Page 1

For Balancing and Flow Measurement Applications

ES-CSM-61

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

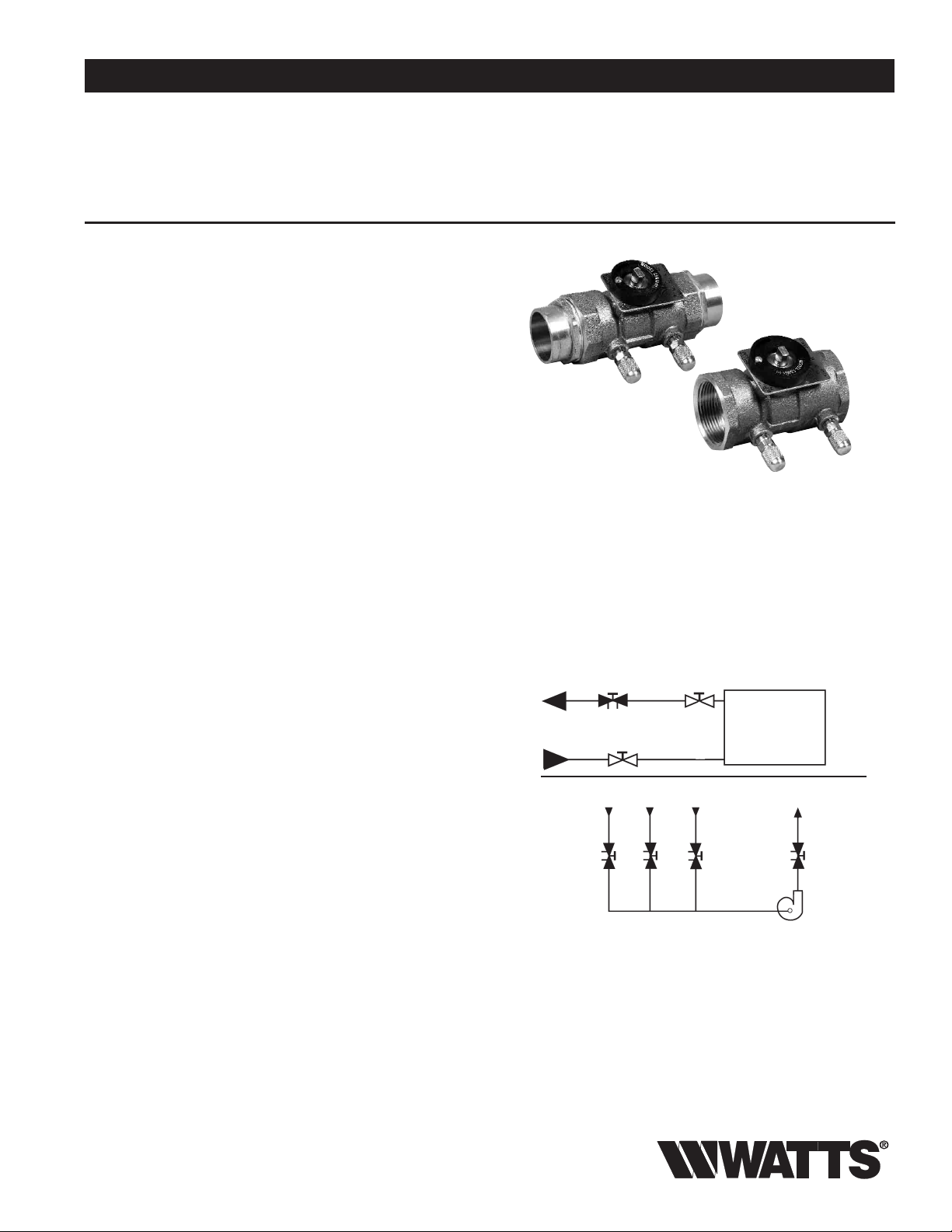

Series CSM-61

Flow Measurement Valves

Sizes: 1⁄2" – 3" (15 – 80mm)

Series CSM-61 Flow Measurement Valves are designed for

application on low or medium flow rate HVAC units. Their

compact size allows for easy installation and use in crowded

piping compartments. The CSM-61’s ball-type design, extended

throttling range, and large indicator plate, make for highly

accurate flow measurement, even in very low flow ranges.

The CSM-61’s positive memory feature is easy to see, access,

and operate, facilitating system balancing and flow measurement.

These valves are also bi-directional, so there is no chance of

installing the valve in the incorrect flow direction.

Series CSM-61 valves provide positive shutoff, eliminating the

need for a separate service valve. The solder style CSM’s may

be installed without disassembly, saving costly installation time.

These valves are also provided with blowout proof stems. Use,

misuse, corrosion, or wear will not allow the stem to “blowout,”

releasing pressurized hot or chilled water.

Features

• Accurate flow measurement

• Easy to use memory

• Bi-directional flow

• Positive shutoff

• Safe “blowout” proof design

• Available with threaded and solder end connections

• Integral drain port

Applications

• Fan coil units

• Water source heat pumps

• Reheat coils

• Panel coils

• Small branch lines

• Unit heaters

• Unit ventilators

• Finned radiation

• Small domestic hot water lines

• Convectors

• Small pumps

Specifications

A flow measurement valve shall be installed on each hot/chilled

water unit or as otherwise shown on plans. The valve shall be of

the bi-directional, blow-out resistant, tight shutoff, ball design, with

position indicator, memory device, checked metering ports with

drip caps and integral drain ports opposite the metering ports.

The valve shall be a Watts Regulator Company Series CSM-61.

CSM-61

Sweat

Threaded

Fan

Coil

Unit

Series CSM-61

Fan Coil Unit

Series CSM-61

Pump and Branches

Series CSM-61

Series CSM-61

Series CSM-61

Typical Installation

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

BAA/ARRA Compliant

*

*This product complies with the Buy American Act and The

American Recovery and Reinvestment Act. For more information,

visit watts.com.

Page 2

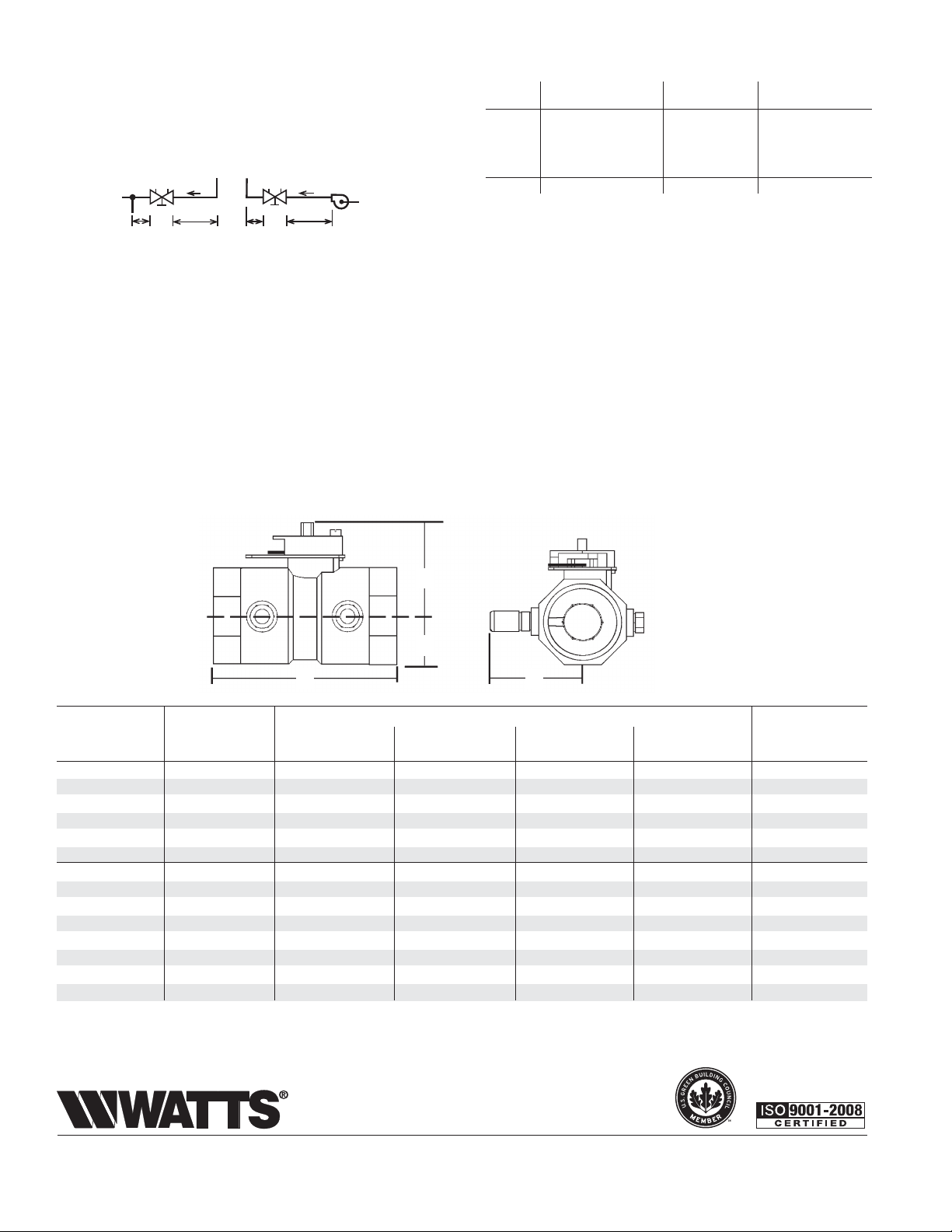

Model Size (DN) Dimensions Weight

ACDR

in. mm in. mm in. mm in. mm in. mm lbs. kgs.

CSM-61-M1-S

1

⁄2 15 211⁄16 68 15⁄8 41

1

⁄2 13 13⁄4 45 1.0 0.45

CSM-61-M1-S

3

⁄4 20 31⁄8 79 111⁄16 43

9

⁄16 15 17⁄8 47 1.3 0.59

CSM-61-M1-S 1 25 313⁄16 97 17⁄8 47

13

⁄16 20 21⁄16 52 1.8 0.82

CSM-61-M2-S 1

1

⁄4 32 49⁄16 116 17⁄8 47 11⁄8 29 23⁄16 56 1.5 0.68

CSM-61-M2-S 11⁄2 40 47⁄8 123 2 50 15⁄16 33 25⁄16 59 1.9 0.86

CSM-61-M2-S 2 50 6 153 2

9

⁄16 66 19⁄16 40 25⁄8 67 3.4 1.54

CSM-61-M1-T

1

⁄2 15 23⁄8 60 15⁄8 41

1

⁄2 13 13⁄4 45 1.0 0.45

CSM-61-M1-T

3

⁄4 20 25⁄8 67 111⁄16 43

9

⁄16 15 17⁄8 47 1.3 0.59

CSM-61-M1-T 1 25 31⁄8 80 17⁄8 47

13

⁄16 20 21⁄16 52 1.9 0.86

CSM-61-M1-T 1

1

⁄4 32 33⁄4 94 17⁄8 47 1 25 23⁄16 56 1.9 0.86

CSM-61-M1-T 11⁄2 40 315⁄16 100 2 50 11⁄16 27 25⁄16 59 2.3 1.04

CSM-61-M1-T 2 50 4

1

⁄2 114 29⁄16 66 15⁄16 33 29⁄16 66 4.0 1.81

CSM-61-M1-T 21⁄2 65 61⁄2 165 41⁄8 104 23⁄16 55 31⁄8 80 13.0 5.90

CSM-61-M1-T 3 80 6

13

⁄16 173 43⁄8 112 27⁄8 73 35⁄8 92 17.0 7.71

Suffix: S = Solder Ends, T = Threaded Ends

C

D

A

R

Dimensions - Weights

Materials

Housing/Body Bronze

Packing Material Viton

®1

⁄2" – 2" (15 – 50mm)

Neoprene 2

1

⁄2" – 3" (65 – 80mm)

Pressure Taps Brass

1

⁄4" SAE 45° Flare

Seats Carbon/Glass filled PTFE -

1

⁄2" – 1", 3" (15 – 25, 80mm)

Virgin PTFE 1

1

⁄4" – 2" (32 – 50mm)

Drain Plug Brass

Pressure -Temperature

Working Temp Max. Working Pres.

Pattern Size °F °C psi bars

Solder1⁄2"-1" (15-25mm) 200* 93 100 7

250 ** 121 200 14

1

1

⁄4"-2" (32-50mm) 200* 93 90 6

250 ** 121 175 12

Thread1⁄2"-3" (15-80mm) 250 121 300 21

*Note 1: Solder used in joints: 50-50 Tin Lead (ASTM B32 Alloy Grade 50A)

**Note 2: Solder used in joints: 95-5 Tin Antimony

Viton

®

is a registered trademark of Dupont Dow Elastomers

Installation

Generally locate the valve five pipe diameters downstream from

a fitting with two diameters downstream from the balancing

valve free from fittings. If a balancing valve is located downstream from a circulation pump, allow a distance of ten (10)

diameters between the pump and balancing valves.

ES-CSM-61 1038 © 2010 Watts

USA: No. Andover, MA • Tel. (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Burlington, ONT. • Tel. (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

A Watts Water Technologies Company

CSM

PUMP

10D

2D

CSM

5D

2D

Loading...

Loading...