact control valve. Damage or improper valve seating may occur.

• Provide adequate clearance for valve servicing and maintenance.

• Install pressure gauges to monitor valve inlet and outlet pressure.

• Connect cover discharge control tubing to oor drain. Consult “Valve Cover Capacity” chart

on page 2 to determine volume of cover uid displaced when valve is operated.

F1113-12RFP (Angle)

FS99 Flow Sensor

• Install FS99 Flow Sensor HORIZONTALLY in RPZ Relief Valve discharge line for proper

operation. Do not install vertically. Consult factory if ow sensor other than FS99 is used.

• Client / Contractor to provide 2” FNPT installation Tee for Flow Sensor. Sensor Probes must

be eld cut to length and installed 1/4” above pipe bottom for proper operation

• Insure sensor probes do not contact installation Tee bottom or sidewalls.

• Line Voltage to FS99 Flow Sensor is 10 volts maximum.

Electrical Connections

• Certied Electrician to connect JB113 Junction Box and FS99 Flow Sensor according to

factory schematic to appropriate power source and terminal strip locations.

• Line Voltage to FS99 Flow Sensor is 10 volts.

• Power supply to JB113 Junction Box is 120 VAC 60HZ Single Phase.

• Connect Limit Switch (if equipped) to remote alarm or auxiliary connection as required by

project specications.

• Pre-set Time Delay to 15 seconds.

• Insure Solenoid is disengaged by turning Manual Operator counterclockwise (out / left).

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 10

F113-12RFP (Globe)

ClassiC series

Start-Up

Proper Automatic Control Valve start-up requires bringing the valve into service in a controlled manner.

All adjustments to control pilots and speed controls should be made slowly, allowing the valve to respond

and the system to stabilize. NOTE: Control Valves should be set-up in a dynamic (owing) condition

for proper start-up. Provisions for ow must be made to insure proper settings.

1. Refer to valve schematic. Disengage Solenoid by turning Manual Operator counterclockwise (out).

Locate and open Manual Reset Ball Valve. Open upstream and downstream isolation valves to

allow controlled lling of the Valve and Backow Assembly. Open all Isolation Ball Valves.

2. Inlet pressure will open the valve fully. Close Manual Reset Ball Valve.

3. Engage Solenoid by turning (red) Manual Operator clockwise (in) to simulate electrical shutdown

signal. Inlet pressure will be indicated on Pressure Gauge and valve will begin to close. Due to

low / no ow condition, valve closure may be slower than normal operation. When valve is fully

closed adjust Limit Switch trip arm and trip collar to actuate Limit Switch.

4. Disengage Solenoid by returning Manual Operator out (counterclockwise) and open Manual Reset

Ball Valve. Pilot System Pressure Gauge will drop to zero. Valve will open fully and is ready for

electrical activation. Allow for cover volume to discharge to oor drain. Refer to chart on Page 2

for Cover Chamber Volume. Close Manual Reset Ball Valve.

F1113-12RFP (Angle)

5. Open JB113 Junction Box. Apply power and observe the clear Electric Relay Control.

6. Pour adequate amount of water into RPZ Relief Valve Air Gap until the RED LED indicator light on

the Electrical Relay illuminates / ashes. This indicates the FS99 Flow Sensor is properly installed

and is sensing water in the discharge piping.

7. Trap water in discharge piping and observe RED LED on Electrical Relay. Solenoid will energize

when duration of Adjust Time Delay elapses. Valve will go closed and must be manually reset.

Adjust Time Delay to Customer / Project specications. To manually reset valve refer to Step 4.

8. For nal test simulate actual RPZ Relief Valve discharge and observe oor drain for excessive

pooling or ooding. Re-adjust time delay and valve speed controls as needed to achieve desired

valve closure time.

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 11

F113-12RFP (Globe)

ClassiC series

Specications

The Flood Protection Shutdown Valve shall be a normally open Diaphragm Valve installed upstream of the

Reduced Pressure Zone Backow Assembly, and automatically close if the RPZ relief valve begins to discharge.

A Time Delay supplied in the JB113 Junction Box shall prevent the valve from closing on intermittent discharges

from the RPZ relief valve. If continuous Relief Valve discharge occurs, the FS99 Flow Sensor installed horizontally

in the RPZ Relief Valve discharge piping shall send a signal to the JB113 Junction Box energizing Solenoid to

close the main valve. Once closed the Flood Protection Shutdown Valve must be manually reset.

The JB113 Junction Box shall be valve mounted with the Solenoid pre-wired. The FS99 Flow Sensor shall

be provided with the valve package and shall be eld installed in a horizontal position in the RPZ Relief Valve

discharge piping. Vertical installation of the Flow Sensor shall not be acceptable. The valve shall be equipped

with a Limit Switch to provide local visual and remote electrical indication of valve closure.

The Reduced Pressure Zone Backow Assembly, Flood Protection Shutdown Valve, JB113 Junction Box and

FS99 Flow Sensor shall be provided by the same manufacturer and be covered by a single warranty policy.

The main valve shall be a hydraulically operated, single diaphragm actuated, globe or angle pattern valve.

Y-pattern valves shall not be permitted. The valve shall contain a disc and diaphragm assembly that forms a

sealed chamber below the valve cover, separating operating pressure from line pressure. The diaphragm shall

be constructed of nylon reinforced Buna-N, and shall not seal directly against the valve seat and shall be fully

supported by the valve body and cover. Rolling diaphragm construction will not be allowed and there shall be no

pistons operating the main valve or any pilot controls.

F1113-12RFP (Angle)

The main valve body and cover shall be Ductile Iron ASTM A536, and all internal cast components shall be

Ductile Iron or CF8M (316) Stainless Steel. All Ductile Iron components, including the body and cover, shall be

lined and coated with an NSF 61 Certied Epoxy Coating applied by the electrostatic heat fusion process. All

main valve throttling components (valve seat and disc guide) shall be Stainless Steel. The valve body and cover

must be machined with a 360-degree locating lip to assure proper alignment.

The disc and diaphragm assembly shall contain a Buna-N synthetic rubber “Quad Seal” that is securely retained on

3-1/2 sides by a disc retainer and disc guide. Diaphragm assemblies utilizing bolts or cap screws for component

retention will not be permitted. Direction of ow through the valve shall be the over-the-disc design, causing the

valve to close upon diaphragm failure.

The exposed portion of the Quad Seal shall contact the valve seat and seal drip-tight. The disc and diaphragm

assembly must be guided by two separate bearings, one installed in the valve cover and one concentrically

located within the valve seat, to avoid deection and assure positive disc-to-seat contact. Center guided valves

will not be permitted. The main valve stem shall be Xylan coated to avoid the effects of mineral or hard water

build-up. The main valve spring shall be the manufacturer’s heavy or extra heavy spring design. All necessary

repairs shall be made from the top of the valve while the body remains in line.

The Pilot Control System shall contain a Flo-Clean Strainer, NEMA 4, 120 VAC 60HZ 3-Way Solenoid with Manual

Operator, Manual Reset Ball Valve, Pressure Gauge, Single Limit Switch, JB113 Junction Box and Isolation Ball

Valves on all body connections. The JB113 Junction Box shall be valve mounted and the FS99 Flow Sensor shall

be eld installed.

The valve shall be Watts Model 113-12RFP (globe) or 1113-12RFP (angle) Flood Protection Shutdown Valve.

12541 Gulf Freeway • Houston, Texas 77034 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 12

For Health Hazard Applications

ES-RVD

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––

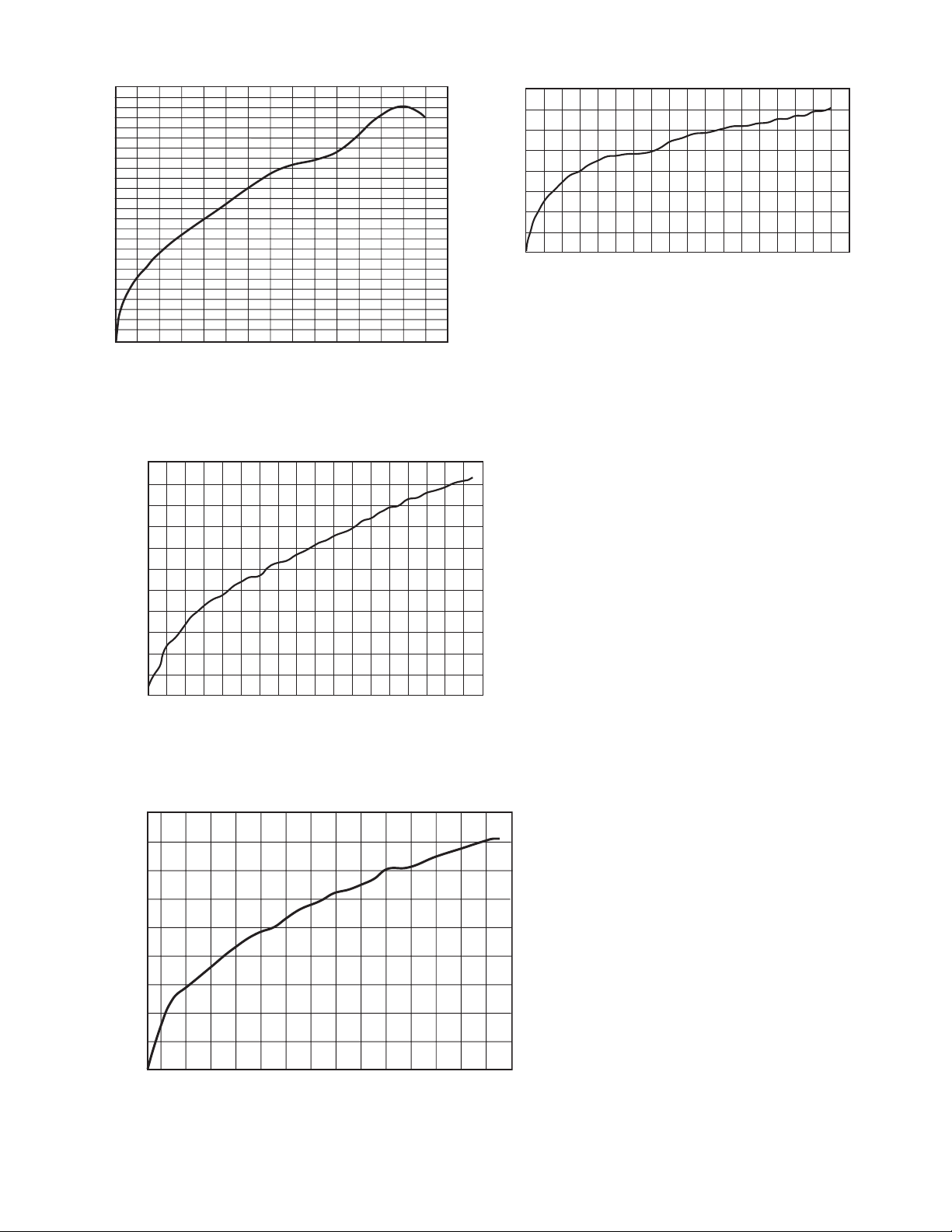

Series 009, 909, 919, 957 and 994

Reduced Pressure Zone Assemblies

Relief Valve Discharge Rates

1

lpm gpm

152 40

133 35

114 30

95 25

76 20

57 15

38 10

19 5

Rate of Flow

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 psi

0 .7 1.4 2.0 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8.3 9.0 9.7 10.3 11.0 11.7 12.4

⁄4", 3⁄8", 1⁄2" 009QT

bar

lpm gpm

266 70

228 60

190 50

152 40

114 30

76 20

38 10

Rate of Flow

0 0

lpm gpm

228 60

190 50

152 40

114 30

76 20

Rate of Flow

38 10

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 psi

0 .7 1.4 2.0 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8.3 9.0 9.7 10.3 11.0 11.7 12.4

0 10 20 30 40 50 60 70 80 90 100 psi

0 69 138 207 276 345 414 483 552 621 690

Pressure

3

⁄4" 009M3QT

Pressure

1" 009M2QT

Pressure

bar

kPa

Note: These curves

represent catastrophic

or worst case discharge

rates. These curves

were developed by pressurizing the outlet of

the backflow preventer

with the second check

valve’s internals removed

from the body.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 13

lpm gpm

532 140

456 120

380 100

304 80

228 60

152 40

Rate of Flow

76 20

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 psi

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8.3 9.0 9.7 10.3 11.0 11.7 12.4

11⁄4" 009M2QT

bar

Pressure

lpm gpm

513 35

456 120

399 105

342 90

285 75

228 60

171 45

114 30

Rate of Flow

57 15

0 0

lpm gpm

836 220

760 200

684 180

608 160

532 140

456 120

380 100

304 80

228 60

Rate of Flow

152 40

76 20

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 psi

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8.3 9.0 9.7 10.3 11.0 11.7 12.4

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 psi

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8.3 9.0 9.7 10.3 11.0 11.7

11⁄2" 009M2QT

Pressure

2" 009M2QT

Pressure

bar

bar

Note: These curves

represent catastrophic

or worst case discharge

rates. These curves

were developed by pressurizing the outlet of

the backflow preventer

with the second check

valve’s internals removed

from the body.

lpm gpm

1330 350

1140 300

950 250

760 200

570 150

380 100

Rate of Flow

190 50

0 0

2

21⁄2", 3" 009

0 10 20 30 40 50 60 70 80 90 100 110 120 130

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8. 3 9.0 9.6

Pressure

140 150 160 170 180

psi

10.3 11.0 11.7 12.4 bar

Page 14

lpm gpm

570 150

475 125

380 100

285 75

190 50

Rate of Flow

95 25

3

⁄4", 1" 909

lpm gpm

1520 400

1330 350

1140 300

950 250

760 200

570 150

380 100

Rate of Flow

190 50

0 0

0 10 20 30 40 50 60 70 80 90

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8. 3 9.0 9.6 10.3 11.0 11.7 12.4

11⁄4", 11⁄2", 2" 909

100 110 120 130 140 150 160 170 180

Pressure

psi

bar

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 psi

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8. 3 9.0 9.6 10.3 bar

lpm gpm

2090 550

1900 500

1710 450

1520 400

1330 350

1140 300

950 250

760 200

Rate of Flow

570 150

380 100

190 50

0 0

lpm gpm

3420 900

3040 800

0 10 20 30 40 50 60 70 80 90

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 8. 3 9.0 9.6 10.3 11.0 11.7 12.4

Pressure

21⁄2" - 3" 909

100 110 120 130 140 150 160 170 180

Pressure

4", 6", 8", 10" 909

psi

bar

Note: These curves

represent catastrophic

or worst case discharge

rates. These curves

were developed by pressurizing the outlet of

the backflow preventer

with the second check

valve’s internals removed

from the body.

2660 700

600

2280

1900 500

1520 400

1140 300

Rate of Flow

760 200

380 100

0 0

0 5 15 25 35 45 55 65 75 85 95 105 115 125 135 145 psi

0 .3 1.0 1.7 2.4 3.1 3.8 4.5 5.5 5.9 6.5 7.2 7.9 8.6 9.3 10

Pressure

bar

3

Page 15

lpm gpm

Capacity w/Second Check Removed

228 60

190 50

152 40

114 30

76 20

38 10

Rate of Flow

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 psi

0 .7 1.4 2.0 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.8 8.3 9.0 9.7 10.3 11.0 11.7 12.4 bar

1" 919 RV

Pressure

lpm gpm

684 180

170

6.8 160

570 150

532 140

130

456 120

110

380 100

342 90

304 80

266 70

228 60

190 50

Rate of Flow

152 40

114 30

76 20

38 10

0 0

0 10 20 30 40 50 60 70 80 90 100 110 psi

0 .7 1.4 2.1 2.8 3.5 4.1 4.8 5.5 6.2 6.9 7.6 psi

Backpressure w/Second Check

2" 919 QT

Poppet & Spring Removed

Pressure

lpm gpm

3420 900

3040 800

2660 700

2280 600

1900 500

Rate of Flow

1520 400

1140 300

760 200

380 100

0 0

900

800

700

600

500

400

300

200

100

0

0 40 80 120 160 200 240 280 psi

0 276 552 827 1103 1379 1655 1931

lpm gpm

1330 350

1140 300

950 250

760 200

570 150

380 100

Rate of Flow

190 50

0 0

0 20 40 60 80 psi

0 138 276 414 552 kPa

40 80 120 160 200 240 280 3000

21⁄2" – 10" 957

Pressure

21⁄2" – 10" 994

Pressure

kPa

Note: These curves

represent catastrophic

or worst case discharge

rates. These curves

were developed by pressurizing the outlet of

the backflow preventer

with the second check

valve’s internals removed

from the body.

Typical Flow Rates as

sized by floor drain

manufacturers

gpm lpm

55 209 2

112 426 3

170 646 4

350 1330 5

Drain

Size

W a t e r S a fe t y & F l o w Co n tr o l Pr o du c t s

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

ES-RVD 0904 © Watts, 2009

Loading...

Loading...