Page 1

For Commercial and Institutional Applications

ES-77F-DI-125

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

LEAD FREE

*

Contractor

Approval

Contractor’s P.O. No.

Representative

Series 77F-DI-125,

77F-DI-FDA-125

Flanged, Wye Pattern, Cast Iron Strainers

Sizes: 2" – 12" (50 – 300mm)

Series 77F-DI-125, 77F-DI-FDA-125 Flanged, Wye Pattern,

Cast Iron Strainers feature 304 stainless steel perforated

screens, a cast iron flanged retainer cap and a drain/blowoff

connection furnished with a closure plug. Series 77F-DIFDA-125 also features a double coated, heat fused epoxy

coating on the interior and exterior for FDA approved sanitary

applications.

Features

• Flanges conform to American National Standards Institute,

Class 125 (ANSI B16.1) and WW-S-2739 Type 2

• Lead Free* cast iron body

• 304 Stainless steel perforated screens

• Cast iron flanged retainer cap with gasket tapped

for closure plug

• Drain/Blowoff connection furnished with closure plug

• Series 77F-DI-FDA-125 comes with heat fused FDA

approved epoxy coating (interior and exterior)

Models

77F-DI-125 — 2" – 12" (50 – 300mm) with flanged connections

for water and steam service

77F-DI-FDA-125 — 2" – 12" (50 – 300mm) with flanged

connections and double coated, heat fused FDA approved

epoxy coating (interior and exterior) for water service only

Specifications (77F-DI-125)

A flanged, wye pattern, cast iron strainer to be installed as

indicated on the plans. The strainer must have flanges that

conform to American National Standards Institute, Class 125,

304 stainless steel perforated screens and a drain/blowoff connection furnished with a closure plug. Pressure rating no less

than 200psi (13.8 bar) WOG non-shock and 125psi (8.6 bar)

WSP. Strainer shall be a Watts Series 77F-DI-125.

Pressure – Temperature

Maximum Operating Pressure:

200psi (13.8 bar) WOG, non-shock, @ 210° F (99° C)

125psi (8.6 bar) WSP @ 353° F (178° C)

Standard Screens

2" – 5" (50 – 125mm): 1/16" perforation

6" – 8" (150 – 200mm):

10" – 12" (250 – 300mm):

Screen Options

Wire Mesh Liners: 304 stainless steel (#20, #40, #60, #80, #100)

Perforated Screens: 304 stainless steel (

Specifications (77F-DI-FDA-125)

A flanged, wye pattern, cast iron strainer with a double coated,

heat fused, FDA approved epoxy coating on the interior and

exterior surfaces for FDA sanitary applications. Flanges to conform to ANSI B16.1 Class 125, 304 stainless steel perforated

screens, and a drain/blowoff connection furnished with a closure plug. Pressure rating 200psi (13.8 bar) WOG. Strainer shall

be a Watts Series 77F-DI-FDA-125.

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

77F-DI-FDA-125

1

/8" perforation

3

/16" perforation

3

/64", 1/16", 1/8", 3/16")

*The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

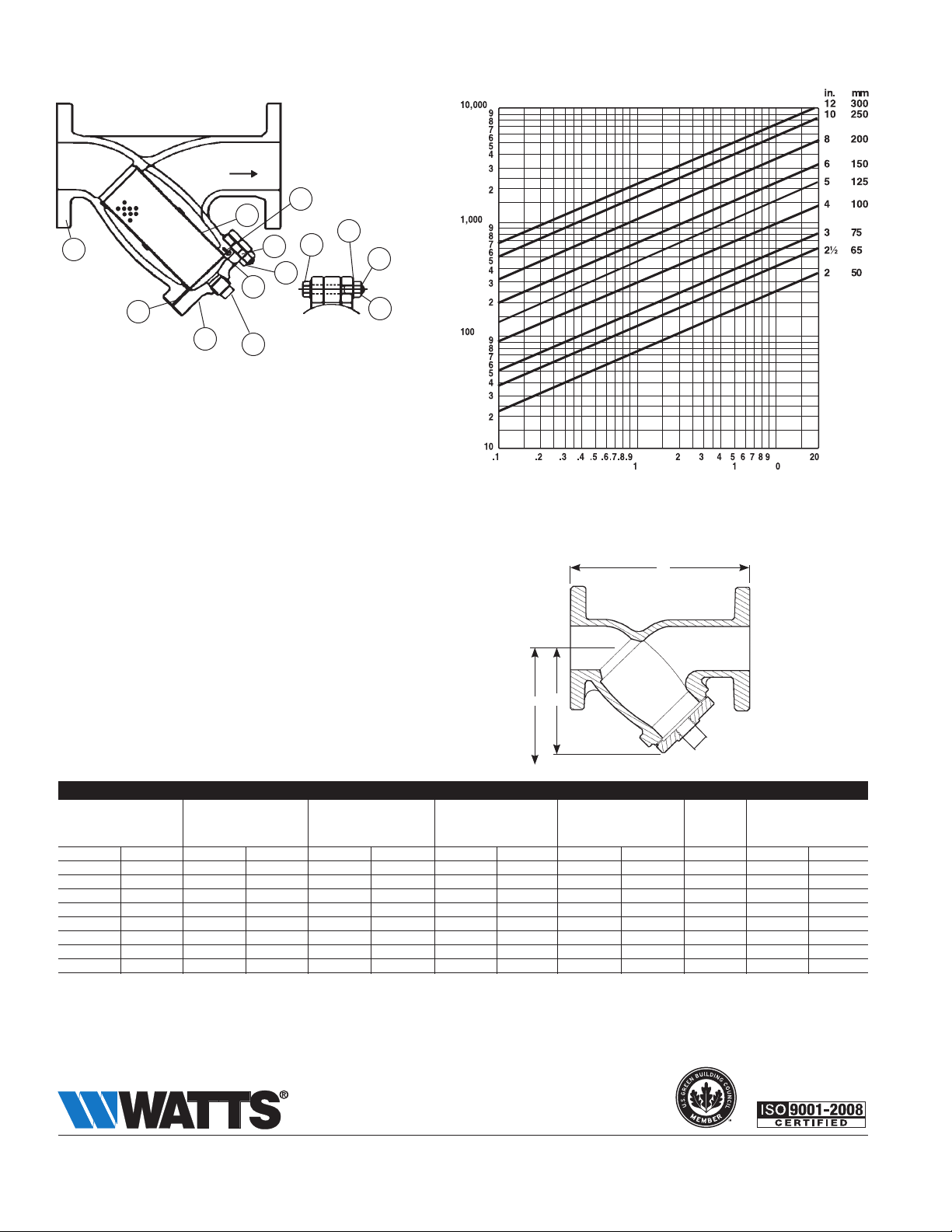

Materials

M

Flow/Pressure Drop Chart

I

A

K

J

F

B

D

H

G

E

Liquid Flow (Water) - gpm

L

C

A. Screen AISI 304SS

B. Cover Gasket Graphite

C. Plug *ASTM A47

D. Washer ASTM A6

E. Cotter Pin ASTM A112

F. Plate *ASTM A6

G. Bolt Nut ASTM A6

H. Bolt ASTM A6

I. Set Screw ASTM B16

J. Cover Bolt Nut ASTM A6

K. Cover Bolt ASTM A6

L. Cover *ASTM A-126 CIass B

M. Body *ASTM A-126 CIass B

Note:* 77F-DI-FDA-125 component parts epoxy

coated internally and externally.

Dimensions – Weights

Pressure Drop - psi

A

BD

C NPT

SIZE (DN) DIMENSIONS WEIGHT

Screen

A B C(NPT) D* Area

in. mm in. mm in. mm in. mm in. mm sq.in. lbs. kgs.

2 50 77⁄8 200 51⁄4 133 1⁄2 13 7 178 36 18 8

21⁄2 65 10 254 61⁄2 165 1 25 93⁄4 248 56 28 13

3 75 101⁄8 257 7 178 1 25 10 254 75 34 15

4 100 121⁄8 308 81⁄4 210 11⁄2 38 12 305 121 60 27

5 125 155⁄8 397 111⁄4 286 2 51 17 432 210 95 43

6 150 181⁄2 470 131⁄2 343 2 51 20 508 278 133 60

8 200 215⁄8 551 151⁄2 394 2 51 223⁄4 578 387 247 112

10 250 26 660 181⁄2 470 2 51 28 711 577 370 168

12 300 297⁄8 759 213⁄4 552 2 51 30 762 795 579 262

* D dimension is minimum clearance for screen removal.

A Watts Water Technologies Company

ES-77F-DI-125 1307 © 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Loading...

Loading...