Page 1

For Commercial and Industrial Applications

ES-77F-CSSI

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

Series 77F-CSSI

Stainless Steel, Flanged,

Wye-Pattern Strainers

Sizes: 1/2" – 6" (15 - 150mm)

Series 77F-CSSI Stainless Steel, Flanged, Wye-Pattern Strainers

are used in liquid and steam applications. They are furnished

with blowdown connections and a machined seat that allows the

screen to be self-aligning and assures a perfect fit.

All sizes come complete with a bolted screen retainer cover

and PTFE gasket. Screen cover is tapped for strainer clean out

by removing the blowdown plug or opening a blowdown valve

piped to the blowdown outlet. The strainer may be installed in

horizontal or vertical pipe with the blowdown connection at the

lower end of the screen retainer cover.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

No. 77F-CSSI

––––––––––––––––––––––––––––––––––

Features

• Stainless steel body

• Wye-pattern

• Self-aligning stainless steel screen

• Screen retainer cover tapped and plugged

Pressure (Non-Shock)-Temperature

Maximum Working Pressure:

150psi (10.3 bar) at 400°F (204°C) WSP

275psi (19.0 bar) at 100°F (38°C) WOG

Materials

Body: ASTM A-351 Grade CF8M

Plug: ASTM A-182 Type 316

Screen: 304 stainless steel

Screen Retainer Cover: ASTM A-351 Grade CF8M

Gasket: PTFE

Type 316 stainless steel

stainless steel

Type 316 stainless steel

*The wetted surface of this product contacted by consumable

water contains less than one quarter of one percent (0.25%) of

lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

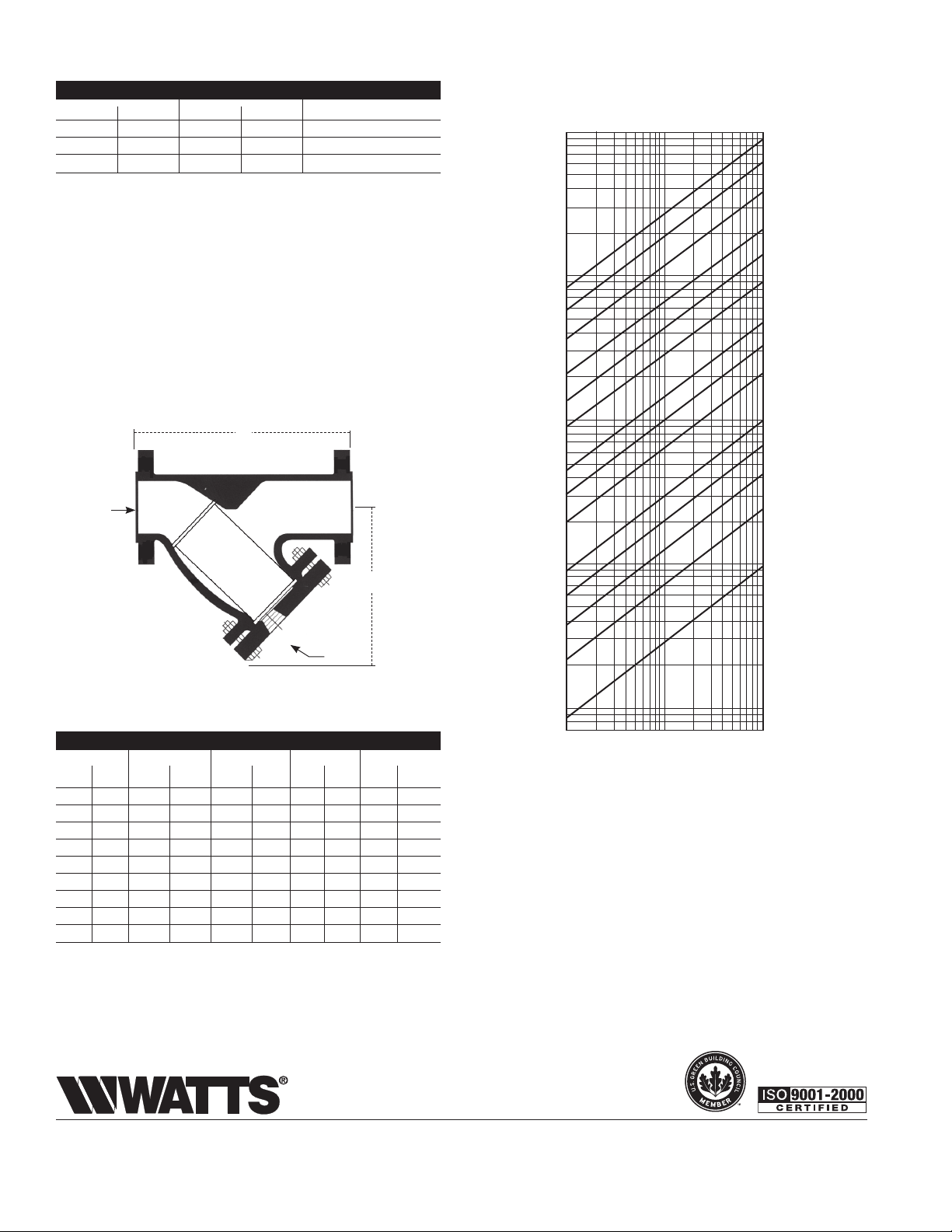

Standard Screens

SIZE OPENINGS STANDARD SCREENS

in. mm in. mm

1/2 - 11/2 15-40 0.032 0.813

2 - 3 50-80 0.045 1.143

4 - 6 100-150 0.125 3.175

A

Inlet

1

⁄32 304SS perf.

3

⁄64 304SS perf.

1

⁄8 304SS perf.

Performance Data

Table shows flows (gpm-water) at various pressure drops (psig)

using standardly furnished screens.

in. mm

10000

1000

100

Flow (water) - gpm

12 300

10 250

8 200

6 150

5 125

4 100

3 80

1

2

⁄2 65

2 50

1

1

⁄2 40

1

⁄4 32

1

1 25

3

⁄4 20

B

C

NPT

Dimensions — Weights

SIZE DIMENSIONS WEIGHTS

A B C (NPT)

in. mm in. mm in. mm in. mm lbs. kgs.

1⁄2 15 6 152 37⁄8 98 1⁄4 8 6 2.4

3

⁄4 20 7 178 41⁄4 108 3⁄8 10 7 2.9

1 25 7

1

1

⁄2 40 9 229 55⁄8 143 1⁄2 15 12 5.4

2 50 8

1

2

⁄2 65 101⁄4 260 71⁄2 191 3⁄4 20 32 14.5

3 80 11

4 100 14

6 150 18

Dimensions shown are subject to change. Contact Watts for exact dimensions

1

⁄2 191 43⁄4 121 1⁄2 15 9 4.0

5

⁄8 219 51⁄4 133 1⁄2 15 20 9.0

5

⁄8 295 7 195 1 25 36 16.3

3

⁄8 365 91⁄8 232 11⁄2 40 61 27.6

5

⁄8 473 13 330 2 50 160 72.5

1

10

1

.7

0.1 1 10

⁄2 15

Strainer Size

Pressure Drop - psi

Flow-coefficient

The flow coefficient (Cv) is the number of gallons per minute

of water flowing through a given size restriction at a pressure

drop of one psi. To obtain the Cv factor for a given size strainer, read capacity at intersection with the one (1)

psi pressure drop.

Conversions: For gpm to lpm, multiply by 3.8

For psi to bars, multiply by .069

A Watts Water Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

ES-77F-CSSI 0930 © Watts, 2009

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...