Page 1

1

X

Y/FC

2

3A

3B

P/L

X

CLOSES VALVE

OPENS VALVE

FLOW

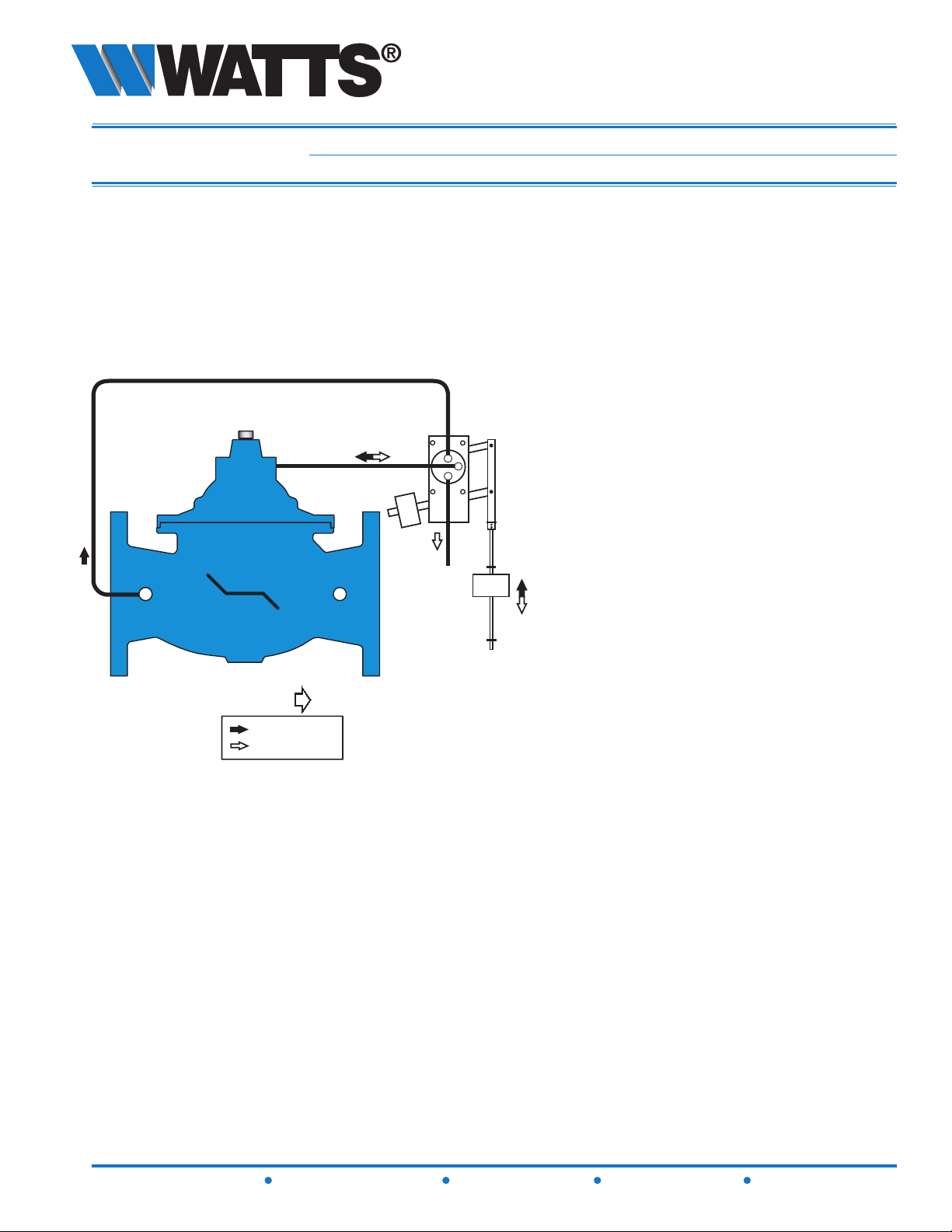

ON-OFF FLOAT CONTROL VALVE

(4” a n d Sm a l l e r )

11/08

Cl a s s i C se r i e s

Schematics

Opens when float reaches low level stop•

Closes when float reaches high level stop•

Low and High Level stop collars are adjustable•

F110-14 (Globe)

F1110-14 (Angle)

Standard Components

1 - Main Valve (Single Chamber)

2 - On-Off Float Control

3A - High Level Adjustment Stop

3B - Low Level Adjustment Stop

Options & Accessories

X - Isolation Cocks ○

FC - Flo-Clean Strainer ○

Y - Y-Strainer (Replaces Flo-Clean) ○

AOS – Adjustable Opening Speed ○

P - Position Indicator ○

L - Limit Switch ○

(3)

(2)

(1)

(3)

(1)

Standard 3” & Smaller

(2)

Standard 4” & Larger

(3)

Optional All Sizes

(2)

(3)

Operations

The Watts ACV On-Off Float Control Valve is designed to open fully or close drip-tight as commanded by

the Float Control Pilot. The Float Pilot may be either valve or remote mounted. The valve closes drip tight

when water level reaches the adjustable high-level setpoint, and opens fully when water level is below the

adjustable low-level setpoint, allowing a calculated “draw-down” of water level to increase tank circulation.

The On-Off Float Pilot commands the routing of uid and pressure into and out of the cover chamber of the

main valve. When water level reaches the adjustable high-level setpoint, the Float Pilot connects the cover

chamber of the valve to upstream pressure, closing the valve drip tight. The valve remains closed as water

level decreases. When water level reaches the adjustable low-level setpoint, the Float Pilot connects the

cover chamber of the valve to atmosphere (wet drain), opening the valve fully. High and low levels are sepa-

rately adjustable by positioning stop collars on the oat rod(s) at desired opening and closing setpoints.

If desired, the on-off action of the valve can be “reversed” by modifying the hydraulic connections of the

On-Off Float Pilot.

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 2

Cl a S S i C Se r i e S

L

M

D

A

B

C

E

F

G

H

I

J

K

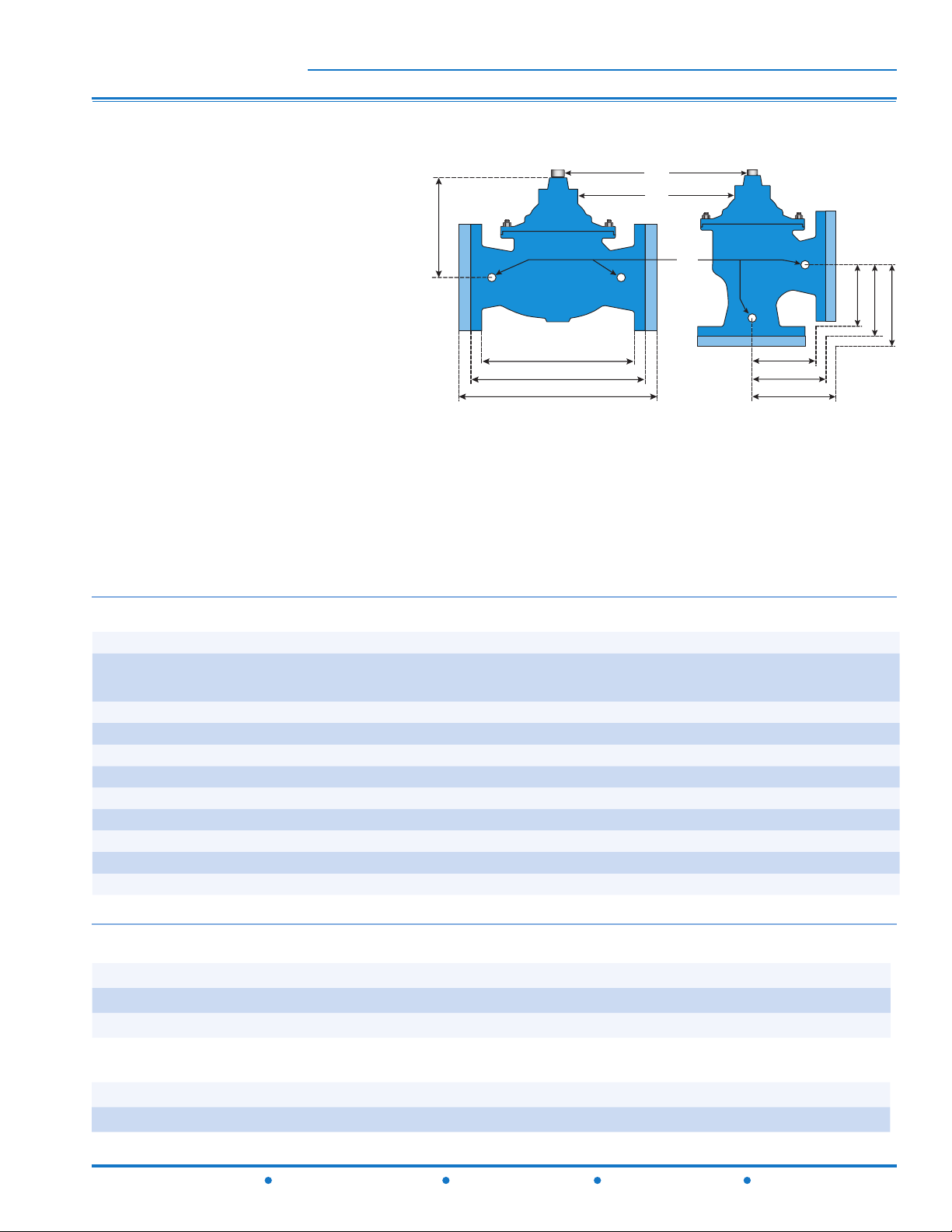

F110-14 (Globe)

F1110-14 (Angle)

Materials

Globe

Angle

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion

Bonded Epoxy Lined

and Coated

Trim: 316 Stainless Steel (1-1/4” – 8”)

ASTM B62 Bronze (10”)

(Stainless Steel Optional)

Elastomers: Buna-N (standard)

EPDM (optional)

Viton (optional)

Stem, Nut & Stainless Steel

Spring:

Operating Pressure Operating Temperature Pilot System Tubing & Fittings

Threaded = 400 psi

150 Flanged = 250 psi

300 Flanged = 400 psi

Buna-N: 160°F Maximum

EPDM: 300°F Maximum

Viton: 250°F Maximum

Float Control Copper / Brass (Standard)

Brass (Standard) Stainless Steel (Optional)

Float Ball

Polyethylene (6” dia.)

Float Rods

(2) 12” Rods (Standard)

Dimensions

A B C D E F G H I J K L M

VALVE

GLOBE

SIZE

THRD.

1-1/4 7-1/4 - - 3-1/2 3-1/4 - - 1-7/8 - - 1/4 1/2 1/8 15

1-1/2 7-1/4 8-1/2 9 3-1/2 3-1/4 4 - 1-7/8 4 - 1/4 1/2 1/8 15

2 9-3/8 9-3/8 10 4-15/16 4 4 4-1/4 4 4 4-1/4 1/2 1/2 1/4 35

2-1/2 11 11 11-5/8 7 5-1/2 5-1/2 5-13/16 4 4 4-5/16 1/2 1/2 3/8 65

3 10-1/2 12 13-1/4 7 5-1/4 5-3/4 6-1/8 5-1/4 5-3/4 6-1/8 1/2 1/2 3/8 95

4 - 15 15-5/8 8-5/8 - 6-3/4 7-1/8 - 6-3/4 7-1/8 1/2 1/2 3/8 190

6 - 20 21 11-3/4 - 8-1/2 8-7/8 - 8-1/2 8-7/8 1/2 1/2 1/2 320

8 - 25-3/8 26-3/8 15-3/4 - 11 11-1/2 - 11 11-1/2 1/2 1 1/2 650

10 - 29-3/4 31-1/8 18-3/4 - 14-7/8 15-5/8 - 14-7/8 15-5/8 1 1 1 940

GLOBE

150#

GLOBE

300#

COVER TO

CENTER

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

PORT

SIZE

PORT

SIZE

PORT

SIZE

SHIPPING

WEIGHTS*

For larger sizes consult factory

Valve Cover Chamber Capacity

Valve Size (in) 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

.oz. 4 4 4 10 10 22 70

U.S. Gal - - - - - - -

- -

1-1/4 2-1/2

Valve Travel

Valve Size (in) 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

Travel (in) 3/8 3/8 1/2 5/8 3/4 1 1-1/2 2 2-1/2

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 3

Cl a S S i C Se r i e S

CAVITATION ZONE

INLET PRESSURE - PSI

OUTLET PRESSURE - PSI

300

280

260

240

220

200

180

160

140

120

100

80

60

40

20

0 10 20 40 50 60 70 80 90

130 14012011 0100

30

CAVITATION CHART

1

1/4

1

1/221/2

2

3

4

6

8

10

1

1/4

2

1/2

1

1/2

2

3

4

6

8

10

10000020000100005000100050010050105

1

1

5

10

50

100

Pressure Difference psi

Headloss

F110-14 (Globe)

F1110-14 (Angle)

Angle

Globe

Cavitation Chart

After selecting the valve size, locate inlet and outlet pressures on this chart. If the intersection point falls

in the shaded area, cavitation can occur. Operation of valves continually in the cavitation zone should be

avoided. Consult Watts ACV for alternatives.

Flow Rate - Gallons per minute (Water)

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 4

Cl a S S i C Se r i e S

3

4

5

6

7

8

9

11

12

13

14

15

16

17

1

2

10

Cross-Sectional Detail

Main Valve

F110-14 (Globe)

F1110-14 (Angle)

ITEM DESCRIPTION MATERIAL

1 Cover ASTM A536 65-45-12 Epoxy Coated Ductile Iron

2 Cover Bearing SAE 841 Bronze

3 Shaft / Stem ASTM A276 304 Stainless Steel

4 Stud ASTM A570 Gr.33 Zinc Plated Steel

5 Cover Nut ASTM A570 Gr.33 Zinc Plated Steel

6 Diaphragm* Buna-N (Nitrile)

7 Body ASTM A536 65-45-12 Epoxy Coated Ductile Iron

8 Quad Seal* Buna-N (Nitrile)

9 Seat Ring ASTM A743 CF8M (316) Stainless Steel (8” and Smaller)

ASTM B62 Bronze (10” and Larger)

10 Spring ASTM A276 302 Stainless Steel

11 Stem Nut ASTM A276 304 Stainless Steel

12 Diaphragm Washer ASTM A536 65-45-12 Epoxy Coated Ductile Iron

13 Spacer ASTM A276 304 Stainless Steel

14

15 O-Ring* Buna-N (Nitrile)

16 Quad Seal Plate ASTM A743 CF8M (316) Stainless Steel (8” and Smaller)

17 Seat Gasket* Buna-N (Nitrile)

Quad Seal Retainer

ASTM A536 65-45-12 Epoxy Coated Ductile Iron

ASTM B62 Bronze (10” and Larger)

* Contained in Main Valve Repair Kit

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 5

F110-14 (Globe)

Cl a S S i C Se r i e S

Installations

Prior to installation, flush line to remove debris.•

Install valve horizontally “in line” (cover facing UP), so flow arrow matches flow through the line. Avoid installing •

valves 6” and larger vertically. Consult factory prior to ordering if installation is other than described.

Install inlet and outlet isolation valves. NOTE: When using butterfly valves, insure disc does not contact control •

valve. Damage or improper valve seating may occur.

Provide adequate clearance for valve servicing and maintenance.•

Install pressure gauge to monitor valve inlet pressure.•

Provide adequate drain for cover chamber discharge. Consult “Valve Cover Capacity” chart on appropriate main •

valve Engineering Bulletin.

If On-Off Float Pilot is remotely mounted it should be field connected with 3/8” minimum copper tubing in •

accordance with factory piping schematic.

Float Pilot, Rods, and Ball should be mounted in a field installed “stilling well” for protection against surface •

turbulence and interference.

Additional 12” Float Rods available. Consult Factory.•

Start-Up

Proper Automatic Control Valve start‑up requires bringing the valve into service in a controlled manner. All adjustments

to control pilots and speed controls should be made slowly, allowing the valve to respond and the system to stabilize.

NOTE: Control Valves should be set‑up in a dynamic (owing) condition for proper start‑up. Provisions for ow

must be made to insure proper settings.

F1110-14 (Angle)

If Float Control is remote mounted, eld installed control lines should be 3/8” minimum copper tubing for •

distances no greater than 10 feet. For greater distances use 1/2” minimum copper tubing or pipe.

Remote mount – without Accelerator (4” and smaller): Port 1 = Supply Pressure•

Port C = Valve Cover

Port 2 = Atmosphere

Remote Mount – with Accelerator (6” and larger): Port 1 = Atmosphere •

Port C = Accelerator Cover

Port 2 = Supply

Close upstream and downstream valves to isolate the valve from line pressure. Open all Isolation Ball Valves, 1.

if so equipped. If valve is tted with adjustable speed controls, turn needle(s) in (clockwise) until seated, and

return out (counterclockwise) 1‑1/2 to 2‑1/2 turns. These are approximate settings, and should be ne tuned to

suit system requirements after level adjustments have been made.

Slowly open upstream isolation valve to allow controlled lling of the valve. Vent entrapped air by carefully 2.

loosening control tubing or pipe plug at the highest point possible. If valve is equipped with a Position Indicator,

open Air Bleed Petcock to vent air. Water will be milky in appearance and will begin to clear as air is vented.

Re‑tighten when water vents clearly.

Setting Float Control:3. Install desired number of Float Rods and Low and High Level Stop Collars (less Float).

Manually position Float Control to the center point in its travel and balance by positioning Counterweight “in” or

“out” until Float Control holds in position. Proper balance is achieved when Float Control moves to the “down/

on” or “up/off” position with minimal force or drag. The position of Counterweight on the Counterweight Rod will

vary based upon the number and material of Float Rods being used. Install Float.

Position Low and High Level Stop Collars on Float Rods to match desired valve opening and closing levels. 4.

Slowly open downstream isolation valve.

Fine tune Speed Controls (if equipped) to suit system requirements. Adjust Closing Speed Control clockwise 5.

for slower closure and counterclockwise for faster closure. Adjust Opening Speed Control clockwise for slower

opening and counterclockwise for faster opening.

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Page 6

F110-14 (Globe)

Cl a S S i C Se r i e S

Specications

The On-Off Float Control Valve shall be a pilot operated diaphragm valve designed to open fully or close

drip-tight as commanded by the Float Control Pilot. The Float Pilot may be either valve or remote mounted.

The valve shall close drip tight when water level reaches the adjustable high-level setpoint, and open fully

when water level is below the adjustable low-level setpoint, allowing a calculated “draw-down” of water level

to increase tank circulation.

The main valve shall be a hydraulically operated, single diaphragm actuated, globe or angle pattern valve.

Y-pattern valves shall not be permitted. The valve shall contain a disc and diaphragm assembly that forms

a sealed chamber below the valve cover, separating operating pressure from line pressure. The diaphragm

shall be constructed of nylon reinforced Buna-N, and shall not seal directly against the valve seat and shall

be fully supported by the valve body and cover. Rolling diaphragm construction will not be allowed and there

shall be no pistons operating the main valve or any pilot controls.

The main valve body and cover shall be Ductile Iron ASTM A536, and all internal cast components shall be

Ductile Iron or CF8M (316) Stainless Steel. All Ductile Iron components, including the body and cover, shall

be lined and coated with an NSF 61 Certied Epoxy Coating applied by the electrostatic heat fusion process.

All main valve throttling components (valve seat and disc guide) shall be Stainless Steel. The valve body

and cover must be machined with a 360-degree locating lip to assure proper alignment.

F1110-14 (Angle)

The disc and diaphragm assembly shall contain a Buna-N synthetic rubber “Quad Seal” that is securely

retained on 3-1/2 sides by a disc retainer and disc guide. Diaphragm assemblies utilizing bolts or cap

screws for component retention will not be permitted.

The exposed portion of the Quad Seal shall contact the valve seat and seal drip-tight. The disc and diaphragm

assembly must be guided by two separate bearings, one installed in the valve cover and one concentrically

located within the valve seat, to avoid deection and assure positive disc-to-seat contact. Center guided

valves will not be permitted. All necessary repairs shall be made from the top of the valve while the body

remains in line.

Pilot control systems for valves 3” and smaller shall contain a Flow Clean Strainer, On-Off Float Pilot, (2)

12” Float Rods and a Float Ball. Pilot control systems for 4” valves shall contain an On-Off Float Pilot, (2)

12” Float Rods, Float Ball, an external Y-Strainer and Isolation Ball Valves on all body connections. All pilot

control systems shall utilize copper tubing and brass ttings regardless of valve size.

The valve shall be Watts ACV Model F110-14 (Globe) or F1110-14 (Angle) On-Off Float Control Valve.

Other Watts ACV Float Control Valves

F110-10 / F1110-10 Modulating Float Control Valve

F110-13 / F1110-13 Modulating Float Control Valve with Pressure Sustaining Feature

F110-AS / F1110-AS Modulating Float Control Valve with Solenoid (On-Off) Feature

F110-18 / F1110-18 On-Off Float Control Valve with Pressure Sustaining Feature

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.watts.com

Loading...

Loading...