Page 1

Series EMVII-6400SS

Electric Motor Valves

Sizes: 21/2"– 3" (65 – 80mm)

IOM-EMV II 21/2"-3"

Installation, Operation and Maintenance

Instructions

The Watts EMVII-6400SS motor valve is an electrically actuated

standard port bronze ball valve with 316 stainless steel ball and

stem. The 2

actuator with a 75% duty cycle NEMA 4, 7 and 9 enclosure.

The installation section of this manual is broken into two parts

1-valve and 2-electrical. Prior to installation it is important to

familiarize yourself with both sections so that the unit is properly

installed.

1

/2" and 3" (65 and 80mm) valves have a reversing

Valve Installation

A. The stem seals on your EMVII-6400SS valve may require

periodic adjustment during its normal service life, therefore,

installations that prevent access to the valve for maintenance

must be avoided. Further, it is important to understand that

no valve’s stem seals will function indefi nitely. Eventually stem

seals will require adjustments. At this point the external leakage would start off as a slight seepage and if left unattended,

could become signifi cant.

B. All Watts EMVII-6400SS’s utilize bidirectional valves and

as such, can be installed to shut off fl ow in either direction.

C. When piping up the valve, be sure that the threads on the

mating pipe are free of excessive grit, dirt or burrs. Take care

to assure that any pipe sealants used are not so excessively

applied to the pipe threads that the valve cavity becomes

fouled.

D. The unit can be installed with the actuator portion in either

the vertical or horizontal plane, however for steam or high

temperature applications see Section E.

E. For installations for steam or other high temperature services

your Watts EMVII-6400SS features an electric actuator with

a maximum ambient temperature rating of 150°F (66ºC).

Higher temperatures will result in a signifi cant reduction of

the duty cycle rating and/or damage to electrical components.

Some steam or other high temperature applications may

require that the actuator be installed horizontal to the pipe

(on horizontal piping) to protect the unit from radiant heat.

All piping in which units are installed and any adjacent piping

must be insulated to further reduce the effects of piping

radiant heat.

Electrical Installation

Note: Prior to making wiring connections, be sure that all

external wiring and electrical components have been properly

selected to suit the power consumption levels of your particular

unit.

Table 1 - Power Consumption

VALVE SIZE VOLTAGE AND MAX AMPERAGE

in. mm CYCLE TIME DRAW

21⁄2"- 3" (65 – 80mm) 115 VAC-25 Second 1.0

21⁄2"- 3" (65 – 80mm) 24 VAC-25 Second 3.0

Note: Not all voltage/cycle time combinations are available for

every valve size. For specifi c model combinations consult your

Watts distributor or representative.

1. Wire per the diagram included inside the cover of the unit.

Note that the diagram refl ects the actuator depicted in the

open position. In order to maintain enclosure integrity, proper

conduit connections for your application (general purpose,

weatherproof, explosion-proof or proof) must be used. (Per

various electrical codes there is a green screw on the actuator base plate for grounding purposes).

2. Replace the cover and tighten all eight hex head bolts. Apply

power to the unit alternately in both directions to assure that

the valve is traveling from its fully open to its fully closed position (on/off applications). If the unit does not travel a full 90°

or if resultant rotation of the valve results in lack of full open

or full closed position, it may be necessary to adjust travel by

adjusting limit switch cams.

Maintenance

During its’ normal service life the only maintenance that may

be required by your EMVII-6400SS should be periodic stem

seal adjustment. It is important that stem seal leaks to not go

unattended as failure to adjust stem packing could signifi cantly

reduce seal life. To adjust stem seals, simply tighten the stem

gland nut.

Do Not Over-Tighten, as in doing so you may over-compress

stem seals which could result in excessive stem seal loading

and reduction of seal life.

Switch Setting (Travel Limits)

When shipped from the factory the actuator will typically be in

the “valve open” position (counterclockwise extreme of travel).

This means that the valve open circuit travel has been completed and the circuit is open.

1. Disconnect Power supply.

2. Loosen set screw in declutching knob, and remove knob.

3. Remove the hex head cover bolts located around the fl ange

of the unit.

4. To set open travel limit switch:

a. Using the declutchable manual override, place valve in its

fully closed position.

b. Loosen the top cam’s set screws and rotate cam until a

“click” is heard from the top unit switch. This “click” indicates that the switch circuit has opened and thus defi nes

the unit’s open travel stop point.

c. Tighten cam set screws taking care not to over tighten.

5. To set close travel limit switch:

a. Using the declutchable manual override, place the valve in

its fully closed position.

b. Loosen the bottom cam’s set screws and rotate cam until

a “click” is heard from the bottom limit switch. This “click”

indicates that the switch circuit has opened and thus

defi nes the units closed travel stop point.

c. Tighten cam set screws taking care not to over tighten.

6. Replace cover and test the unit. It may be necessary to

repeat step(s) 4 and/or 5.

7. Replace and tighten all cover fl ange bolts.

8. Replace and properly secure declutching knob.

9. Unit is now ready for operation.

Page 2

Operational Characteristics and Ratings

1. Valve type - Quarter-turn ball valve, bronze body, 316SS ball

and stem, reinforced Tefl on

2. Valve Ratings: 2

1

⁄2" - 3" (65 – 80mm)

400 WOG; 100psi (6.9 bar) WSP

3. Valve end connections: All sizes NPTF.

4. Max. actuator ambient temperature rating: 150°F (66ºC).

5. Max. amperage rating of aux. switch - 10 AMPS @ 115 VAC.

®

seats, standard port.

Terminal Function 21⁄2” - 3” (65 – 80mm)

21/2”and 3” (65 – 80mm) motor valves are supplied with wire

terminal strips having 16 terminals. Terminals 1, 2 and 3 operate

the motor valve. Terminals 4 and 5 are for customer provided

indicator lights

Note: 24 VAC or 115 VAC models, the following terminal

explanation will always apply.

Table 2

VALVE SIZE C

21⁄2" (65mm) 200.0

3" (80mm) 300.0

V

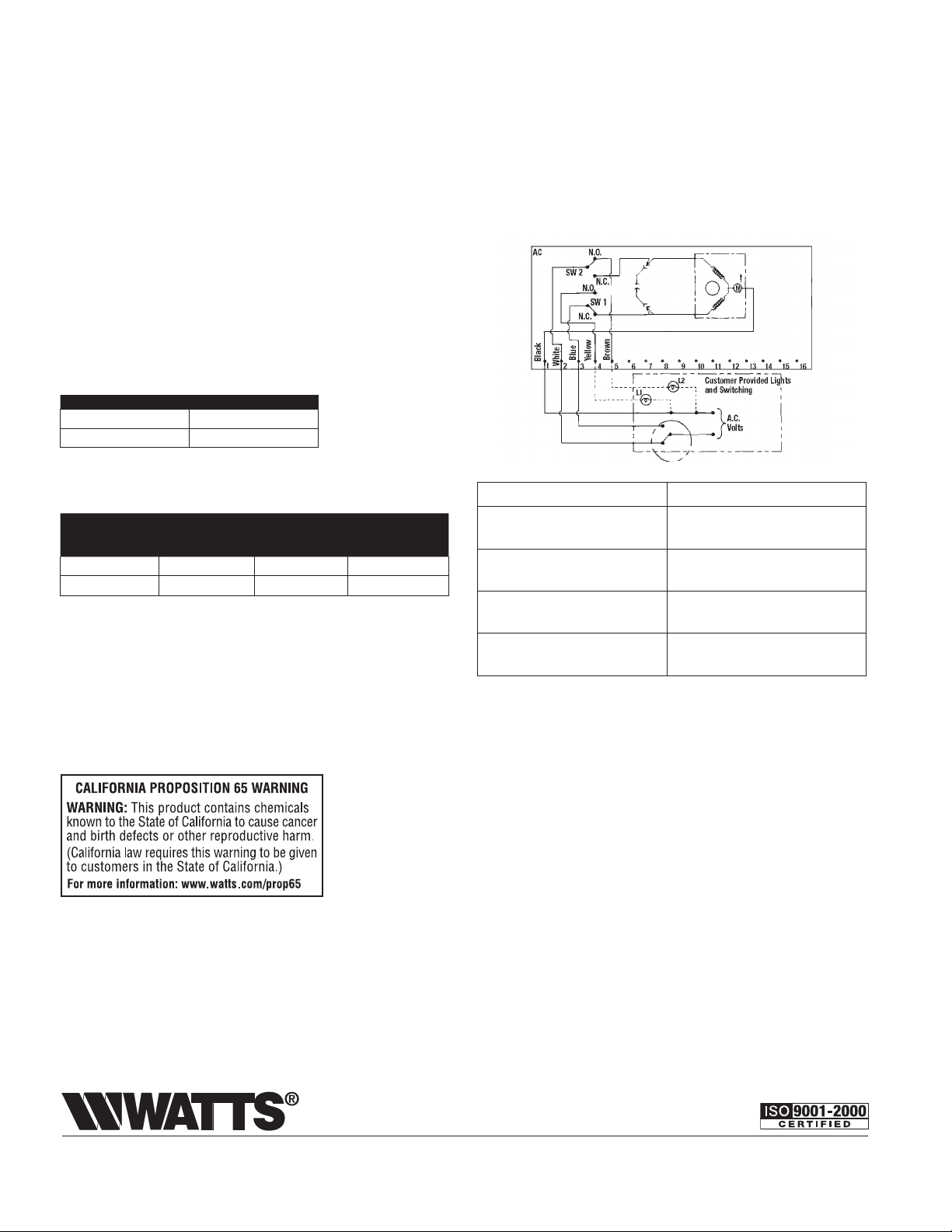

Wiring Diagram #1 for 21/2" - 3" (65 – 80mm)

Actuator shown in counterclockwise extreme of travel,

or “Open” position.

Notes:

1

1. 2

⁄2" and 3" (65 – 80mm) motor valves are supplied with wiring

terminal strips having 16 terminals.

2. Each actuator must be powered through its own individual

switch contacts to avoid cross feed.

3. Motor has a thermal protector as shown in diagram.

Table 3 - Steam Flow (#hr)-Full Open Valve

VALVE

SIZE

21⁄2" (65mm) 2920 6260 4500 6920 8100 11.060

3" (80mm) 4380 9390 203 311 12.150 16.590

10 psi INITIAL 15 psi INITIAL 25 psi INITIAL

1 psi 10 psi 1 psi 15 psi 1 psi 25 psi

ΔP ΔP ΔP ΔP ΔP ΔP

Terminal No. Function

Operating Terminal #1 When power is applied,

valve will open.

Operating Terminal #2 When power is applied,

valve will close.

Operating Terminal #3

Makes when valve is fully

closed.

Operating Terminal #3

Makes when valve is fully

open.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has

no control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

Water Safety & Flow Control Products

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

IOM-EMV-II 21/2"-3" 0845 EDP# 1915930 ©Watts, 2008

Loading...

Loading...