Page 1

For Commercial and Industrial Applications

ES-77SI

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

Series 77SI

Wye-Pattern Cast Iron

Threaded Strainers

Sizes: 1/4" – 3" (8-80mm)

The Series 77SI Threaded, Wye-Pattern, Cast Iron Strainers

are manufactured overseas. These strainers are designed to

protect system components from dirt, rust, and other damaging debris in the piping system. Series 77SI strainers are

used in steam and liquid applications. They are furnished with

a machined seat that allows the screen to be self-aligning to

assure a perfect fit. All sizes come with a PTFE gasket, threaded screen retainer cap, tapped blowdown connection, and an

easily removable stainless steel screen.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

No. 77SI

––––––––––––––––––––––––––––––––––

Features

• Cast iron body

• Wye-pattern

• Tapped retainer cap

• Threaded connections

Pressure – Temperature

Maximum Working Pressure:

400psi (27.6 bar) at 150ºF (66º C) WOG

250psi (17.2 bar) at 406ºF (208ºC) WSP

Specifications

A wye-pattern cast iron strainer to be installed as indicated on

the plans. The strainer must have a tapped retainer cap and

threaded end connections. Strainer shall be rated to 400psi

(27.6 bar) at 150ºF (66ºC) WOG; 250psi (17.2 bar) at 406ºF

(208ºC) WSP. Strainer shall be a Watts Series 77SI.

Materials

Body: Cast iron

Retainer Cap: Cast iron

Standard Screen:

2

304 stainless steel perforated screen

Gasket: PTFE

1

/4" – 2" (8-50mm): 304

stainless steel #20 mesh,

1

/2"- 3" (65-80mm): 3/64" (1.2mm)

*The wetted surface of this product contacted by consumable

water contains less than one quarter of one percent (0.25%) of

lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

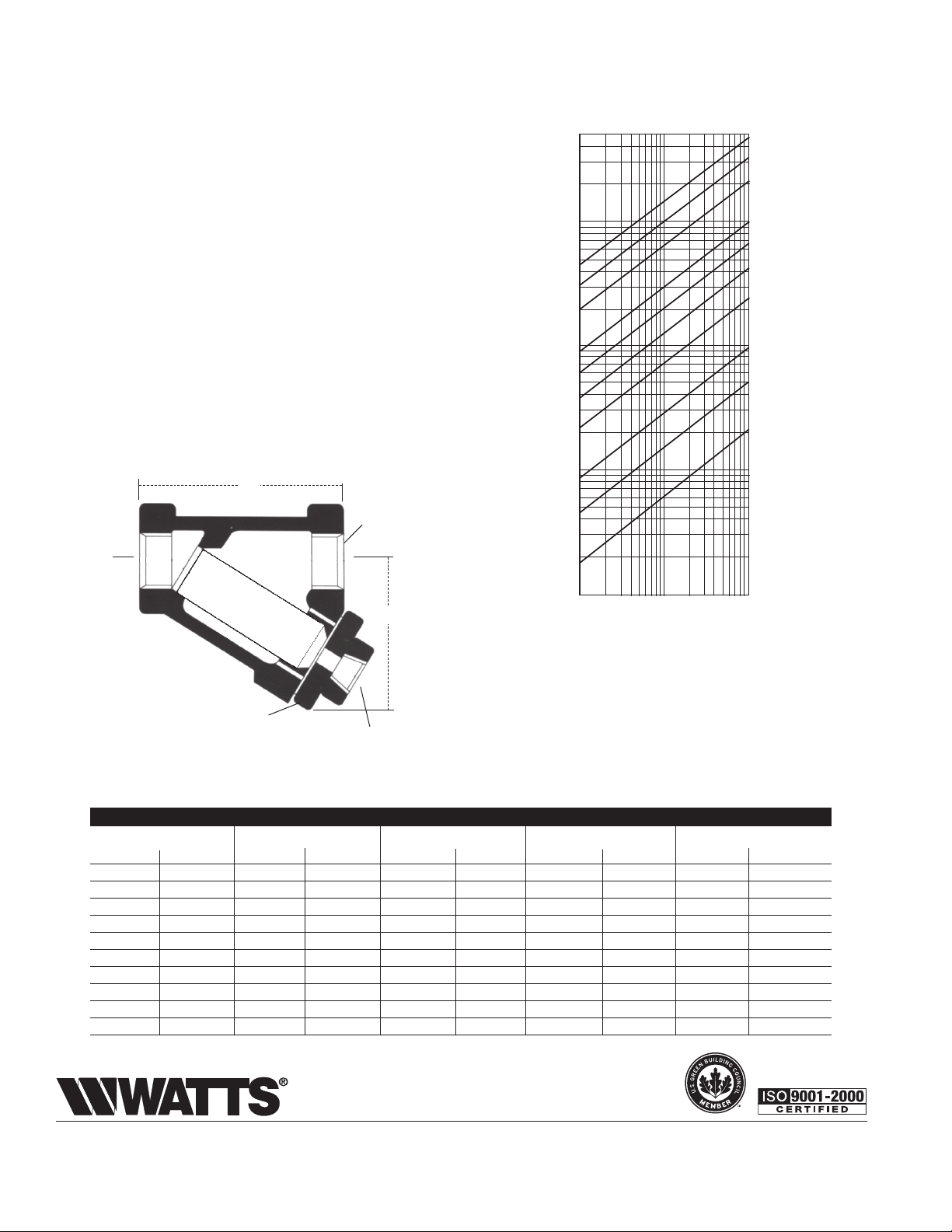

Performance Data

Table shows flow rates (gpm) at various pressure drops (psi)

for 77SI strainers using standard screens.

500

in. mm

3 80

1

⁄2 65

2

2 50

Inlet

100

10

Flow (water) - gpm

1

11⁄2 40

1

1

⁄4 32

1 25

3

⁄4 20

1⁄

2

3⁄

8

1⁄

4

15

10

8

A

NPT

Threads

Strainer Size

0.1

B

0.1 1 10

Pressure Drop - psi

Flow-coefficient

The flow coefficient (Cv) is the number of gallons per minute

of water flowing through a given size restriction at a pressure

drop on one psi. To obtain the Cv factor for a given size strainer,

Cap

C

NPT

read capacity at intersection with the one (1) psi pressure drop.

Conversions: For gpm to lpm, multiply by 3.8

For psi to bars, multiply by .069

Dimensions — Weights

SIZE (DN) DIMENSIONS WEIGHTS

A B C (NPT)

in. mm in. mm in. mm in. mm lbs. kgs.

1⁄4 8 33⁄16 81 21⁄16 52

3

⁄8 10 33⁄16 81 21⁄16 52

1

⁄2 15 33⁄16 81 21⁄16 52

3

⁄4 20 33⁄4 95 27⁄16 62

1 25 4 102 2

1

1

⁄4 32 5 127 33⁄8 86

1

1

⁄2 40 53⁄4 146 37⁄8 98

2 50 7 178 4

1

2

⁄2 65 91⁄4 235 57⁄8 149 1 25 22.0 10.0

7

⁄16 62

3

⁄4 121

3 80 10 254 6 152 1

1

⁄4 8 1.5 0.7

1

⁄4 8 1.5 0.7

1

⁄4 8 1.5 0.7

3

⁄8 10 2.5 1.1

3

⁄4 20 3.0 1.4

3

⁄4 20 5.5 2.5

3

⁄4 20 8.0 3.6

3

⁄4 20 13.0 5.9

1

⁄4 40 30.0 13.6

A Watts Water Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

ES-77SI 0936 © Watts, 2009

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...