Page 1

Installation, Maintenance, & Repair

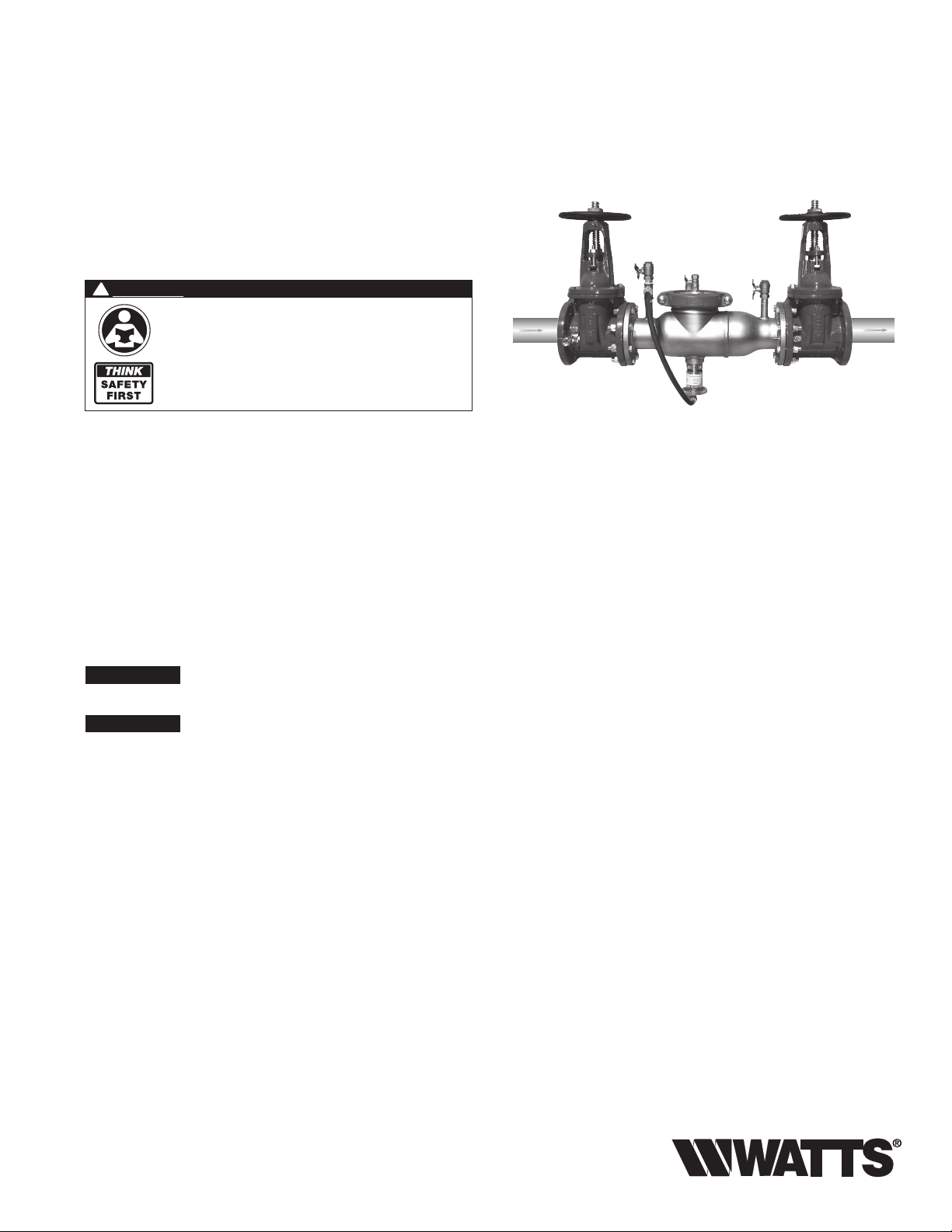

Series 994/994RPDA

Reduced Pressure Zone Assemblies

Reduced Pressure Detector Assemblies

Sizes: 21⁄2" – 10" (65 – 250mm)

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

RP/IS-994/994RPDA

Local building or plumbing codes may require modifications to the

information provided. You are required to consult the local building and

plumbing codes prior to installation. If this information is not consistent

with local building or plumbing codes, the local codes should be followed.

Need for Periodic Inspection/Maintenance: This product must be

tested periodically in compliance with local codes, but at least once per

year or more as service conditions warrant. Corrosive water conditions,

and/or unauthorized adjustments or repair could render the product

ineffective for the service intended. Regular checking and cleaning of the

product’s internal components helps assure maximum life and proper

product function.

NOTICE

Inquire with governing authorities for local installation requirements

NOTICE

For Australia and New Zealand: Pipeline strainers should be installed

between the upstream shutoff valve and the inlet of the backflow

preventer.

Testing

For field testing procedure, refer to Watts installation sheets

IS-TK-DP/DL, IS-TK-9A, IS-TK-99E and IS-TK-99D found on

www.watts.com.

For troubleshooting guide, refer to literature S-TSG.

For other repair kits and service parts, refer to our Backflow Prevention Products Repair Kits & Service Parts price list PL-RP-BPD

found on www.watts.com.

For technical assistance, contact your local Watts representative.

994

Page 2

Basic Installation Instructions

Series 994 Reduced Pressure Zone Assemblies

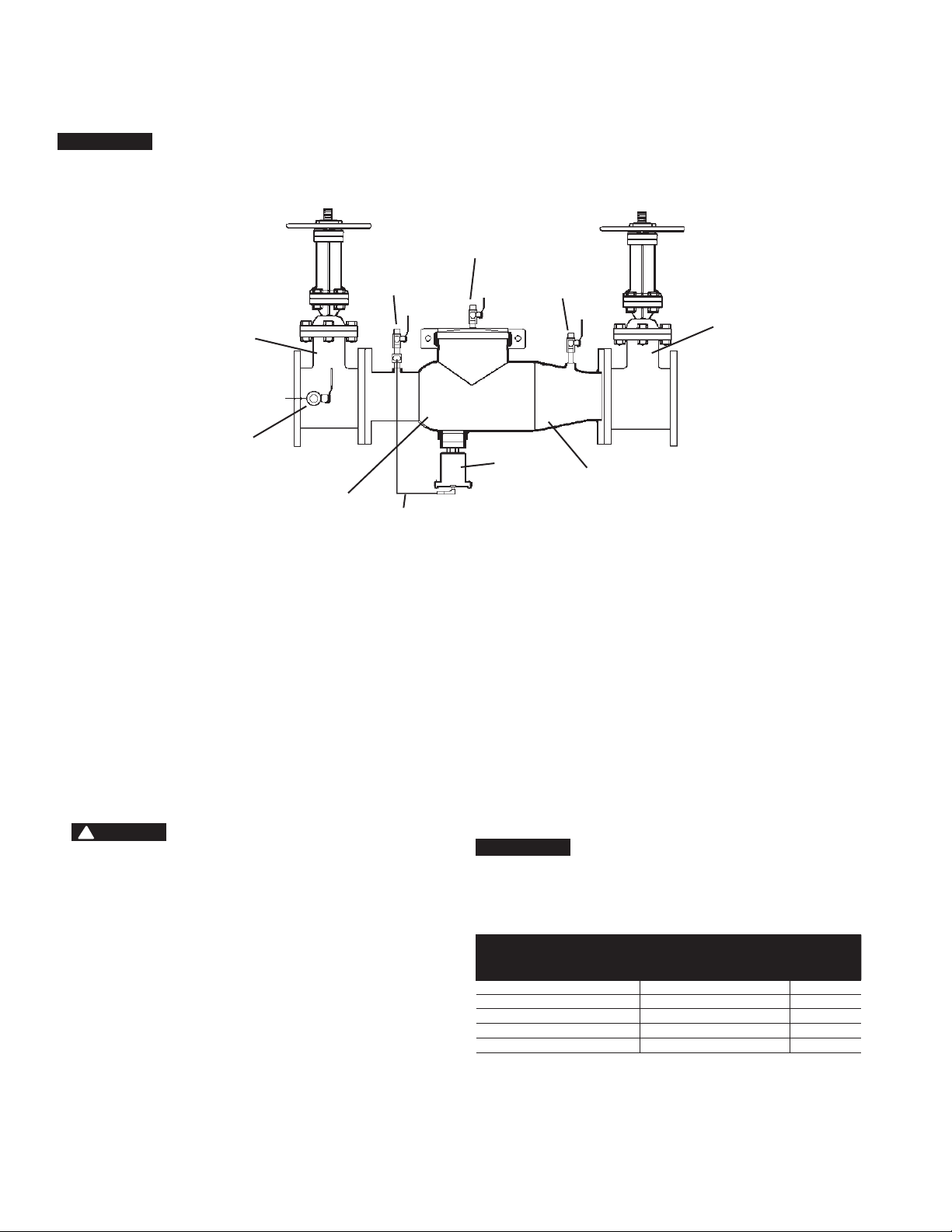

NOTICE

The flange gasket bolts for the gate valves should be re tight ened during

in stal la tion as the bolts may have loos ened due to storage and ship ping.

#3 Test Cock

#2 Test Cock

Inlet Shutoff

Valve

#1 Test Cock

1st Check

Sensing

Line

Location and Installation Considerations

1. Backflow preventers must be installed in high-visibility lo ca tions in

order to allow for immediate notice of telltale discharge or oth er

mal func tion. This location should also facilitate testing and ser vicing and protect against freezing and vandalism.

2. Installation procedures must comply with all state and lo cal

codes.

3. Installing a backflow preventer in a pit or vault is not rec om mended. An air gap be low the relief port must be maintained so as to

avoid flood ing and sub mer sion of the assembly, which may lead

to a cross-connection. Watts recommends installations in doors

or above ground in an in su lat ed enclosure. (Refer to literature

ES-WB)

4. A strainer should be installed ahead of the backflow pre ven ter to

protect the discs from unnecessary fouling.

!

CAUTION

Do not install a strainer ahead of the backflow pre ven ter on

seldom-used, emergency water lines (i.e. fire sprinkler lines). The

strainer mesh could potentially become clogged with debris present in the water and cause water blockage during an emer gen cy.

5. Normal discharge and nuisance spitting are ac com mo dat ed by

the use of a Watts air gap fitting and a fabricated indirect waste

line. Floor drains of the same size MUST be provided in case of

ex ces sive discharge.

6. When a Series 994 backflow preventer is installed for dead-end

ser vice applications, dis charge from the relief vent may occur

due to wa ter supply pressure fluc tu a tion during static no-flow

con di tions. A check valve may be re quired ahead of the backflow

preventer.

#4 Test Cock

Outlet

Shutoff

Relief

Valve

7. ASSEMBLY: If the backflow preventer is disassembled dur ing

in stal la tion, it MUST be reassembled in its proper order. The gate

valve with the test cock is to mounted on the inlet side of the

back flow pre ven ter. The test cock must be on the inlet side of the

wedge. Failure to reassemble correctly will result in possible wa ter

damage due to excessive discharge from the relief port/vent and

possible mal func tion of the backflow preventer.

8. Prior to installation, thoroughly flush pipe line to re move any foreign matter.

9. START UP at Initial Installations and After Servicing: The down-

stream shutoff should be closed. Slowly open upstream shutoff

and allow the backflow preventer to fill slowly. Bleed air at each

test cock. When backflow preventer is filled, slowly open the

down stream shut off and fill the water supply system. This is neces sary to avoid water hammer or shock damage.

#2 Check

NOTICE

Assembly body should not be painted.

Figure 1

VALVE SIZE

in. mm

21⁄2 65 55 gpm 2

3 80 112 gpm 3

4 100 170 gpm 4

6, 8, 10 150, 200, 250 350 gpm 5

TYPICAL FLOW RATES AS

SIZED BY FLOOR DRAIN

MANUFACTURERS

DRAIN SIZE

2

Page 3

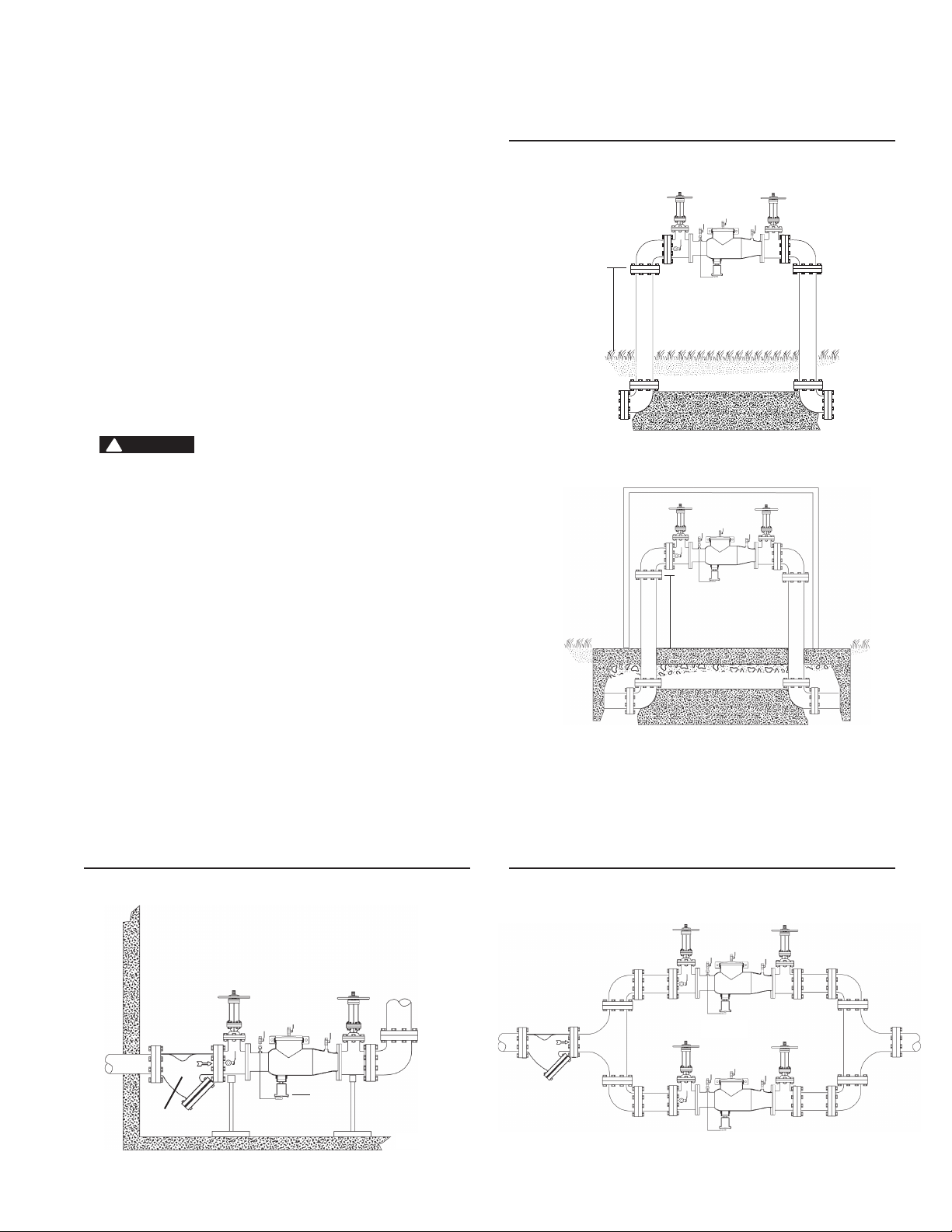

Series 994 Installation Instructions

Installation

A. Series 994 shall be installed in a horizontal po si tion. The shutoff

valve with the test cock is to be mounted on the inlet side of the

back flow pre ven ter. The test cock is on the in let side of the shutoff valve.

B. The 994 should always be installed in an ac ces si ble lo ca tion to

fa cil i tate test ing and ser vic ing. Check the state and local codes

to en sure that the back flow pre ven ter is installed in com pli ance,

such as the prop er height above the ground. The back flow preventer must be sup port ed and is not de signed to car ry full weight

of the stand pipe.

C. Water discharge from the relief valve should be vented in ac cor-

dance with code re quire ments. The relief valve should never be

sol id ly piped into a drain age ditch, sew er or sump. The dis charge

should be funneled through a Watts air gap fitting piped to a floor

drain.

D. Watts recommends a strainer be in stalled ahead of Watts Series

994 as sem blies to pro tect the discs from un nec es sary foul ing.

!

CAUTION

Do not install a strainer ahead of the backflow pre ven ter on

seldom-used, emergency water lines (i.e. fire sprinkler lines). The

strainer mesh could potentially become clogged with debris present in the water and cause water blockage during an emer gen cy.

Start Up

E. The downstream shutoff should be closed. Open up stream slow-

ly, fill the valve and bleed the air through Test cock 2, 3 and 4.

When valve is filled, open the down stream shutoff slowly and fill

the wa ter sup ply sys tem. This is nec es sary to avoid wa ter hammer or shock dam age.

F. The installation of a Watts air gap with the drain line ter mi nat ing

above a floor drain will handle any normal dis charge or nuisance

spit ting through the relief valve. How ev er, floor drain size may

need to be de signed to pre vent water damage caused by a cat astroph ic fail ure con di tion. Do not reduce the size of the drain line

from the air gap fit ting.

G. Two or more smaller size valves can be piped in parallel (when

ap proved) to serve a large supply pipe main. This type of in stal lation is employed where in crease capacity is needed be yond that

pro vid ed by a single valve and per mits test ing or ser vic ing of an

in di vid u al valve with out shut ting down the com plete line.

The number of assemblies used in par al lel should be de ter mined

by the en gi neer’s judge ment based on the op er at ing conditions

of a spe cif ic in stal la tion.

Above Ground

12” (300mm) min.

Refer to

Local Codes

994

12” (300mm) min.

Refer to

Local Codes

*Insulated Enclosure

Indoors

Strainer

Parallel

994

12” (300mm) min.

Refer to Local Codes

994

*For additional information on Watts insulated enclosures refer to literature ES-WB.

3

Page 4

Servicing First and Second Checks

Series 994/994RPDA 4" and 6" (100 – 150mm)

Removing Check Assemblies (Before servicing

be sure shutoff valves are closed)

1. Slowly open all ball valves to relieve air and water pressure.

Loosen bolts on groove coupler and remove groove couple

and cover plate from valve body.

2. Remove #1 Check Assembly by using your hands to un screw

(turn counterclockwise) Check and remove through top access

port. Do not use Check Arm as a handle to unscrew. If Check

can not be loosened by hand, insert a long screwdriver between

valve body and Check (see figure 2). Gently apply pressure

against the Check until loos ened. Fin ish unscrewing by hand. Unscrew #2 Check (turn counter-clock wise) by placing along screwdriv er across lugs and applying pres sure to loosen #2 Check.

Fin ish un screw ing by hand.

3. To clean #1 Check 6" (150mm) only, locate the Check Arm

opening stud on the outlet flange of the valve assembly. Slide the

Check Arm over the stud with the check threads facing downward (figure 5A). Tighten

bar. Slowly pull the assembly outward to open check allowing exposure of the seat clapper area for clean ing. To clean #2 Check,

lift Cam Arm and hold in open po si tion. Raise clapper so that the

end of the Check Arm rests between roller and clapper (fig ure

5B). Thoroughly clean the seat area and clapper sealing sur fac es

of both Checks. In spect seats, clap per sealing surfaces, Check

Arms, and O-rings for damage, nicks, and debris. If not damaged, gently close the clap per. If damaged, install a new Check

assembly and/or O-ring.

4. Before reinstallation of Checks, thoroughly clean O-ring groove

and lubricate O-ring with FDA approved lubricant. Insert and

thread #2 Check first and then #1 Check. #2 Check should be

tightened by in sert ing a long screwdriver between lugs to tighten

firm ly (see fig ure 2). Do not over tighten. Tighten #1 Check firmly

by hand only. Replace cover plate, clean groove coupler gas ket

and groove. Replace groove coupler. Repres-surize and bleed air

from all test cocks.

1

/4" (8mm) nut on stud to secure cam

Figure 3

1

#1 Check 2

O-ring Seal &

Groove

Seat

Note: See page 6 for additional 1st check servicing

Figure 4

O-ring Seal & Groove

Lug

Seat

⁄2" – 6" (65 – 150mm)

Roller

Clapper

#2 Check

Spring

O-ring Seal & Groove

Spring

Cam Arm

Cam Arm

Roller

6” Only

Clapper

Figure 1

Figure 2

4

#1 Check

Figure 5A

7

A

B

Screwdriver

Figure 5B

#2 Check

C

Cam Bar Open Pin

Valve Outlet Flange Threaded

Stud on Flange

6" (150mm)

2nd Check RP

Cleaning Position

Page 5

Servicing First and

Second Checks

Series 994/994RPDA

8" and 10" (200 – 250mm)

DANGER

!

Use extreme caution when servicing the first check!

Servicing the

First Check

Removing Check Assemblies (Before servicing

be certain shutoff valves are closed)

1. Slowly open all ball valves to relieve air and water pressure.

Loosen bolts on groove coupler and remove groove couple and

cover plate from valve body.

2. #1 CHECK

Using a

from the #1 check studs (see fig. 1). Using two hands, place

them at 12 o’clock and 6 o’clock, wiggle the check assembly free.

Remove through access port with back of clapper first with spring

end down. Pull check assembly out of main body. Inspect seats

and clap per seal ing surfaces. (See page 6.)

#2 CHECK

After loosening bolts with a

Using the centerline access bar, spin the check assembly from the

9 o’clock position to the 12 o’clock position, then (without letting

go of the ac cess bar) push the cam assembly slightly down stream

so that the clapper is now parallel to the valve body. Now bring

the check as sem bly through the check retaining wall. Leave the

check assembly par al lel to the valve body. Pull the check assembly through the access port.

3. Using a

on the check arm torsion spring and move away from and move

away from and around the torsion spring retaining bracket so as

to relieve the tor sion spring tension. This will allow the check arm

to move free ly, en abling you to inspect the clapper face and check

seat. Thor ough ly clean the seat area and clapper sealing surfaces,

check arms, and O-rings for damage, nicks, and debris. If damaged, in stall a new check as sem bly and or O-ring.

4. Before reinstallation of check assembly, thoroughly clean O-ring

groove and lubricate O-ring with F.D.A. approved lubricant.

Figure 1

9

⁄16" socket wrench or nut driver, remove the four nuts

9

⁄16" socket, remove bolts completely.

3

⁄8" nut driver or a piece of small diameter pipe, place

Figure 2

#1 Cam-Check RP

To inspect the seat and clean the seat and

clapper washer:

1. After removing the first check from the backflow valve body, place

on a flat surface with the coil spring facing up.

2. In order to gain access to the seat and clapper rubber ring, you

must compress the spring (#3) that surrounds the clapper shaft

(#1). To do so, you must place the

holes of the spring retaining plate #2.

3. After placing the

plate, Screw the threaded rod into the holes (#4) at the base of

spider (#5 next to shaft). Be sure to use two nuts on the threaded

rod to tighten them into the holes. The depth of the threaded

holes should be approximately

to use two piec es of threaded rod (see drawing below).

4. Compressing the spring. To do so you need to loosen the top

nut and back it off without unthreading the threaded rod from the

spider. Place a box end wrench or crescent wrench on the

nut clos est to the spring retaining plate and tighten. Tighten both

thread ed and nut evenly; put a few turns on one threaded rod nut

and a few turns on the other.

5. During compression, the clapper will slowly move up, away from

the seat. To examine the seat, continue spring compression un til

the clapper has moved approximately 1" from the seat. This will

allow de bris to be removed and or the seat to be examined.

6. To unload the spring compression, loosen the all-thread and then

double nut the all-thread and unscrew the rod from the spider and

shaft base.

3

⁄8” all-thread rod through the spring retaining

3

⁄8" threaded rod through two

1

⁄2". This operation will require you

3

⁄8”

3

⁄8”

To disassemble the first check, you will need

the following:

•Twopiecesof3⁄8" threaded rod (approximately 14" long)

•Adjustablecrescentwrench

•Pipewrenchorchannellockpliers

Check Studs

Figure 3

#2 Cam-Check DC & RP

Check Studs

Figure 4

1. Shaft

2. Spring retaining plate

3. Spring

3

⁄8” threaded hole (maintenance)

4.

5. Spider

6. Spider retaining bolt

7. Seat ring

8. Clapper to shaft bolt

9. Seat ring retainer

9

3

⁄8 - 16

var.

#1 Check

Valve 8" & 10"

(200 & 250mm)

Threaded Rod

1

2

3

4

5

6

7

8

5

Page 6

Servicing the Relief Valve

1. The relief valve may be serviced while on or off the backflow

preventer valve.

NOTICE

2.

DO NOT USE A PIPE WRENCH TO REMOVE THE RE LIEF VALVE

ASSEMBLY FROM THE BACKFLOW PREVENTER.

3. Shut down water system.

Relief Valve Disassembly

1. Disconnect the relief valve hose from the elbow in the bottom

flange cover at the swivel hose connection. Do not remove the

el bow.

2. If the valve is to be removed from the backflow preventer for

service, place a screw driver blade or flat bar across the edges

of two of the hex head screws in the bottom flange cover and

turn counter-clock wise to loosen the relief valve assembly. (See

Figure 2 page 4)

3. Remove the four bottom bolts from the bottom of the relief valve

assembly with a

bottom flange cover.

4. Remove the piston assembly & sleeve from the relief valve body

by placing your index fingers through the slots in the side of the

body and pressing down on the top of the disc retainer in the top

of the piston as sem bly. (See Figure 7.)

5. Pull the piston assembly free of the body by grasping the sleeve

and pulling down.

6. Grip the sleeve and the piston assembly by the head of the hex

head bolt. Pull up on the sleeve to extend the diaphragm. Slide

the sleeve (item #26) completely off of the diaphragm and inspect the diaphragm for tears, holes or excessive wrinkles. If the

diaphragm is dam aged, or der a new piston/diaphragm assembly.

5

⁄16” socket or open-end wrench. Remove the

8. Position the bottom flange cover on the bottom of the relief valve

body and secure by hand tightening the four bottom bolts.

9. Now tighten the four bottom bolts to approximately 15 ft.-lbs.

10. Reattach the relief valve hose to the elbow in the bottom flange

Figure 6

Figure 7

5

/16" socket or open-end wrench.

with a

cover.

21

22

23

27

24

25

26

28

29

30

Relief Valve Reassembly

1. Thoroughly clean all inside surfaces of the relief valve body.

2. Inspect the relief valve body seat surface located at the top edge

of the three discharge slots near the top of the body by rubbing

the end of the index finger around the entire seat surface; access

the seat sur face through the slots or the bottom of the body. The

seat must be free of nicks. If nicks are discovered, remove the

body & install a new relief valve assembly.

3. Position the diaphragm on the piston assembly so that it is fac ing

up as shown in Figure 8.

4. Now fold the top (ribbed) edge of the diaphragm inward, grasp

the sleeve with the ribbed edge up and slide the sleeve down

over the piston assembly as shown in Figure 8.

5. While still holding the sleeve, slide it up over the diaphragm

and, using your thumb & index finger, position the bead of the

diaphragm so that it wraps over the outside of the rib on the top

of the sleeve so that the sleeve is held by the diaphragm. Now

place the pis ton as sem bly on a flat, firm surface with diaphragm

facing up as shown in Figure 9.

6. Cup your hand slightly to form an air trap and force the sleeve

down over the piston assembly with a rapid slap (hard) on the

open end of the diaphragm with your cupped hand. The trapped

air in the di a phragm will force the diaphragm between the inside

of the sleeve and the out side of the piston. Ensure that the diaphragm is fully seat ed. If di a phragm is wrinkled, repeat previous

step.

7. Slide the piston assembly and sleeve into the relief valve body

with the hex head bolt entering the flanged end of the body first.

Slide the piston assembly in until the diaphragm lip is smoothly

seated in the ma chined groove in the flanged end of the body.

By running your in dex finger around the outside of the diaphragm

bead, you will ensure it is seated smoothly

6

Figure 8

Figure 9

PARTS TABLE #2

Item # Part Description Qty.

21 Relief Valve Body 1

22 Rubber Shutoff Disc 1

23 Piston Diaphragm Assembly 1

24 Hex Head Bolt 4

25 Disc Retainer 1

26 Sleeve 1

27 Bottom Bolt 1

28 Bottom Flange (w st. elbow) 1

29 Bottom st. elbow 1

30 O-ring disc 1

Page 7

Testing - Reduced Pressure Zone Assemblies

The following Test Procedure is one of several that is recognized

throughout the United States for testing Backflow Preventers.

The following procedure is not a specific recommendation. The

Watts series of test kits are capable of performing any of the recognized Backflow test procedures.

A. Open TC #4 and flush test cocks No’s. 1, 2 and 3 on BF assem-

bly, then close TC #4.

B. Turn tester on (before connecting hoses). Tester must read all

zeros. Close VA and VB.

Test No. 1 - Relief Valve

1. Install high-side hose between TC #2 and tester connection A.

2. Install low-side hose between TC #3 and tester con nec tion B.

3. Open TC #3 then VB. Now open TC #2 slowly, then VA. Close

VA then VB.

4. Close #2 shutoff valve.

5. Observe the apparent first check valve differential pressure (A - B).

6. Install bypass hose between VA and VB. Open VB and bleed air

by loosening hose connection at VA. Tighten hose connection

and close VB.

Push - Print Head (wait) then Push - Start Test

7. Open VA, then slowly open VB (no more than 1⁄4 turn). When

relief valve drips, push the “hold button” for 2 seconds. Record

reading (must be 2 PSID or more).

Push - Stop Test

8. Close VA and VB.

RPZ

Test 1

Watts TK-DL

A

B

VA

A

B

VB

Series 994

Test No. 2 - Test No. 2 Check Valve

9. Install bypass hose between VA and TC #4. Open VA, then

bleed air by loosening hose connection at TC #4. Tighten hose

connection. Close VA.

Push - Start Test

10. Open VB to reestablish pressure within the “zone”. Close VB.

11. Open TC #4, then open VA. If relief valve does not drip, record

second check valve as “close tight”.

Test No. 3 - Test No. 1 Check Valve

12. Open VB to reestablish first check valve dif fer en tial pressure.

Close VB. Record pressure differential.

Stop Test (Push Stop Test twice)

13. Close test cocks and remove tester, return as sem bly to nor mal

operating condition.

!

WARNING

It is important that this device be tested periodically in com pli ance

with local codes, but at least once per year or more as ser vice condi tions warrant. If installed on a fire sprinkler system all me chan i cal

checks, such as alarm checks, single checks and backflow preventers

should be inspected internally every one to five years in accordance

with NFPA 13 A and NFPA 25

RPZ

Test 2

RPZ

Test 3

VA

VA

A

VB

Series 994

B

VB

Series 994

For additional testing information refer to literature IS-TK-DL, IS-TK-9A and IS-TK-99E

7

Page 8

⁄4

3

11

7.00

2” Pipe

Thread

Air Gap Drain

For repair kits and parts, refer to our

Backflow Prevention Products Repair

Kits & Service Parts price list PL-RP-BPD

found on www.watts.com.

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

Troubleshooting Guide

Problem Cause Solution

A. Assembly discharges

from differential relief

valve during no flow

condition.

B. Assembly discharges

from differential relief

valve during a flow

condition.

C. Differential pressure

relief valve does not

open during test

D. Pressure relief valve

does not close

Fouled first check Disassemble and clean No. 1

check valve

Fluctuating inlet pressure Control supply line water

pressure.

Install a soft seated, spring

loaded, check valve upstream of the assembly.

Outlet pressure higher than

inlet pressure & leak in No. 2

check valve

Leak through diaphragm or

Disassemble, clean #2 check

valve & identify cause of

backpressure

Service relief valve

around flange bolt holes of

relief valve

Pressure relief valve does not

See problem D

close

No. 1 check valve wedged

open

O-ring displaced from groove

Disassemble and clean No. 1

check valve

Disassemble and replace

in 1st check

Pressure relief valve does not

See problem D

close

Fluctuating line pressure

Differential pressure across

Repair shutoff valves

No. 1 check valve stays above

2.0psi due to leaking outlet

gate valve

Weak or broken relief valve

spring

Shutoff seat tube bound in

Disassemble and replace

relief valve spring

Disassemble and repair

body

Plugged hydraulic hose Disassemble and repair

Debris on sealing surface Remove relief valve and clean

Plugged hydraulic hose Disassemble and clean

Damaged seat or rubber

shutoff disc

Remove relief valve assembly

and replace

Ruptured diaphragm Disassemble and replace

diaphragm

Wrinkled or improperly installed diaphragm

Disassemble and properly

position diaphragm

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

RP-IS-994/994RPDA 1319 EDP# 1915230 © 2013 Watts

USA:Tel:(978)688-1811•Fax:(978)794-1848•www.watts.com

Canada: Tel:(905)332-4090•Fax:(905)332-7068•www.watts.ca

Loading...

Loading...