Page 1

For Fire Protection Applications

ES-97FB

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

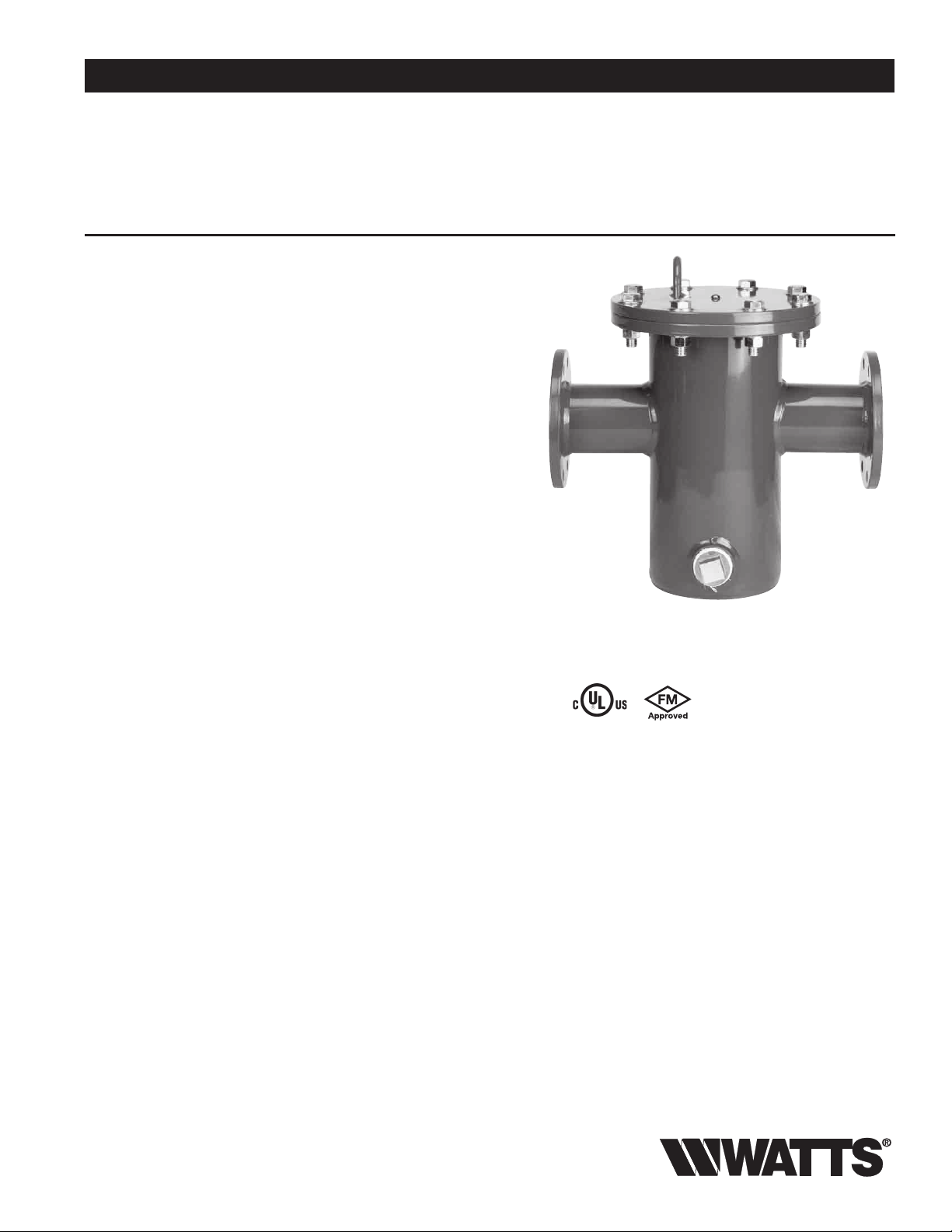

Series 97FB-FSFE

UL/FM Fire Service Strainers

Sizes: 3" – 10" (80 – 250mm)

Series 97FB-FSFE (flanged) UL/FM Fire Service Strainers are

used in water spray fire protection systems to protect against

clogging that can be caused by particles fouling the discharge

opening of the sprinkler heads. Strainers for fire systems are

designed to trap foreign material

This type of strainer is usually installed upstream of most

of the devices in the system including the meters, backflow

preventers (or detector check valves) and flow alarms, in order

to protect these devices from damage caused by dirt

and debris.

Features

• Fabricated steel, epoxy lined and coated

body and cover

• With cleanout port

• Large solids trap to minimize screen blockage

• 304 Stainless Steel strainer element

Pressure – Temperature

Suitable for supply pressure up to 175psi (12.1 bar)

Water temperature up to 140˚F (60˚C)

Materials

Body and cover: corrosion resistant fusion-bonded epoxy

lined and coated steel.

Screen: 304 Stainless Steel, .25 diameter perforation

Clean-Out Plug: Brass or Bronze

Flanges: AWWA Class “D”

1

⁄4" diameter or larger.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

97FB-FSFE

Approvals

Listed 321 Class 5551

Specifications

The strainer shall be designed to permit removal of the strainer

screen for replacement and repair without removing the body

from the line. A flush outlet shall be provided with each strainer.

The strainer screen shall withstand 125psi (8.6 bar) when

plugged. Friction loss shall not exceed 10psi (69 kPa) when

tested with foreign materials (gravel) equal to 2

of filled pipe trapped in the strainer. Open screen area shall be

at least 6 times greater than the nominal pipe size open area.

Friction loss shall not exceed 3psi (21 kPa) at rated flow when

tested with clean strainer screen and clean water. The strainer

shall be a Watts Series 97FB-FSFE.

1

⁄2' (762mm)

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For

precise measurements, please contact Watts Technical Service. Watts reserves the right to change or modify product

design, construction, specifications, or materials without prior notice and without incurring any obligation to make such

changes and modifications on Watts products previously or subsequently sold.

Page 2

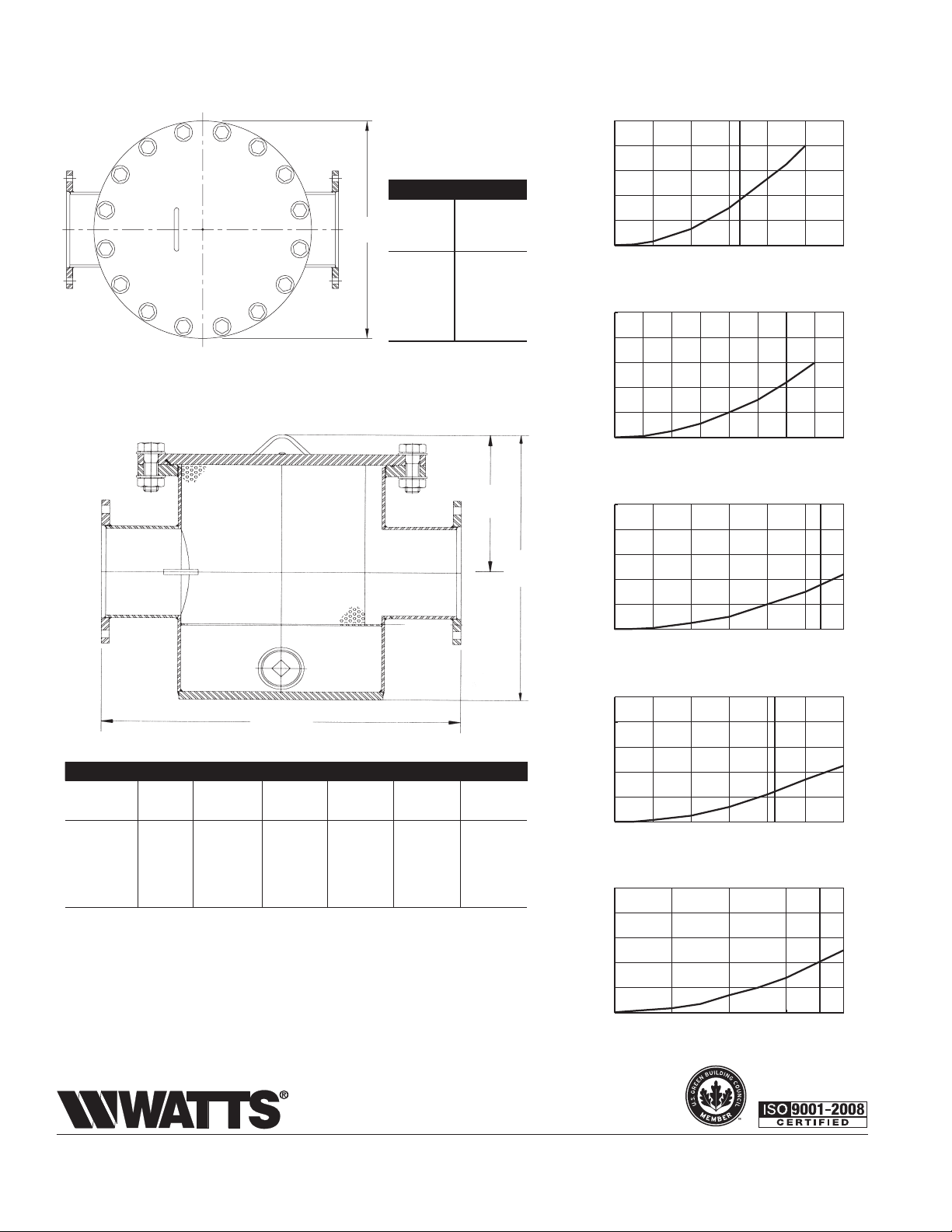

Dimensions – Weights

Top View Dimensions

Lid

Size Diameter (D)

D

in. mm in. mm

3 80 13

4 100 13

6 150 19 483

8 200 25 635

10 250 27

A

NOM RATED FLOW SIZE (DN) DIMENSIONS WEIGHT STD STD PERF DIA

*

GPM LPM in. mm in. mm in. mm in. mm lb. kg in. mm

325 1235 3 80 14

600 2280 4 100 21 533 205⁄8 524 105⁄8 270 120 541⁄4 6.4

1350 5130 6 150 26

2100 7980 8 200 31

3600 13680 10 250 30 762 29

A B C

1

⁄8 359 205⁄8 524 10 254 70 321⁄4 6.4

7

⁄8 683 223⁄8 568 111⁄4 286 232 1051⁄4 6.4

1

⁄4 794 251⁄16 637 13 330 560 2541⁄4 6.4

5

⁄16 744 141⁄2 368 570 2561⁄4 6.4

1

/2 343

1

/2 343

1

/2 699

C

Flow vs. Pressure Drop

psi

kPa

35

5

28

4

21

3

14

2

Pressure DropPressure DropPressure DropPressure DropPressure Drop

7

1

0

0

0 100 200 300 400 500 600 gpm

0 380 760 1140 1520 1900 2280 lpm

psi

kPa

35

5

28

4

21

3

14

2

7

1

0

0

0 100 200 300 400 500 600 700 800 gpm

0 380 760 1140 1520 1900 2280 2660 3040 lpm

psi

kPa

35

5

28

4

21

B

3

14

2

7

1

0

0

0 250 500 750 1000 1250 1500 gpm

0 950 1900 2850 3800 4750 5700 lpm

psi

kPa

35

5

28

4

21

3

14

2

7

1

0

0

0 500 1000 1500 2000 2500 3000 gpm

0 1900 3800 5700 7600 9500 11400 lpm

psi

kPa

35

5

28

4

21

3

14

2

7

1

0

0

0 1000 2000 3000 4000 gpm

0 3800 7600 11400 15200 lpm

3" (80mm)

*

Flow Rate

4" (100mm)

Flow Rate

6" (150mm)

Flow Rate

8" (200mm)

Flow Rate

10" (250mm)

Flow Rate

*

*

*

*

A Watts Water Technologies Company

USA: No. Andover, MA • Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Burlington, ON • Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

ES-97FB 1123 © 2011 Watts

Loading...

Loading...