Page 1

“Installation & Specification Guide”

Backflow Irrigation Control Station

BIC-1000

Table of Contents

I. BIC Station Description & Features ............................................................................................................... 2

Automatic Control Valve Data .................................................................................................................... 3-4

Specification Drawing

Configuration Data

Valve Station Component Requirements

Typical Performance Data

Typical Configuration Drawing

Customer Inputs

Auto Shift Valve Data .................................................................................................................................. 5-6

Specification Drawing

Configuration Data

Valve Station Component Requirements

Typical Performance Data

Typical Configuration Drawing

Customer Inputs

II. BIC Station Operation .................................................................................................................................... 7

ES/IS-BIC-1000

Page 2

Description

The primary purpose of this valve station is to provide pressure

control over a large range of flow rates at a fixed point in the irrigation system. The station shall be designed such that -

A. System pipe breaks and leakage are minimized, based on

best practice design principles.

B. Ease of System Maintenance is of primary importance.

C. System Performance is reliable and consistent and matches

certified design criteria.

A secondary purpose of this valve station may be to provide onoff flow control to the system.

Features

A. System pipe breaks and leakage are minimized based on

best practice design principles

The valve station shall be designed such that the following

capabilities may be achieved -

1. Maintain system pressure at a constant pressure that will

provide adequate discharge from the worst case Station or

Head from 20% to 100% of design flow.

• No more than 10psi variation at steady state flow over

entire operating range from 20% to 100% of continuous

flow range.

2. Reduce or eliminate pressure spike or "Water Hammer"

events by minimizing operating pressure during operation.

• Field adjustable closing speed on pressure or flow control

valves.

• Field adjustable set point with minimal "drop off" as flow

rate increases.

• Ability to set the stable pressure as low as possible while

maintaining "A1" (see above). Range: 40 – 120psi set

point.

3. Provide a means to drastically reduce system pressure when

the system is idle.

• Provides a small pre-load valve to maintain a constant low

pressure to the system during idle times.

• A low flow rate valve is ideal in order to conserve water

should pipe leaks be prevalent.

4. Minimize the amount of piping that is subjected to high

purveyor supply pressure.

• Provide a valve station as near to the purveyor connection

as possible.

B. Ease of System Maintenance is of primary importance.

1. Provide for ease of access.

• Valve Station shall be designed to be installed so that all

equipment that may require scheduled maintenance or

repair is above ground.

2. Provide for means to determine functionality.

• All equipment subject to inspection for maintenance /

repair / or performance evaluations shall be designed such

that proper operation can be determined through external

test methods rather than solely by disassembly and

inspection.

3. Provide for means of in-line repair or ease of replacement.

• All equipment shall be flanged, or installed with unions or

grooved couplers.

• Adequate Spacer Flanges shall be used to ensure that

compensation for manufacturing variations in equipment

lay length may be made.

C. System Performance is reliable and consistent and matches

certified design criteria.

1. Provide fully matched and certified components in a preassembled and certified valve station.

• Wherever possible, a single manufacturer's components

shall be used in the Valve Station Assembly.

• Valve Station vendor shall provide a certified submittal with

bill of materials which will detail the primary customer connection dimensions, the installed equipment, and the

materials of construction for approval prior to fabrication.

• Vendor shall provide a pre-assembled Valve Station that

has received at a minimum full hydro-test to 1.5 times the

design supply pressure for 5 minutes.

• Vendor shall provide performance data submittals for comparison of proposed Valve Station performance to system

design criteria.

2

Page 3

3

H

Height from

Flange To Top

Automatic Control Valve Data

BIC 1000 Specification Drawing

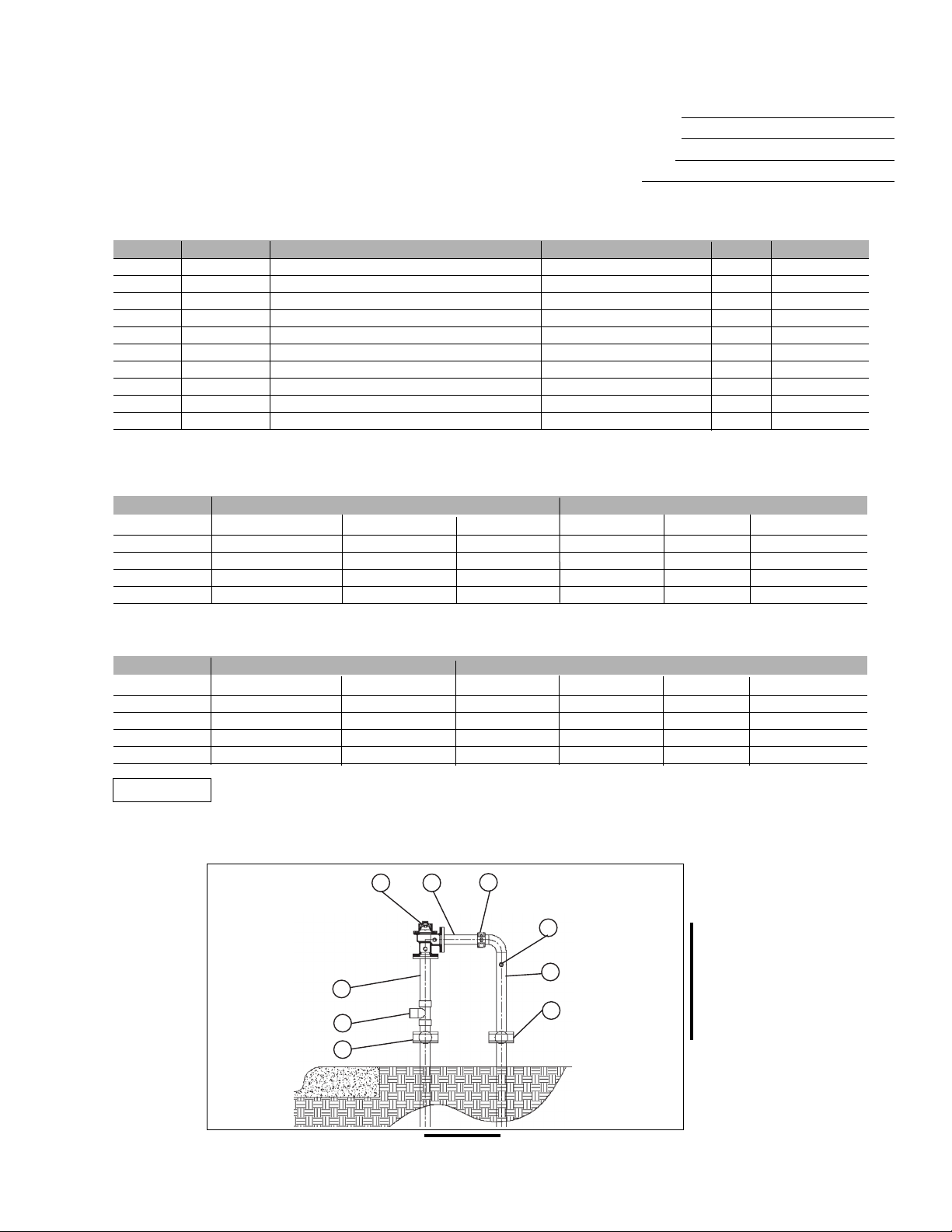

Configuration Data Typical BOM and Drawing

Valve Station Component Requirements

ITEM QTY DESCRIPTION MATERIAL SIZE CONNECT

1 1 SHUT-OFF VALVE Contact Factory FLANGE

2 OPTIONAL FLOW METER Contact Factory FLANGE

3 1 FLANGE X THREAD ADAPTOR 304 SS / ZN PLATE STEEL FLANGE

4 1 DIAPHRAGM ACTUATED CONTROL VALVE FBE / DI / SST FLANGE

5 1 FLANGE X GROOVE ADAPTOR 304 SST FLG X GRV

6 1 GROOVE COUPLER EPOXY COATED DI GROOVE

7 1 RELIEF VALVE BRASS / BRONZE FLANGE

8 1 OUTLET HEADER 304 SST FLANGE

9 1 SHUT-OFF VALVE Contact Factory FLANGE

10 3 SPACER FLANGE - SLOTTED - NOT SHOWN 304 SST FLANGE

NOTE: See specific component specifications or literature for detailed component material descriptions

FLOW RATE CAPACITIES - GPM PRESSURES - PSI

LINE SIZE CONTINUOUS INTERMITTENT* MINIMUM MAX INLET MIN DP SET POINT RANGE

2 210 260 1 170 20 40 - 120

3 460 570 30 170 20 40 - 120

4 800 1000 50 170 20 40 - 120

6 1800 2300 115 170 20 40 - 120

*Based on:

a - Max capacity through the ACV for a system with a 20psi or greater pressure reduction requirement

FLOW RATES - GPM FALL OFF FROM SET POINT @ - PSI

LINE SIZE 20% CONT 20% INTERMIT 20% CONT 20% INTERMIT 100% CONT 100% INTERMIT

242 52 0 146

3 92 114 0 0 1 2

4 160 200 0 1 2 4

6 360 460 0 0 1 2

X Hydro test the fully assembled Valve Station to 175psi for 5 minutes without leakage.

JOB NAME

CUSTOMER

ENGINEER

RFQ#

ACV ONLY

Typical Performance Data

CC - Center Line of Inlet / Outlet Pipes

Typical Configuration Drawing - Above Ground Installation

4

3

2

1

5

6

7

8

9

Page 4

Typical Dimensional Data

Certified Drawing Supplied with Order

Station Specifications

Backflow - Irrigation Control Valve Station (BIC)

Description

Backflow Irrigation Control Valve Station

Pre-Engineered / Pre-Assembled / Certified

To meet the material list, Customer Connection Dimensions,

Installed Equipment and Materials of Construction with individual

components supplied and supported by Watts Regulator as

shown featuring:

• Flanged or Grooved Connections between all components.

• Stable Field adjustable set point for outlet condition within

10psi over a range of flow from 20% - 100% of continuous

design flow rate

• Water Hammer reduction is enhanced by field adjustable

closing speeds on pressure or flow control valves …

equipped with a small pre-load valve.

Size Check One

2

3

4

6

Style Check One

LAUSD

MASTER

AUTO SHIFT

NONE

Style Check One

SS WYE

NONE

Style Check One

909PCQT

009M2PCQT

NONE

Style Check One

DBF

NONE

Customer Inputs

Customer Connections — Input Header Size

ACV — Item 3

Backflow Preventer — Item 4

Lug Type Butterfly Shutoff Valves — Item 1 & item 9

Pipe Size – NPS Typical Dims – Inch

Inlet Outlet CC Dim H

2 2

3 3

4 4

6 6

Component Customization

Strainer — Item 2

Standard

Standard

Standard

Standard

Standard

4

Page 5

H

Height from

Flange To Top

ITEM QTY DESCRIPTION MATERIAL SIZE CONNECT

1 1 SHUT-OFF VALVE Consult Factory FLANGE

2 1 STRAINER - WYE 304 SS / ZN PLATED FLG FLANGE

3 1 DIAPHRAGM ACTUATED CONTROL VALVE FBE / DI / SST FLANGE

4 1 FLANGE X THREAD ADAPTOR 304 SS / ZN PLATE STEEL FLANGE

5 1 BACKFLOW PREVENTER - WATTS 009M2PCQT TEFLON COATED BRONZE FLG X GRV

6 1 GROOVE COUPLER EPOXY COATED DI GROOVE

7 1 OUTLET HEADER 304 SST FLANGE

8 1 RELIEF VALVE BRASS / BRONZE FLANGE

9 1 SHUT-OFF VALVE Consult Factory FLANGE

10 3 SPACER FLANGE - SLOTTED - NOT SHOWN 304 SST FLANGE

NOTE: See specific component specifications or literature for detailed component material descriptions

FLOW RATE CAPACITIES - GPM PRESSURES - PSI

LINE SIZE CONTINUOUS INTERMITTENT* MINIMUM MAX INLET MIN DP SET POINT RANGE

2 160 220 1 170 20 40 - 120

3 320 480 30 170 20 40 - 120

4 500 750 50 170 20 40 - 120

6 1000 1500 115 170 20 40 - 120

*Based on:

a - 150% Emergency Flow rate through Backflow Preventer (90 Minute UL/FM Test)

b - Max Capacity through the ACV for a system with a 20psi or greater pressure reduction requirement

FLOW RATES - GPM FALL OFF FROM SET POINT @ - PSI

LINE SIZE 20% CONT 20% INTERMIT 20% CONT 20% INTERMIT 100% CONT 100% INTERMIT

232 44 45818

364 96 33411

4 100 150 5 6 7 9

6 200 300 4 4 5 6

X Hydro test the fully assembled Valve Station to 175psi for 5 minutes without leakage.

Typical Configuration Drawing - Above Ground Installation

AUTO SHIFT VALVE

Typical Performance Data

CC - Center Line of Inlet / Outlet Pipes

5

Automatic Shift Valve Data

BIC 1000 Specification Drawing

Configuration Data Typical BOM and Drawing

Valve Station Component Requirements

JOB NAME

CUSTOMER

ENGINEER

RFQ#

4

3

2

1

5

6

7

8

9

Page 6

Typical Dimensional Data

Certified Drawing Supplied with Order

Station Specifications

Backflow - Irrigation Control Valve Station (BIC)

Description

Backflow Irrigation Control Valve Station

Pre-Engineered / Pre-Assembled / Certified

To meet the material list, Customer Connection Dimensions,

Installed Equipment and Materials of Construction with individual

components supplied and supported by Watts Regulator as

shown featuring:

• Flanged or Grooved Connections between all components.

• Stable Field adjustable set point for outlet condition within

10psi over a range of flow from 20% - 100% of continuous

design flow rate.

• Water Hammer reduction is enhanced by field adjustable closing speeds on pressure or flow control valves … equipped

with a small pre-load valve.

Size Check One

2

3

4

6

Style Check One

LAUSD

MASTER

AUTO SHIFT

NONE

Style Check One

SS WYE

NONE

Style Check One

909PCQT

009M2PCQT

NONE

Style Check One

DBF

NONE

Customer Inputs

Customer Connections — Input Header Size

ACV — Item 3

Backflow Preventer — Item 4

Lug Type Butterfly Shutoff Valves — Item 1 & item 9

Pipe Size – NPS Typical Dims – Inch

Inlet Outlet CC Dim H

2 2

3 3

4 4

6 6

Customer Customization

Strainer — Item 2

Standard

Standard

Standard

Standard

Standard

6

Page 7

7

BIC Station Operation

A. Turning on the system

1. Pressurize pressure system slowly from meter to inlet butterfly

at closed position.

2. Open inlet butterfly

1

/4" turn slowly about 2-3 notches.

3. Vent trapped air from top of Remote Control Valve cover and

tubing at connection high point.

4. Open solenoid manual override. This will allow master valve

and regulator to open and close.

5. Vent backflow at TC4-TC3-TC2 when applicable.

6. Open inlet butterfly to full capacity. The system is now ready

to flow water.

7. Open outlet butterfly to slowly pressurize system.

8. With system flowing 5-10 GPM adjust pilot on Automatic

Control Valve by adjusting screw clockwise to raise pressure.

Adjust screw counterclockwise to lower pressure. Be sure

Preload Pilot is closed at inlet ball valve.

9. Shut off downstream flow, observe psi as the holding set psi.

Regulator is now set for system flowing pressure.

B. Placing the system into static condition

10. Close solenoid manual override. This will close Master Valve

and Regulator. It will now not open to downstream pressure

loss (placing the system into static condition), until the 24

volt solenoid is activated by controller.

C. Setting preload regulator to maintain LP static condition

11. Bleed off system’s static pressure at any downstream outlet

of the system or at TC4 on backflow to approximate 25psi

close TC4 when applicable. System should be holding the

25-30psi tight (there is no supply of water to system

because Master Valve is closed).

12. Open water supply ball valve to Preload Pilot, observe pres-

sure, adjust pilot clockwise to raise system pressure above

gauge, pressure holding at 25psi.

13. Adjust pilot counter clockwise to lower system pressure

below 25psi. Observe gauge. Preload Regulator is set for

the entire system static standby pressure. System Preload

Regulator is now set.

14. Verify system static standby low pressure/shifting to system

dynamic demands.

15. Turn on controller to station #1 and observe pressure set-

ting, adjust as needed.

D. Setting system high pressure relief valve

16. Raise system operating to 20 pounds higher than set pressure.

17. Adjust Automatic Control Valve / Master Valve pilot clock-

wise to increase pressure reading to highest setting allowable over set pressure.

18. Adjust the Relief Valve until water starts to discharge. The

Relief Valve should now be opening at the desired maximum pressure above system set point which should be

approximately 20psi. Relief Valve is now set.

E. Setting the pressure control stat

19. With the system at static 20psi +/- above system set point,

adjust the pressure control switch until it turns off the

Master Valve 24 volt system. Pressure control stat is now

adjusted.

20. Fine tune Remote Control Valve to minimize/eliminate water

hammer to system.

Note

It is recommended that you fine tune each Remote Control Valve

by closing down the throttle stem on each Remote Control Valve

while flowing to help eliminate closing pressure spike.

This should have a large affect on water hammer on your system.

Adjust throttle stem on Remote Control Valve until the system

starts to show a decrease in coverage. This is where the throttle

stem should stay for the Remote Control Valve to function correctly.

All rubber parts are standard across the valve line. All hard stainless steel wetted parts are above industry standards and are not

found in the typical automatic control valve, master valves, pilot

valves, etc.

The backflow is also above industry standards by encompassing

the valve in fully polymer coated internals to the highest degree

of corrosion resistance.

Always follow your local agency codes and procedures when

installing, operating, and maintaining the BIC Station.

Page 8

ES/IS-BIC-1000 0437 © Watts Regulator Company, 2007

For additional information, visit our web site at: www.watts.com

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

Water Safety & Flow Control Products

Loading...

Loading...