Page 1

For Balancing and Flow Measurement Applications

ES-CSM-91-INS

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

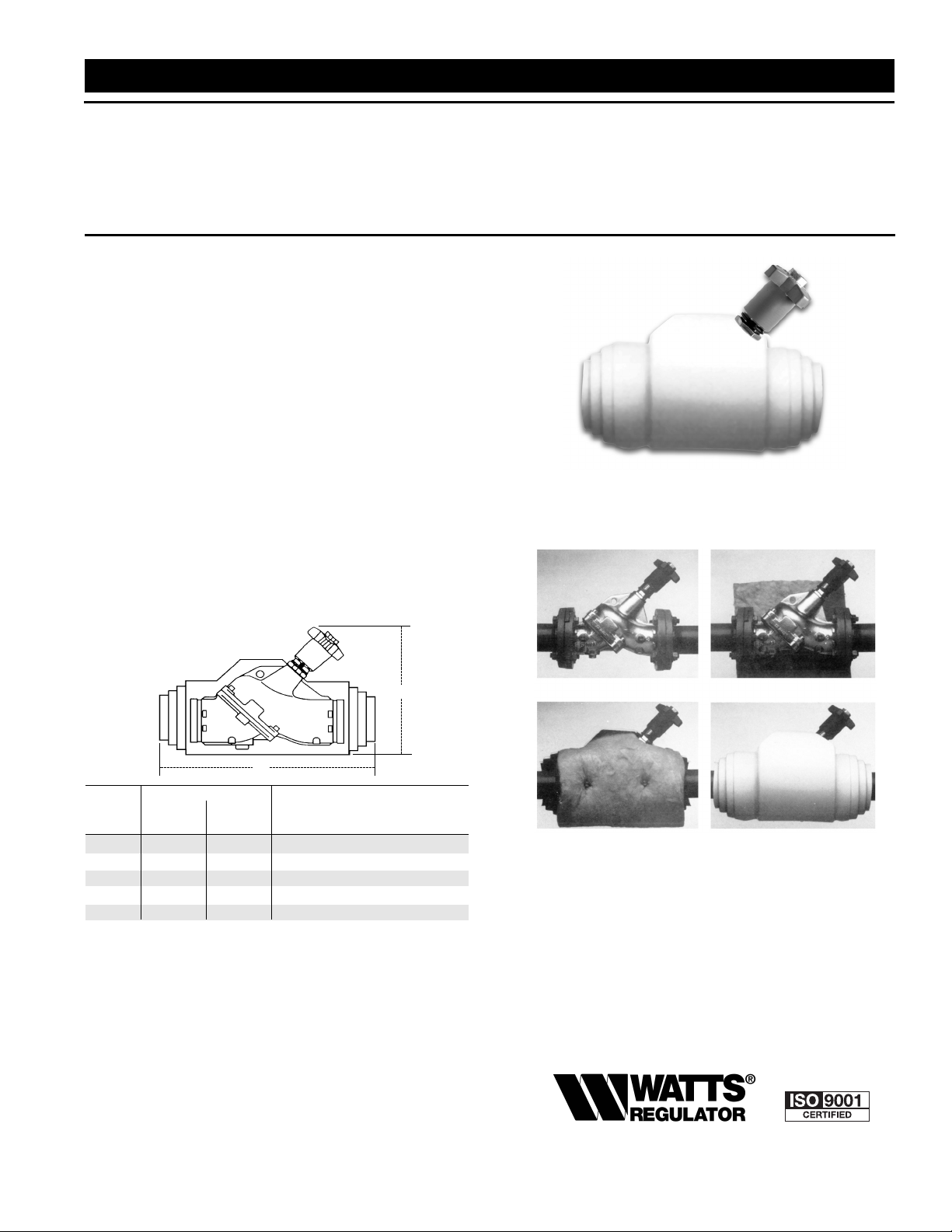

Insulation Systems

Sizes: 21⁄2" – 6" (65 – 150mm)

Watts Insulation Systems are available in sizes 21/2" – 6"

(65 – 150mm) to suit series CSM-91 circuit balancing valves

and series TDV Triple Duty Combination Valves.

The outside shell is a preformed, removable PVC jacket to meet

ASTM D 1784/class 14253-C, MEA #7-87, ASTM-E-84 and

ASTM-136 with a flame spread rating of 50 or less. There is provided sufficient mineral fiberglass insulation to meet ASHRAE

90.1-1989 specifications in operating conditions with Maximum

Fluid Design Operating Temperature Range of 141˚F – 200˚F

(61˚C – 93˚C) and Mean Rating Temperature of 125˚F (52˚C).

Materials

Outside Shell (2): Zeston 2000 PVC

Insulation Batten: Mineral Fiberglass

Fastener (4): Stainless steel

Dimensions

CSM-91-INS

Fig. 1 Fig. 2

Fig. 3 Fig. 4

ES-CSM-91-INS 0317 © Watts Regulator Company, 1996 Printed in U.S.A.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscda.com

1. Wrap fiberglass insulation around valve keeping insulation

tight around valve neck and body as shown in figs. 2 & 3.

2. Cut out insulation around pressure taps so that when diagnostic checks are required, plugs are visible when outside

shell is removed as shown in fig. 3.

3. Slide 2-Piece outer shell over insulation snugly and then use

fastening tacks on top and bottom to secure shell as shown

in fig. 4.

Size (DN) Dimensions L x W x T

AB Insulation Batten Size

in. mm in. mm in. mm in. mm

21/2 65 201/2 521 10 254 32 x 15 x 11/2 813 x 381 x 38

38020508 11 279 37 x 15 x 11/2 940 x 381 x 38

4 100 22

1

/2 572 121/2 318 40 x 17 x 11/2 1016 x 432 x 38

5 125 26 660 14 356 481/2 x 21 x 11/2 1232 x 533 x 38

6 150 30

1

/2 775 16 406 511/2 x 221/2 x 11/2 1308 x 572 x 38

A

B

Installation Instructions

Loading...

Loading...