Page 1

Series 994HMB

Hydrant Meter Backflow Preventer

Sizes: 21⁄2" – 7NST x 3"

Model 994 HMB Hydrant Meter Backflow Preventer is for use

in measurement of potable water from a fire hydrant or other

non-permanent installation where flow is in one direction only

and the possibility of cross-connection exists. The Watts

994HMB fire hydrant preventer meter is designed to protect

the potable water system by preventing backflow through the

fire hydrant. This model can be used where approved by the

local authority having jurisdiction on health hazard cross-connections.

Features

• Heavy duty relief valve cover prevents vandalism and protects relief valve from damage when 994HMB is transported

to another fire hydrant location

• In-line flow restrictor protects the meter measuring element

and the backflow preventer components from damage due

to excessive flow

• Backflow preventer made from 300 Series stainless steel for

corrosion resistance

• Portable, lightweight design makes device easily transportable between job sites

• Accurately measures flow and protects the water supply from

possible contamination

• Built-in support leg is adjustable in the field

• Factory assembled and tested; no field assembly required;

eliminates leaks and improper assembly

Specifications

• Typical Operating Range (100%±1.5%): 5 to 660 gpm

(1.1 to 150 m

3

/h)

• Maximum Continuous Flow: 450 gpm (102 m

3

/h)

• Maximum Intermittent Flow: 660 gpm (150 m

3

/h)

• Typical Low Flow (Min. 95%): 4 gpm (0.9 m3/h)

• Pressure Loss at Maximum: 37psi @ 450 gpm (2.6 bar

@102 m

3

/h); standard couplings with orifice and screen

• Continuous Operation: 23psi @ 350 gpm

• Maximum Operating Pressure: 150psi (10.3 bar)

• Standard Hose Coupling: 2

1

⁄2" - 71⁄2 NST threads

National Standard thread fire hose coupling

Materials

All Internal Metal Parts: 300 Series Stainless Steel

Main Valve Body: 300 Series Stainless Steel

Check Assemblies: Noryl

®

Shutoff Valve: Brass

Relief Valve Guard: 300 Series Stainless Steel

Meter Materials

• Housing: Heat treated aluminum alloy

• Nose Cone and Straightening Vanes: Thermoplastic

• Rotor: Thermoplastic

• Rotor Radial Bearings: Lubricated thermoplastic

• Rotor Thrust Bearings: Sapphire jewels

• Rotor Bearing Pivots: Passivated 316 stainless steel

• Calibration Mechanism: Stainless steel and thermoplastic

• Flow Restriction Orifice: Heat treated aluminum alloy

• Magnet: Ceramic

• Register Cover: Bronze

• Trim: Stainless steel

• Inlet Screen: Stainless steel with elastomer

Maintenance

The Watts 994HMB fire hydrant backflow preventer meters are

designed and manufactured to provide long-term service with

minimal maintenance. When maintenance is required, it can be

performed easily either at the meter installation or at any other

convenient location. As an alternative to repair by the utility,

Watts can arrange various maintenance and meter component

exchange programs to fit the needs of the utility.

For Health Hazard Applications

ES-994HMB

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

IMPORTANT: INQUIRE WITH GOVERNING AUTHORITIES

FOR LOCAL INSTALLATION REQUIREMENTS

994HMB

Page 2

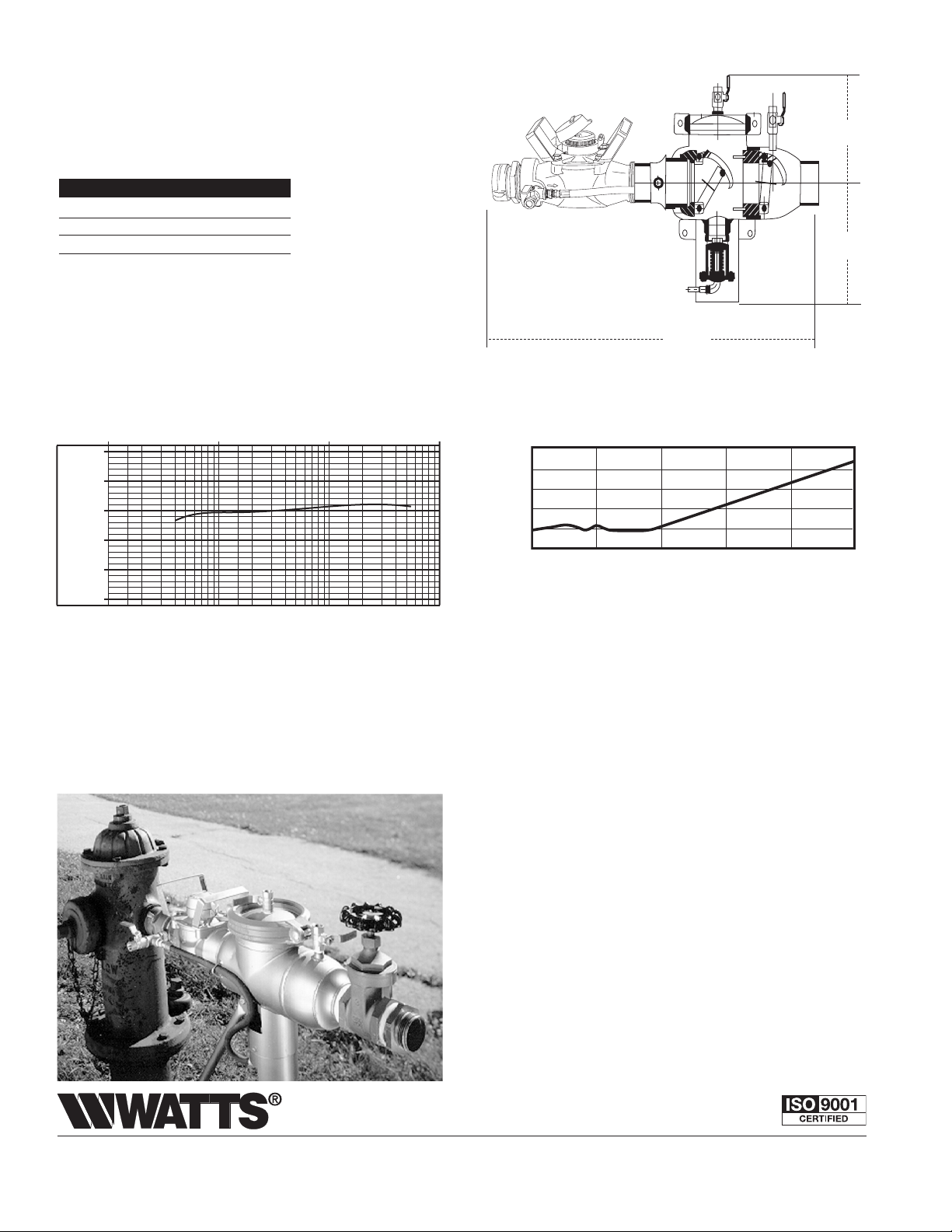

Dimensions – Weights

• Overall lay length: 371⁄2" (953mm)

• Weight: 66 lbs. (30 kgs)

• Height from top of open gate valve to bottom

of relief valve: 19" (483mm)

• Width: 10" (254mm)

Capacity

Approvals

Model 994HMB Hydrant Meter Backflow Preventer meets the

design requirements of most national standards. Due to the

portability of the unit, there are no national approvals available.

Contact the factory for specific approvals on the reduced pressure backflow preventer.

ES-994HMB 0708 © Watts Regulator Company, 2007

81⁄4"

93⁄16"

371⁄2"

MODEL WEIGHT

lbs. kgs.

994HMB-GPM 66 30

994HMB-CFM 66 30

Pressure Loss

kPa psi

345 50

276 40

207 30

138 20

69 10

00

0 100 200 300 400 500 gpm

0 380 760 1140 1520 1900 lpm

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

Backflow Prevention Products

Typical Installation – Hydrant Meter Backflow

0100100010

10

5

Over

Register

+

0

-

5

Accuracy Per Cent

10

Under

Register

15

246 200 400 600 800820406080

Loading...

Loading...