Page 1

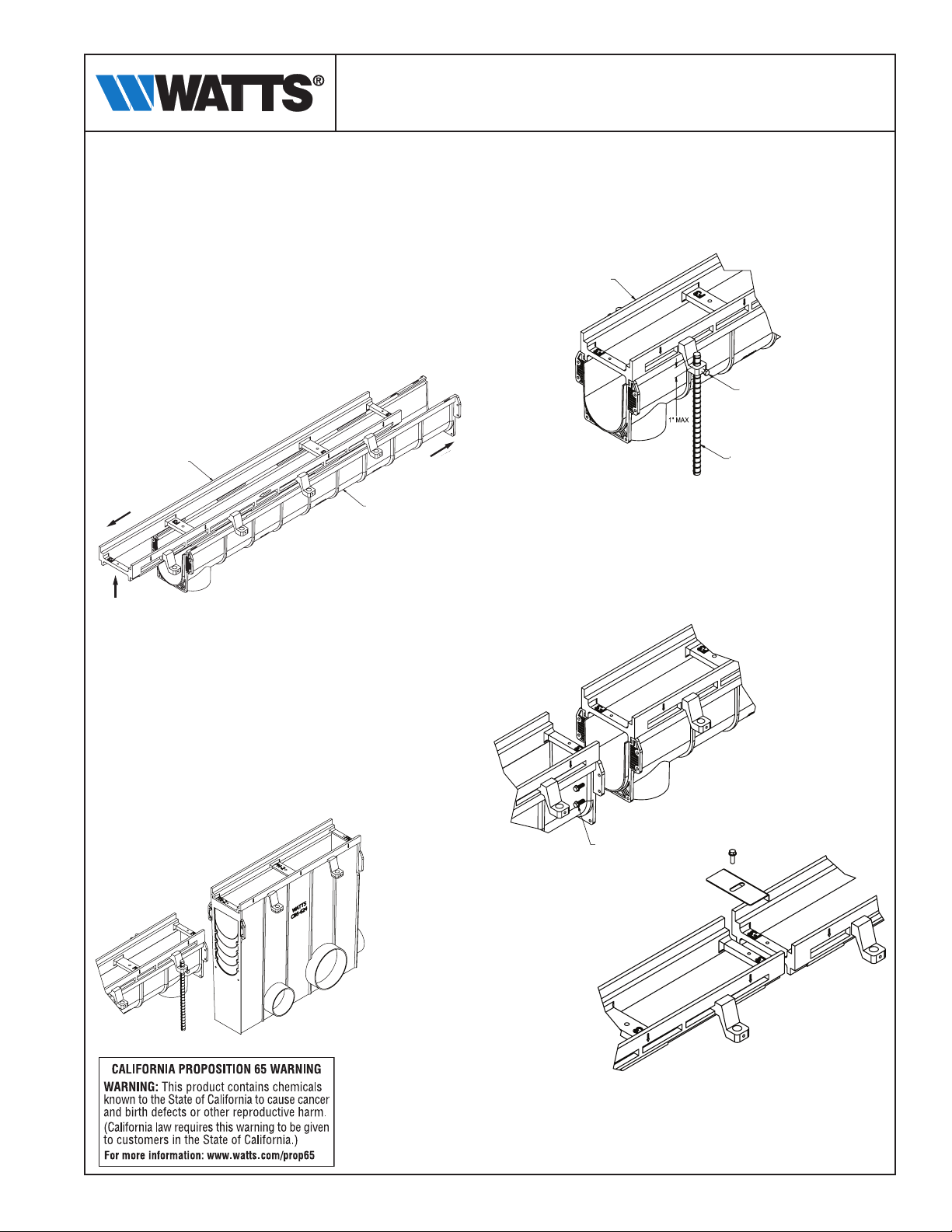

Dead Level Trench Drain Installation

Excavation

The excavation must be sufcient to allow a minimum 4" concrete

pour below, and on both sides of the trench drain.

Excavation for a catch basin must allow for 4" of concrete below the

basin.

Layout

Dead Level trench drains are generally shipped with channels assembled to the corresponding frames. A channel can be disengaged

from the frame by sliding it approximately 4" in either direction, and

pulling the channel and frame in opposite directions (Fig. A).

Working from the deepest outlet connection(s) back upstream, lay

the trench drain sections in order of installation along side the open

trench. Each channel and frame section is marked with arrows, indicating the direction of ow. The installer may wish to run a string line

along the trench to indicate the desired nished grade.

Lift

Slide

Frame

Channel

Slide

FIG. A

Catch Basins & Piping Connections

Catch basins, if used, should be set rst. Using a reciprocating or

hole saw, remove the circular pipe connection cut-out(s) where the

basin will connect to discharge piping. Invert the catch basin on a at

surface, and butt the corresponding channels against the pattern on

the basin. Use a reciprocating saw to remove the cutout on the basin.

With the cutout correctly removed, the channel tongue should slide inside the hole in the basin, with the channel ange ush against basin’s

exterior wall (Fig. B).

If a catch basin is not used, pipe connections are made to the bottom

of the channel, or to an end cap. Drill through the molded pipe hub

with a 4" hole saw or reciprocating saw, taking care not to rake the

inside wall of the hub. Make No Hub pipe connections with a suitable

coupling (by others).

Rebar Anchoring & Leveling

Starting from the outlet or catch basin, align the structural frames

along the excavated trench. Drive a minimum of 4 pieces 1/2" #4 rebar

to support each frame section. The rebar should reach a depth sufcient to provide stability for the system, and prevent oating during

the concrete pour. Level the system by sliding the frame ears along

the rebar. Secure the frame to the rebar using 3/8" hex bolts (Fig. C).

FRAME

1/4-20x3/8" Hex Bolt

1/2" #4 REBAR

FIG. C

Joint Connections

Making sure all sections are aligned with ow arrows pointing towards

the outlet, connect channels and end caps through the anges using

1" anged hex bolts (Fig. D). Using frame connectors F-L, join the

frames from the top using 3/8" hex bolts (Fig. E).

It is usually unnecessary to seal channel joints in on-grade installations. If corrosive solutions are present, or sealed joints are otherwise

desired, use a small bead of silicone caulk to seal each channel joint.

FIG. D

FIG. B

1/4 x 1" SELF-TAPPING

HEX BOLTS

FIG. E

Page 2

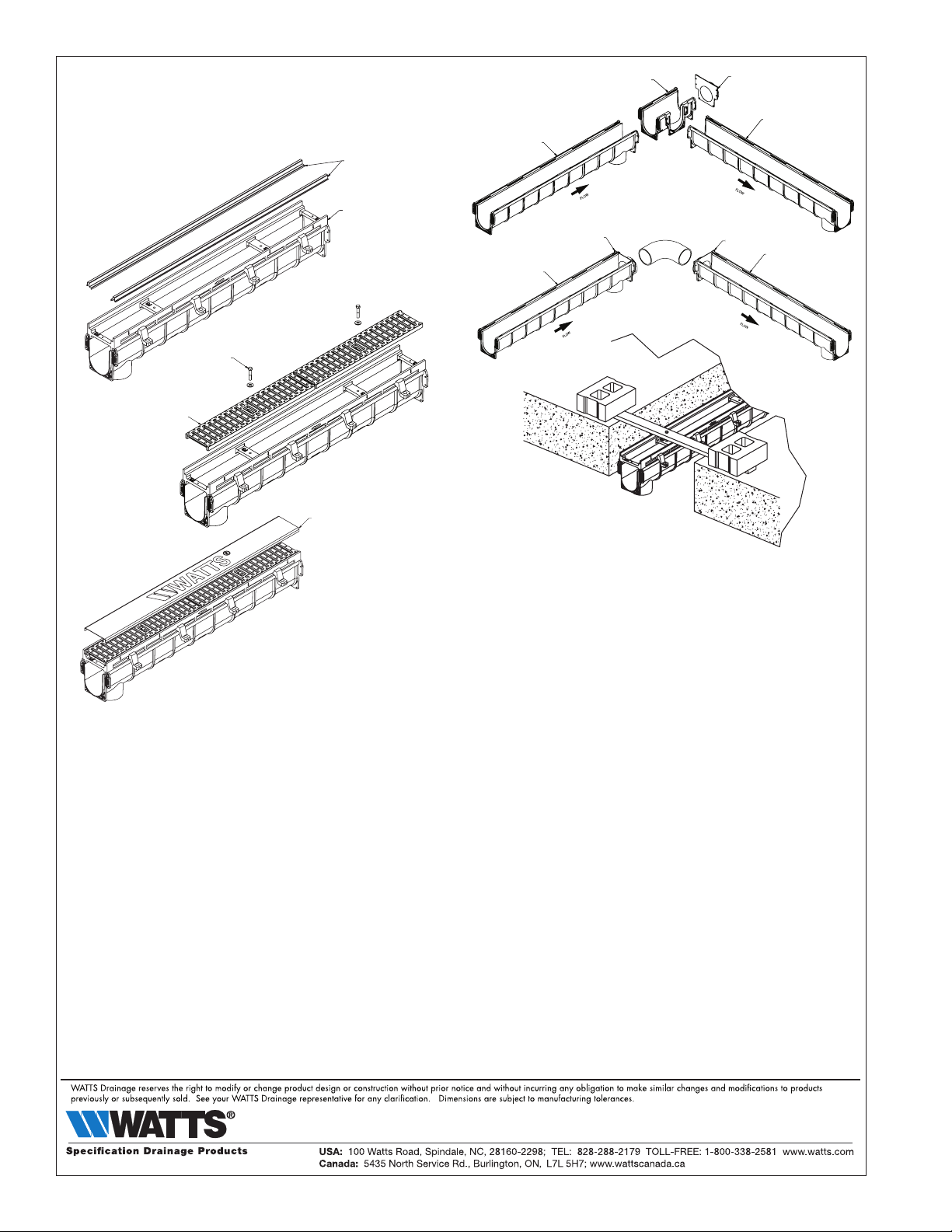

Grate Installation

Grates should always be installed prior to the concrete pour.

If used, install Frames Guards prior to setting the grates (Fig. F). Install

grates along the length of the trench, and secure with hex head or

countersunk lock bolts provided (Fig. G). Position Construction Covers

over the grates, with the ange between the grate and frame (Fig. H).

FRAME GUARDS

(OPTIONAL)

STANDARD

SECTION

CORNER / TEE SECTION

END CAP

STANDARD

SECTION

FIG. I

FIG. F

CHANNEL & FRAME

STANDARD

SECTION

END CAP

END CAP

STANDARD

STANDARD SECTION

SECTION

FIG. J

LOCK DOWN

GRATES

CONSTRUCTION COVER

FIG. G

FIG. K

Concrete Pour

Check the entire trench system for proper anchoring, alignment, and

leveling, prior to pouring concrete. Although the Dead Level frameanchored design dramatically reduces the risk of oating, a poorly

anchored system can shift during the pour. Check the excavation to

be sure a minimum of 4" of concrete can be poured under, and on

all sides of the channels. The concrete must be adequately vibrated

as it is placed, to ensure complete lling of all potential voids around

the trench. The top edge of the trench frame should be approx. 1/16"

below grade after nish troweling to keep the frame at or below grade

FIG. H

after the concrete is fully cured.

Final Inspection

Corners/Tees

If the system layout requires Corner/Tee Sections, follow the general

installation guidelines. Invert the Corner/Tee section on a at surface,

and use a reciprocating saw to remove the appropriate cutout(s) on

the section. Be sure to note whether the connecting channel(s) have

a tongue or groove connection prior to cutting the Corner/Tee, and

remove a cutout opposite the connecting channel. With the cutout

correctly removed, the tongue should slide inside the mating groove,

and the anges should sit ush against each other (Fig. I). Secure the

channels and frames with the appropriate hardware (see “Joint Connections").

Note Dead Level corners or tees can also be formed with a Catch Basin (See “Catch Basins & Piping Connections"), or underground piping. To pipe underground, terminate the trench drains a short distance

from the corner joint. Attach the appropriate endcaps, then connect

the endcaps with 4" Sch40 90’s, tees, and piping as required (Fig. J).

LIMITED WARRANTY:

Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event of such defects within

the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THE

COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special or consequential damages,

including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling

caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper

installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you.

This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE

STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM

THE DATE OF ORIGINAL SHIPMENT.

After the concrete is dry, remove the construction covers, and retighten the grate lockdowns. If construction covers will not pry out

easily, cut the cover, and loosen the grate lockdown to free the sides

of the cover.

Retro-Fit or Suspended Installations

Cut the existing slab or form a cavity which will enable a 4" concrete

pour below and around the Dead Level system. Cut 2x4’s at least

30" in length to span the cavity, and align 2x4’s with the cross bars

in the trench frame. Drill 1/2" holes to secure the 2x4’s to the frame

cross bars, using 3/8-16x4-1/2" (minimum) bolts and washers (Fig. K

). Insert a thin shim between 2x4’s and the frame to ensure the trench

will sit slightly below nished grade after the pour. Securely anchor the

2x4’s to grade to prevent oating. Once the concrete is initially set,

remove 2x4’s and complete unnished areas with concrete. Install the

grates & lockdowns.

IS-WD-DL-Installation 1104 EDP# 2915867 DL-Instatllation

Loading...

Loading...