Page 1

For Non-Health Hazard Applications

ES-9BD

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

Model 9BD

Backflow Preventer for Vend ing

Machine Water Supply Lines

Sizes: 1⁄4" and 3⁄8" (6 and 10mm)

Model 9BD backflow preventer for vending machine water supply lines prevents backflow of carbon dioxide gas and car bonat ed water into the water supply system to vend ing ma chines,

thus elim i nat ing the hazardous re ac tion of car bon di ox ide with

cop per tub ing.

Its design features include a dual check valve to as sure pos itive, dependable seating protection. For trouble-free longevity, it

is also equipped with a ball check valve which is a third-check

mem ber, its main func tion being to pre vent backpressure on

each pump cycle from unnecessarily acting di rect ly on the

check members. In stant check valve re sponse pre vents un neces sary vent dis charge dur ing pump "off cycle".

Vent discharges C02 gas to atmosphere in the event of foul ing

or mal func tion of check No. 2 thereby safe guard ing the po ta ble

water sys tem from CO2 gas con tam i na tion. In line design mini miz es pres sure drop across the valve thereby assuring max imum pump per for mance.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

Typical Installation

9BD Backflow Preventer

Water

Supply

––––––––––––––––––––––––––––––––––

9BD

Features

• Available in Flare or NPTM end connections

• Stainless steel body and parts

• Instant check valve response

• Minimum pressure drop

• Triple check protection of the water supply

Valve

Filter

Backpressure 60-120psi

Pressure - Temperature

Temperature Range: 33ºF-140ºF (0.5ºC-60ºC)

Maximum Working Pressure; 150psi (10.34 bar)

All stain less steel body and heavy duty rubber parts as sure the

long est and most dependable operating life. All rubber compounds com ply with FDA food additive reg u la tions.

Standards

Designed to meet the requirements of New York City Health

Code Sec tion 81.47.

NSF Standard No. 25, Revised Items 4.35.2 and 4.35.3.

*The wetted surface of this product contacted by consumable

water contains less than one quarter of one percent (0.25%) of

lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Approvals

Approved by independent testing, completing over 2,000,000

successful pump cycles with positive backflow protection and

trou ble-free performance.

All rubber compounds comply with FDA food additive reg u la-

tions.

Pump

100psi

Carbonator

H

2O and CO2

CO

Cooler

2 Gas

Page 2

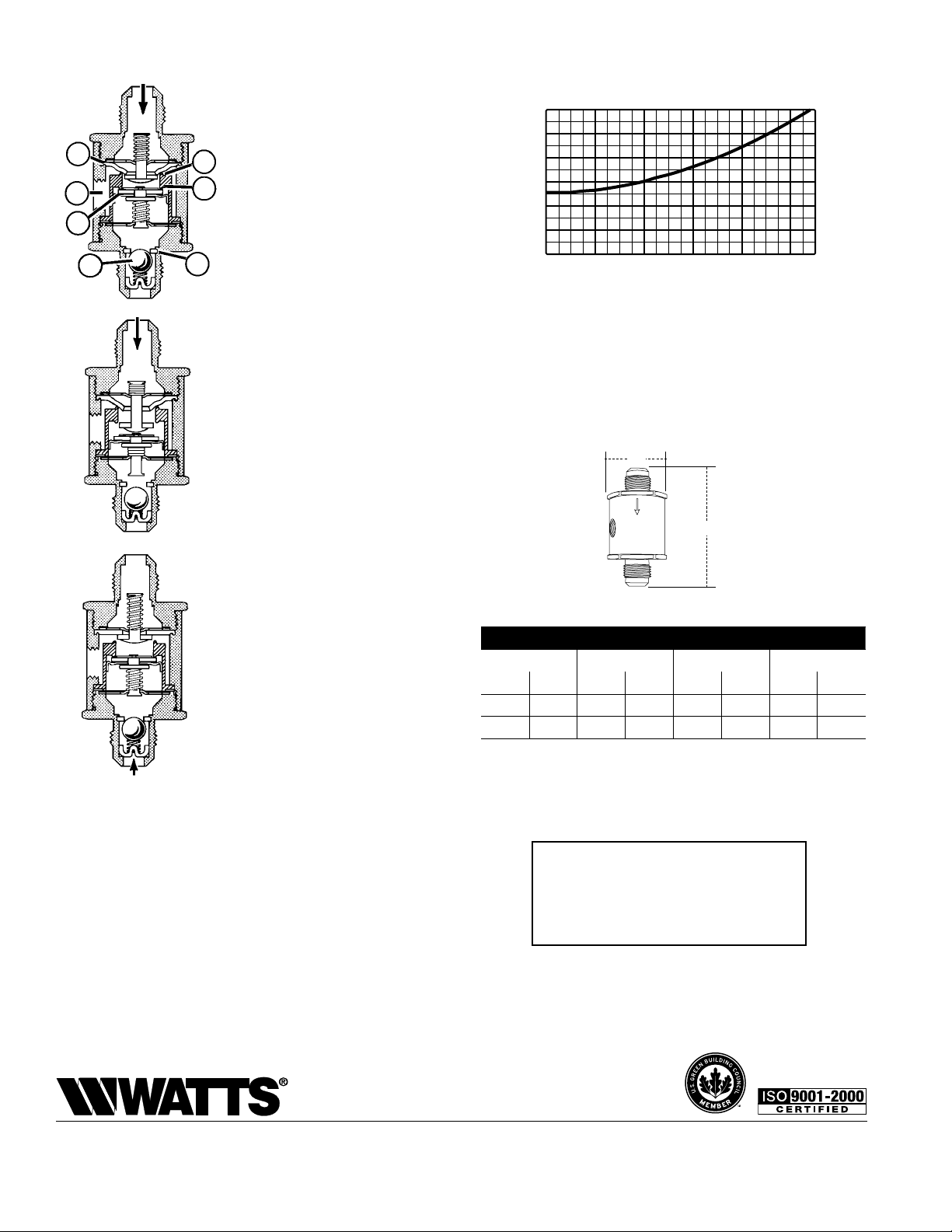

How it Operates

kPa psi

207 30

172 25

138 20

103 15

69 10

35 5

00

.5 11.5 2. 2.5 gpm

1.93.8 5.77.6 9.5 lpm

2

2

4

3

4

6

6

Static Pressure-No Flow

Primary disc (1) seats against

diaphragm (2) with diaphragm

(2) sealing off the atmospheric

1

port (3). Secondary disc (4) seals

against downstream seat (5). Ball

5

7

check (6) seals against ball check

seat (7). This is the normal posi-

tion taken by the device when

there is no demand on downstream equipment.

7

Valve Opened Flowing Under

Pressure

With flow through valve, primary

disc opens away from diaphragm

seal. Atmospheric port remains

closed by deflection of diaphragm

seal. Secondary disc opens

away from downstream seat.

Ball check opens away from ball

check seat permitting flow of

water through valve.

Capacity

Dimensions - Weights

B

Valve Closed by Back

Pressure in System

With a backpressure condition created, ball check seats

firmly against ball check seat.

Secondary disc seals tightly

against downstream seat.

Primary disc seals tightly against

diaphragm. Atmospheric port is

now open permitting air to enter

air break chamber. In the event

of fouling of downstream check

valve, leakage of CO

2 gas would

be vented to atmosphere through

the vent port thereby safeguarding the potable water system

from CO

2 gas contamination.

A

SIZE(DN) DIMENSIONS WEIGHT

A B

in. mm in. mm in. mm lbs. kgs.

1

⁄4 6 23⁄4 70 13⁄8 35 .38 .17

3

⁄8 10 23⁄4 70 13⁄8 35 .38 .17

This valve should only be used in areas

where spillage of water could not cause

damage. Install a vent discharge line to the

vent outlet of 9BD and vent to a safe place

of disposal with adequate ven ti la tion where

CO

2 discharge is not a hazard.

A Watts Water Technologies Company

ES-9BD 0940 © Watts 2009

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...