Page 1

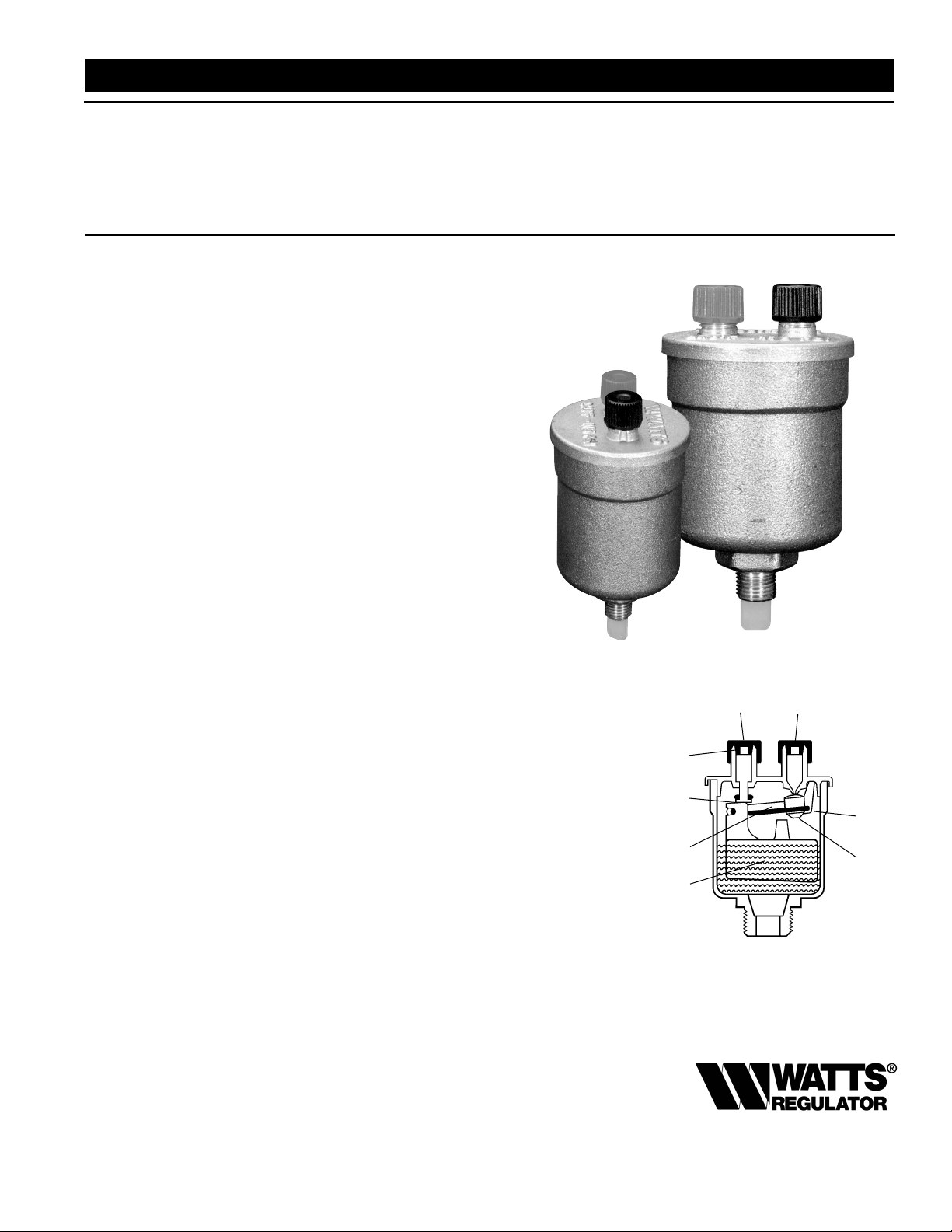

A Automatic Vent

(Black Cap)

B Manual Vent

(Red Cap)

1 Shutter

2 Spring

3 Lever

4 Float

5 Shutter head

6 Shutter button

Series DuoVent

High Capacity Air Vents with

Manual Vent Feature

Sizes: 1⁄8", 1⁄4" (3, 8mm)

Series DuoVent high capacity air vents with manual vent feature provide automatic air venting for hot or cold water distribution systems. The manual vent feature provides tremendous air

elimination capability for lightening fast venting of residential

and commercial systems.

The DuoVent valve utilizes a float to actuate the valve plug

which is located at the top of the valve. Once the air is displaced and the system pressure is sustained, the valve plug

seals and prevents any water from escaping from the system.

The float vent can also operate as an anti-vacuum device since

it will permit air to enter the system when it must be drained.

Features

• Body and cover are brass construction

•Air vent with silicone rubber seal

•Impurities do not usually affect function as maximum float line

of water is always lower than the valve seal

• Float is high temperature resistant polyethylene

• Suitable for use with glycol systems

Specifications

Air vent shall have brass body, cover and silicone rubber seal.

Float shall be constructed of high temperature resistant polyethylene and shall be for use with glycol systems. Air vent shall

be Watts Regulator Company Series DuoVent.

Pressure – Temperature

Minimum working pressure: 1.45psi (10 kPa)

Maximum working pressure: 150psi (10 bars)

Temperature Range: 33˚F – 240˚F (5˚C – 116˚C)

Maintenance

No maintenance is normally necessary, however the DuoVent

can be disassembled for inspection or cleaning.

For Hydronic Heating Applications

ES-DuoVent

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

A

B

6

5

3

4

2

1

DuoVent

Page 2

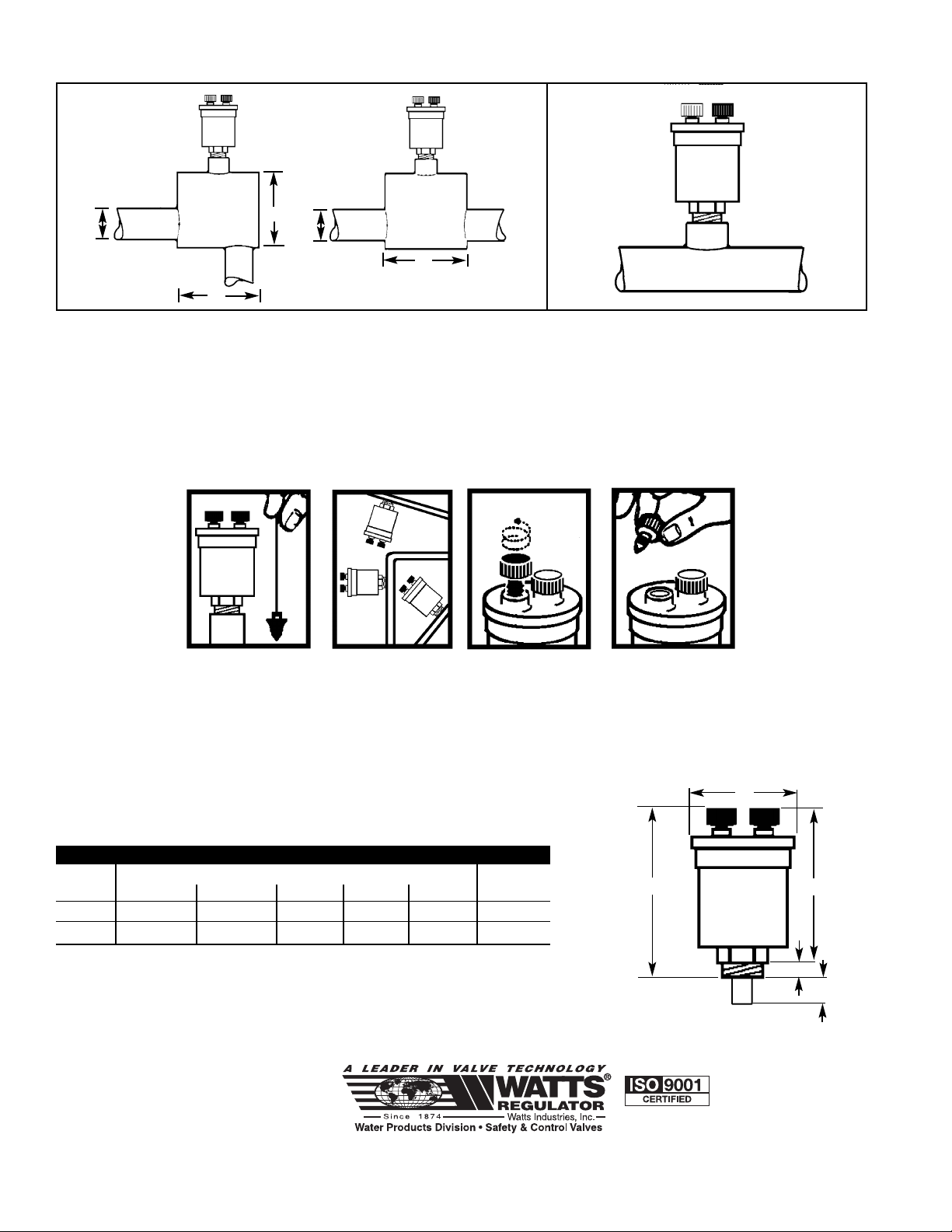

X

X

Installation – DuoVent

ES-DuoVent 0314 © Watts Regulator Company, 2003 Printed in U.S.A.

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscda.com

Fig. 1

*2.5 times pipe ID

ID = Inside Dimensions

*

*

Pipe

ID

Pipe

ID

Figure 1 shows the installation of the DuoVent for the venting of

air while the fluid is circulating in the system. The figure shows

the required increase in pipe size in order to obtain proper separation of air from water. Watts Series AS Air Scoop which is

designed for efficient separation of air from water in hydronic

heating systems can also be installed.

Figure 2 – When the DuoVent is installed as shown, the air will

not be vented while the fluid is circulating in the system, but it

can vent when the system is shut off.

The DuoVent should be mounted only in a vertical position as its

operation is based on the vertical movement of the float (see Fig. 3).

Fig. 3

Fig. 4

Loosen 2 turns

for proper

venting

SIZE (DN) DIMENSIONS WEIGHT

ABCDD

1

in. mm in. mm in. mm in. mm in. mm in. mm oz. gm.

1

⁄8 315⁄16 33 3 76 211⁄16 685⁄16 85⁄16 8 4.2 119

1

⁄4 815⁄16 33 31⁄8 79 211⁄16 687⁄16 115⁄16 8 4.2 119

*

Note: In order to get the best results in venting air from risers,

use connecting pipes of at least

1

⁄2" diameter between the “Float Vent” valves and the installation.

Operation: IMPORTANT!

After installing the DuoVent, back off the black vent cap two turns (see Fig. 4). This is the

proper operating setting which will allow air to be vented from the system. It is advisable

to leave the cap on to prevent impurities from entering the valve.

Warning! system fluid may be hot. Use Caution when manual venting hot water systems.

Dimensions – Weights

D

D

1

C

A

B

Fig. 2

Loading...

Loading...