Page 1

ASME Water Pressure Relief Valves

For Pressure Protection of Hot

Water Heating Boilers

Sizes:

3

⁄4" – 2" (20 - 50mm)

Series 174A

Bronze body safety relief valves for pressure protection only

of all types of hot water heating boiler equipment. Pressure

range 30 to 150psi (2 - 10 bar) with corresponding high ratings

from 650,000 to 14,370,000 BTU/hr. Female inlet and outlet

connections. Sizes

3

⁄4" - 2" (20 - 50mm).

Series 374A

Iron body with forged bronze inlet, 550,000 BTU/hr rating.

3

⁄4" (20mm) only.

Series 740

Iron body with expanded outlets for hot water space heating

boilers. Pressure range 30 to 75psi (2 to 5 bar) with corresponding high ratings from 925,000 to 10,700,000 BTU/hr.

Features

• Seat located above drain; water can’t be trapped and

sediment can’t foul seat.

• Non-mechanical seat-to-disc alignment will not stick

or freeze.

• Water seal of high temperature resisting material isolates

spring working parts from water during relief.

Specifications

Boiler Relief Valves

An ASME Section IV certified pressure relief valve shall be

installed on each boiler as noted. The valve shall have a BTU

rating in excess of the BTU rating of the boiler's heating output.

Each hot water space heating boiler shall be equipped with a

pressure relief valve set to relieve below the maximum boiler

working pressure. The valve shall feature a raised seat and

non-mechanical disc alignment. Working parts and spring shall

be isolated from any discharge by a high temperature resistant

material. Valve shall be a Watts Regulator Company Series

174A, 374A or 740.

Operation

As thermal expansion conditions develop, pressure builds up to

the setting of the relief valve. This will cause discharging of small

quantity of water.

Should operating controls fail, permitting runaway firing, the

boiler water may reach steam temperatures. The valve will then

open to discharge steam at the rate or faster than the boiler can

generate it, thus restoring system pressure to a safer level.

Important: The discharge line must be the same size as the

valve outlet, and must pitch downward from the valve to a safe

place for disposal.

Valve lever must be tripped at least once a year to ensure that

waterways are clear. This device is designed for emergency

safety relief and shall not be used as an operating control.

For Hot Water Boiler Applications

ES-174A-740

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Series 174A

Series 740

Series 174A, 374, 740

Page 2

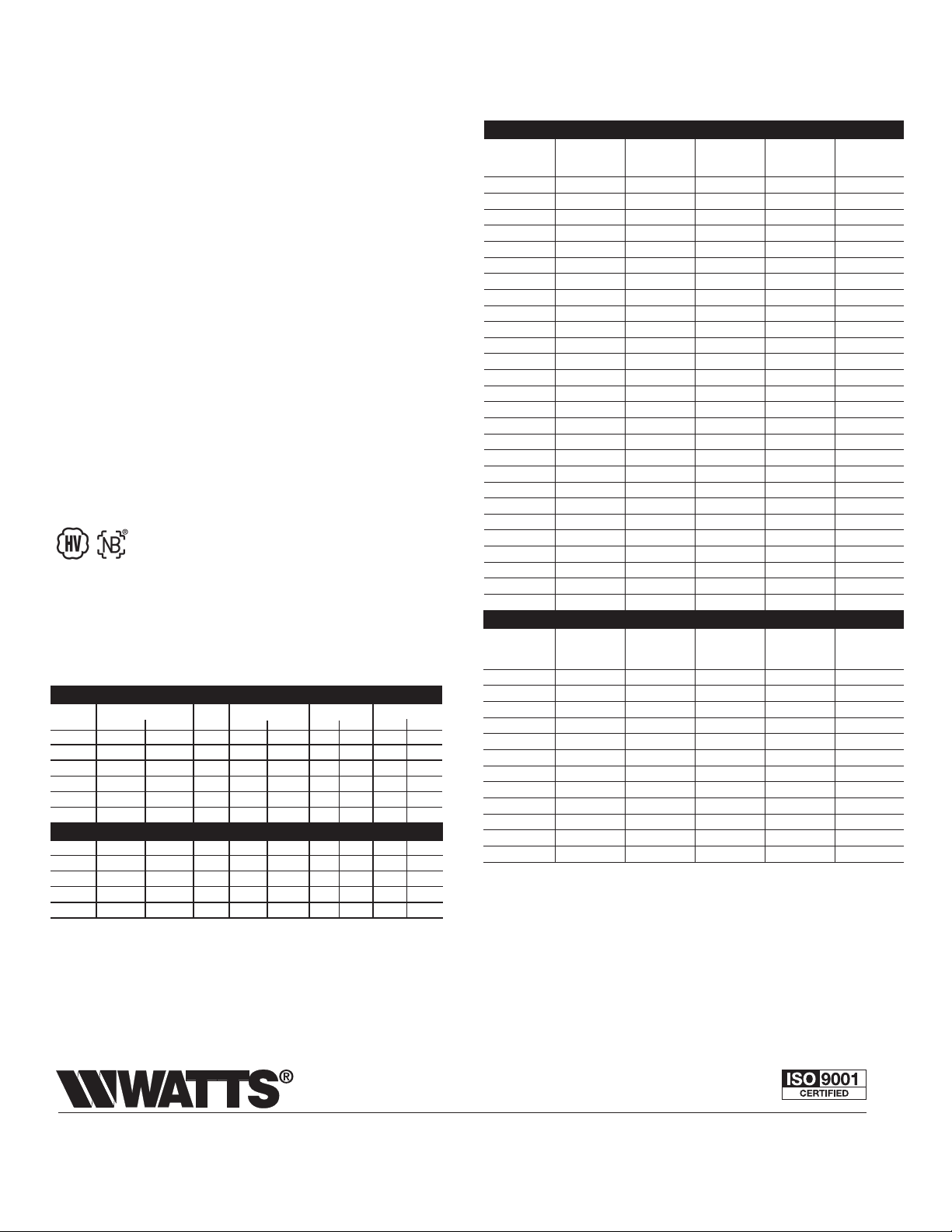

SERIES 174A

Set

3

⁄4" x 3⁄4" 1" x 1" 11⁄4" x 11⁄4" 11⁄2" x 11⁄2" 2" x 2"

Pressure 20 x 20mm 25 x 25mm 32 x 32mm 40 x 40mm 50 x 50mm

psi bar Model M3 Model M1 Model M1 Model M Model M

30 2.07 650,000 1,005,000 1,682,000 2,020,000 3,815,000

33 2.27 695,000 1,075,000 1,788,000 2,150,000 4,080,000

35 2.41 725,000 1,125,000 1,877,000 2,250,000 4,250,000

36 2.48 740,000 1,145,000 1,916,000 2,310,000 4,344,000

40 2.76 800,000 1,240,000 2,071,000 2,490,000 4,690,000

45 3.10 875,000 1,355,000 2,265,000 2,720,000 5,130,000

50 3.45 950,000 1,470,000 2,459,000 2,950,000 5,575,000

55 3.79 1,025,000 1,590,000 2,653,000 3,190,000 6,010,000

60 4.13 1,100,000 1,702,000 2,847,000 3,425,000 6,450,000

65 4.58 1,170,000 1,820,000 3,041,000 3,660,000 6,890,000

70 4.82 1,245,000 1,935,000 3,325,000 3,890,000 7,330,000

75 5.17 1,320,000 2,055,000 3,429,000 4,125,000 7,770,000

80 5.51 1,400,000 2,166,000 3,605,000 4,360,000 8,215,000

85 5.86 1,470,000 2,285,000 3,817,000 4,590,000 8,650,000

90 6.60 1,545,000 2,400,000 4,011,000 4,825,000 9,090,000

95 6.55 1,620,000 2,520,000 4,205,000 5,060,000 9,530,000

100 6.89 1,695,000 2,635,000 4,399,000 5,290,000 9,970,000

105 7.23 1,770,000 2,750,000 4,593,000 5,525,000 10,410,000

110 7.58 1,845,000 2,865,000 4,787,000 5,760,000 10,850,000

115 7.92 1,920,000 2,980,000 4,981,000 5,990,000 11,290,000

120 8.27 1,995,000 3,100,000 5,175,000 6,225,000 11,730,000

125 8.61 2,070,000 3,215,000 5,370,000 6,460,000 12,170,000

130 8.96 2,145,000 3,330,000 5,564,000 6,690,000 12,610,000

135 9.30 2,220,000 3,445,000 5,758,000 6,925,000 13,050,000

140 9.65 2,295,000 3,565,000 5,952,000 7,160,000 13,490,000

145 9.99 2,370,000 3,680,000 6,146,000 7,390,000 13,390,000

150 10.34 2,445,000 3,795,000 6,340,000 7,630,000 14,370,000

Capacity*

BTU/hr Steam Pressure Discharge Capacities

As tested and rated by the National Board of Boiler and

Pressure Vessel Inspectors

Materials

Series 174A

• Bronze body construction

• Nonmetallic disc-to-metal seating

Series 740

• Iron body construction

• Nonmetallic disc-to-metal seating

Pressure – Temperature

Series 174A

Pressure range: 30psi to 150psi (2 to 10 bar) with corresponding high BTU/hr ratings from 650,000 to 14,370,000 BTU/hr.

Maximum Temperature: 250ºF (121ºC)

Series. 374A

Pressure range: rated up to 550,000 BTU/hr at a 30psi (2 bar)

setting only.

Series 740

Pressure range: 30psi to 75psi (2 to 5 bar) with corresponding

high ratings from 925,000 to 10,700,000 BTU/hr.

Maximum Temperature: 250ºF (121ºC)

Standards

Tested and rated by the National Board of Boiler and Pressure

Vessel Inspectors to the requirements of ASME. Meets Military

Spec. MIL-V-18634B, Type I, Class 3A, Style A (Bronze Body),

Style B (Iron Body).

ASME

Dimensions – Weights

SERIES 174A

Size (Dn) Height Length Weight

Model in. mm Model in. mm in mm lbs. kg.

374A3⁄4 x 3⁄4 20 x 20 – 35⁄8 92 21⁄2 64 1.13 .5

174A3⁄4 x 3⁄4 20 x 20 M3 51⁄8 130 21⁄2 64 1.50 .7

174A 1 x 1 25 x 25 M1 53⁄4 146 3 76 3.13 1.4

174A 11⁄4 x 11⁄4 32 x 32 M1 83⁄8 213 43⁄4 121 6.25 2.8

174A 11⁄2 x 11⁄2 40 x 40 M 9 229 47⁄8 124 7.25 3.3

174A 2 x 2 50 x 50 M 115⁄8 295 61⁄4 159 13.75 6.2

SERIES 740

Set

3

⁄4" x 1" 1" x 11⁄4" 11⁄4" x 11⁄2" 11⁄2" x 2" 2" x 21⁄2"

Pressure 20 x 20mm 25 x 25mm 32 x 32mm 40 x 40mm 50 x 50mm

psi bar Model M1 Model M Model M Model M Model M

30 2.07 925,000 1,300,000 2,105,000 2,900,000 5,250,000

33 2.27 989,000 1,390,000 2,250,000 3,100,000 5,613,000

35 2.41 1,032,000 1,450,000 2,345,000 3,235,000 5,855,000

36 2.48 1,053,000 1,480,000 2,395,000 3,300,000 5,975,000

40 2.76 1,139,000 1,600,000 2,590,000 3,569,000 6,461,000

45 3.10 1,245,000 1,750,000 2,830,000 3,903,000 7,067,000

50 3.45 1,352,000 1,899,000 3,075,000 4,237,000 7,672,000

55 3.79 1,459,000 2,049,000 3,315,000 4,572,000 8,277,000

60 4.13 1,566,000 2,200,000 3,560,000 4,907,000 8,883,000

65 4.58 1,672,000 2,349,000 3,800,000 5,241,000 9,488,000

70 4.82 1,779,000 2,499,000 4,045,000 5,575,000 10,093,000

75 5.17 1,886,000 2,649,000 4,285,000 5,909,000 10,700,000

SERIES 740

7403⁄4 x 1 20 x 25 M1 55⁄8 143 3 76 1.88 9

740 1 x 11⁄4 25 x 32 M 71⁄4 184 31⁄2 89 3.13 1.4

740 11⁄4 x 11⁄2 32 x 40 M 83⁄4 222 45⁄8 117 6.13 2.8

740 11⁄2 x 2 40 x 50 M 91⁄4 235 51⁄4 133 7.50 3.4

740 2 x 21⁄2 50 x 65 M 115⁄8 295 63⁄4 171 16.50 7.5

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

Water Safety & Flow Control Products

ES-174A-740 0610 © Watts Regulator Company, 2006

Loading...

Loading...