Page 1

For Commercial and Industrial Applications

ES-B6080

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

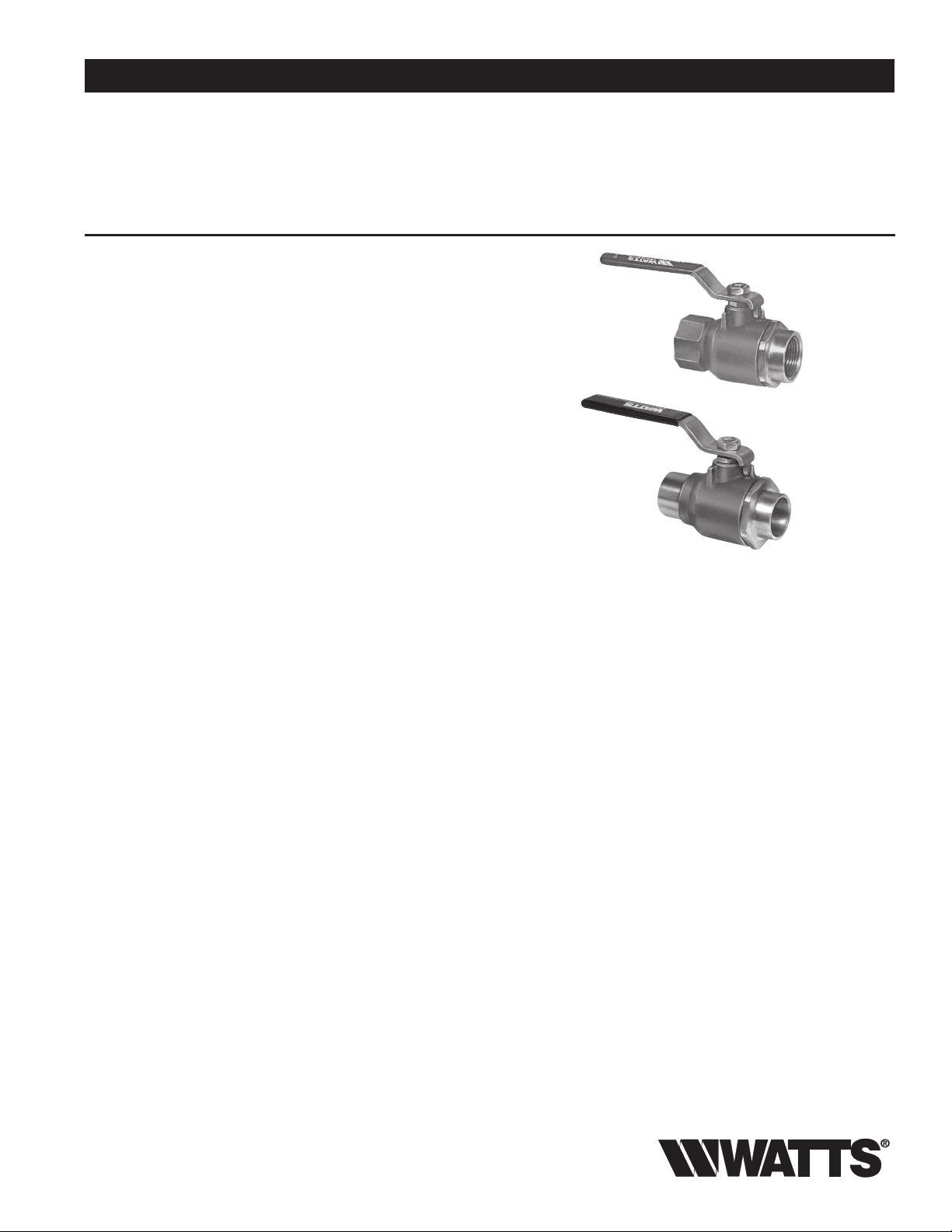

Series B6080, B6081

2-Piece, Full Port,

Bronze Ball Valves

Sizes: 1⁄2" – 2" (15 – 50mm)

Series B6080, B6081 2-Piece, Full Port, Bronze Ball Valves

feature virgin PTFE seats and seals. The B6080, B6081’s full

port orifice ensures minimal pressure drop, while virgin PTFE

stem packing seal, thrust washer and chrome plated brass ball

provide lasting service.

Features

• Virgin PTFE seats and seals are standard

• Suitable for a full range of liquids and gases

• Minimal pressure drop due to full port design

• Blowout proof pressure retaining stem

• Pressure rated at 600psi (41 bar) WOG non-shock; 150psi

(10 bar) WSP

• Virgin PTFE stem packing seal and thrust washer

• Vinyl insulator on heavy duty, zinc-plated carbon steel

handles

• Fast quarter-turn open or close operation

• Excellent for throttling and balancing applications of nonabrasive fluids where minimum flow is 20% to 100% of valve

capacity

• Low operating torque

• Adjustable stem packing

• Each valve factory tested

Models

B6080 1⁄2" – 2" (15 – 50mm) threaded NPT end connections

B6081

Specifications

A 2-piece full port bronze ball valve to be installed as indicated

on the plans. The valve must have a blowout proof pressure

retaining stem, chrome plated brass ball, virgin PTFE seats,

seals, stem packing seal and thrust washer. Valve must have

adjustable packing. Valves with O-ring stem seal only is not

acceptable. Pressure rating no less than 600psi (41 bar) WOG

non-shock, 150psi (10 bar) WSP. Valve shall be manufactured

to the MSS-SP-110 standard and shall be a Watts Regulator

Company Series B6080 (threaded) or B6081 (solder).

1

⁄2" –2" (15 – 50mm) solder end connections

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

B6080

B6081

BAA/ARRA Compliant

*This product complies with the Buy American Act and The

American Recovery and Reinvestment Act. For more information,

visit watts.com.

Options

Suffix

SS – Stainless steel ball and stem

OV – Oval handle

RH – Round handle

SH – 304 Stainless steel handle and nut

BS – Balancing stop

XH – Extended handle

TH – Tee handle

G – All SS models (grounded ball & stem)

GS – Ground washer

**This valve is designed to be soft soldered into lines without disassembly, using a low temperature solder 420°F (215°C). Other solders such

as 95/5 tin antimony 460°F (238°C) can be used. However, extreme

caution must be used to prevent seat damage. Higher temperature

solders will damage the seat material. ANSI B.15.18 states that the

maximum operating pressure of 50-50 solder connections is 200psi

(14 bar) at 100°F (38°C) and decreases with higher temperature.

Apply heat with the flame directed AWAY from the center of the valve

body. Excessive heat can harm the seats. After soldering, the packing

nut may have to be tightened.

Pressure — Temperature

Temperature Range: 0°F - 350°F (-18°C – 177°C)

@ 50psi (3.5 bar)

Maximum Working Pressure: 600psi (41 bar) WOG non-shock;

150psi (10 bar) WSP

*

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

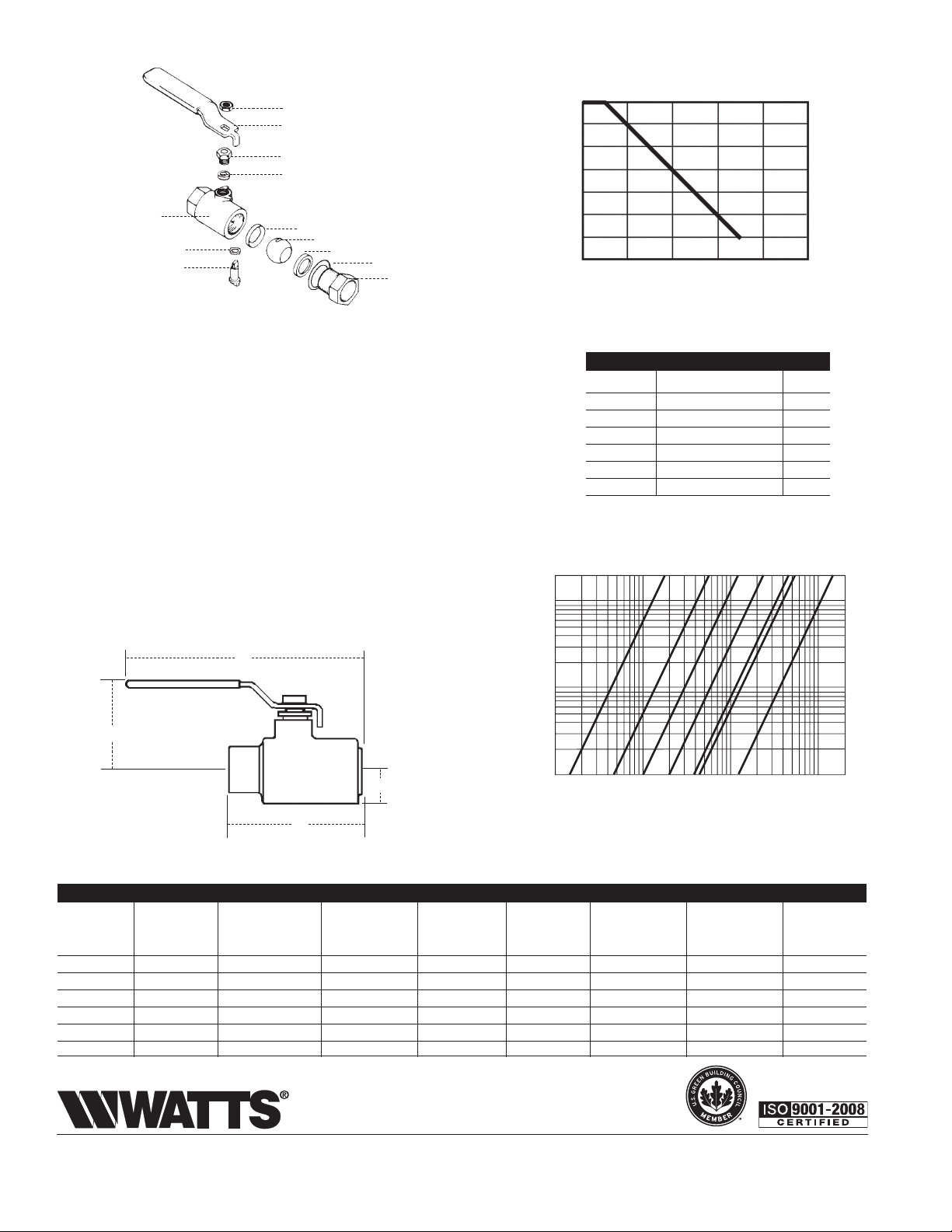

Materials

Valve Seat Rating

bar psi

A

B

C

D

G

E

F

H

I

H

K

J

41.3 600

34.5 500

27.6 400

20.7 300

13.8 200

Pressure

6.9 100

3.4 50

0 0

0 100 200 300 400 450 °F

-18 38 93 149 204 232 °C

Temperature

A Handle Nut Zinc Plated Carbon Steel

B Handle Zinc Plated Carbon Steel

with Vinyl Insulator

C Packing Nut Brass ASTM B16, C36000

D Stem Packing PTFE

E Thrust Washer PTFE

F Stem Brass ASTM B16, C36000

G Body Bronze ASTM B584, C84400

H Seats Virgin PTFE

I Ball Chrome Plated Brass

J Adapter Brass ASTM B16, C36000

K Body Seal PTFE (1

1

⁄4" – 2")

Dimensions — Weights

A

C

Valve Torque Rating

SIZE (DN) OPERATING TORQUE

in. mm in.– lbs. N-m Cv

1

⁄2 15 60 6.8 15

3

⁄4 20 150 16.95 30

1 25 200 22.60 60

1

1

⁄4 32 250 28.25 110

1

1

⁄2 40 320 36.16 130

2 50 500 56.50 360

Pressure Drop vs. Flow

bar psi

69 10

53 8

41 6

28 4

21 3

14 2

7 1

6 .8

4 .6

Pressure Drop

3 .4

2 .3

1 .2

D

.7 .1

1 3.8

2 7.6

3 11.4

4 15.2

6 22.8

8 30.4

1

⁄2" 3⁄4" 1" 11⁄4" 11⁄2" 2"

gpm lpm

2000 7600

1000 3800

800 3040

600 2280

400 1520

300 1140

200 760

100 380

80 304

60 228

40 152

30 114

20 76

10 38

L

Flow

SIZE (DN) DIMENSIONS WEIGHTS

A A C D L L

Ball Orifice (B6080) (B6081) (B6080) (B6081)

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

1

⁄2 15 1⁄2 13 425⁄32 121 47⁄8 124 15⁄8 41

3

⁄4 20 3⁄4 19 5 127 55⁄16 135 13⁄4 45 1 25 213⁄16 71 213⁄16 71 1.0 0.5

1 25 1 25 5

1

1

⁄4 32 11⁄4 32 79⁄16 192 79⁄16 192 27⁄8 73 11⁄2 38 41⁄8 105 45⁄16 110 4.0 1.8

1

1

⁄2 40 11⁄2 38 711⁄16 195 77⁄8 200 3 76 15⁄8 41 47⁄16 113 43⁄4 121 5.5 2.5

2 50 2 51 10

A Watt s Water Technolo gies Company

7

⁄16 138 511⁄16 145 2 51 11⁄4 32 39⁄16 91 37⁄8 98 1.8 0.8

11

⁄16 272 11 279 4 102 2 51 53⁄8 137 6 152 10.0 4.5

USA: No. Andover, MA • Tel. (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Burlington, ONT. • Tel. (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

7

⁄8 22 29⁄32 58 29⁄16 65 0.6 0.3

ES-B6080 1038 © 2010 Watts

Loading...

Loading...