Page 1

For Commercial and Industrial Applications

ES-97FD-CIB

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

Series 97FD-CIB

Cast Iron Duplex Strainers

Flanged Connections, Bolted Covers,

and Butterfly Isolation Valve

Sizes: 5" – 14" (125 – 350mm)

For liquid service only.

Models

97FD-CIB: Cast iron body with bolted cover.

Standard Screens

1

⁄8" 304 stainless steel perforation

Pressure — Temperature

97FD-CIB:

Maximum Pressure 200psi (14 bar) WOG (non-shock)

Maximum Temperature: 100°F (38°C)

Material

Body: Class B Cast Iron ASTM A-126

Flange: Class 125 ANSI B16.1

Dimensions — Weights

Contractor

Approval

Contractor’s P.O. No.

Representative

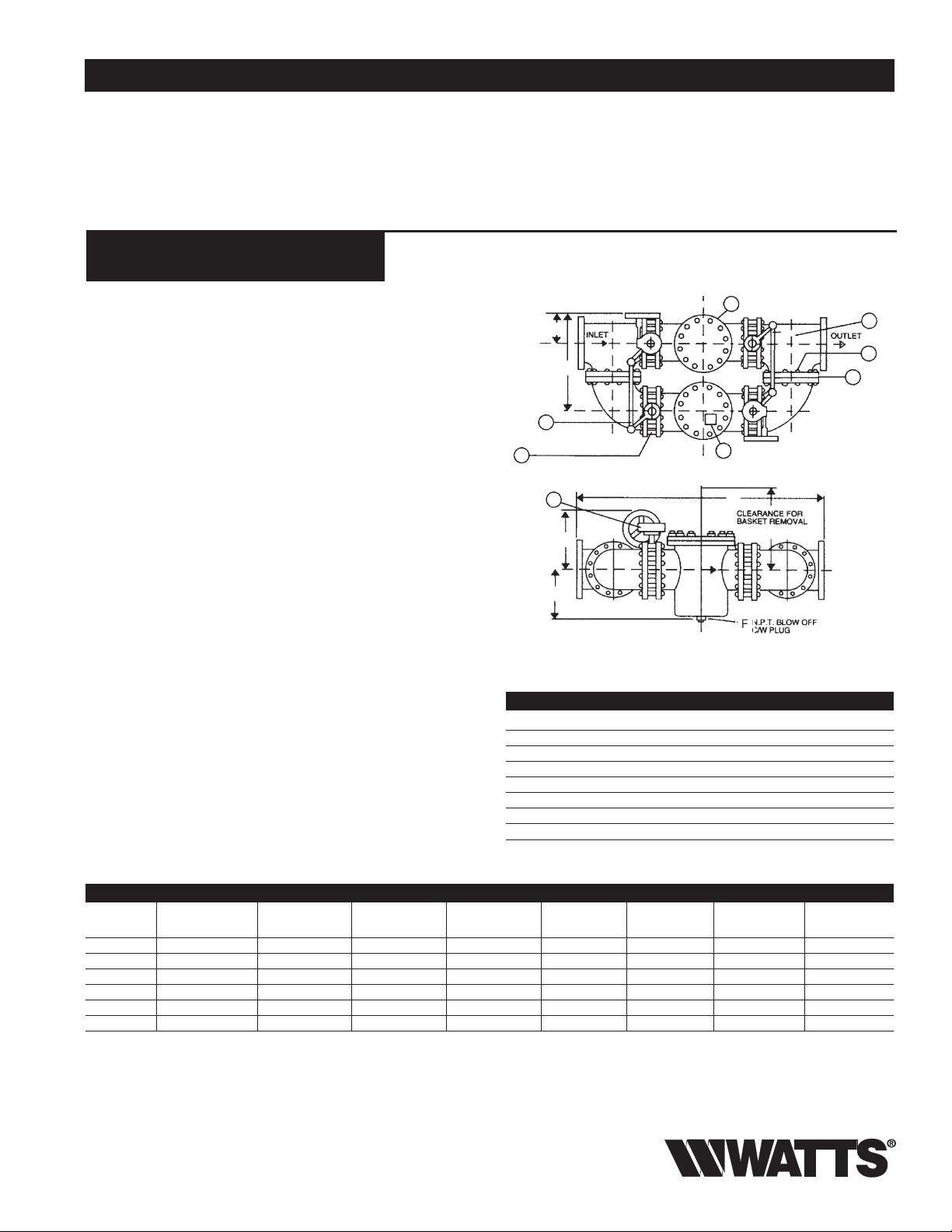

4

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

6

D

E

7

5

8

B

C

A

G

F

Materials — Specifications

Item descrIptIon materIal quantIty

1 Inlet/Outlet Manifold Cast Iron ASTM A-126 2

2 Studs and Nuts B7 & 2H Cast Steel as required

3 Gaskets Red Rubber as required

4 Butterfly Valves Cast Iron w/EPDM Liner 4

5 Nameplate Aluminum 1

6 Basket Strainer Cast Iron 2

*7 Slave Linkage Assembly Cast Steel 2

*8 Gear Actuator Steel 2

* Optional Features

1

2

3

sIZe (dn) dImensIons WeIGHt

A B C D E F G

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

5 125 48 1219 121⁄2 318 8 203 8 203 15 381 1 25 17 432 500 227

6 150 52 1321 131⁄8 333 85⁄8 219 73⁄4 197 16 406 11⁄4 32 19 483 800 363

8 200 61 1549 141⁄2 368 113⁄4 298 73⁄4 197 18 457

10 250 703⁄4 1797 16 406 133⁄4 349 73⁄4 197 22 559

12 300 83 2108 191⁄2 495 163⁄8 416 101⁄2 267 24 610 1 25 37 940 4700 2132

14 350 961⁄2 2451 26 660 221⁄4 565 101⁄2 267 30 762 11⁄2 40 41 1041 6300 2857

*The wetted surface of this product contacted by consumable

water contains less than one quarter of one percent (0.25%) of

lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

3

⁄4 20 25 635 1350 612

3

⁄4 20 29 737 2050 930

Page 2

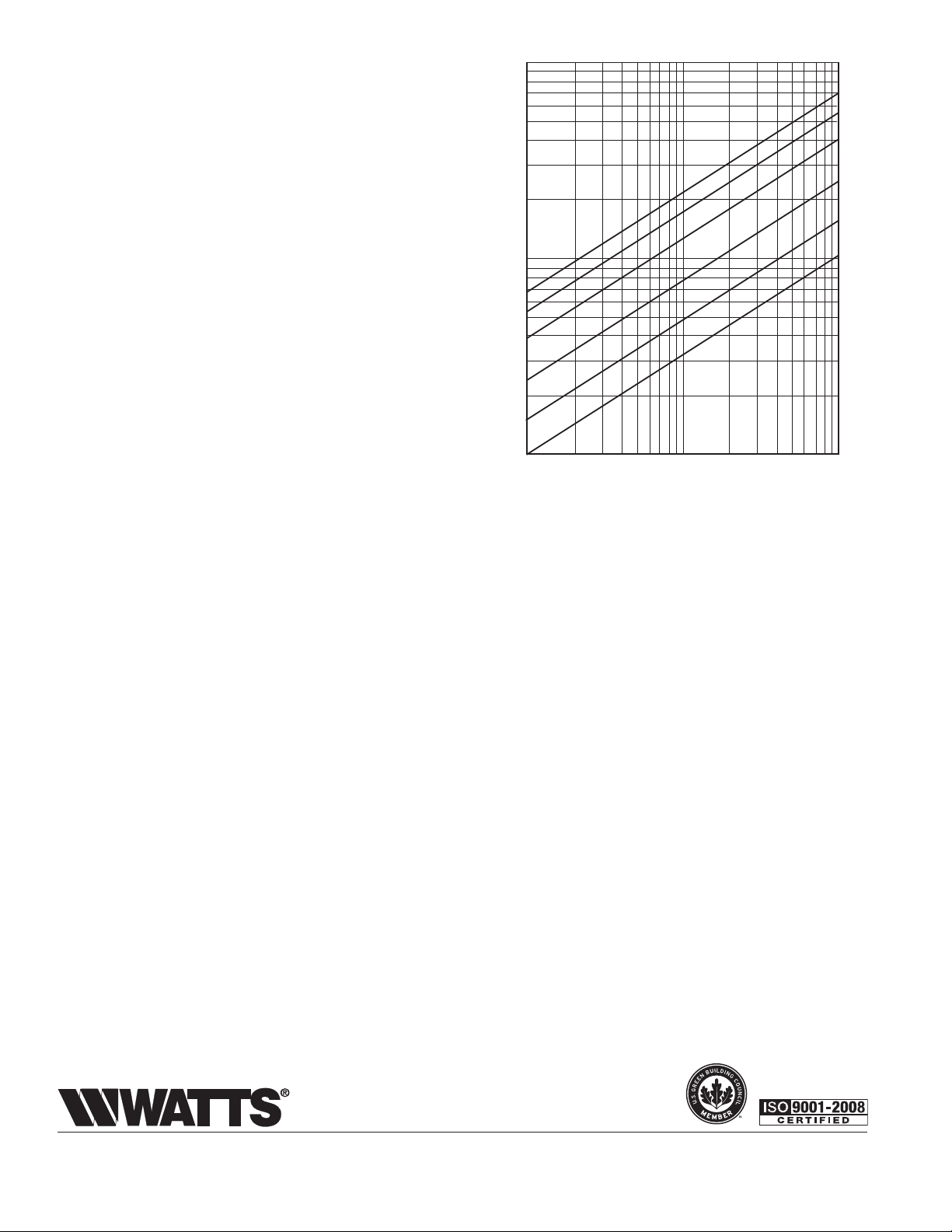

Performance Data

Table shows flows (gpm – water) at various pressure drops (psi)

using standard screens.

Flow-coefficient

The flow coefficient (Cv) is the number of gallons per minute of

water flowing through a given size restriction at a pressure drop of

one psi. To obtain the Cv factor for a given size strainer, read

capacity at intersection with the one (1) psi pressure drop.

10000

14"

12"

10"

8"

6"

1000

Flow (water) – gpm

100

0.1 1 10

Pressure Drop – psi

Conversions: For gpm to lpm, multiply by 3.8.

For psi to bar, multiply by .069.

5"

A Watt s Water Technolo gies Company

USA: No. Andover, MA • Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Burlington, ON • Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

ES-97FD-CIB 1123 © 2011 Watts

Loading...

Loading...