Page 1

For HVAC, Irrigation, OEM, Commercial and Institutional Applications

ES-DBF

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

LEAD FREE

*

Contractor

Approval

Contractor’s P.O. No.

Representative

Butterfly Valves

Series DBF-03 Full Lug and DBF-04 Wafer

Sizes: 2" - 12" (50-300mm) 200psi (13.8 bar)

Watts Series DBF resilient seated butterfly valves are available in

sizes 2"-12" (50-300mm), wafer or lug body design. This series

was designed to meet the stringent requirements for HVAC,

Irrigation, OEM, Commercial and Institutional applications, and

wherever positive shutoff is required for liquids, gases, and slurries. Incorporating a 200psi (13.8 bar) pressure rating for 2"-12"

(50-300mm), the Series DBF is standardly constructed of a

ductile iron body, an aluminum bronze, ductile iron or 316SS

disc, and a 416SS or 316SS shaft. Standard seat materials

available include Buna-N, EPDM, and Viton

seat prevents the seat from collapsing or dislodging. In addition

to the above features, the Series DBF mounting pad is designed

to ISO 5211 standard to accommodate lever handles, gear

operators or actuator.

The Watts Series DBF butterfly valves are designed and manufactured for use with ANSI 125 or 150 Class flanges and to

comply with API 609 and MSS-SP-67.

®

. A phenolic-backed

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

Full Lug

Wafer

Features

Operators – Ten-position handle is standard. An infinite

positioning/locking handle is also available on valve sizes 2"-12"

(50-300mm). The infinite position Pos-Lok throttle plate incorporates a memory stop and a padlocking device in the fully closed

position. Manual, worm-gear operators are available for all valves

and are recommended on 8" (200mm) and larger sizes. Watts

butterfly valves are also available with electric or pneumatic

actuators and chain wheel operators to satisfy a wide variety

of requirements.

Shaft

– One-piece shaft delivers positive disc-to-seat location

with maximum strength. 416SS is standard with aluminum

bronze and ductile iron discs and 316SS shaft with stainless

steel disc.

Shaft Bushings – Duralon

for proper shaft alignment and minimal shaft deflection.

Shaft Seal

seal prevents external contamination of stem area and provides

a backup seal to the primary shaft seal formed by the disc/seat

interface.

Body

and Wafer (DBF-04) types designed for use between ANSI 125

and 150 flanges. Face-to-face dimensions comply with API 609

and MSS-SP-67. All valves are designed to accommodate 2"

of insulation. The standard body material is ASTM A-536

ductile iron.

– To prevent shaft leakage, the bidirectional shaft

– Watts Butterfly Valves are available in Full Lug (DBF-03)

®

bushings (3) provide shaft support

Disc – Disc edge is machined and polished 360° to assure leak-

tight shutoff while minimizing operating torque. Positive, disc-toshaft connection is provided by stainless steel precision taper

pins that are vibration proof.

Seat – Phenolic-backed, non-collapsible, resilient seat is me-

chanically secured to provide dead-end service to the full 200psi

(13.8 bar) pressure rating. Seat face eliminates the need for

flange gaskets. Full 360° sealing isolates the body components

from the media and provides the primary shaft seal. Available in

EPDM, Buna-N, and Viton

Duralon® is a Registered Trademark of Rexnord Corporation

®

is a Registered Trademark of E.I. DuPont de Nemours, Co., Inc.

Teon

®

is a registered trademark of DuPont Dow Elastomers.

Viton

*The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

®

.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

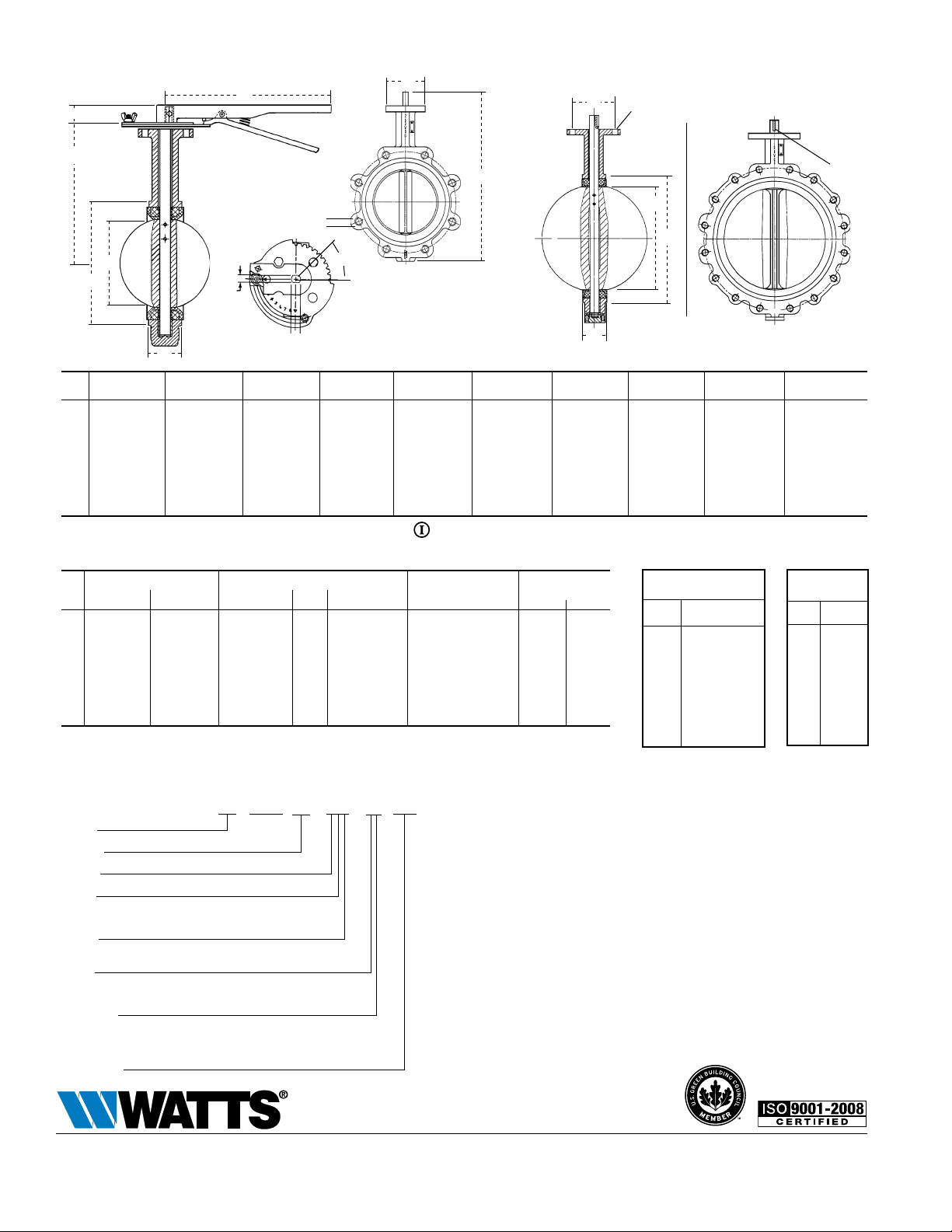

Dimensions

2" through 24"

G

D

F

(4) “O” Diameter of

holes on the “N”

N

bolt circle 45° off center.

B(CL)

A

Q

E

P

▼

E

I

J

45°

▼

I

Across

ats

C

A B C D E F G H I J

Size in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

2" 103⁄4 273 63⁄8 161 15⁄8 42 11⁄4 32 21⁄8 54 31⁄16 77 101⁄2 267 1⁄2 13 33⁄4 95 3⁄8 9

1

2

⁄2" 115⁄8 295 67⁄8 175 13⁄4 45 11⁄4 32 29⁄16 65 31⁄16 77 101⁄2 267 1⁄2 13 41⁄4 108 3⁄8 9

3" 12

4" 13

5" 14

6" 15

8" 18

10" 21

12" 24

1

⁄8 308 71⁄8 181 13⁄4 45 11⁄4 32 31⁄8 79 31⁄16 77 101⁄2 267 1⁄2 13 43⁄4 120 3⁄8 9

5

⁄8 346 77⁄8 200 2 52 11⁄4 32 41⁄8 105 35⁄8 92 101⁄2 267 5⁄8 16 61⁄16 154 3⁄8 10

5

⁄8 372 83⁄8 213 21⁄8 54 11⁄4 32 47⁄8 124 35⁄8 92 101⁄2 267 3⁄4 19 71⁄8 181 1⁄2 13

5

⁄8 397 87⁄8 226 23⁄16 55 11⁄4 32 61⁄8 156 35⁄8 92 101⁄2 267 3⁄4 19 83⁄16 208 1⁄2 13

7

⁄8 479 101⁄4 260 23⁄8 60 13⁄4 45 8 200 41⁄2 115 14 356 7⁄8 22 101⁄4 260 5⁄8 16

1

⁄4 540 111⁄2 292 25⁄8 66 13⁄4 45 97⁄8 251 41⁄2 115 14 356 11⁄8 29 125⁄8 320 3⁄4 19

5

⁄8 626 131⁄4 337 3 76 13⁄4 45 117⁄8 301 51⁄2 140 14 356 11⁄4 32 143⁄4 375 11⁄4 32

H

Dia.

C

For 14"- 24" BF Series Dimensional Data,

Request Engineering Spec Sheet ES-BF-03-M2/BF-04-M2.

Top Plate Drilling Tapped Lug Data Key Way Weight†

N O Bolt Circle No. Bolt Q DBF-03 DBF-04

Size in. mm in. mm in. mm Holes P in. mm lbs. kgs. lbs. kgs.

1

⁄4 57 1⁄4 6 43⁄4 121 4 5⁄8"-11UNC x 11⁄4" – – 8 3.6 6 2.7

2" 2

1

2

⁄2" 21⁄4 57 1⁄4 6 51⁄2 140 4 5⁄8"-11UNC x 13⁄8" – – 10 4.5 7 3.2

1

3" 2

⁄4 57 1⁄4 6 6 150 4 5⁄8"-11UNC x 13⁄8" – – 10 4.5 7 3.2

3

4" 2

⁄4 70 3⁄8 10 71⁄2 191 8 5⁄8"-11UNC x 11⁄2" – – 17 7.7 12 5.4

3

5" 2

⁄4 70 3⁄8 10 81⁄2 216 8 3⁄4"-10UNC x 13⁄4" – – 25 11.3 16 7.3

3

6" 2

⁄4 70 3⁄8 10 91⁄2 241 8 3⁄4"-10UNC x 2" – – 27 12.2 20 9.1

1

8" 3

⁄2 89 5⁄8 16 113⁄4 298 8 3⁄4"-10UNC x 21⁄8" – – 40 18.1 29 13.2

1

10" 3

⁄2 89 5⁄8 16 141⁄4 362 12 7⁄8"-9UNC x 21⁄4" – – 63 28.6 48 21.8

1

12" 4

⁄4 108 5⁄8 16 17 432 12 7⁄8"-9UNC x 21⁄4" 1⁄4 x 1 6 x 25 107 48.5 78 35.4

†

Weights are for valves with ductile iron or aluminum bronze discs and 10-position lever handles.

Refer to Watts’ folder F-CDBF for butterfly valve weights with gear actuators, or consult factory.

SEATING TORQUE

Buna-N, EPDM, Viton

Size Normal Conditions

WET/DRY

2" 134/214

1

⁄2" 190/289

2

3" 250/387

4" 390/644

5" 600/959

6" 907/1,542

8" 1,697/2,919

10" 2,500/4,857

12" 3,300/7,071

CV RATING

(Full Open)

Size CV Rating

2" 135

21⁄2" 220

3" 302

4" 600

5" 1,022

6" 1,579

8" 3,136

10" 5,340

12" 8,250

How to Order Watts Series DBF

10 - DBF- 03 - 121 - G - M2

Size:

2" thru 12"

Series:

03; Full Lug, 04; Wafer

Body:

1; Ductile Iron

Disc:

1; Ductile Iron

2; Aluminum Bronze

3; 316 Stainless Steel*

Shaft:

1; 416 Stainless Steel

316SS on stainless steel disc models*

Seat:

1; EPDM

2; Buna-N

3; Viton

Operator:

0; No handle - 2" through 12"

G; Gear Operator - 2" through 12"

5; Standard handle (10-position) - 2" through 12"

P; Positioning / Locking Kit with handle - 2" through 12"

M2 Series:

A Watts Water Technologies Company

Materials

Body: ASTM A-536 Ductile Iron.

Bushing: Duralon (3): Teflon

to fiberglass - epoxy resin outer shell.

Stem O-rings: Buna-N

Disc: ASTM A-395 Ductile Iron / Electroless

Nickel Plated.

ASTM B-148 Aluminum Bronze

ASTM A-351 type 316SS

Shaft: 416 Stainless Steel

316 Stainless Steel on 316SS Disc Models

Seat: EPDM: +5°F to 248°F (-15°C to +120°C)

Buna-N: +14°F to 176°F (-10°C to +80°C)

Viton: -4°F to 302°F (-20°C to +150°C)

Note: Do not use EPDM when hydrocarbons are present.

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

®

- Dacron liner bonded

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

ES-DBF 1412 © 2014 Watts

Loading...

Loading...