Page 1

Magnum Cv and Magnum IT Valves

Installation and Service Manual

Page 2

Page 3

Table of Contents

Section

1.0 Installation Profile Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

2.0 Introduction to the Magnum Cv and Magnum IT Series - - - - - - - - - - - - - - - 2

2.1 Assembling the Control to the Valve - - - - - - - - - - - - - - - - - - - - 3

2.2 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - 7

2.3 Dimensional Specifications - - - - - - - - - - - - - - - - - - - - - - - - 8

3.0 General Installation Information - - - - - - - - - - - - - - - - - - - - - - - - - 10

3.1 Typical Installation Drawings - - - - - - - - - - - - - - - - - - - - - - - 12

4.0 Flow Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

5.0 Control Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

5.1 Manual Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

5.2 Mechanical Control - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

5.2.1 Common Settings - - - - - - - - - - - - - - - - - - - - - - - 24

5.2.2 Regenerating Iron Filter - - - - - - - - - - - - - - - - - - - - - 25

5.2.3 Backwashing Filter - - - - - - - - - - - - - - - - - - - - - - - 25

5.2.4 Salt Use Table - - - - - - - - - - - - - - - - - - - - - - - - - 26

5.2.5 Potassium Permanganate Use Table- - - - - - - - - - - - - - - 27

5.3 Impulse Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

5.4 Electronic Controls- - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

5.4.1 Connecting the 962 Control- - - - - - - - - - - - - - - - - - - 31

5.4.2 Connecting the 962M and the 962S Control - - - - - - - - - - - 32

5.4.3 Connecting the 962 Twin and Triple Parallel Control- - - - - - - - 33

6.0 Programming Tables for Electronic Controls - - - - - - - - - - - - - - - - - - - 34

6.1 Table I - Level I Values - - - - - - - - - - - - - - - - - - - - - - - - - - 34

6.2 Table IIA - Level II Program Values 962 Single Twin or Triple Parallel

Tank Softener or Dealkalizer - - - - - - - - - - - - - - - - - - - - - - - 35

6.3 Table IIB - Level II Program Values 962F

Single Tank Filter Mode Parameters - - - - - - - - - - - - - - - - - - - 36

6.4 Table IIC - Level II Program Values 962 Twin Tank Alternating

Softener - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

6.5 Table IID - Level II Program Values - Electronic Timeclock

Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

6.6 Table IIE - Level II Program Values - Electronic Timeclock

Softener - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

6.7 Explanation of Parameter Values for the 962 Single and Parallel

Tank Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

6.8 New Features in the 962 Family Controls - - - - - - - - - - - - - - - - - 42

6.9 Table III Historical Data - - - - - - - - - - - - - - - - - - - - - - - - - 43

6.10 Table IV Error Messages - - - - - - - - - - - - - - - - - - - - - - - - 44

Page 4

7.0 Multi-Tank Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

7.1 Twin Alternating - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

7.1.1 Control Set-up - - - - - - - - - - - - - - - - - - - - - - - - - 46

7.1.2 Additional Checks - - - - - - - - - - - - - - - - - - - - - - - 47

7.2 Twin and Triple Parallel - - - - - - - - - - - - - - - - - - - - - - - - - 48

7.2.1 Control Set-up - - - - - - - - - - - - - - - - - - - - - - - - - 50

8.0 Start-Up Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

9.0 Service Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

9.1 Magnum Valve Cartridge Removal Procedure - - - - - - - - - - - - - - - 54

10.0 Performance Data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

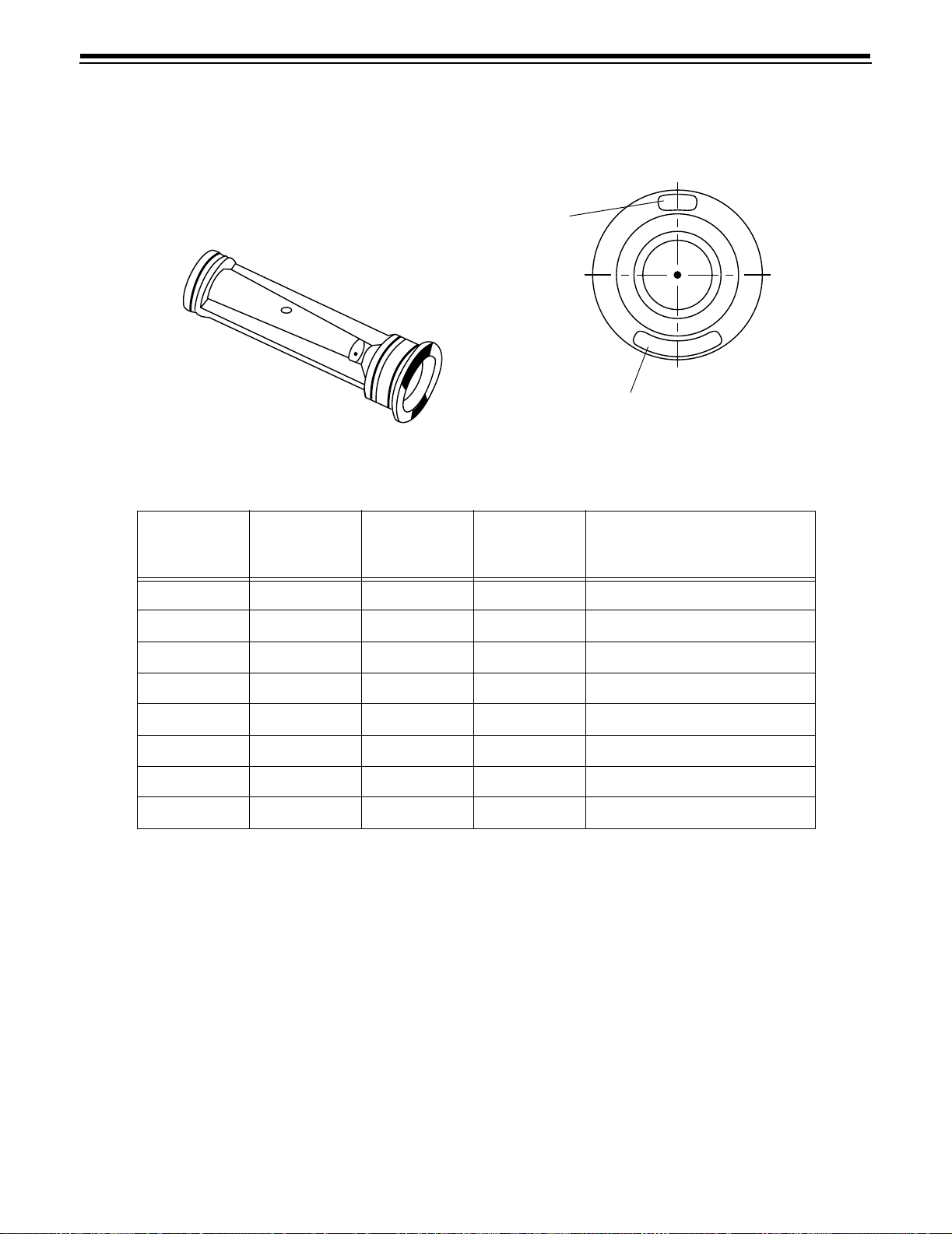

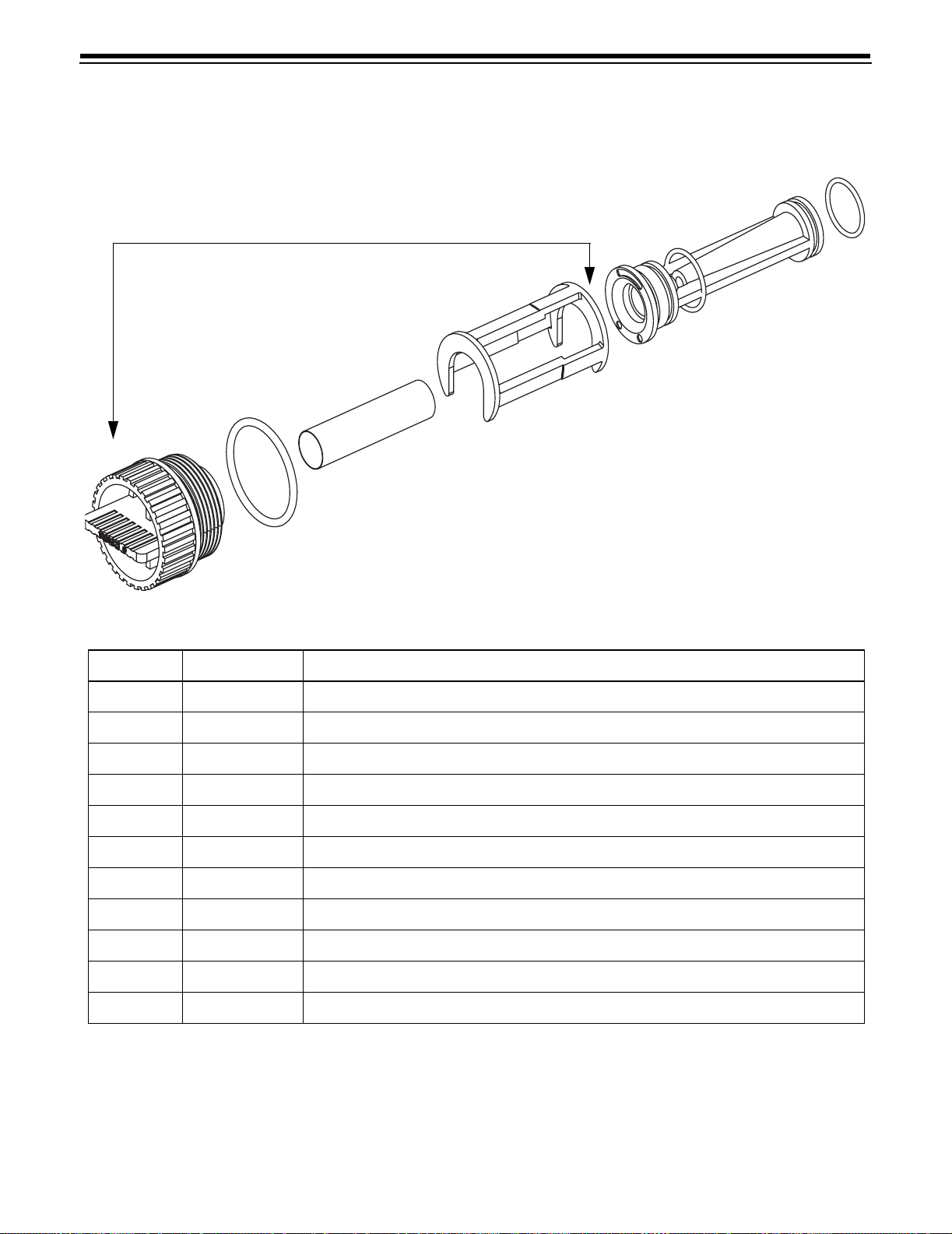

10.1 Injector Data- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

10.2 Refill Control Chart (P6 Values) - - - - - - - - - - - - - - - - - - - - - 57

10.3 Injector Chart (P7 Values) - - - - - - - - - - - - - - - - - - - - - - - - 58

10.4 Drain Line Flow Control Chart- - - - - - - - - - - - - - - - - - - - - - 59

10.5 Autotrol Drain Line Flow Controls (5 gpm - 40 gpm)- - - - - - - - - - - - 60

11.0 Wiring Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

11.1 962 Series Remote Start - - - - - - - - - - - - - - - - - - - - - - - - 61

11.2 952 Impulse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

11.3 952 QC Impulse - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

11.4 962 Twin and Triple Parallel - - - - - - - - - - - - - - - - - - - - - - - 63

11.5 962 Twin Alternating - - - - - - - - - - - - - - - - - - - - - - - - - - 64

12.0 Assembly Drawings and Parts Lists - - - - - - - - - - - - - - - - - - - - - - 65

12.1 942Man and 942FMan Manual Controls - - - - - - - - - - - - - - - - - 65

12.2 942 and 942F Timeclock Controls - - - - - - - - - - - - - - - - - - - - 66

12.3 952,952F, and 952QC Impulse Controls - - - - - - - - - - - - - - - - - 67

12.4 962, 962F, 962TC, 962FTC, 962M, and 962S Electronic Controls - - - - - 69

12.5 Injector Assemblies - - - - - - - - - - - - - - - - - - - - - - - - - - 72

12.6 Refill Control Assemblies - - - - - - - - - - - - - - - - - - - - - - - - 73

12.7 2-inch Turbine Assembly - - - - - - - - - - - - - - - - - - - - - - - - 74

12.8 Installation Adapters - - - - - - - - - - - - - - - - - - - - - - - - - - 75

12.9 Valve Cartridges - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

12.10 Cam and Pilot Valve Assemblies - - - - - - - - - - - - - - - - - - - - 78

12.11 Kits and Assemblies - - - - - - - - - - - - - - - - - - - - - - - - - - 80

12.12 962 Optional Switch Kits Available - - - - - - - - - - - - - - - - - - - 81

Page 5

1.0 Installation Profile Summary

Installation Date: ______________________________

Installation Location: ___________________________

Installer(s): ____________________________________

Phone Number:________________________________

Valve Number:_________________________________

Application Type: (Softener) (Filter) (Dealkalizer)

Water Source:

(Public Well) (Private Well)

(Surface Supply)

(Other)

Water Test Results:

Hardness:_______________ Iron:_______________

Other: ________________________________________

Misc:

Capacity: _______ Flow Rates:______ min. ____ max.

Tank Size: Diameter ________ Height: __________

Resin or Media Volume:_________________________

Resin or Media Type: ___________________________

Brine Tank Volume:_____________________________

Salt Setting per Regeneration: ___________________

Control Valve Configuration:

Valve Type:____________________________________

Impulse

(480) (Other) ___________________________________

Salt Setting:____________________________________

Electronic Demand Settings

P1 Time of Day _________________

P2 Time of Day Regen _________________

P3 Hardness of Water _________________

P4 Salt Amount _________________

P5 Capacity of Unit _________________

P6 Refill Control Value _________________

P7 Brine Draw Value _________________

P9 Backwash Time _________________

P10 Slow Rinse Time _________________

P11 Fast Rinse Time _________________

P12 Units of Measure _________________

P13 Clock Mode _________________

P14 Calendar Override _________________

P15 Reserve Type _________________

P16 Fixed Reserve Cap.

or Initial Ave. Value _________________

P17 Operation Type _________________

P18 Salt Change Lock Out _________________

P19 Flow Sensor Size _________________

(Hard Water Bypass) (No Hard Water Bypass)

Refill Control:______________________________ gpm

Injector Control: ___________________________ gpm

Backwash Control: _________________________ gpm

Manual Control:

(Softener) (Filter)

Mechanical Timeclock:

(7 day) (12 day)

Salt Setting: __________________________________

Regeneration Frequency:

SM T W T F S

123456789101112

______________________________________________

______________________________________________

P20 K-Factor or Pulse

Equivalent _________________

P21 Remote Regeneration

Switch Delay _________________

P22 Factory Use Only _________________

Twin Parallel Triple Parallel

Regeneration Type (P15): ___________

3 = Fixed Reserve with

Immediate Regeneration

Fixed Reserve (P16):____________% (0% only)

Twin Alternating

Regeneration Type (P15): ___________

0 = Immediate Regen

1 = Delayed Regen

Fixed Reserve (P16): _____________ %

1

Page 6

2.0 Introduction to the Magnum Cv and Magnum IT Series

The Magnum Cv

TM

and Magnum ITTM Series valves

offer a high degree of installation simplicity and

flexibility.

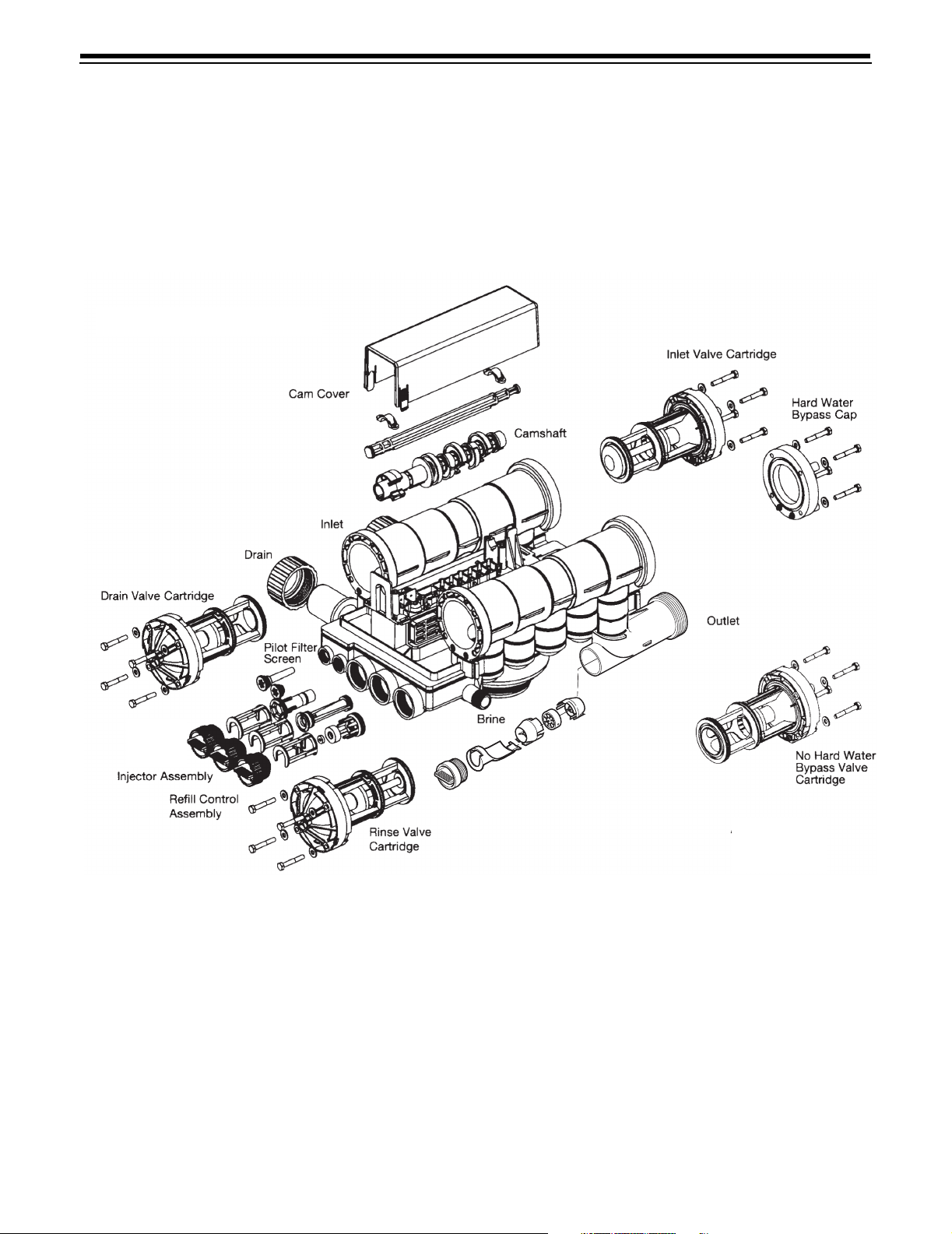

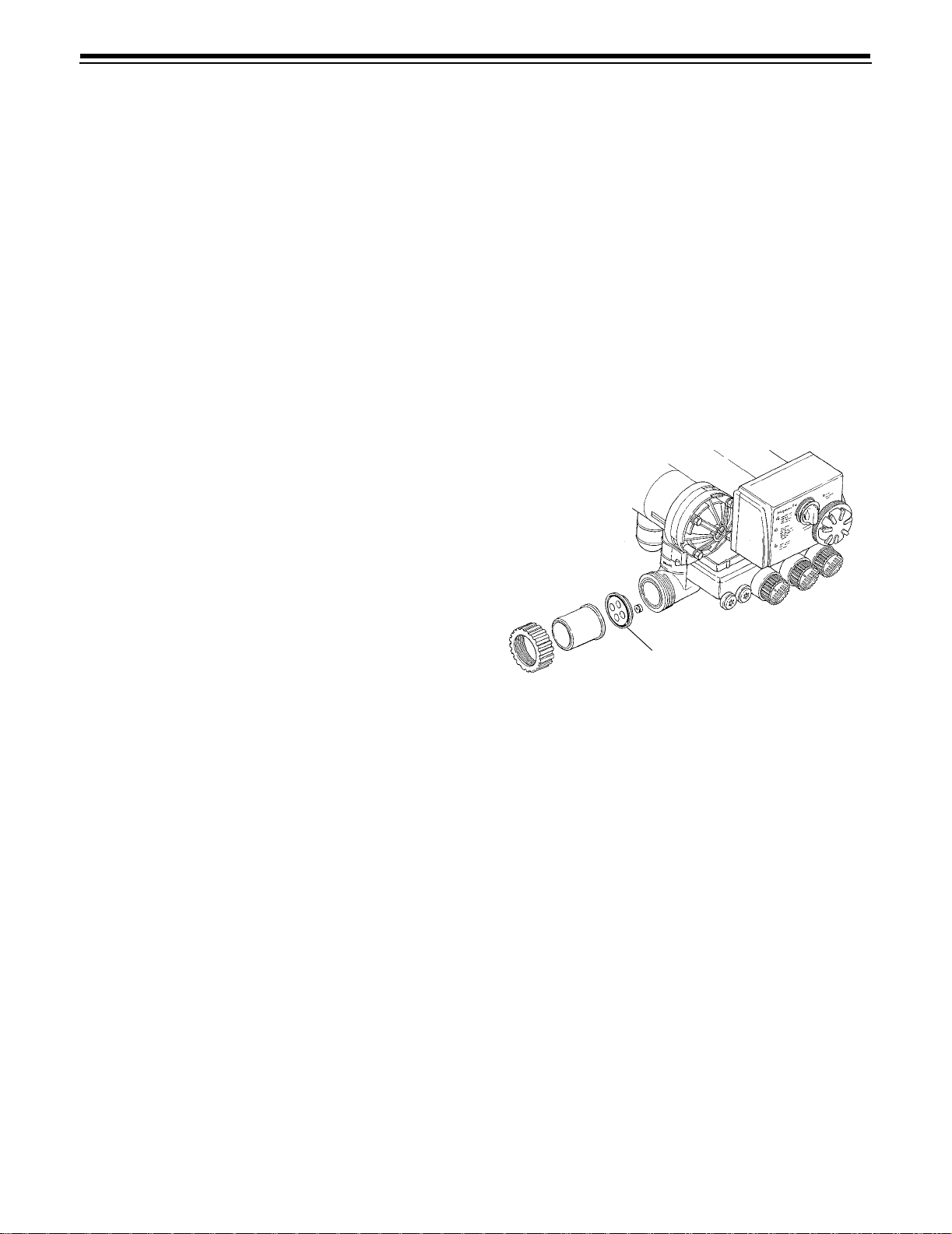

Figure 2.1 provides an overview of the major

components and connections of the 2-inch

(5.08-cm) Magnum IT valve.

Magnum IT Series Valve

TM

The Magnum valve is available in either a

1-1/2-inch (3.81-cm) (Magnum Cv

TM

) or a 2-inch

(5.08-cm) (Magnum IT™) configuration. Throughout

this manual, the 2-inch (5.08-cm) Magnum Cv is shown

in illustrations where the model type is irrelevant to

what is being demonstrated.

Figure 2.1

2

Internal Turbine

Assembly

Page 7

2.1 Assembling the Control to the Magnum Valve

The control and the Magnum valve work together as an

integral system to ensure synchronization. Follow the

steps outlined below to install the control on the

Magnum valve.

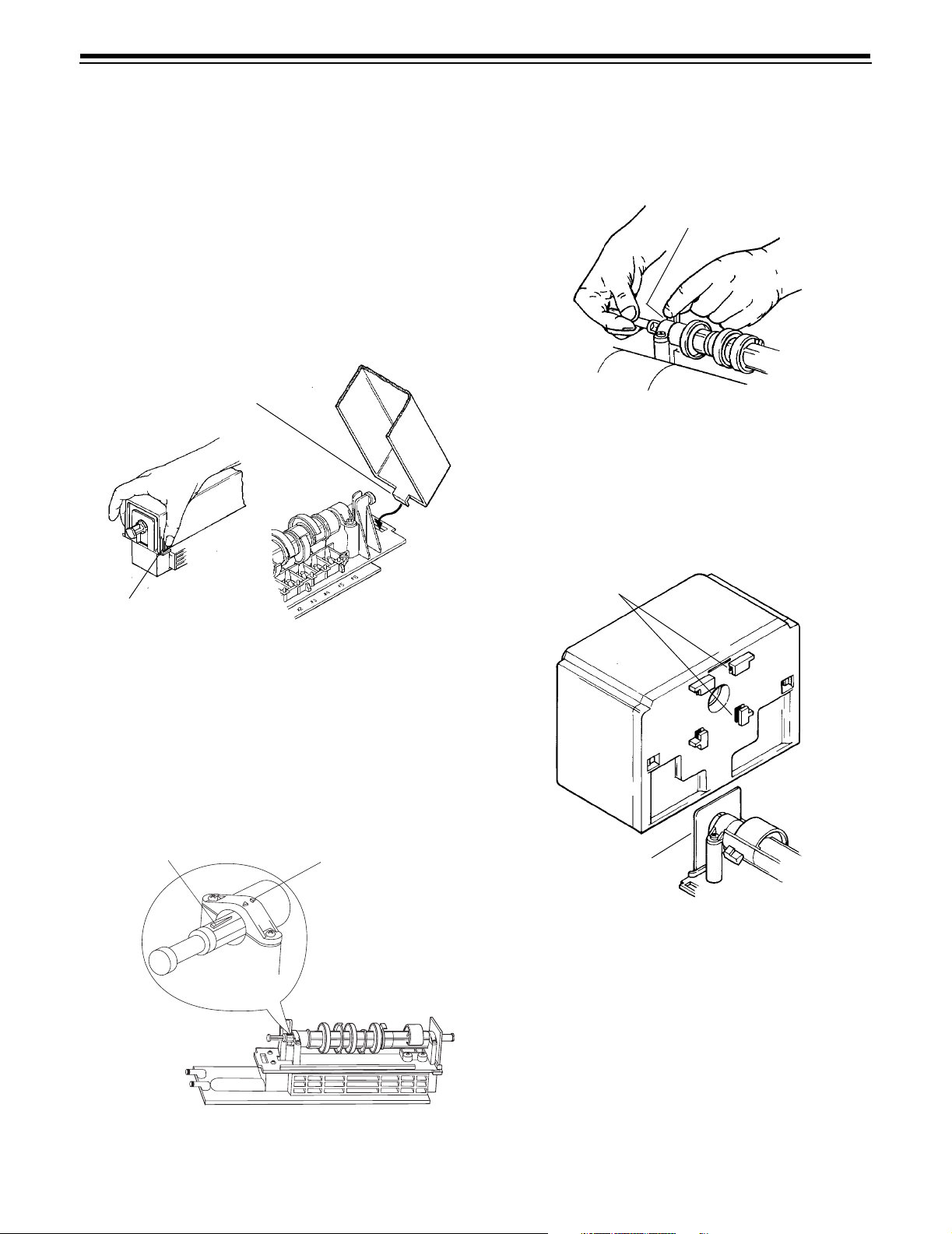

Remove Cam Cover

Remove the cam cover by pressing in on the cover

release tabs (Figure 2.2). Note the cover locking tab

and the slot in the top plate. When you reassemble the

cover, the locking tab is placed in the slot first and the

cover lowered into position.

Locking Tab and Slot

Slide Camshaft

Slide the camshaft toward the back of the valve by

pressing on the release tab and pulling on the back end

of the camshaft (Figure 2.4). The front end of the

camshaft will be flush with the mounting plate.

Release Tabs

Figure 2.4

Mount Control

Mount the control onto the valve by sliding the

mounting tabs over the mounting plate. Note that all

models of Magnum controls mount to the valve in the

same manner (Figure 2.5).

Cover Release Tabs

Figure 2.2

Align Camshaft

The camshaft is keyed and should only be engaged or

disengaged when in the position illustrated (Figure 2.3).

If the camshaft is not in the proper position, rotate the

cam assembly counterclockwise until the camshaft

arrow aligns with pillow block arrow.

Camshaft Arrow

Figure 2.3

Pillow Block Arrow

Mounting Tabs

Mounting Plate

Figure 2.5

Engage Assembly

Engage the control by pressing on the release tab and

pushing the camshaft into the control (Figure 2.6). Do

not force the camshaft. If the camshaft does not slide

freely into the control, check the alignment of the

camshaft to ensure it is in the proper position

(Figure 2.3). The control indicator must be in the

REGENERATION COMPLETE position for the 942,

942Man, 952, and 962 when engaging the camshaft

into the control. The control indicator must be in the

BACKWASH COMPLETE position for the 942F,

942FMan 952F, and 962F when engaging the camshaft

3

Page 8

into the control. The control indicator must be in the

midpoint of the SERVICE position for the 962M and

962S when engaging the camshaft into the control.

Release Tab and

Camshaft

Figure 2.6

Important:

When 942, 942Man, 952, or 962 controls are installed,

control dials must be in the REGENERATION

COMPLETE position.

When 942F, 942FMan, or 952F controls are installed,

control dials must be in the BACKWASH COMPLETE

position.

When 962M or 962S controls are installed, control dials

must be in the SERVICE position.

Figure 2.7

No Hardwater Bypass Feature

The Magnum control valve may be configured for “Hard

Water Bypass” or “No Hard Water Bypass”. With Hard

Water Bypass, unsoftened or unfiltered water is

allowed to bypass the Magnum control valve during

regeneration or backwash. With No Hard Water

Bypass, a valve cartridge ensures that no unsoftened

or unfiltered water bypasses the valve during

regeneration or backwash.

It is easy to observe which option is installed in the

valve. Note that the Hard Water Bypass End Cap has

much longer standoffs than the No Hard Water Bypass

cartridge. The No Hard Water Bypass assembly will

look identical to the other three valve cartridges on the

valve and will have a label identifying the cartridge

assembly (Figure 2.8).

No Hard Water Bypass

No Unfiltered Water Bypass

Normal Standoffs

To disassemble the control from the valve, reverse the

assembling procedure.

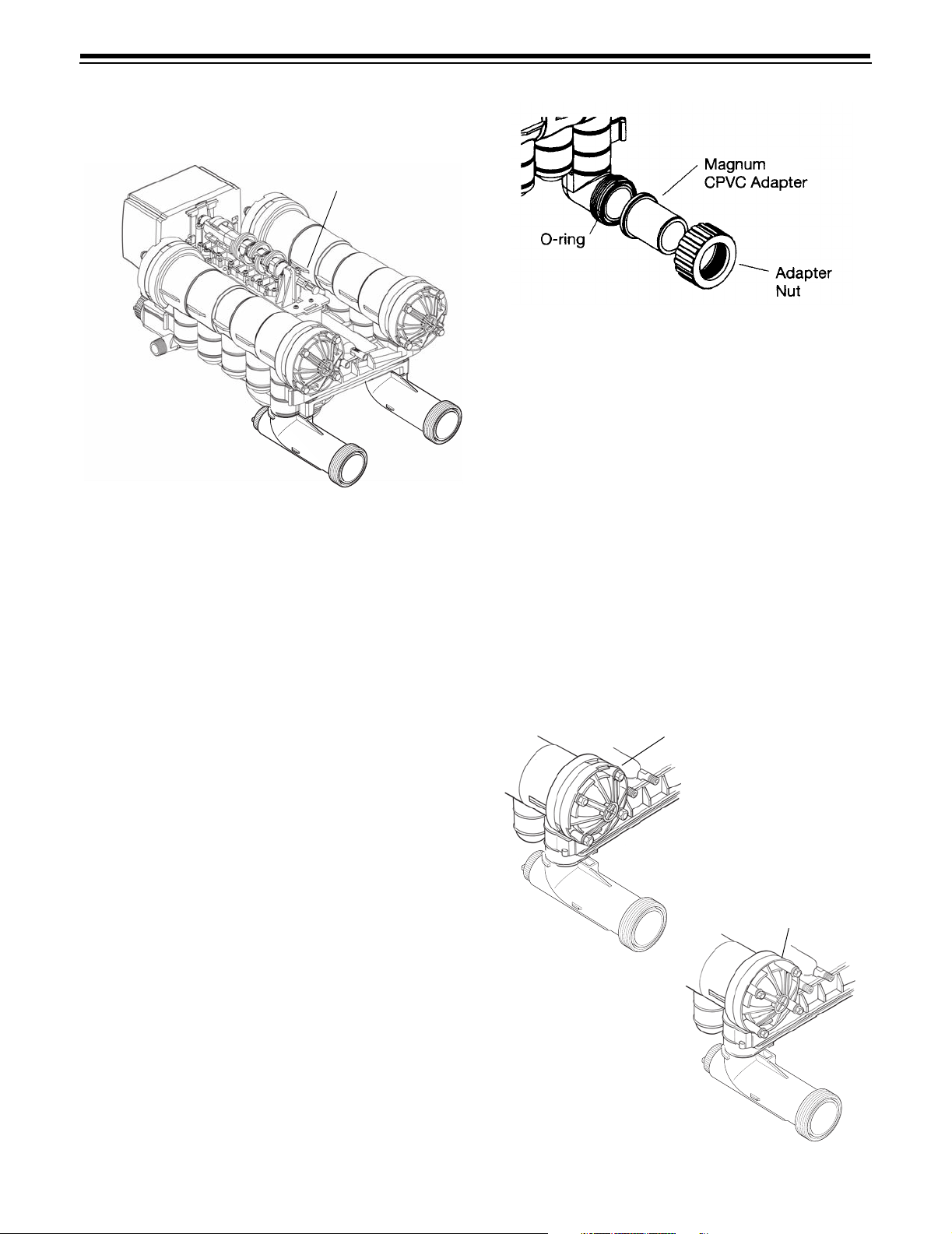

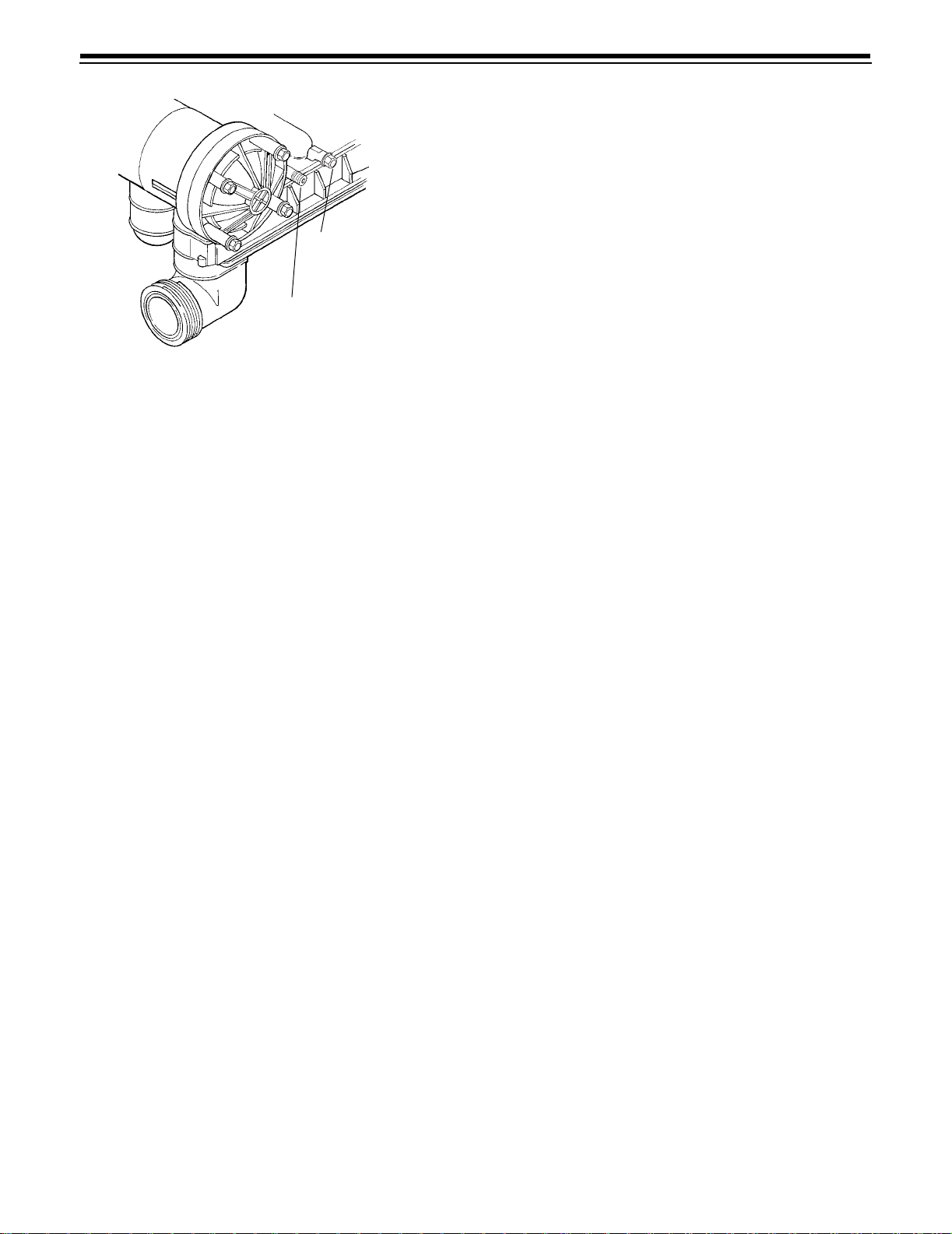

Inlet, Outlet and Drain Connections

The inlet, outlet, and drain connections are designed to

accept an GE Osmonics supplied CPVC or brass

adapter (Figure 2.7). The adapters provide a convenient

union for the three connection ports on the valve. In

addition, they incorporate a positive O-ring face seal

for ease of installation and leak free operation. DO NOT

OVERTIGHTEN THE ADAPTERS. As a general

guideline, hand tightening the nut onto the valve will be

adequate. If additional tightening is required, never

exceed a quarter turn beyond the hand tight position.

The outlet of the 2-inch Magnum IT has an integrated

turbine. The turbine measures the flow of water through

the outlet. This information is used by the control to

determine the best time to recycle.

Extended Standoffs

With Hard Water Bypass

End Cap

Figure 2.8

4

Page 9

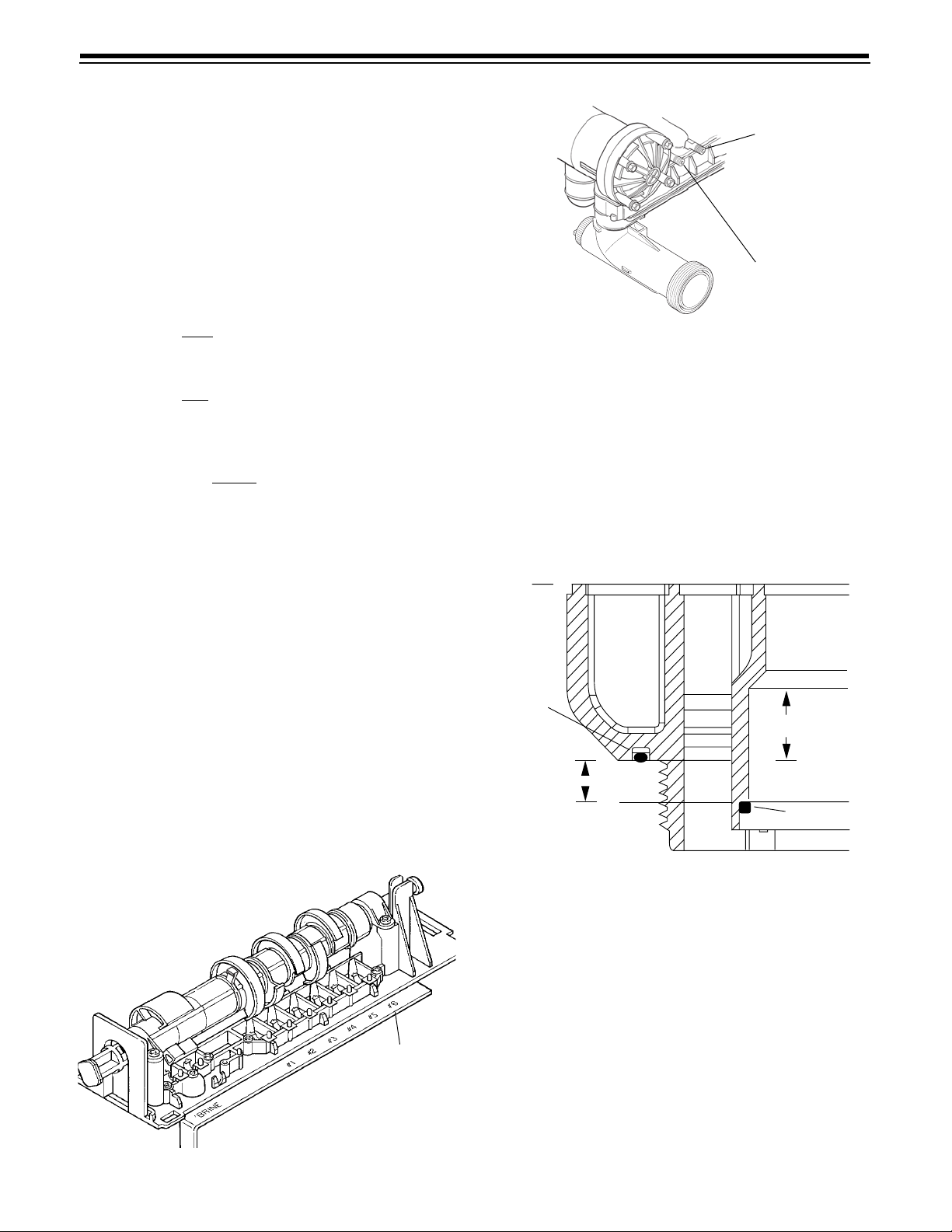

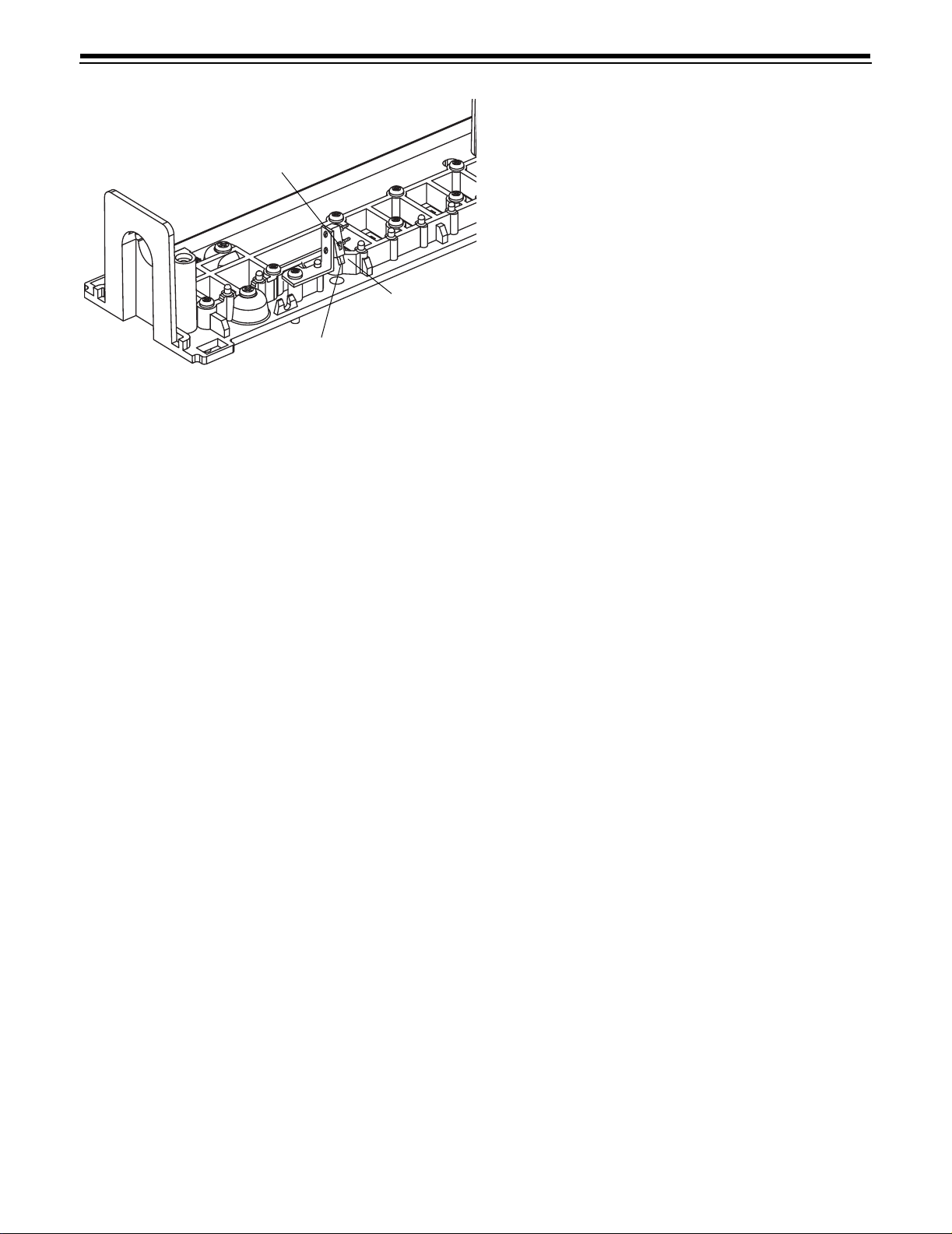

Hydraulic Output Signal

An optional hydraulic output signal is available on the

valve. An optional cam lobe on pilot valve #6 is used on

the camshaft assembly to initiate the hydraulic output

signal during regeneration or backwash (Figure 2.9).

The hydraulic line pressure signal will be available

through the 1/4-inch connection on the back of the

valve marked “AUX”. (Remove the tube cap installed

for shipping.)

Optional cam lobes available are:

P/N 1000554 Provides a hydraulic signal from the

beginning of BACKWASH through the

of REFILL.

start

P/N 1000553 Provides a hydraulic signal from the

beginning of BACKWASH through the

of REFILL.

end

P/N 1001622 Used on Twin Alternating Systems

Only. Provides a hydraulic signal from

the beginning of BACKWASH through

and during

STANDBY.

P/N 1041064 Breakaway cam. Can be programmed

to send a hydraulic signal at any time

during the REGENERATION or

BACKWASH cycle. Note: The camshaft

must be turning for the signal to change

states, i.e. switch from OFF to ON, or

from ON to OFF.

Auxiliary

Hydraulic

Output Port

“AUX”

Pilot Drain Port

Figure 2.10

Magnum Tank Adapter

The tank adapter on the control valve is designed to be

compatible with a 4 inch-8UN (8 threads per inch) tank

opening. In addition, the adapter is designed to accept

a full 1-1/2-inch (3.81-cm) riser pipe with outside

diameter of 1.90 to 1.91 inches (48.26 to 48.51 mm)

(Figure 2.11). The riser pipe is sealed by an O-ring on

the inside of the tank adapter, Figure 2.11. It is

recommended that the riser pipe extend beyond the

top of the tank by 1/4 inch ± 3/8 inch (6 mm ± 9 mm).

For hydraulic output signal

install one of following cam

lobes:

1000553

1000554

1001622

1041064

Optional Cam

Lobe Position #6

“Hydraulic Output

Signal”

O-ring

Tank O-ring

Top of Tank

.375" (9.52 mm)

0.8125"

(20.64 mm)

Riser O-ring

O-ring

Figure 2.11

Optional Switch Assembly

On single, twin parallel, and triple parallel tank

configurations, a single optional feedback switch kit is

available to provide an electrical signal during the

entire regeneration or backwash cycle (Figure 2.12).

The switch may be wired in the “Normally Open” or

“Normally Closed” position and is rated for 0.1 amp at

125 volts AC. An optional 5.0 amp switch at 1/10 HP

125/250 volts AC is available upon request.

Figure 2.9

5

Page 10

Common

Normally Open

Normally Closed

Figure 2.12

On ALL Magnum tank configurations, optional multiswitch kits are available to provide additional electrical

or switch closure signals during the regeneration or

backwash cycles. Coupled with the optional

breakaway cams, signals can be sent to external

system equipment at virtually any time while the

control/camshaft motor is running. Consult the

instruction sheet covering the multi-switch option for

additional application and programming information.

The instruction sheet is sent with the switch kit.

6

Page 11

2.2 Magnum General Specifications

Operating and Environmental

Operating Pressure ............................................................................................... 25 to 125 psig (172 to 862 kPa)

100 psig (688kPa) maximum in Canada

o

Operating Water Temperature Range................................................................................. 34 to 100

Ambient Temperature Range.............................................................................................. 34 to 120

F (1 to 36oC)

o

F (1 to 50oC)

Cap Bolt Torque ...................................................................................................35-40 inch lbs. (3.95 to 4.51 N

m

Connections

Inlet and Outlet................................................................................................................... 1-1/2 inch-Magnum Cv

2-inch-Magnum IT

Tank ....................................................................................................................................................... 4-inch-8UN

Brine ....................................................................................................................................................3/4-inch NPT

Pilot Drain and Auxiliary Hydraulic Out .................................................................................... 1/4-inch tube fitting

Riser Pipe Fitting .....................................................................................................................1-1/2-inch (3.81-cm)

Drain ........................................................................................................................................ 1-1/2-inch (3.81-cm)

Physical

Dimensions..................................................................................................... Refer to drawings on pages 8 and 9

Approximate Weight (Valve and Control).................................................................................... 23.3 lbs. (10.6 kg.)

Electrical*

Voltage - 962 Series Control .......................................................................... 12 VAC wall mount transformer only

)

Voltage - 942 Series Control ..................................................................120 VAC, 12 VAC wall mount transformer

Voltage - 952 Series Control ........................................................................................................ 24 VAC, 120 VAC

Power Draw........................................................................................................................................4.5 volt-amps

*See section on Electronic Controls for alternative electrical configurations.

7

Page 12

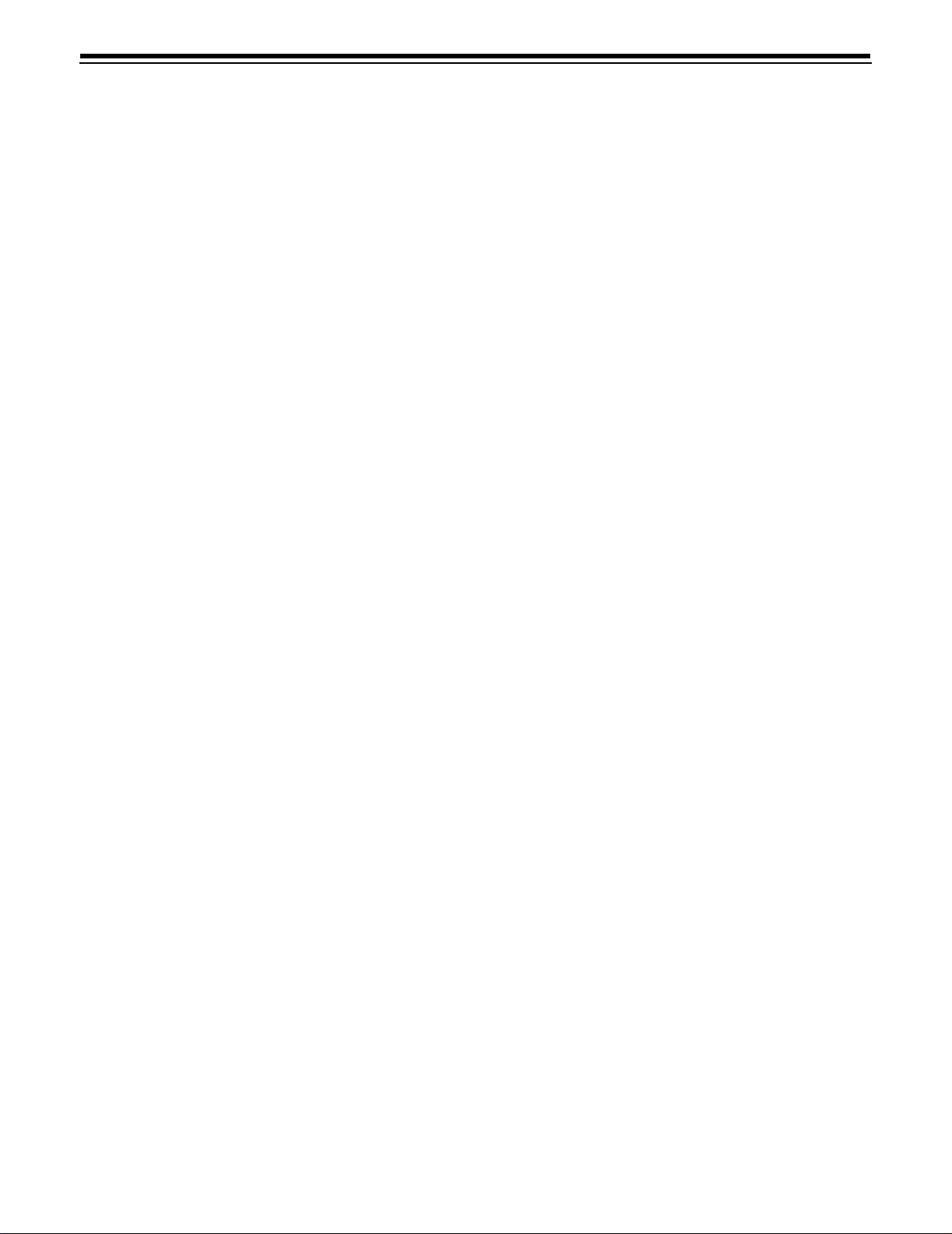

2.3 Magnum Cv Dimensional Specifications

1 1/2-inch Inlet, Outlet and Drain

15.539 (39.47 cm)

1.113 (2.82 cm)

3.993 (10.14 cm)

9.000 (22.86 cm)

13.481 (34.24 cm)

11.471 (29.13 cm)

8.680 (22.04 cm)

4.018 (10.20 cm)

2.817 (7.15 cm)

7.000 (17.78 cm)

14.000 (35.56 cm)

19.500 (49.53 cm)

6.493 (16.5 cm)

7.500 (19.05 cm)

22.796 (57.90 cm)

8

Page 13

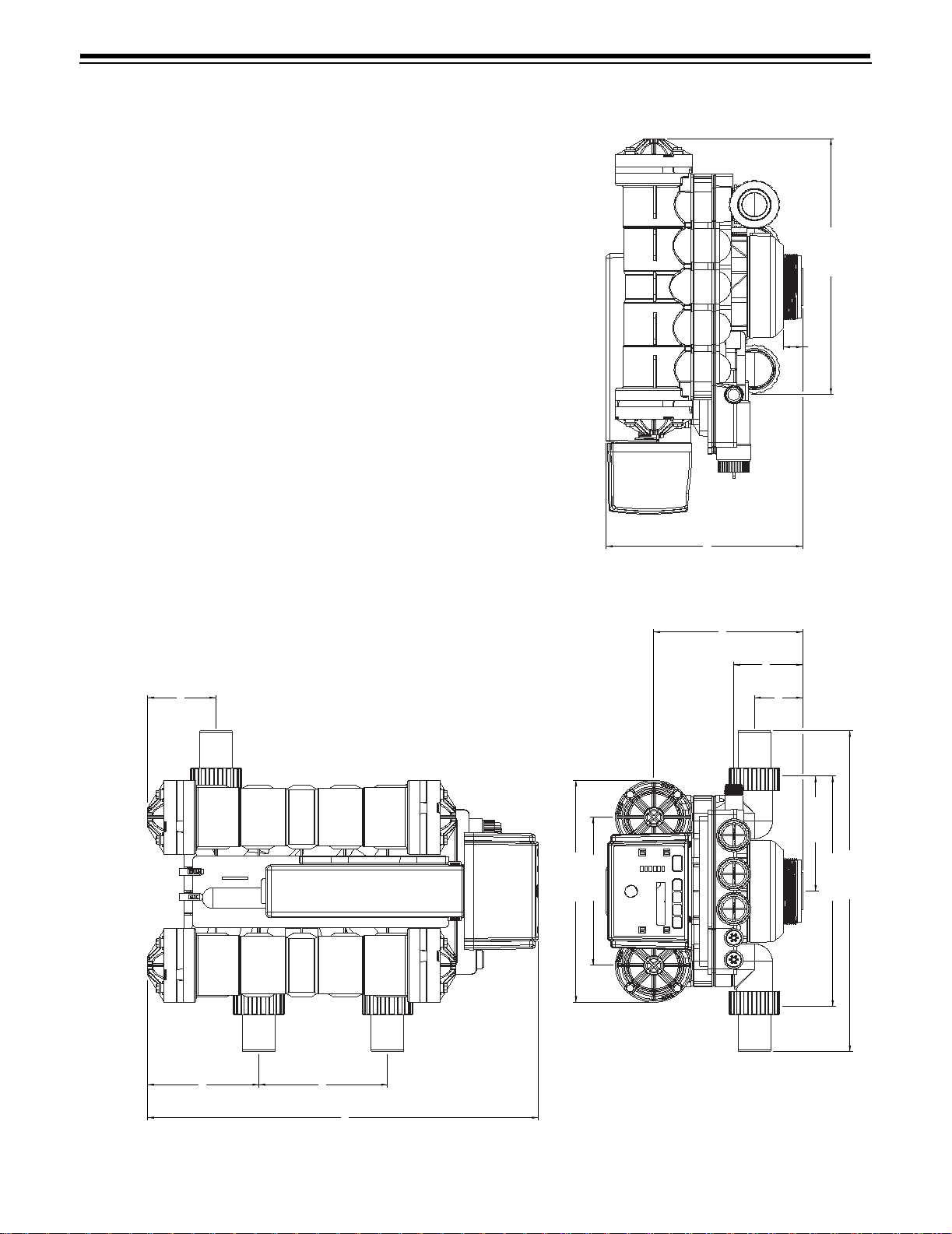

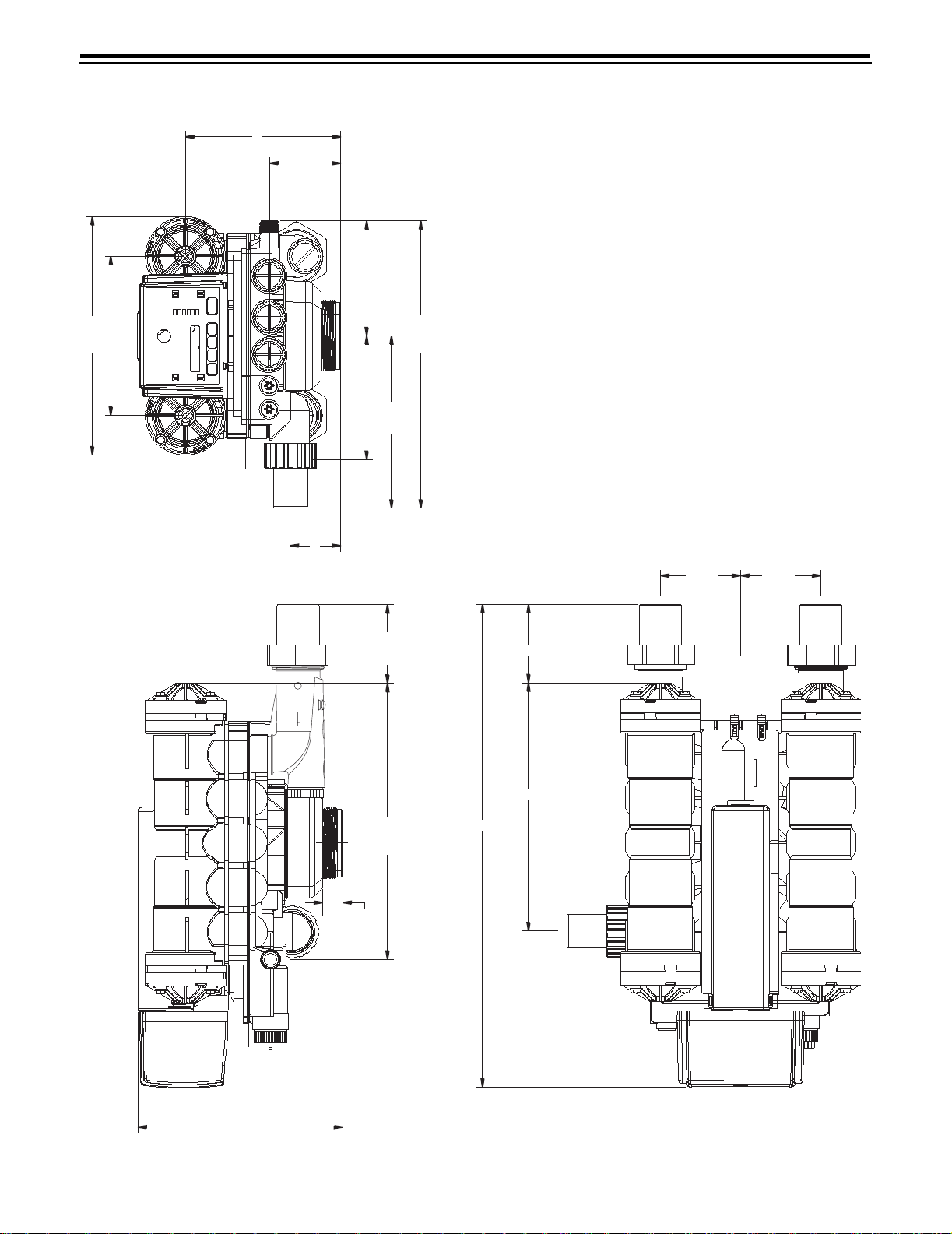

Magnum IT Dimensional Specifications

2-Inch Inlet and Outlet, 1 1/2-Inch Drain

8.710

3.998

13.481

9.000

2.817

7.000 6.500

9.750

4.429

16.250

4.500 4.500

4.429

13.993

11.376

27.224

15.539

1.113

9

Page 14

3.0 General Installation Information

Please review the following items thoroughly to ensure

an efficient and safe installation of the water treatment

system. Page 12 shows typical installation line

drawings for the Magnum valves.

Operating Conditions -

A minimum dynamic

operating water pressure of 25 psig (172 kPa) is

required for the Magnum control valve to

operate properly.

125 psig (862 kPa). In Canada, water pressure is not to

exceed 100 psig (688 kPa). Water temperature is not to

exceed 100

freezing conditions.

Space Requirements - Allow adequate space for the

water treatment system and associated piping. The

General Specifications section (pages 7-9) provides

the overall dimensions of the control valve as well as

the dimensional reference information for each of the

connection ports. A minimum of 4 1/2 inches (11.5 cm)

front and rear clearance is required for cartridge

assembly and removal.

Plumbing - Always follow good plumbing practices

and conform to local codes. Check existing pipes for

lime and/or iron buildup. Replace piping if heavy

buildup exists and initiate the proper treatment to

prevent additional occurrences. Locate the equipment

close to a drain that is capable of handling the

maximum drain flow rate during backwash.

Flexible Connectors - Some tanks expand and

contract over the acceptable range of operating water

pressures of the Magnum control valve. The use of

flexible connectors is recommended on polywound or

fiberglass tank installations of 24-inch (60.96-cm)

diameter and larger. Follow the tank manufacturer’s

instructions for more information.

Inlet and Outlet Piping - Inlet and outlet plumbing

should be adequately supported to avoid excessive

loads on the valve. Install a manual bypass system to

provide for occasions when the water conditioner must

be bypassed for servicing.

Drain LIne Piping - To prevent mineral loss during

backwash, and to ensure proper operation of the

Magnum Cv Series control valve, A DRAIN LINE

FLOW CONTROL must be plumbed into the drain line

prior to placing the valve in the service mode. Flow

controls from 5 to 40 gpm (18.92 to 151.4 Lpm) are

available from GE Osmonics and can be easily installed

in the drain line (Figure 3.1). Flow controls greater than

40 gpm (151.4 Lpm) must be plumbed externally.

Selection of the proper drain line flow control will

depend on the tank size and media used for the

installation. See Table 10.3.

o

F (36oC). Do not subject the valve to

Water pressure is not to exceed

The following general drain line piping guidelines

should be observed:

• 1 inch (2.54 cm) or larger piping

• Should not exceed 20 feet (6.1 m)

• Should not be elevated higher than the control

valve

• No shut-off valves should be installed in drain line

• Minimal number of elbows and fittings should be

installed in drain line

• Piping must be self-supporting

• Install air gap to provide a siphon break

• Flow control should be installed as close to the

Magnum Cv Series control valve as possible if an

external flow control is used.

Drain Line Flow Control Disk

Figure 3.1

Brining System - The Magnum control valve utilizes

timed water refill to add water to the salt tank. A refill

tube with check ball is required in the brine tank that will

not restrict the refill or brine draw flow rate capabilities

of the valve. Although not required, a separate brine

valve (safety float) system is recommended for use with

Magnum installations. Select a “High-Flow” brine valve

that will not restrict the refill or brine draw flow rate

capabilities of the valve. The “Performance Data and

Charts” section (Section 10.0) of this manual contains

flow rate information for various size injectors and refill

controllers.

Pilot Drain - During regeneration, a small amount of

water (200 ml or 1 cup) is discharged from the 1/4-inch

(6.3-mm) tube fitting on the back of the valve marked

DRAIN (Figure 3.2). To prevent this water from being

discharged to the floor, plumb this connection to a nonpressurized drain or to the brine tank. Do not plug or

apply back pressure to the pilot drain at any time.

Crimping the pilot drain line or installing the line to go

up, which causes backpressure, will prevent the

diaphragm cartridges from shifting properly through

the cycles of regeneration or backwash.

10

Page 15

Auxiliary Hydraulic

Output Port - Plugged

Pilot Drain Port

Figure 3.2

Electrical

1. Electrical requirements for the installation will

depend on the configuration of the control.

2. The standard North American Series 962 electronic

control is supplied with a 12 volt wall mount

transformer. Optional wall mount transformers are

available in the following configurations: Japanese

plug @ 100 volts/50 or 60 Hz, Australian/Argentine

plug @ 240 volts/50 Hz, British plug @ 240 volts/50

Hz, European/Italian plug @ 230 volts/50 Hz.

Optional transformers must be ordered separately

for all international 12 VAC configurations.

3. The standard North American Series 952 impulse

controls use 120 VAC or 24 VAC/50 or 60 Hz power.

Lubricants

It is very important that 100% silicone lubricant is the

only lubricant used for installing the Magnum control

valve. Any other lubricant may cause material

degradation and potential failure of the valve

components.

NOTE: Some silicone based lubricants contain

petroleum-based ingredients. If there is a question

about the lubrication that you are using contact the

manufacturer of that lubricant.

11

Page 16

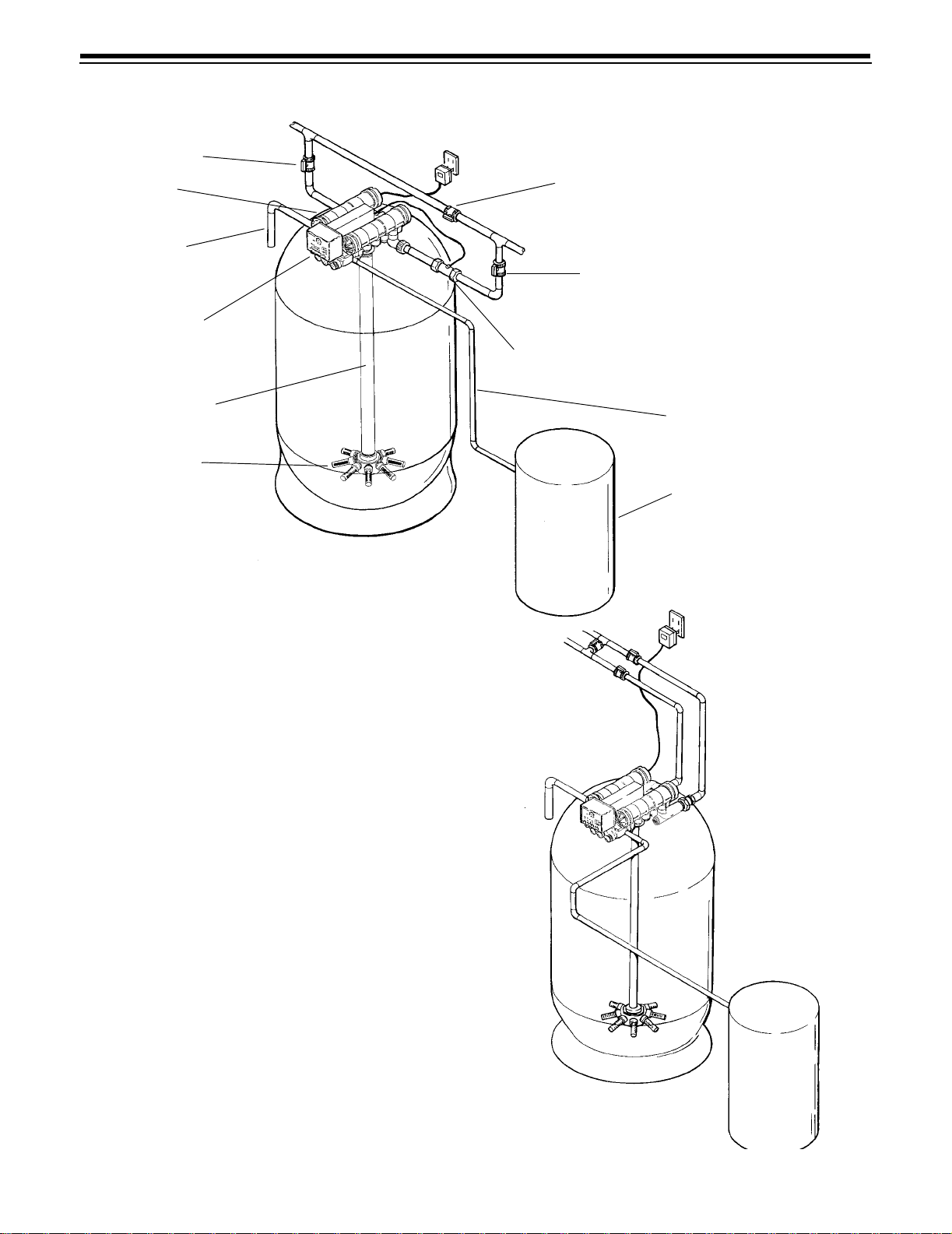

3.1 Typical Installation Drawings

Inlet Valve

Drain Line Flow Control

(Required)

Drain

962 Control

1.5” Riser Tube

Hub & Lateral

Magnum Cv

Manual Bypass Valve

Outlet Valve

Turbine (standard

with 962 Control)

Note: Support Inlet and

Outlet Piping

Adequately.

Brine Line

Brine Tank

Magnum IT

Figure 3.3 Magnum Cv and Magnum IT, Single Tank Softener Units with 962 Electronic Control

12

Page 17

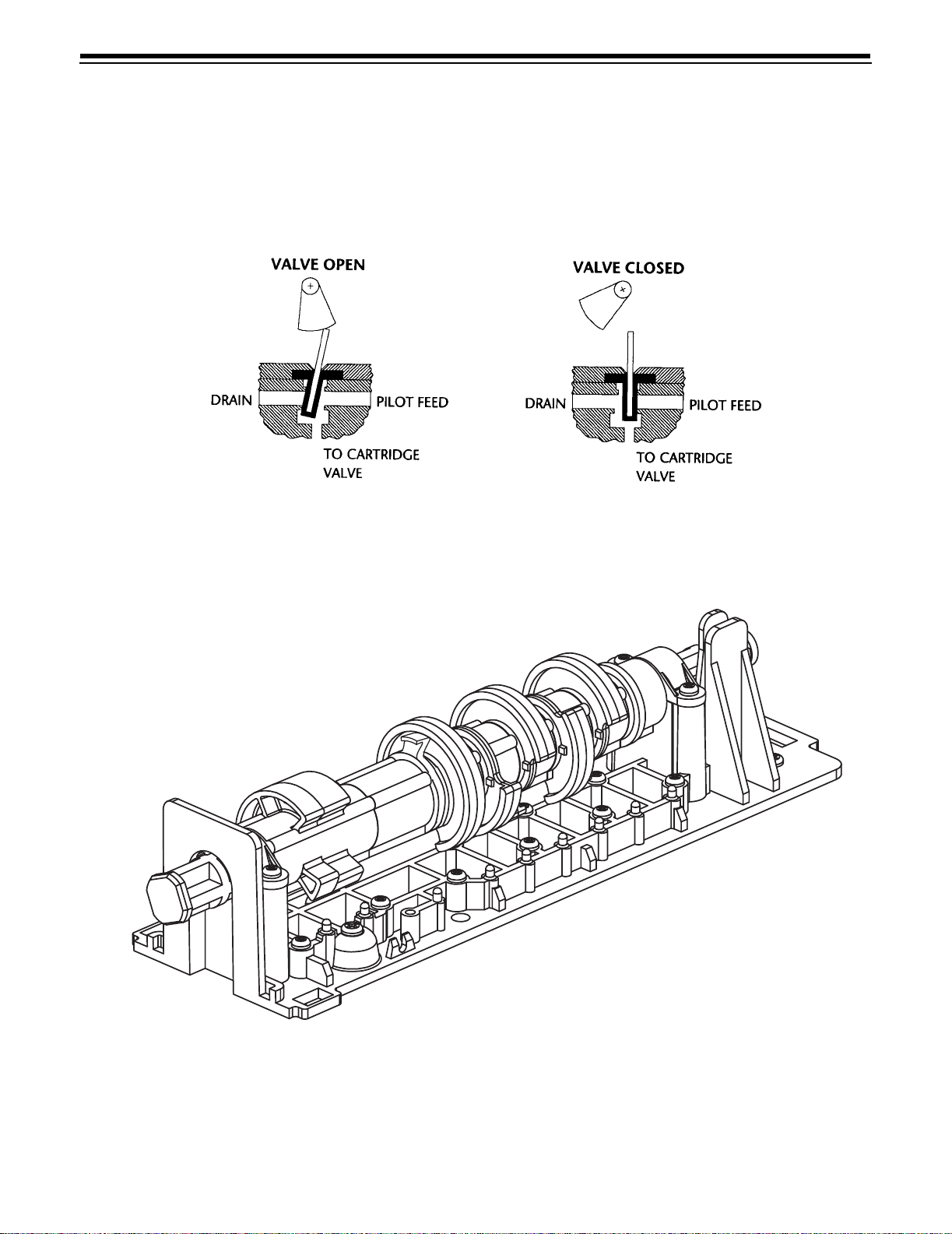

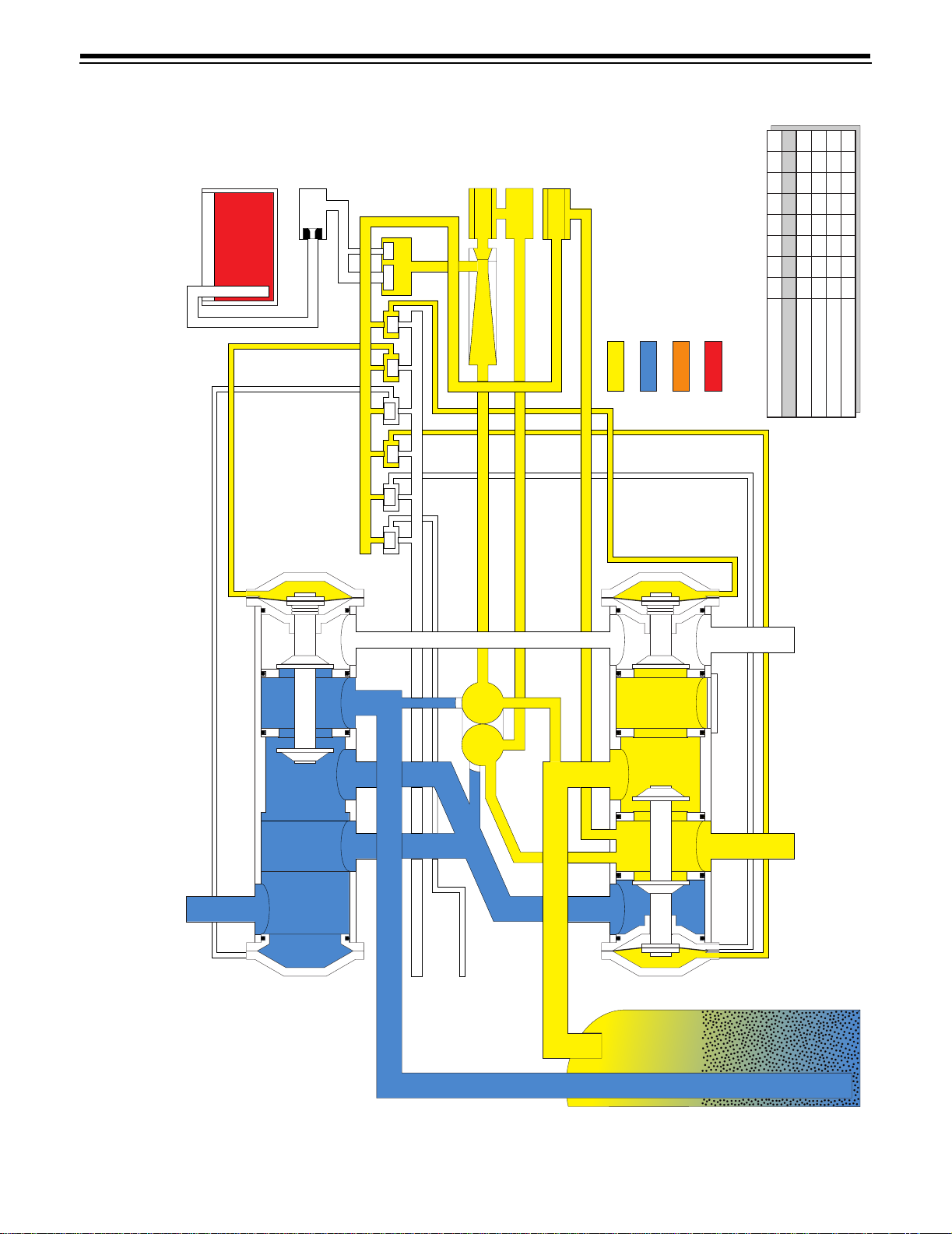

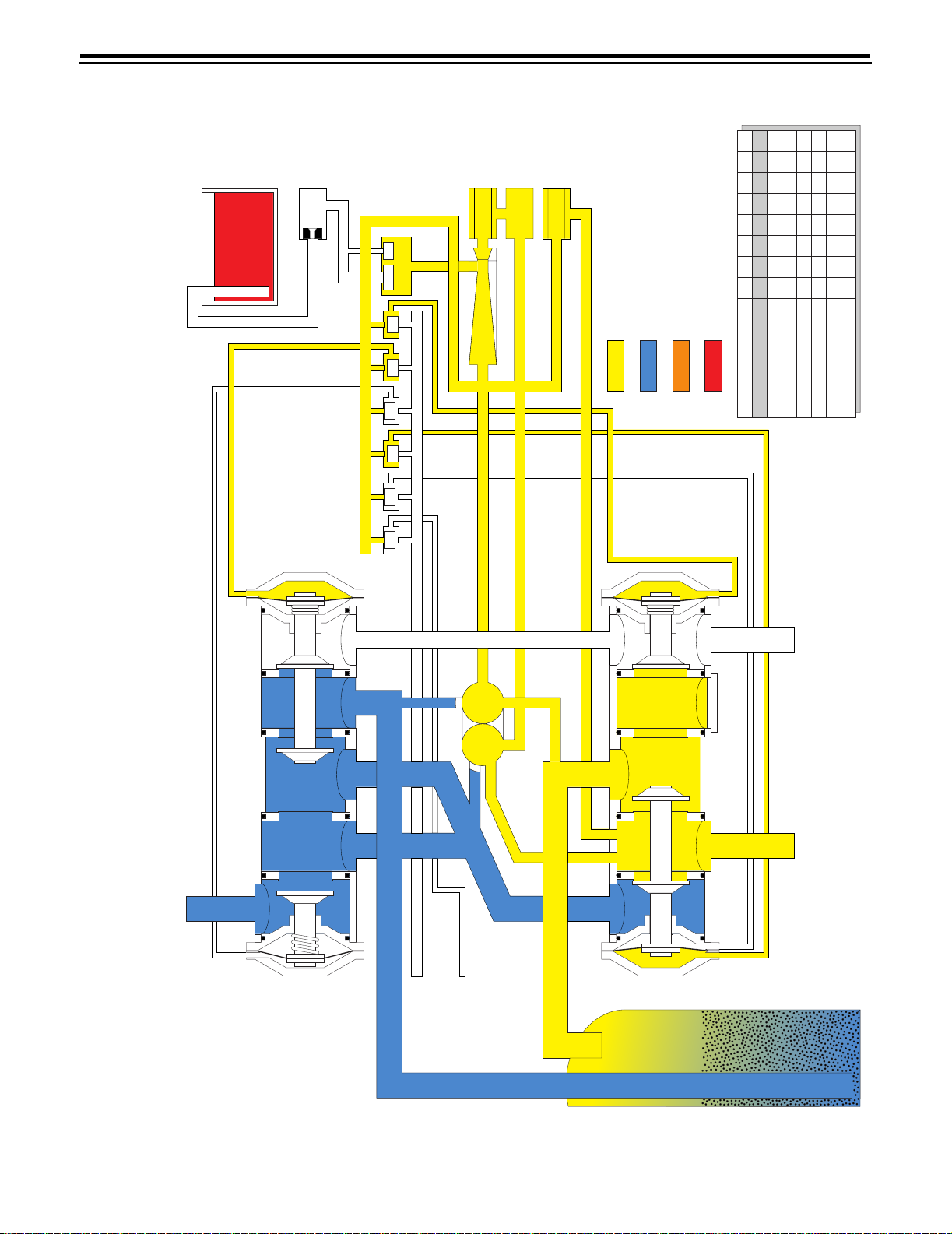

4.0 Flow Diagrams

The Magnum control valve utilizes a series of pilot

valves to properly position the diaphragm valve

cartridges (Figure 4.1). The pilot valves are activated by

the camshaft (Figure 4.2). The flow diagrams that follow

represent the Service Cycle for a 5-cycle softener,

3-cycle filter, and 5-cycle twin alternating softener

Figure 4.1 Pilot Valve Principle of Operation

configuration. Both the Hardwater Bypass and No

Hardwater Bypass service flow diagrams are

presented.

Figure 4.2 Cam Assembly

13

Page 18

Brine

M

Service Cycle

Tank

Refill

Control

Pilot

B1B2

Valves

Injector

Screen

Pressure

Regulator

Pilot

Screen

654321B2B1

OPEN OPEN OPENCLSD CLSDCLSDCLSD

CLSD

OPEN OPEN CLSDCLSDOPEN CLSD CLSD

CLSD

OPEN OPEN

OPENOPENOPEN CLSD CLSD

CLSD

CLSDCLSD

OPEN OPEN OPEN OPENCLSD

CLSD

OPEN OPENCLSD OPEN OPENOPEN

CLSD CLSD

12

3

4

56

Injector

2

5 Cycle - Co-current - Hard Water Bypass - Softener

Untreated

Water

Treated

1

Water

Backwash

Water

Regenerant

Service

Backwash

Brine/Slow Rinse

Drain

Fast Rinse

Refill/Service

Outlet

agnum

3

Bypass

Hard Water

Pilot Drain

Tank Bottom

Aux. Pilot

Output

14

Inlet

4

Resin Tank

Tank Top

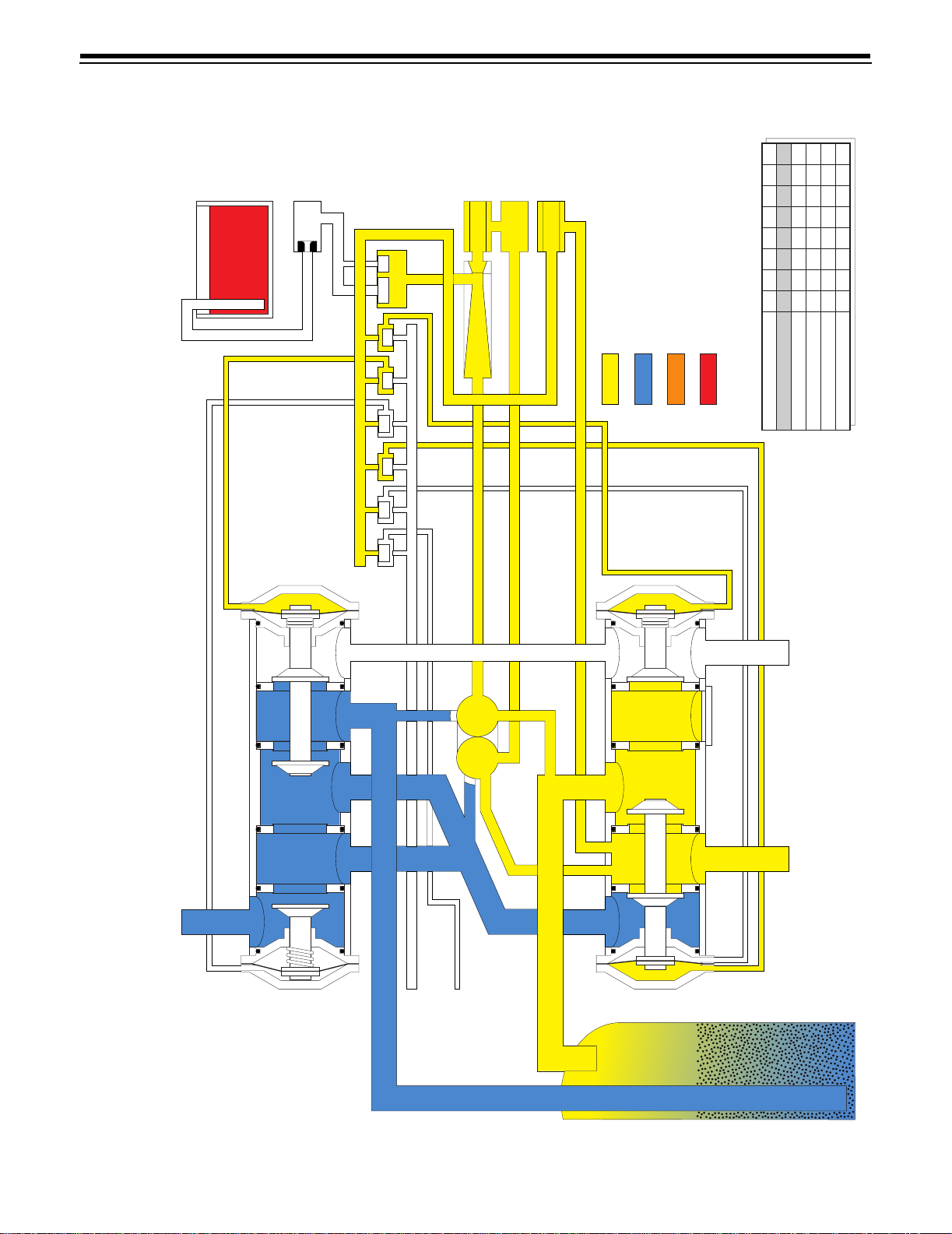

Page 19

Brine

M

Service Cycle

Tank

Refill

Control

Pilot

B1B2

Valves

Injector

Screen

Pressure

Regulator

Pilot

Screen

654321B2B1

OPEN OPEN OPENCLSD CLSDCLSDCLSD

CLSD

OPEN OPEN CLSDCLSDOPEN CLSD CLSD

CLSD

OPEN OPEN

OPENOPENOPEN CLSD CLSD

CLSD

CLSDCLSD

OPEN OPEN OPEN OPENCLSD

CLSD

OPEN OPENCLSD OPEN OPENOPEN

CLSD

CLSD

12

3

4

56

2

Injector

Untreated

Water

1

5 Cycle - Co-current - No Hard Water Bypass - Softener

Treated

Water

Backwash

Water

Regenerant

Service

Backwash

Brine/Slow Rinse

Drain

Fast Rinse

Refill/Service

Outlet

agnum

3

No Hard

Water Bypass

Pilot Drain

Tank Bottom

Aux. Pilot

Output

15

Inlet

4

Resin Tank

Tank Top

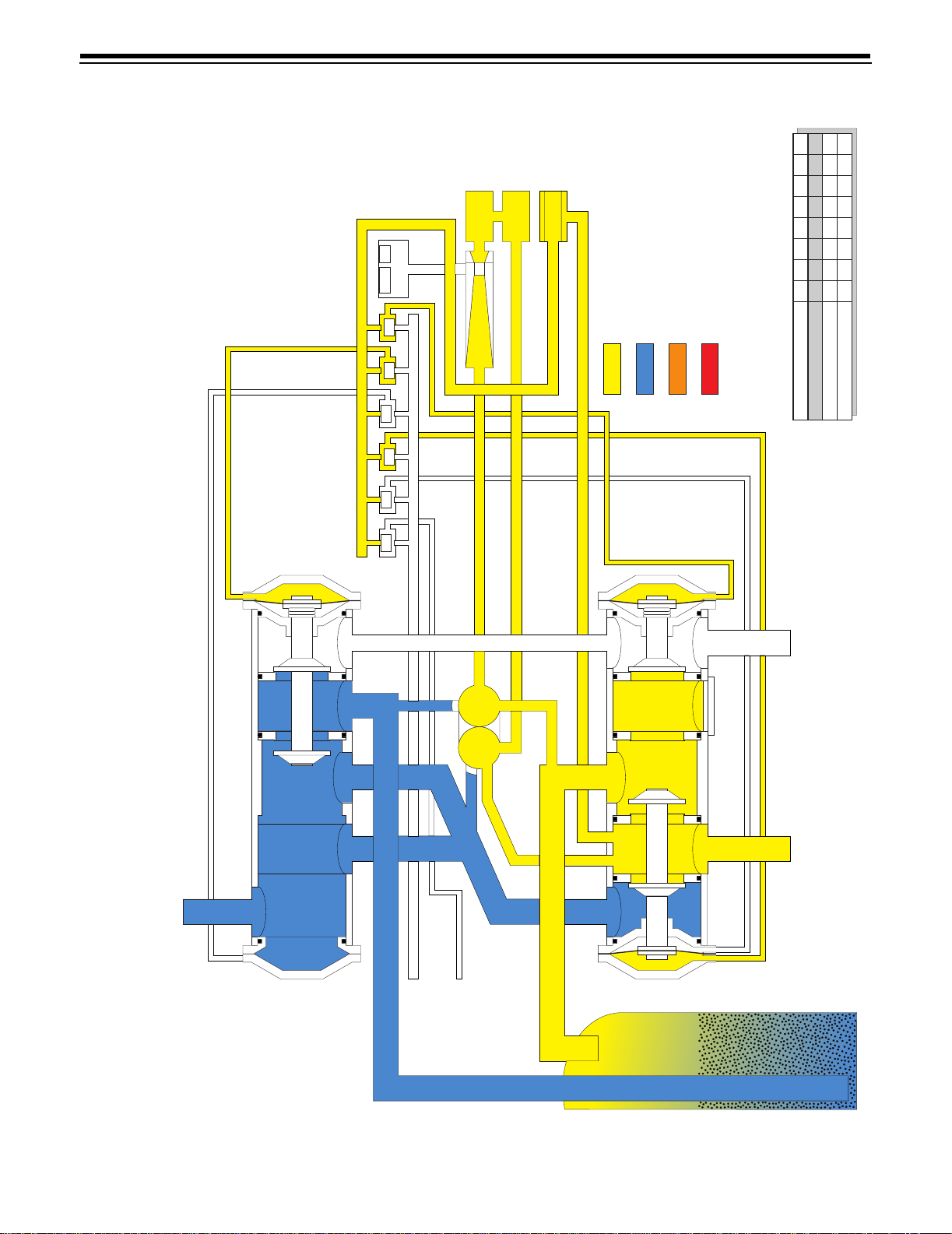

Page 20

M

leService Cycle

Service Cyc

Pilot

B1B2

Valves

Pressure

Regulator

Pilot

Screen

654321B2B1

OPEN OPEN OPENCLSD CLSDCLSDCLSD

CLSD

OPEN OPEN CLSDCLSDOPEN CLSD CLSD

CLSD

CLSDCLSDOPEN OPEN OPEN OPENCLSD

CLSD

12

3

4

56

3 Cycle - Unfiltered Water Bypass - Filter

2

Plugged Injector

Untreated

Water

1

Treated

Water

Backwash

Water

Regenerant

Service

Drain

Backwash

Fast Rinse

Outlet

agnum

3

Unfiltered

Water Bypass

Pilot Drain

Tank Bottom

Aux. Pilot

Output

16

Inlet

4

Media Tank

Tank Top

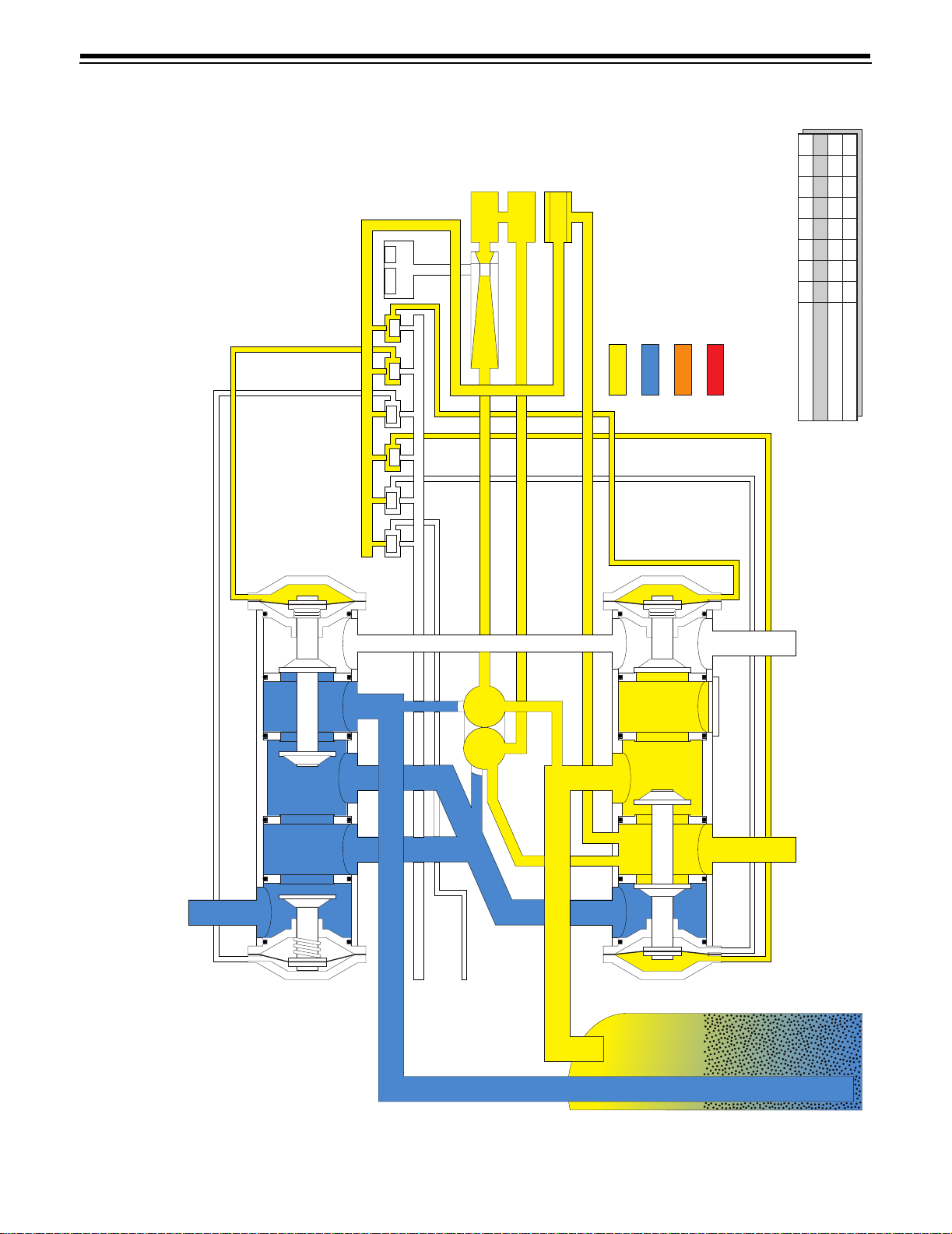

Page 21

M

leService Cycle

Service Cyc

Pilot

B1B2

Valves

Pressure

Regulator

Pilot

Screen

654321B2B1

OPEN OPEN OPENCLSD CLSDCLSDCLSD

CLSD

OPEN OPEN CLSDCLSDOPEN CLSD CLSD

CLSD

CLSDCLSDOPEN OPEN OPEN OPENCLSD

CLSD

12

Plugged Injector

3

4

56

3 Cycle - No Unfiltered Water Bypass - Filter

2

Untreated

Water

1

Treated

Water

Backwash

Water

Regenerant

Service

Drain

Backwash

Fast Rinse

Outlet

agnum

3

No Unfiltered

Water Bypass

Tank Bottom

Pilot Drain

Aux. Pilot

Output

17

Inlet

4

Media Tank

Tank Top

Page 22

M

leService Cycle

Service Cyc

Brine

Tank

Refill

Control

Pilot

B1B2

Valves

Injector

Screen

Pressure

Regulator

Pilot

Screen

654321B2B1

OPEN OPEN OPENCLSD CLSDCLSDCLSD

CLSD

OPEN OPEN OPENCLSD CLSDCLSDOPEN

CLSD

OPEN OPEN CLSDCLSDOPEN CLSD CLSD

CLSD

OPEN OPEN

OPENOPENOPEN CLSD CLSD

CLSD

CLSDCLSD

OPEN OPEN OPEN OPENCLSD

CLSD

OPEN OPEN

OPEN

CLSD OPEN OPENOPEN

CLSD

CLSDCLSD

OPEN

CLSD OPEN OPENOPEN

CLSD

12

3

4

56

5 Cycle - Co-current - Twin Alternating Softener

2

Injector

Untreated

Water

Treated

1

Water

Backwash

Water

Regenerant

Service

Backwash

First Standby

Refill

Fast Rinse

Second Standby

Brine/Slow Rinse

Drain

Outlet

agnum

3

No Hard

Water Bypass

Pilot Drain

Tank Bottom

Aux. Pilot

Output

18

Inlet

4

Resin Tank

Tank Top

Page 23

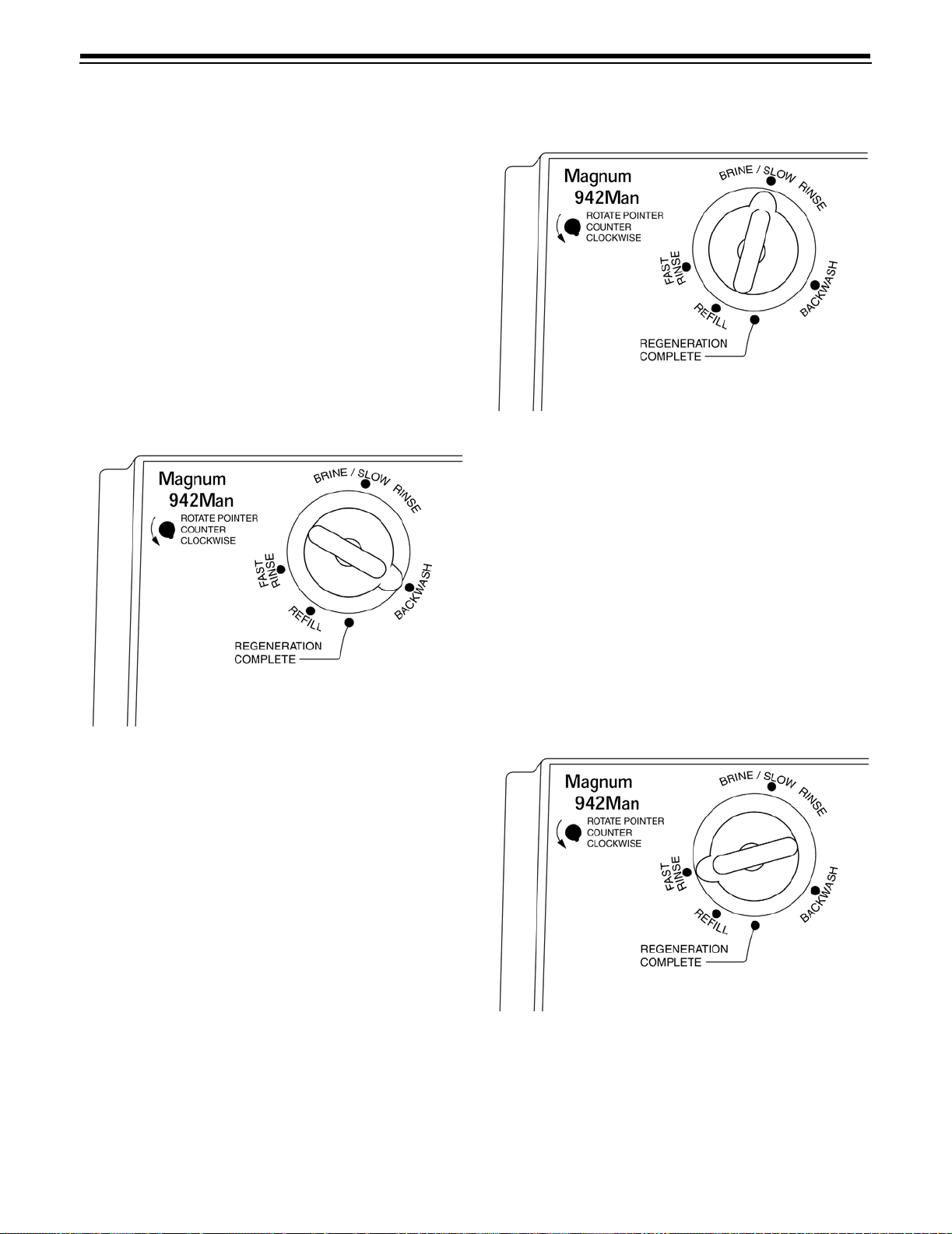

5.0 Control Settings

5.1 Manual

Series 942Man Controls

The 942Man represents the maximum in versatility and

ease of operation for the manual control valve system.

Upgrade to an automatic system is easily

accomplished by switching the manual control to a

clock or demand control.

DO NOT TURN THE INDICATOR KNOB CLOCKWISE

AT A N Y T IM E .

Regeneration Instructions

1. Move indicator knob COUNTERCLOCKWISE from

the Regeneration Complete position to the center

of the Backwash (Figure 5.1) position. DO NOT turn

the knob clockwise.

Figure 5.2

4. When the slow rinse is complete, move the

indicator knob COUNTERCLOCKWISE to the

center of the Fast Rinse position (Figure 5.3). The

indicator knob should remain in the Fast Rinse

position for the appropriate amount of time.

specific fast rinse times are determined by water

quality, clarity of drain water, water pressure, and

flow. Fast rinse serves to eliminate excess salt and

repack the resin bed for the service run. Typically

fast rinse should continue for 5 - 15 minutes*.

Important: If excessive fast rinse time is required to

return the service effluent to quality, there could be an

underlying cause, such as low pressure, fouled resin

bed, fouled injector, etc.

Figure 5.1

2. The indicator knob should remain in the Backwash

position for the appropriate amount of time.

Specific backwash times are determined by the

inlet water quality (i.e.: the amount of iron,

manganese, turbidity), the amount of time between

regenerations, water pressure, and flow. The

typical backwash time is 10-15 minutes*. The unit

should be in backwash until water at the drain is

clear.

3. When the backwash is complete, move the

indicator knob COUNTERCLOCKWISE to the

center of the Brine/Slow Rinse position

(Figure 5.2). See the “Suggested Brine Draw/Slow

Rinse Table” to determine the correct draw/rinse

time. Please note that the tables are given at three

salting levels and four pressures. The indicator

knob should remain in the Brine/Slow Rinse

position for the time* indicated in the table.

*Note: The times given are only general guidelines.

Adjustment of the times may be necessary for specific

applications and conditions.

Figure 5.3

5. When the fast rinse is complete, move the indicator

knob COUNTERCLOCKWISE to the Refill position

(Figure 5.4). Determine the correct refill time* from

Table 5.1 below. The indicator knob should remain

in the Refill position for the time indicated in the

table.

19

Page 24

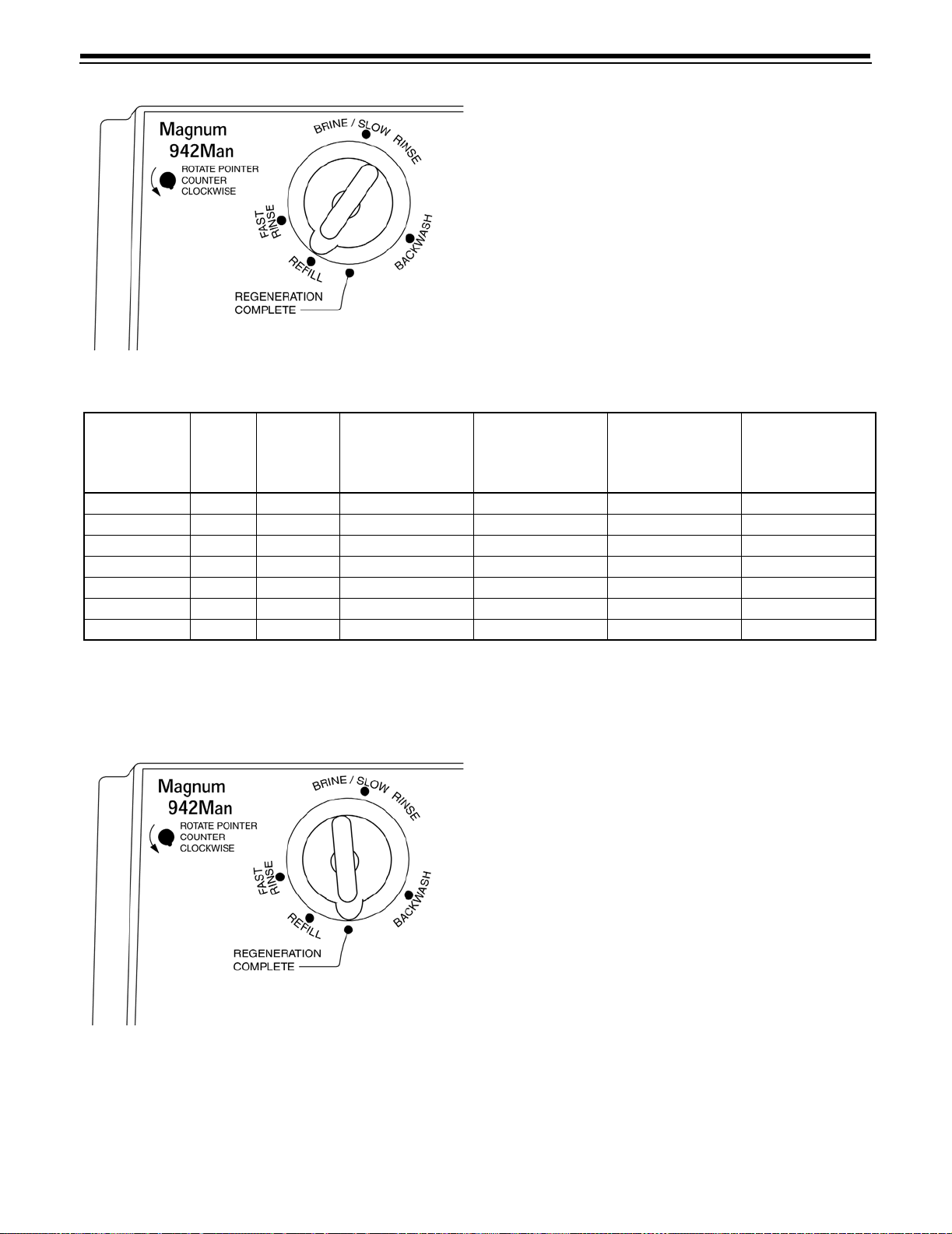

Figure 5.4

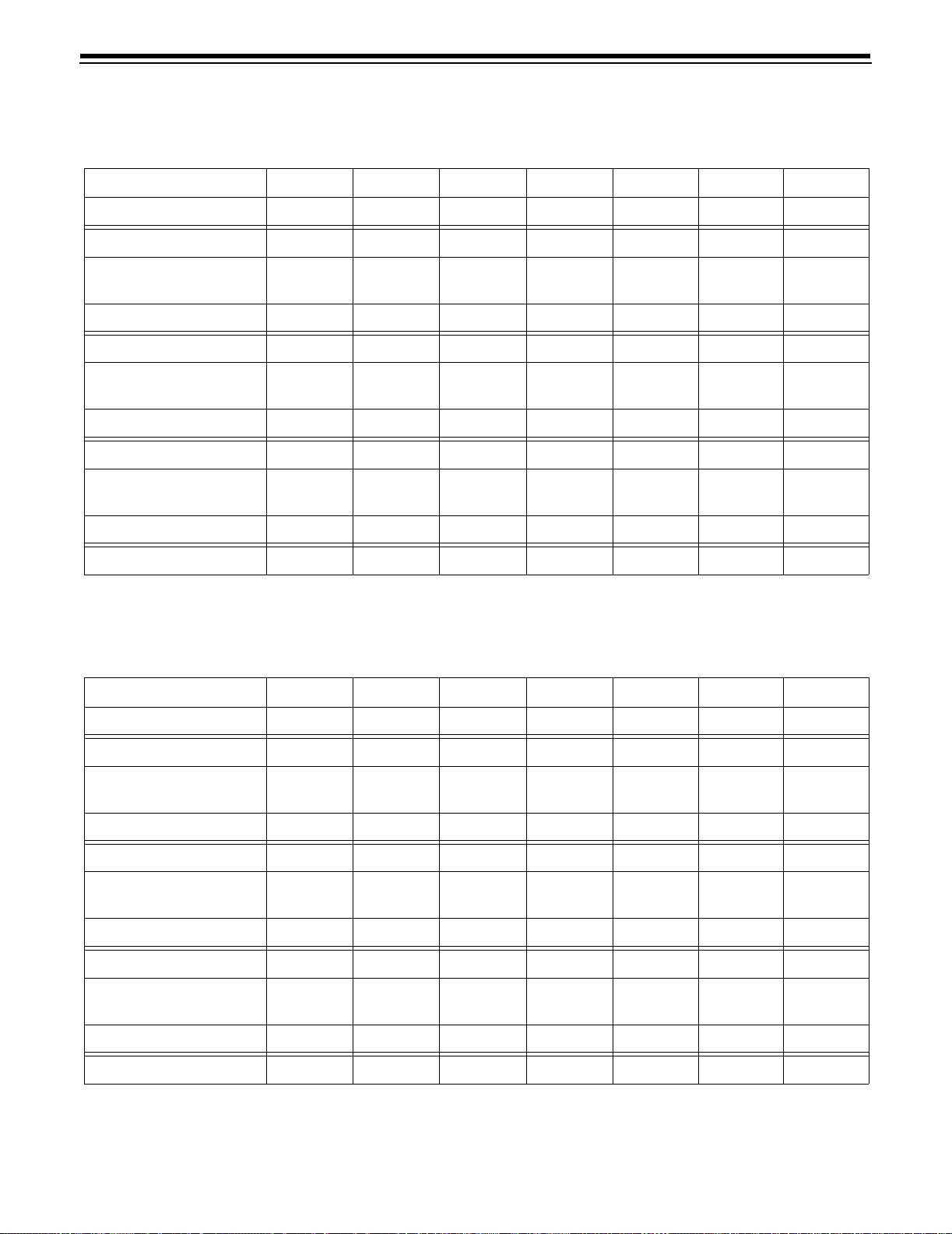

Table 5.1 Suggested Refill Times

Refill Flow Rate

Tank

Diameter

Resin

cu.ft.

Refill PN

gpm (lpm)

@ 60 psig

(414 kPa)

14 in (35.5 cm) 3 1040679 0.7 (2.6 lpm) 9 minutes 15 minutes 22 minutes

16 in (40.6 cm) 4 1040680 0.8 (3 lpm) 10 minutes 17 minutes 25 minutes

18 in (45.7 cm) 5 1040681 1.0 (3.8 lpm) 10 minutes 17 minutes 25 minutes

21 in (53.5 cm) 7 1040682 1.4 (5.31 lpm) 10 minutes 17 minutes 25 minutes

24 in (60.9 cm) 10 1040683 2.0 (7.6 lpm) 10 minutes 17 minutes 25 minutes

30 in (76.2 cm) 15 1040684 3.0 (11.4 lpm) 10 minutes 17 minutes 25 minutes

36 in (91.4 cm) 20 1040685 5.0 (18.9 lpm) 8 minutes 14 minutes 20 minutes

6. When the refill is complete move the indicator knob

COUNTERCLOCKWISE to the Regeneration

Complete position (Figure 5.5). The unit will now

provide softened water.

Minimum Salting

3

(6 lbs/ft

)

(96.1 kg/m

Regenerating Iron Filters - Model 942Man

Refer to Regenerating Iron Filters Model 942 in Section

5.2 for information on this type of system application.

All common control settings, control regenerant

Medium Salting

3

)

( 160.18 kg/m

(10 lbs/ft

3

Salting (15 lb/ft

)

3

)

(240.27 kg/m

settings, and regenerant usage which apply to the

942Man control are the same as those used on the 942

control.

When using the 942Man control however, the time of

each cycle cannot be predicted exactly. Note the

following regeneration cycle parameters:

• Backwash the filter until the drain water flows clear,

typically 5 - 15 minutes.

• Regenerant draw continues until the check ball

closes to end draw.

• Slow Rinse should continue until there is NO pink

color to the drain water flow. This is typically four

times that of the regenerant draw time.

• Fast Rinse time continues until there is no pink

Figure 5.5

*Note: The times given are only general guidelines.

Adjustment of the times may be necessary for specific

applications and conditions.

color to the drain water flow, typically 5 - 15

minutes.

• Refill time is determined by the size of the refill flow

control and the amount of regenerant required for a

particular size system. Refer to Regenerant Use

Table in Section 5.2.

Maximum

3

)

3

)

20

Page 25

Table 5.2 Suggested Brine Draw/Slow Rinse Times Based on 25 psi and 2.5 Bed Volumes of

Slow Rinse

Tank Size in. (cm) 14 (35.5) 16 (40.6) 18 (45.7) 21 (53.3) 24 (60.9) 30 (76.2) 36 (91.4)

Resin Vol. cu. ft. (cu m) 3 (0.085) 4 (0.113) 5 (0.142) 7 (0.200) 10 (0.283) 15 (0.425) 20 (0.566)

Brine/ Rinse Time 78 min 72 min 85 min 73 min 79 min 89 min 77 min

Total Lb. Salt [Min.] (kg) 18 (6.72) 24 (8.96) 30 (11.2) 42 (15.68) 60 (22.39) 90 33.59)

Capacity (kgr) 60 80 100 140 200 300 400

Brine/Rinse Time 87 min 83 min 98 min 87 min 89 min 100 min 86 min

Total Lb. Salt [Mid] (kg) 30 (11.2) 40 (14.93) 50 (18.66) 70 (21.13)

Capacity (kgr) 75 100 125 175 250 375 500

Brine/Rinse Time 99 min 98 min 113 min 103 min 102 min 114 min 98 min

Total Lb. Salt [Max] 45 (16.8) 60 (22.39) 75 (27.99) 105 (39.19

Capacity (kgr) 90 120 150 210 300 450 600

Injector Number 1000441 1000442 1000443 1000444 1000445 1000446 1000447

100

(37.32)

150

(55.99)

150

(55.99)

225

(83.98)

120

(44.79)

200

(74.65)

300

(111.97)

Table 5.3 Suggested Brine Draw/Slow Rinse Times Based on 50 psi and 2.5 Bed Volumes of

Slow Rinse

Tank Size in. (cm) 14 (35.5) 16 (40.6) 18 (45.7) 21 (53.3) 24 (60.9) 30 (76.2) 36 (91.4)

Resin Vol. cu. ft. (cu m) 3 (0.085) 4 (0.113) 5 (0.142) 7 (0.200) 10 (0.283) 15 (0.425) 20 (0.566)

Brine/ Rinse Time 65 min 58 min 70 min 65 min 66 min 76 min 68 min

Total Lb. Salt [Min.] (kg) 18 (6.72) 24 (8.96) 30 (11.2) 42 (15.68) 60 (22.39) 90 33.59)

Capacity (kgr) 60 80 100 140 200 300 400

Brine/Rinse Time 74 min 70 min 83 min 77 min 77 min 87 min 77 min

Total Lb. Salt [Mid] (kg) 30 (11.2) 40 (14.93) 50 (18.66) 70 (21.13)

Capacity (kgr) 75 100 125 175 250 375 500

Brine/Rinse Time 99 min 85 min 98 min 94 min 90 min 101 min 89 min

Total Lb. Salt [Max] 45 (16.8) 60 (22.39) 75 (27.99) 105 (39.19

Capacity (kgr) 90 120 150 210 300 450 600

Injector Number 1000441 1000442 1000443 1000444 1000445 1000446 1000447

100

(37.32)

150

(55.99)

150

(55.99)

225

(83.98)

120

(44.79)

200

(74.65)

300

(111.97)

21

Page 26

Table 5.4 Suggested Brine Draw/Slow Rinse Times Based on 75 psi and 2.5 Bed Volumes of

Slow Rinse

Tank Size in. (cm) 14 (35.5) 16 (40.6) 18 (45.7) 21 (53.3) 24 (60.9) 30 (76.2) 36 (91.4)

Resin Vol. cu. ft. (cu m) 3 (0.085) 4 (0.113) 5 (0.142) 7 (0.200) 10 (0.283) 15 (0.425) 20 (0.566)

Brine/ Rinse Time 55 min 52 min 61 min 57 min 58 min 66 min 55 min

Total Lb. Salt [Min.] (kg) 18 (6.72) 24 (8.96) 30 (11.2) 42 (15.68) 60 (22.39) 90 33.59)

Capacity (kgr) 60 80 100 140 200 300 400

Brine/Rinse Time 64 min 64 min 73 min 70 min 69 min 76 min 64 min

Total Lb. Salt [Mid] (kg) 30 (11.2) 40 (14.93) 50 (18.66) 70 (21.13)

Capacity (kgr) 75 100 125 175 250 375 500

Brine/Rinse Time 75 min 79 min 88 min 85 min 82 min 90 min 75 min

Total Lb. Salt [Max] 45 (16.8) 60 (22.39) 75 (27.99) 105 (39.19

Capacity (kgr) 90 120 150 210 300 450 600

Injector Number 1000441 1000442 1000443 1000444 1000445 1000446 1000447

100

(37.32)

150

(55.99)

150

(55.99)

225

(83.98)

120

(44.79)

200

(74.65)

300

(111.97)

Table 5.5 Suggested Brine Draw/Slow Rinse Times Based on 100 psi and 2.5 Bed Volumes of

Slow Rinse

Tank Size in. (cm) 14 (35.5) 16 (40.6) 18 (45.7) 21 (53.3) 24 (60.9) 30 (76.2) 36 (91.4)

Resin Vol. cu. ft. (cu m) 3 (0.085) 4 (0.113) 5 (0.142) 7 (0.200) 10 (0.283) 15 (0.425) 20 (0.566)

Brine/ Rinse Time 50 min 48 min 56 min 53 min 54 min 59 min 50 min

Total Lb. Salt [Min.] (kg) 18 (6.72) 24 (8.96) 30 (11.2) 42 (15.68) 60 (22.39) 90 33.59)

Capacity (kgr) 60 80 100 140 200 300 400

Brine/Rinse Time 59 min 60 min 68 min 65 min 64 min 69 min 59 min

Total Lb. Salt [Mid] (kg) 30 (11.2) 40 (14.93) 50 (18.66) 70 (21.13)

Capacity (kgr) 75 100 125 175 250 375 500

Brine/Rinse Time 70 min 75 min 83 min 81 min 77 min 82 min 70 min

Total Lb. Salt [Max] 45 (16.8) 60 (22.39) 75 (27.99) 105 (39.19

Capacity (kgr) 90 120 150 210 300 450 600

Injector Number 1000441 1000442 1000443 1000444 1000445 1000446 1000447

100

(37.32)

150

(55.99)

150

(55.99)

225

(83.98)

120

(44.79)

200

(74.65)

300

(111.97)

Minimum salting: 6 lb. salt = 20 kgr/cu. ft.

Medium salting: 10 lb. salt = 25 kgr/cu. ft.

Maximum salting: 15 lb. salt = 30 kgr/cu. ft.

22

Page 27

942FMan - Manual Filter Control for the Magnum

Valve

The 942FMan represents the maximum in versatility

and ease of operation for the manual control valve

system. Upgrade to an automatic system is easily

accomplished by switching the manual control to a

clock or demand control.

DO NOT TURN THE INDICATOR KNOB CLOCKWISE

AT A N Y T IM E .

Backwash Instructions:

1. Move the indicator knob COUNTERCLOCKWISE

from the Backwash Complete position to the

center of the Backwash (Figure 5.6) position. DO

NOT turn the knob clockwise. The knob should

remain in the Backwash position for 5 to 20

minutes*, or until the water runs clear at the drain.

3. After the fast rinse is complete, return the filter to

service by rotating the indicator knob

COUNTERCLOCKWISE to the Backwash

Complete position (Figure 5.8).

Figure 5.8

Figure 5.6

2. When the backwash is finished, move the indicator

knob COUNTERCLOCKWISE to the center of the

Fast Rinse position (Figure 5.7). The knob should

remain in the Fast Rinse position for 5 to 20

minutes*, or until the water runs clear at the drain.

*Note: the times given are only general guidelines.

Adjustment of the times may be necessary for specific

applications and conditions.

Figure 5.7

23

Page 28

5.2 Mechanical

regeneration. Reset day pins when completed.

Series 942 Mechanical Controls

The Series 942 mechanical controls provide

mechanical timeclock function for water softening and

filter applications; 942 model for softening

applications, (Figure 5.9) 942F model for filtering

applications. Identification of the specific model is

provided on the front of the control. The controls are

very similar in appearance, function, and settings.

However, they require different gear drives and

camshafts to function properly. The softener and filter

camshafts are identified in the Assembly Drawings and

Parts List, Section 12.10, of this manual.

Setting the Days of Regeneration

Setting the days that the conditioner will regenerate is

accomplished in two simple steps:

1. Pull all of the day pins outward.

2. Push in the day pin(s) for the day(s) on which a

regeneration or backwash is desired.

NOTE: The NEXT DAY pin is noted on the control face.

Pushing this pin will insure a regeneration the next day

at approximately 2:00 a.m. since the Calendar Cap

progresses in a clockwise direction, pushing the day

pin immediately following the NEXT DAY pin

counterclockwise will insure a regeneration occurs the

following day at approximately 2:00 a.m. This

progression is noted on the control face as “FUTURE

DAYS”.

Manual Regeneration

Excessive water usage or other service related issues

may create the need to manually regenerate the

conditioner. This function is performed by rotating the

Indicator Knob COUNTERCLOCKWISE to the

“START” position. Once in this position, the conditioner

will begin a regeneration or backwash within a few

minutes. The normal schedule, established with the

pushed in day pins, will not be disrupted by a manual

regeneration or backwash.

Indicator Knob

Day Pin

Calendar Cap

Figure 5.9

Clock Dial

5.2.1 Common Settings

Setting the Time of Day, the Days of Regeneration or

Backwash and performing manual regenerations or

backwashing are the same for 942 and 942F controls.

Setting the Time of Day

Rotate the Clock Dial clockwise until the pointer

indicates the correct time of day. With the time of day

set, the conditioner will regenerate at approximately

2:00 a.m. If it is desired to have the unit regenerate at

an earlier or later time, simply offset the current time of

day accordingly. For example, to have the unit

regenerate at 4:00 a.m., set the Clock Dial 2 hours

earlier than the actual current time of day.

Note: Do not rotate the Calendar Cap by hand. The

Clock Dial indexes the Calendar Cap daily. To manually

index the Calendar Cap, rotate the Clock Dial

clockwise one complete turn for every day to be

indexed. Day pins should be in the outward position

during Clock Dial rotation to prevent an undesired

24 Hour Clock

All Magnum 942 and 942F controls utilize a 24 hour

clock dial. This is typically referred to as “Military Time”.

The hours of the day between 12:00 a.m. (midnight)

and 12:00 p.m. (noon) are designated on the clock dial

by the numbers 1 through 12, with 1 being 1:00 a.m.

The hours of the day between 12:00 p.m. (noon) and

12:00 a.m. (midnight) are designated on the clock dial

by the numbers 13 through 24, with 13 being 1:00 p.m.

Be sure to set the correct time of day accordingly.

Adjusting the Salt Setting - Model 942

The Salt Dial (Figure 5.10) controls the total amount of

salt used per regeneration. With the Indicator Knob in

the REGENERATION COMPLETE position, rotate the

Salt Dial counterclockwise at least one full turn to

cancel out the current setting. A light clicking sound will

be replaced by a heavier clicking sound when the

previous setting is cancelled. Once the heavier clicking

is heard, the new setting may be set by rotating the Salt

Dial counterclockwise to the desired setting.

24

Page 29

Salt Dial

Indicator Knob

Figure 5.10 Regeneration Complete

It is important to note that the numbers on the Salt Dial

represent “MINUTES” of water refill time. To determine

the total pounds of salt that will be used for a

regeneration, it is necessary to know the refill control

that is used in the conditioner. The refill control

determines the flow rate of water into the salt tank

during the refill cycle. Refer to the Salt Use Table 5.8 to

determine the total pounds of salt used per

regeneration for the various size tanks.

NOTE: Only two sizes of refill flow controls are

recommended when the Magnum Cv Series control

valve is used in a manganese greensand filter system.

The Magnum control valve must be ordered with the

proper size refill flow control or changed in the field.

The incorrect refill flow control could underfill or overfill

the regenerant tank resulting in a system malfunction.

5.2.3 Backwashing Filter - Model 942F

Adjusting the Backwash Setting

The Backwash Dial (Figure 5.11) controls the backwash

time. With the Indicator Knob in the BACKWASH

COMPLETE position, rotate the Backwash Dial

counterclockwise at least one full turn to cancel out the

current setting. A light clicking sound will be replaced

by a heavier clicking sound when the previous setting

is cancelled. Once the heavier clicking is heard, the

new setting may be set by rotating the Backwash Dial

to the desired setting. The numbers on the Backwash

Dial represent “MINUTES” of backwash time.

Table 5.6 Cycle Times for 942 Control

Cycle Time (Minutes)

Backwash 17

Brine/Slow Rinse 95

Purge 9

Refill 2 to 24

5.2.2 Regenerating Iron Filters - Model 942

Filter medias used in the water treatment industry

generally require only a periodic backwashing with

water to maintain their filtering efficiencies. These type

of filters would use the 942F control described in the

next section. Manganese greensand media, typically

used for iron removal, requires regular regeneration

with an oxidizing chemical, potassium permanganate

(KMNO

with salt. This application requires the use of the Model

942 control.

Common Settings

Setting the Time of Day, Days of Regeneration, and the

initiation of a Manual Regeneration are as previously

described in this section.

) similar to the regeneration of a water softener

4

Backwash Dial

Figure 5.11 Backwash Complete

Table 5.7 Cycle Times for 942F Control

Cycle Time (Minutes)

Backwash 8 - 30

Purge 9

Adjusting The Regenerant Setting - Model 942

Refer back to the previous heading in this section

Adjusting the Salt Setting - Model 942. Setting the

number of “MINUTES” of refill time determines the

amount of regenerant chemical used per regeneration.

Refer to the Regenerant Use Table 5.9 for the proper

setting based on tank size and the number of cubic feet

of media used.

25

Page 30

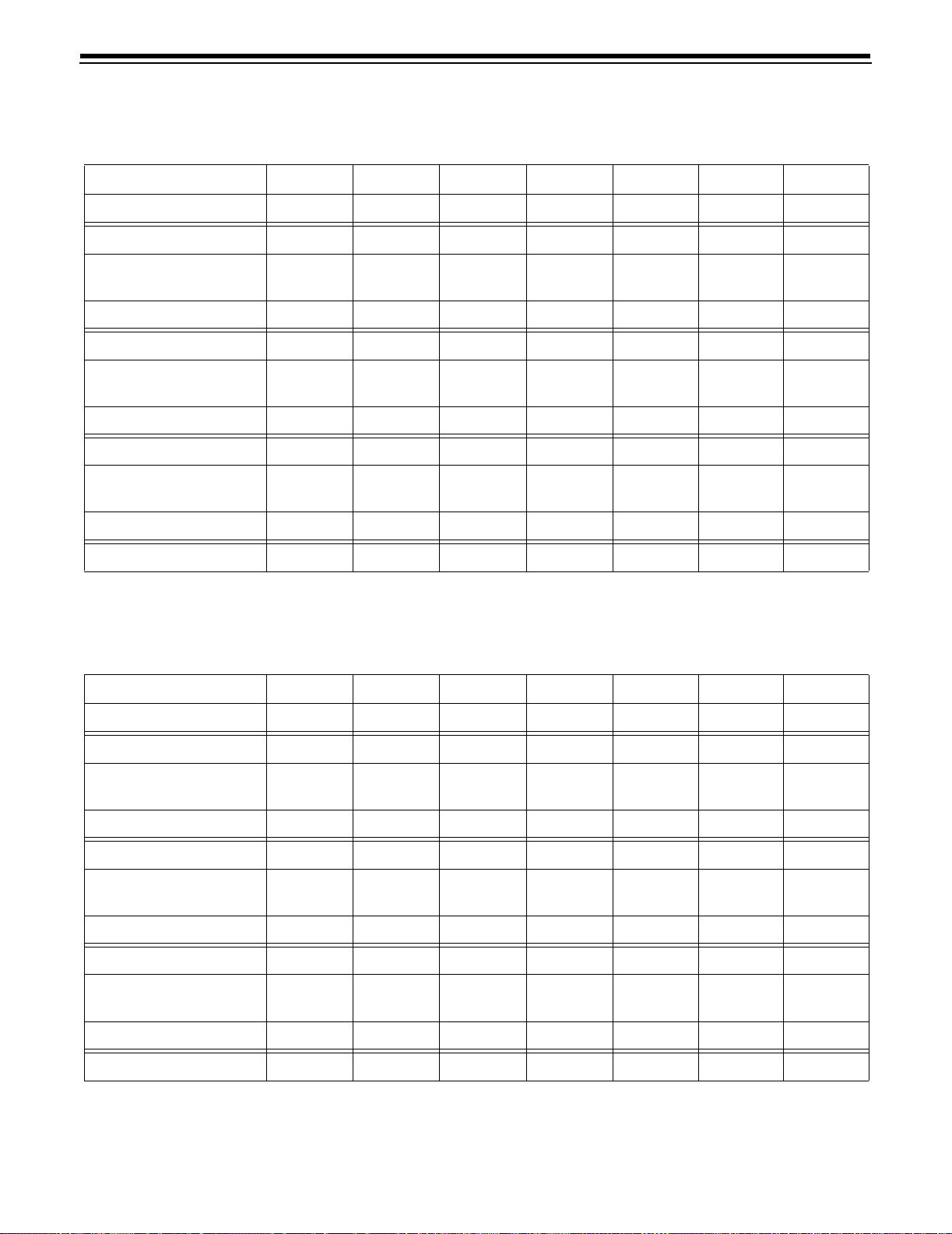

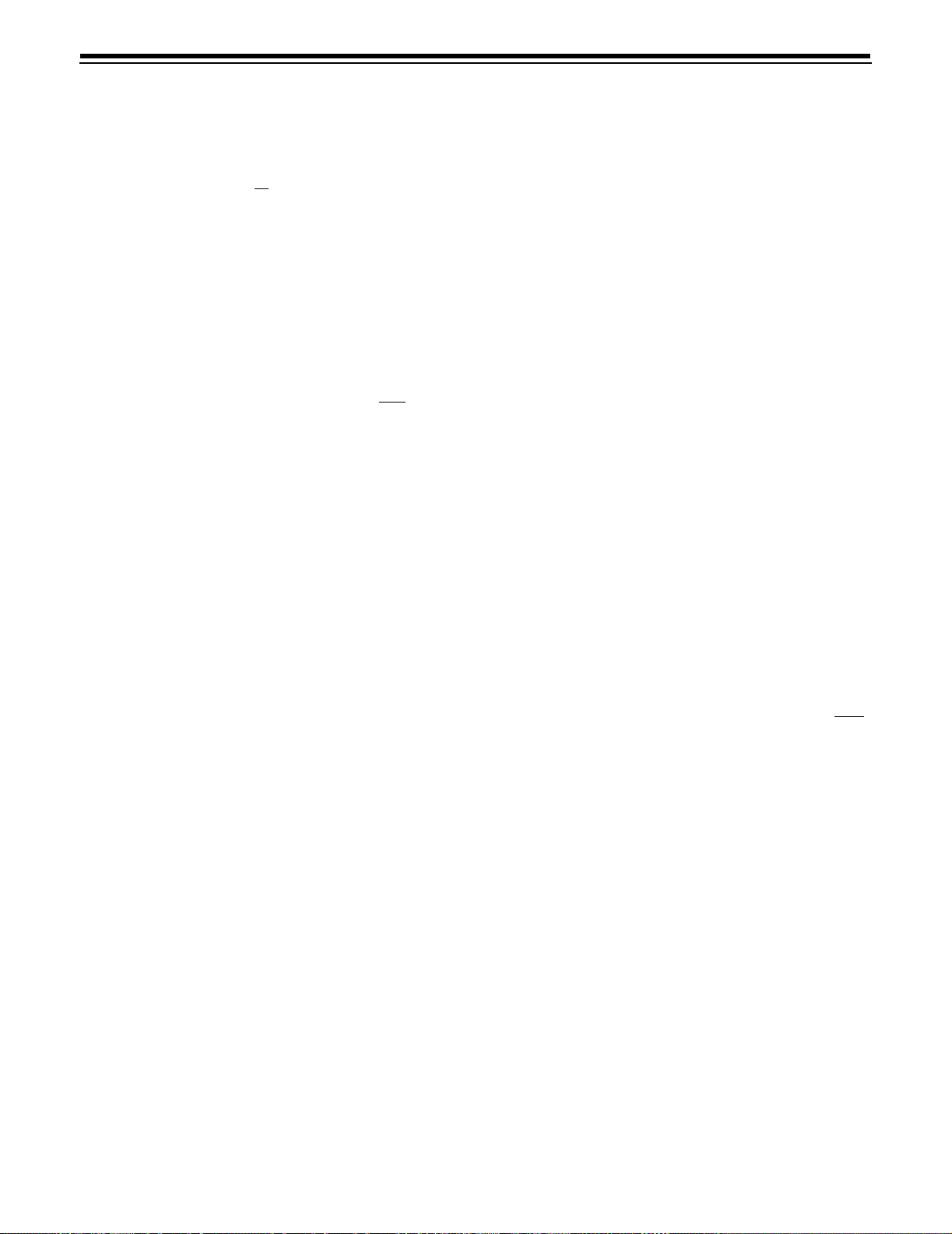

5.2.4 Salt Use Table

Table 5.8 Model 942, 952, 952QC - Salt Used per Regeneration

Tank Size/Dia.

inches (cm)

Resin Volume

cu. ft. (cu. m.)

Refill Flow

Rate

GPM (LPM)

14 (35.5) 16 (40.6) 18 (45.7) 21 (53.3) 24 ( 60.9) 30 (76.2) 36 (91.4)

3 (0.85) 4 (0.113) 5 (0.142) 7 (0.200)

10

(0.283)

0.7 (2.65) 0.8 (3.03) 1.0 (3.78) 1.4 (5.30) 2.0 (7.57)

15

(0.425)

3.0

(11.36)

Salt Dial

Setting

Approximate Pounds of Salt per Regeneration

(Minutes)

8 18----------120

10 21 24 30 42 60 90 150

12 25 29 36 50 72 108 180

14 29 34 42 59 84 126 210

16 34 38 48 67 96 144 240

18 38 43 54 76 108 162 270

20 42 48 60 84 120 180 300

22 45 53 66 92 132 198 --

20

(0.566)

5.0

(18.93)

24 -- 60 75 105 150 225 --

Notes:

1. Flow rates for refill controls are based on 60 psig (414 kPa) inlet pressure.

2. Take into account the type of brine system used when determining the actual amount of salt delivered during

regeneration. (i.e. dry salt/grid plate or wet salt)

3

3. Salt Use Table reflects minimum salting of 6 lbs./cu.ft. (96.11 kg/m

(240.27 kg/m

3

).

) through maximum salting of 15 lbs./cu.ft.

4. To use potassium chloride (KCl) increase salt dosage by approximately 25%.

3

5. Chloride/Anion dealkalizers regenerate with 5 lbs./cu.ft. (80.09 kg/m

) salt (NaCl) which yields approx. 7500 gr/

cu. ft. Injecting sodium hydroxide (NaOH) i.e. caustic soda, at a rate of 1/10 that of the salt dosage, during the

brine draw cycle, increases capacity to approx. 10000 gr./cu. ft. Exact capacity, based on tank size, must be

calculated using water analysis and resin manufacturer’s capacity curves.

26

Page 31

5.2.5 Regenerant Use Table - Potassium Permanganate (KMnO4)

Table 5.9 Model 942, 952, 952QC - Regenerant Used Per Regeneration

Tank Size/Dia.

inches (cm)

Media Volume

cu. ft. (cu. m.)

Refill Flow

Rate

GPM (LPM)

Salt Dial

Settings

(minutes)

KMnO4

oz. (grams)

Refill Water

gal. (liters)

Notes:

1. Chemical dosage recommendations typify

requirements for single batch regenerations.

2. When combining batch regeneration with continual

feed of either chlorine or potassium permanganate,

reduce recommended chemical dosages above by

50%.

3. Table above reflects a 4 oz./cu. ft. of media,

regenerant dosage, dissolved in 1 gallon of

water/cu. ft. of media. Dosage rates will vary with

various media manufacturers’ recommendations.

Check manufacturers’ specifications for dosage

recommendations.

14 (35.5) 16 (40.6) 18 (45.7) 21 (53.3) 24 ( 60.9) 30 (76.2) 36 (91.4)

3 (0.085) 4 (0.113) 5 (0.142) 7 (0.200)

0.8 (3.03) 0.8 (3.03) 0.8 (3.03) 1.0 (3.78) 1.0 (3.78) 1.0 (3.78) 1.0 (3.78)

4 6 7 7 10 15 20

12(340) 16 (454) 20 (567) 28 (794) 40 (1134) 60 (1701) 80 (2268)

3 (11.36) 4 (15.14) 5 (18.93) 7 (26.50)

10

(0.283)

10

(37.85)

15

(0.425)

15

(56.78)

20

(0.566)

20

(75.71)

27

Page 32

5.3 Impulse

Series 952 Impulse Controls

The Series 952 impulse controls initiate a regeneration,

or backwash, upon receiving an external line powered

switch closer signal for a minimum of three minutes.

The three models available are:

Control Description

952 5 Cycle Softener

952F 3 Cycle Filter

952QC 5 Cycle Softener with Quick-Connect Cables

Once the external signal is received, the control

automatically steps the valve through the appropriate

cycles. Cycle positions are identified by the Indicator

Knob.

Once the control has reached the REGENERATION

COMPLETE position, the 952 control will be ready for

the next external line powered switch closure signal. If

a switch closure signal is received during a

regeneration or backwash, it will be ignored.

Regenerating Iron Filters - Model 952

Refer to the heading Regenerating Iron Filters - Model

942 in Section 5.2 for information on this type of system

application. All common control settings, control

regenerant settings, and regenerant usage which apply

to the 942 control are the same as those used on the

952 control. This iron filter information applies to

potassium permanganate regenerated manganese

greensand filter systems only.

Adjusting the Backwash Setting - Model 952F

The Backwash Dial (Figure 5.13) controls the backwash

time. With the Indicator Knob in the BACKWASH

COMPLETE position, rotate the Backwash Dial

counterclockwise at least one full turn to cancel out

the current setting. A light clicking sound will be

replaced by a heavier clicking sound when the previous

setting is cancelled. Once the heavier clicking is heard,

the new setting may be set by rotating the Backwash

Dial to the desired setting. The numbers on the

Backwash Dial represent “MINUTES” of backwash

time.

Adjusting the Salt Setting - Model 952 and 952QC

The Salt Dial (Figure 5.12) controls the total amount of

salt used per regeneration. With the Indicator Knob in

the REGENERATION COMPLETE position, rotate the

Salt Dial COUNTERCLOCKWISE at least one full turn

to cancel out the current setting. A light clicking sound

will be replaced by a heavier clicking sound when the

previous setting is cancelled. Once the heavier clicking

is heard, the new setting may be set by rotating the Salt

Dial counterclockwise to the desired setting.

Salt Dial

Indicator Knob

Figure 5.12 Regeneration Complete.

It is important to note that the numbers on the Salt Dial

represent “MINUTES” of water refill time. To determine

the total pounds of salt that will be used for a

regeneration, it is necessary to know the refill control

that is used in the conditioner. The refill control

determines the flow rate of water into the salt tank

during the refill cycle. Reference the Salt-Use Table on

page 26 to determine the total pounds of salt used per

regeneration for various size tanks.

Backwash Dial

Figure 5.13 Backwash Complete.

Table 5.11 Cycle Times for 952F Control

Cycle Time (Minutes)

Backwash 8 - 30

Purge 9

Wiring the 952 Series Controls

The 952 and 952F controls come with 21-foot (6.4-m)

of wire for connection to the external signaling device.

Refer to wiring illustration in the Wiring Diagram

Section of this manual for further installation

information. The 952QC is pre-wired with a standard

7-foot (2.13-m) cable assembly designed to plug

directly into an Autotrol 480QC. Optional 14-foot

(4.27-m) and 21-foot (6.4-m) cable assemblies are

available. An optional feed back switch assembly,

mounted on the Magnum control valve, is required,

when operating in the 952QC configuration.

Table 5.10 Cycle Times for 952 Control

Cycle Time (Minutes)

Backwash 17

Brine/Slow Rinse 95

Purge 9

Refill 2 - 24

28

Page 33

5.4 Electronic

Series 962 Electronic Demand Controls

The Series 962 Electronic Controls provide

sophisticated, demand-based water conditioning by

combining a microprocessor with a flow meter to

electronically monitor the amount of water used. This

fully programmable series of controls provide the ability

to fine tune the conditioner’s operation to meet the

application requirements. There are four basic 962

Demand models available:

Control Description

962 Single or Multi Tank Softener

962F Single or Multi Tank Filter

962M Main Control for Twin Alternating

962S Secondary Control for Twin Alternating

Series 962 Electronic Time Clock Controls

The 962 Time Clock Controls allow regeneration/

backwash initiation several different ways. Choose the

day of the week to regenerate/backwash or set it to

regenerate/backwash on an interval basis. External

initiation is also available. This fully programmable

series of controls provide the ability to fine tune the

conditioners application to meet the operations

requirements. There are two basic 962 Time Clock

models available:

Control Description

962TC Softener or Multitank Softener

962FTC Filter or Multitank Filter

This section of the manual defines the basic operating

and programming features for each of these models.

Special Features of the Series 962 Controls

• Memory Retention - During a power outage,

critical operating information is stored in memory.

This information includes all programming data and

the number of days since the last regeneration.

When power is restored, the information is returned

to the microprocessor and operation resumes as if

an outage never occurred. The time of day will be

late by the length of the power outage and must be

reset. No other reprogramming is necessary. An

optional rechargeable battery backup will allow the

control to keep track of time and water usage for

up to eight hours during a power outage. The

control will not initiate a regeneration or backwash

while on battery backup.

• Programmable Cycles - The control is flexible in

defining the appropriate cycles of operation.

• Double Regeneration - For single tank

applications (Model 962 and 962F) the control

automatically calls for a second regeneration or

backwash the following day if the current operating

cycle exceeds the defined capacity by 150% or

more.

• Capacity and Salt Setting Lockout - The control

can be programmed to lock the values for Salt

Amount and Capacity so they cannot be altered

after installation.

Reserve Type Control

Specific time of day regeneration 962 and 962M

Immediate regeneration 962 and 962M

Fixed reserve 962

Variable reserve 962

• U.S. or Metric Units of Measure - To meet your

display and programming requirements, the 962

control uses grains per gallon of hardness, pounds

of salt and kilograins of capacity for U.S. units, or,

parts per million of hardness, kilograms of salt and

kilograms of capacity for metric units. The 962

control displays capacity as gallons or cubic

meters.

• Calendar Override - If the volume of water used

has not caused a regeneration, the 962 control can

be set to regenerate every one to thirty days.

• Manual Regeneration - A separate REGEN button

is provided for manual regenerations. A double

manual regeneration feature is included that allows

back-to-back regenerations.

• Operating Histories (Demand Controls Only) -

Important operating data is stored in memory and

is retrievable upon demand. The historical data

includes peak flow rate as well as average daily

water usage for each day of the week.

• Remote Regeneration - A set of terminals is

provided as a standard feature on the 962 control

that allows for a regeneration to be initiated from a

remote location. This feature can be used to

facilitate manual regeneration requirements or

assist in further automating the control system.

• Selectable Automatic Regenerations/

Backwashes - There are two automatic

regeneration/backwash methods - immediate and

delayed. Immediate regeneration is used to start

automatic regenerations/backwashes when the

softening capacity is exceeded. Delayed

regeneration is used to start automatic

regenerations/backwashes at a predetermined

time of day. A regeneration/backwash will start at

the programmed regeneration time when the

remaining capacity falls below the reserve capacity,

which may be fixed or variable.

29

Page 34

• Selectable Reserve Options (Demand Controls

Only) - To meet the conditioned water

requirements of the application, the 962 control

allows selection of one of two reserve types:

– Fixed Reserve - The reserve is fixed at a

progammable percentage (30% factory preset)

of the total softening capacity.

– Variable Reserve - The controller monitors the

daily water usage and at the programmed time

of regeneration, calculates the average water

used for each day of the week. The reserve

capacity is set to 120% of the average water

usage for the next day.

• Delayed Regeneration on Twin-alternating

Systems - The twin-alternating system does not

use a reserve capacity. The service tank switches

when the softening capacity is exhausted.

Regeneration of the exhausted tank will occur at

the specified time of day when using the delayed

regeneration feature.

• Immediate Regeneration on Twin and Triple

Parallel Systems - The twin and triple parallel

systems use a reserve capacity of “0” along with

immediate regeneration. Regeneration of an

exhausted tank in the system will occur

immediately after reaching its maximum capacity,

IF, there are no other tanks within the system

already regenerating.

Normal Display Modes

In the normal operating mode the Series 962 control

will alternate between Capacity Remaining (gallons or

3

) and Flow Rate (gallons per minute or m/hr). In the

m

event of power loss, the display will alternate between

Time of Day and Capacity Remaining once power

has been restored. The normal operating display mode

of the twin alternating system scrolls through three

displays. They are: Capacity Remaining of tank 1 in

gallons, Capacity Remaining of tank 2 in gallons, and

Flow Rate. If a power outage has occurred, the flow

rate display will change to Time of Day. In both cases

the control will remain in Power Loss display mode

until the Time of Day is reset or until any button is

pressed. (Electronic Time Clock displays Time of Day

only).

Programming the Series 962 Controls

This section contains common aspects of

programming the 962, 962F, and 962M controls and

retrieving historical operating data. The 962S control is

a secondary unit that always works in conjunction with

the 962M main control for twin alternating tank

applications. The operating values for the 962S are the

same as the operating values in the 962M control. An

adhesive installation label is provided with each 962,

962F, and 962M control. It is recommended that this be

filled out with programming parameters on start-up and

placed on the inside of the cam cover.

Factory Default Values - The control is shipped from

the factory with a default value for Salt Amount of 10 lb.

(4 kg for metric units). Capacity, Hardness, Refill and

Brine Draw values are set to 0 and must be changed

to appropriate values before the control will

operate. “Err 4” will be displayed until a valid

number is entered for each of these items. Program

variable P12 is preset at the factory to define the U.S.

units of measure for North American application or

metric units of measure for application outside North

America.

Program Levels - The Series 962 controls have been

designed to facilitate different levels of programming

requirements. Level I includes program variables that

are frequently referenced by users, operators,

installers, and service personnel, and is accessible

without the requirement of codes. Level II includes

variables that are most typically used at the time of

installation and initial setup and is accessible with

special access codes. Level III locations are used

primarily for accessing operating history information.

Level III parameters also require access codes.

Programming levels are further defined in Section 6

(page 34).

Levels Access Code

I None required

II

III

Press and hold the ↑ ↓ for approximately

3 seconds

Press and hold the ← ↑ arrow buttons for

approximately 3 seconds

Table I on page 34 lists the Level I program values for

the 962, 962F, 962TC, 962FTC and 962M controls.

Tables IIA through IIE, on pages 35-41, list the Level II

program values for all 962 series controls.

Program Values and Locations - The P values that

are programmed into the Series 962 controls are listed

in the Level I and Level II tables.

Locating a Program Value - To locate and display a P

value in Level I press the UP [↑ ] or DOWN [↓] arrow

button until the desired value is displayed.

To locate and display a P value in Level II,

simultaneously press the UP [↑ ] and

DOWN [↓] arrow

buttons for 3 seconds to gain access. Press the UP [↑ ]

DOWN [↓] arrow buttons until the desired location is

or

displayed. Press LEFT [←] to display a value in P

locations.

To locate and display an L value in Level III,

simultaneously press the LEFT [←] and

UP [↑ ] arrow

buttons for 3 seconds to gain access and the press the

UP [↑ ] or

DOWN [↓] arrows buttons until the desired

location is displayed. Press LEFT [←] to display value in

the L location.

30

Page 35

Changing a Program Value - Once the P value you

want to change is displayed, press the LEFT [←] arrow

button to display the current entry for that value. To

change or modify the value, press the SET button. The

character on the right hand side of the display will begin

to flash. Use the UP [↑ ] or

select the desired entry. Once the desired entry is

obtained, press the LEFT [←] button to move to the next

character and change as needed. Once you have

completed the appropriate changes, press the SET

button. When you press the SET button the new entry

is stored and the control automatically scrolls to the

next P value. If a beep sounds, the new entry was not

accepted. Tables I and II list the range available for a

specific program value.

Exit Mode - To exit the Level II programming mode,

simultaneously press and hold the UP [↑ ] and

[↓] arrow buttons for 3 seconds, or wait 30 seconds

without pressing a button, and the display will return to

alternate between Capacity Remaining and Flow Rate.

Level I Program Values (Table I)

Level I Program Values are identified by the legend on

the faceplate of the control. Each Level I P value has a

green LED that is illuminated when displayed.

Following are the Level I P values:

DOWN [↓] arrow buttons to

DOWN

• Time of Day P1

• Time of Regen P2

• Hardness P3

• Salt Amount P4

• Capacity P5

Time of Day - How to Change AM and PM

Press the SET button. The display will show the Time of

Day with the minutes digit blinking. To change this

number press the UP [↑ ] arrow button to increase the

number or the DOWN [↓] arrow button to decrease the

number. To skip the number without changing, press

the LEFT [←] arrow button. The first digit will stop

flashing and the next digit will start flashing. You can

only change the flashing number. When the far left digit

is reached, pressing the LEFT [←] arrow button returns

the flashing to the far right digit. Continue changing

numbers until the desired Time of Day is displayed.

Press the SET button to enter the value.

Use the same procedure to modify any of the other

Level I or Level II P values.

The PM indicator is set when changing the left most

digit in the time display. The left most digit will be a zero

"O" or a "1”. When the PM indicator light is illuminated

the time will be PM.

Level II Program Values (Tables IIA, IIB, IIC, IID, IIE

and III)

The Level II Parameters are defined as P6 through P22.

The available range for the Refill Controller (P6), and the

Brine Draw Value (P7), may be found in the section

entitled Performance Data and Charts Section of this

manual (pages 55 and 55).

Table IV on page 43 lists the Level III historical data.

Manual Regeneration or Backwash

To initiate a manual regeneration or backwash, simply

press and hold the REGEN button for 3 seconds. If an

immediate second regeneration or backwash is

desired, wait for at least one minute after the first

regeneration or backwash begins and then press and

hold the REGEN button for 3 seconds. A second

regeneration or backwash will be performed

immediately following the first. The display will freeze

and only show the Regeneration Time Remaining as an

indication that the second regeneration or backwash

will be initiated.

When the first regeneration or backwash is complete,

the second regeneration or backwash will begin and

the display will alternate between Flow Rate and

Regeneration Time Remaining.

Note: Series 962M and 962S Twin Alternating Systems

have a two minute time period, after the manual

regeneration button is pressed, where the standby unit

drives to service. If an immediate second regeneration

is required of the OTHER unit in the system, wait for at

least three minutes after pressing the manual

regeneration button the first time, then press and hold

the REGEN button for three seconds.

Battery Backup

If the battery backup is provided with the Series 962

control, make sure that it is properly connected.

Reference pages 32 and 33. Water usage and time of

day will be maintained. The control has a trickle charge

circuit that will recharge a rechargable but not a

standard battery in the event it is depleted by a power

outage.

31

Page 36

5.4.1 Connecting the 962 Control

When the 962 control is used for single tank

applications, two standard connections are required for

operation: the power transformer and the flow sensor.

Figure 5.14 outlines these standard features as well as

how to connect the battery backup parallel connector

and the optional remote regeneration feature.

Battery Backup

Wall Transformer

Flow Sensor

Parallel Connector

AC Power Jack

Figure 5.14

5.4.2 Connecting the 962M and the 962S Control

The 962M and 962S controls are used for twin

alternating tank applications. Five standard

connections are required for operation: the power

transformer, the flow sensor, feedback switches and

the connection between the 962M and 962S controls.

Figure 5.15 outlines these standard features as well as

the battery backup and the optional remote

regeneration feature.

Battery Backup

Feedback Switch

Wall Transformer

Optional Remote

Regeneration

Feature

Important: The normally-closed position of the

feedback switch is protected with a rubber boot. DO

NOT REMOVE. The normally-closed position is not

available to provide an auxiliary electrical signal.

Flow Sensor

Feedback Switch

962M

Figure 5.15

32

962 M + S

Connection

962S

Optional Remote

Regeneration Feature

Page 37

5.4.3 Connecting the 962 Twin and Triple

Parallel Control

The 962 control can be used for twin and triple tank

applications, operating in a parallel mode. Six standard

connections are required for twin parallel operations;

the power transformer and flow sensor for each control

and the twin interconnecting cable between the

controls. Nine standard connections are required for

triple parallel operation: the power transformer and flow

sensor for each control and the triple interconnecting

cable between the controls. Figure 5.16 outlines these

standard features, as well as the battery backup and

the optional remote regeneration feature.

PARALLEL SYSTEM CONNECTION PROCEDURE

1

Connect turbine flow meters

2

Connect interlock cables

3

Attach optional batteries

4

Plug transformers into outlets on common circuit

Twin Cable

Optional Remote

Regeneration Feature

Figure 5.16

Triple Cable

PARALLEL INTERCONNECT CABLES

PN 1034312 - Twin System Cable - 10 feet

PN 1035587 - Triplex System Cable - 10 feet

each

PN 1035593 - Extension Cable - 2 feet

33

Page 38

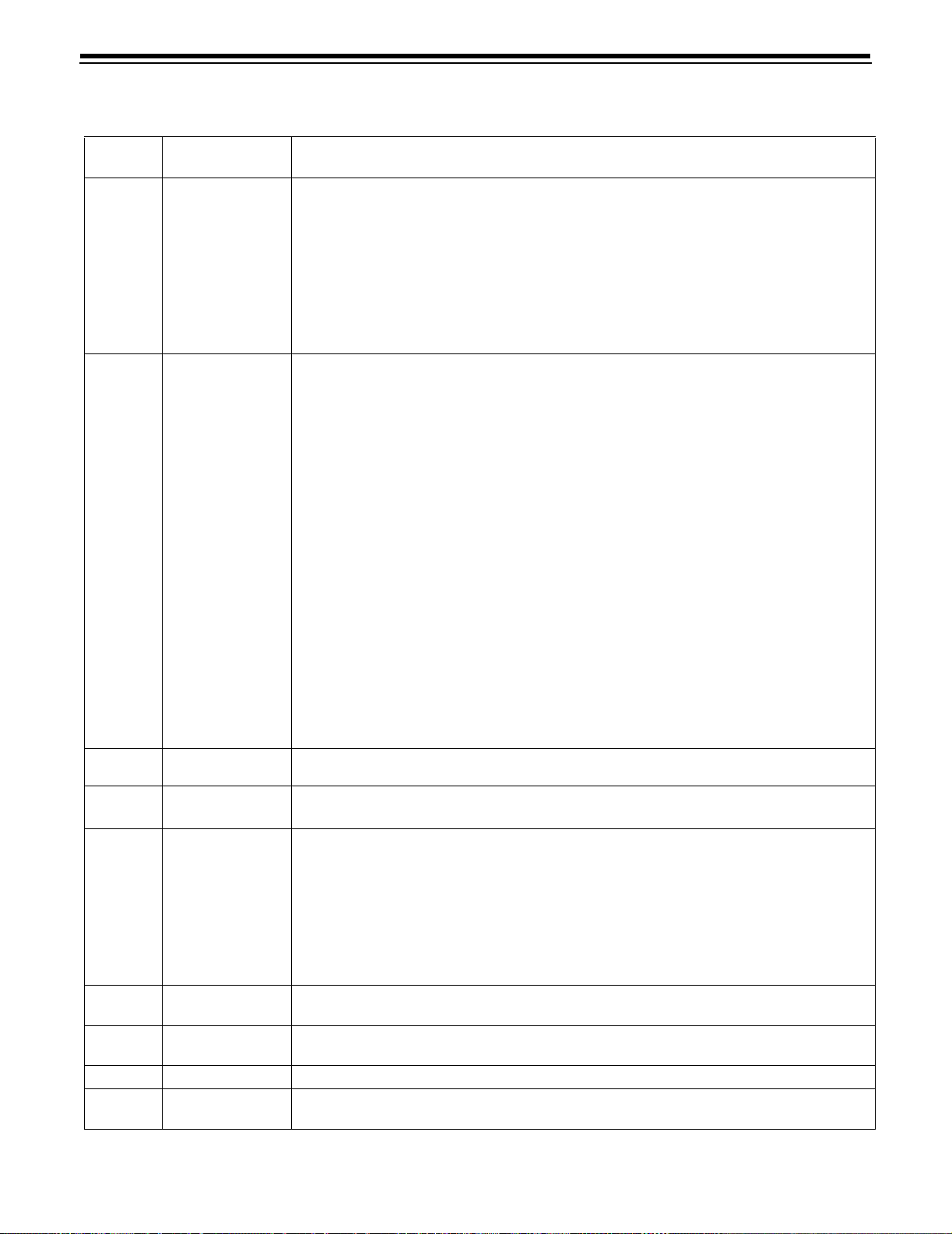

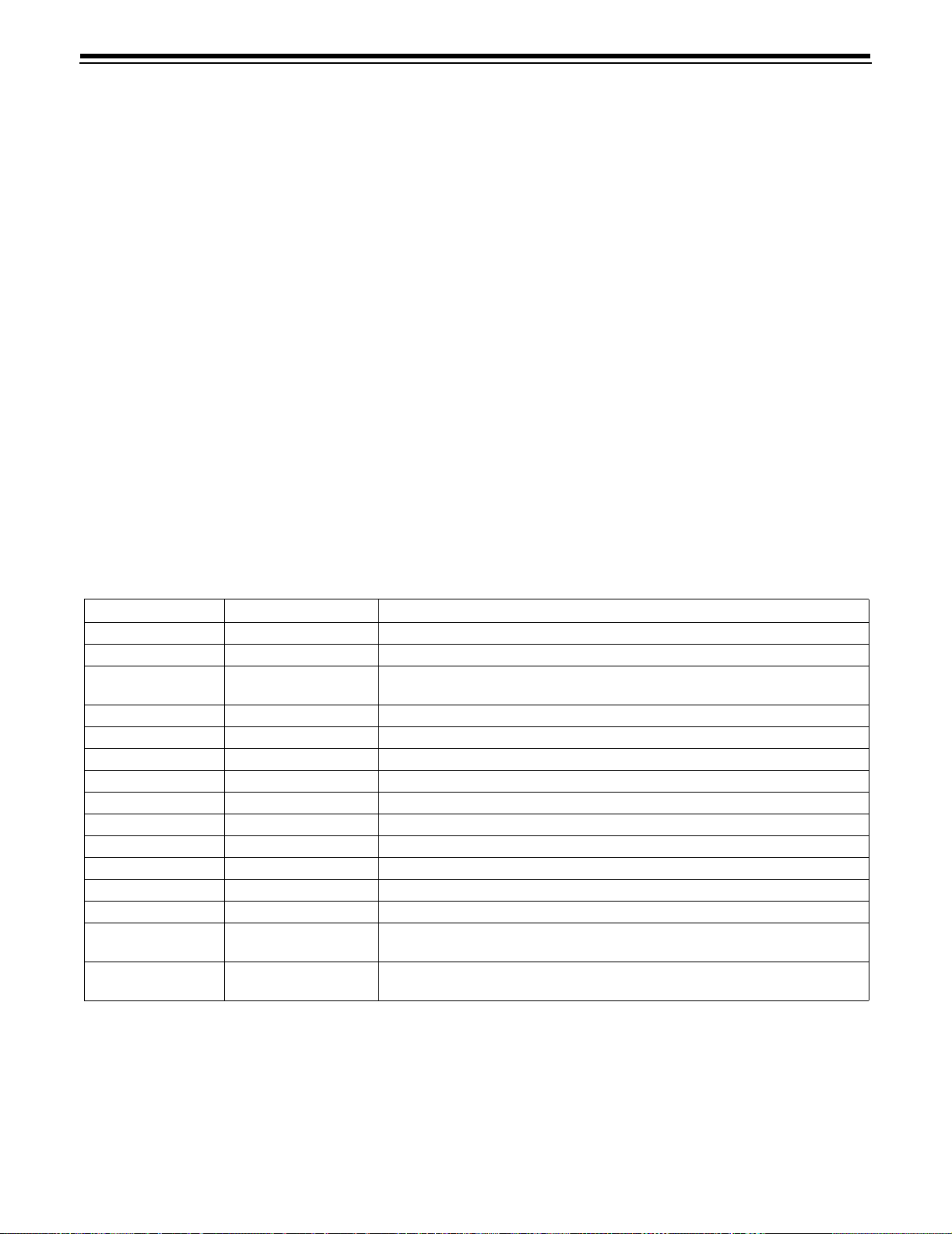

6.0 Programming Tables

6.1 Table I - Level 1 Values

Level I Program Values for 962, 962F, 962TC, 962FTC, and 962M Controls

Description of