Page 1

The Automatic Answer to Fluid Control

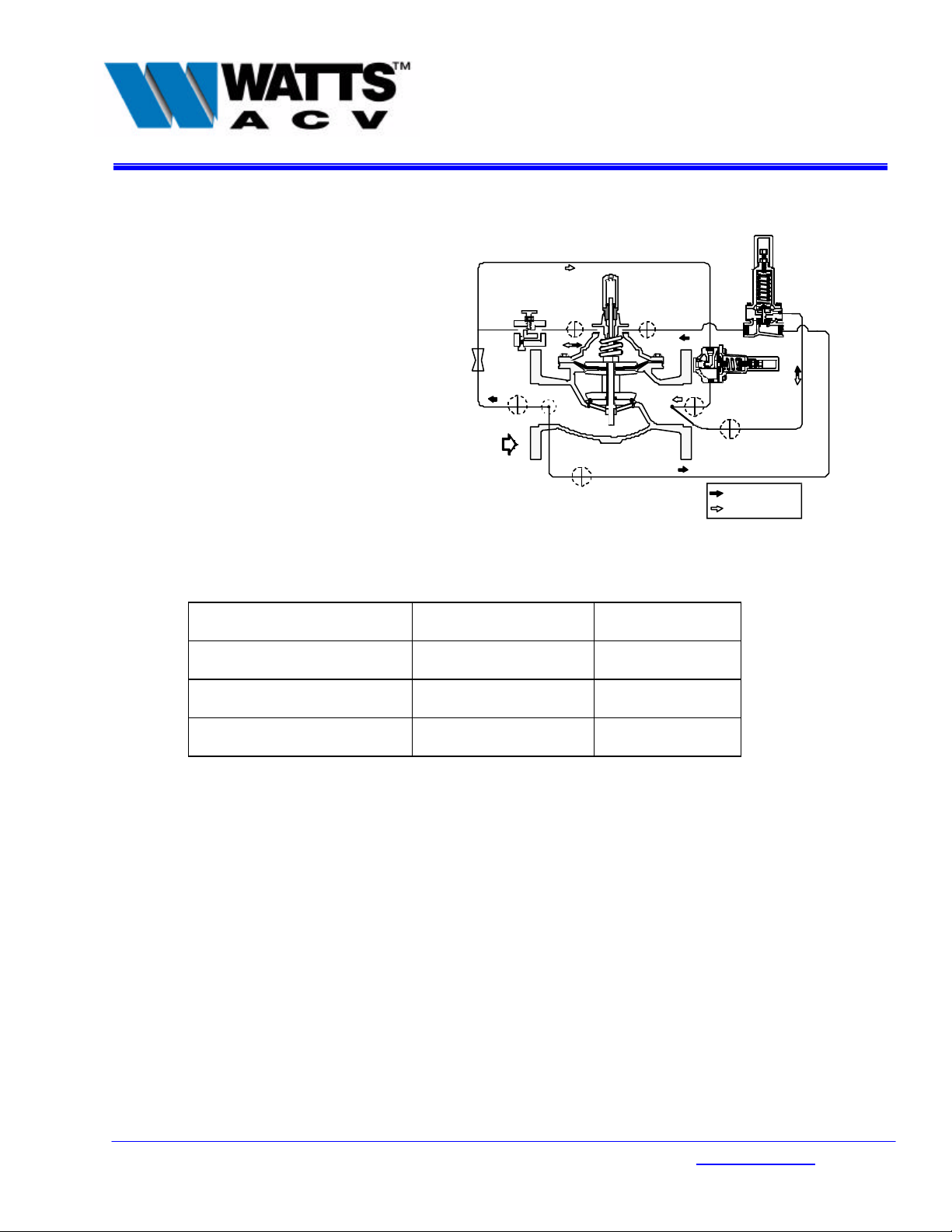

Model 6115-7JM

Components

1) Main Valve

2) Reducing Pilot

3) Supply Orifice

4) Adjustable Opening Speed

5) Position Indicator

6) Flow Clean Strainer

7) Ball Valve

8) Surge Control Pilot

Technical BulletinTechnical Bulletin

Pressure Reducing & Downstream Pressure Reducing & Downstream

Surge Control ValveSurge Control Valve

5

4

7

3

6

Flow

Flow Direction: Under the Seat

1

Closes Valve

Opens Valve

8

2

Part Number List

Item Description Complete Assembly Repair Kit

Model 6115-7JM 234802 3313-01

Reducing Pilot 0661-01 221101

Surge Control Pilot 0680-02 221201

Operation

The Model 6115-7JM is designed to automatically reduce a fluctuating higher upstream (inlet) pressure to a constant

lower downstream (outlet) pressure and will rapidly modulate towards a closed position if downstream pressure

suddenly becomes greater than the desired regulated setpoint. The quick closing action prevents possible damaging

high pressure from passing through valve. Regulating action is controlled by a normally open Pressure Reducing

Pilot designed to: 1) Open (allowing fluid out of the main valve cover chamber) when downstream pressure is below

its adjustable setpoint, and, 2) Close (allowing fluid to fill the main valve cover chamber) when downstream pressure

is above its adjustable setpoint. A decrease in downstream pressure causes the valve to modulate towards an open

position, raising downstream pressure. An increase in downstream pressure causes the valve to modulate towards a

closed position, lowering downstream pressure.

If downstream pressure suddenly becomes greater than the desired regulated setpoint, the normally closed Surge

Control Pilot opens and rapidly admits higher inlet pressure into the valve cover, increasing rate of valve closure.

Normal pressure reducing operation resumes when downstream pressure is again below the desired regulated

setpoint.

8550 Hansen Road . Houston, TX 77075 . Telephone 713.943.0688 . FAX 713.944.9445 www.wattsacv.com

Page 2

Model 6115-7JM Installation

Prior to installation, flush line to remove debris.

1. Install valve horizontally “in line” (cover facing up), so flow arrow matches flow through the line. Consult

factory prior to ordering if installation is other than described.

2. Install inlet and outlet isolation valves.

Note: When using butterfly valves, ensure disc does not contact control valve. Damage or improper valve

seating can occur.

3. Provide adequate clearance for valve servicing and maintenance.

4. Install pressure gauges to monitor valve inlet and outlet pressure.

Note: If installation is subjected to very low flow or potentially static conditions, It is recommended that a

pressure relief valve (1/2" minimum) be installed downstream of the Pressure Reducing Valve for additional

system protection. See Watts Model PV20-CB.

Start-Up Instructions

Note: Set-up the Model 6115-7JM in a flowing condition for proper start-up. Automatic Control Valve start-up

requires bringing the valve into service in a controlled manner. All adjustments to control pilot and speed

controls should be made slowly, allowing the valve to respond and the system to stabilize. For proper

operation, the Surge Control Pilot is adjusted approximately 5 psi higher than the Pressure Reducing Pilot.

1. Close upstream and downstream isolation valves.

2. Turn the Reducing Pilot (item 2) adjustment screw counterclockwise, releasing the spring tension. Isolate

the Surge Control Pilot by turning its adjustment screw clockwise. Open all isolation Ball Valves.

3. Turn Adjustable Opening Speed Control (item 4) clockwise until seated, and then counterclockwise 2-1/2

turns. This is an approximate setting and should be fine tuned to suit system requirements once pressure

adjustments have been made.

4. Slowly open the upstream isolation valve. Loosen air bleed petcock on Position Indicator (item 5) allowing air

to vent. Close the air bleed petcock when all air is vented.

5. Slowly open the downstream isolation valve. Gradually turn the Reducing Pilot adjustment screw clockwise

to raise the downstream pressure. There must be a demand for flow for proper start-up. Continue to adjust

Reducing Pilot until downstream pressure is approximately 5 psi higher than the desired outlet pressure.

6. While observing downstream pressure gauge (or position indicator) slowly turn Surge Control Pilot

adjustment screw counterclockwise until downstream pressure quickly falls. The Surge Control Pilot is set

at the point when the Model 6115-7JM begins to close. Tighten the locknut on the Surge Control Pilot. Turn

adjustment screw counterclockwise on Pressure Reducing Pilot, decreasing setpoint, until desired

downstream pressure is achieved. Tighten locknut on Pressure Reducing Pilot. The Surge Control Pilot is

set approximately 5 psi higher than the reduced pressure setpoint.

7. Fine tune Opening Speed Control to suit system requirements. Adjust Opening Speed Control clockwise for

slower opening, and counterclockwise for faster opening.

TB6115-7JM Rev. A Page 2 of 2

Loading...

Loading...