Page 1

ENGLISH INSTRUCTIONS

Series 2300

Water Pressure Reducing Valve

Sizes: 3"– 4" (80-100mm)

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

!

WARNING

Local building or plumbing codes may require modifications to the information provided. You are required to

consult the local building and plumbing codes prior

to installation. If the information provided here is not

consistent with local building or plumbing codes, the

local codes should be followed. This product must be

installed by a licensed contractor in accordance with

local codes and ordinances.

!

WARNING

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes,

but at least once per year or more as service conditions

warrant. All products must be retested once maintenance

has been performed. Corrosive water conditions and/or

unauthorized adjustments or repair could render the product

ineffective for the service intended. Regular checking and

cleaning of the product’s internal components helps assure

maximum life and proper product function.

IS-2300

Series 2300

Installation Instructions:

The 2300 Direct Operated Reducing Valve is designed for deadend water service where the flow is intermittent and changes

rapidly, as on domestic water systems. It is especially effective

in regulating the flow of water to such fast acting equipment as

flushometers and snap cocks. The design is self contained, no

control pipe is required.

The preferred position for the 2300 is in a horizontal line with the

spring chamber up. When so mounted, the tendency of sediment to settle in the control ports is practically eliminated.

RATINGS (Maximum Inlet Conditions)

Valve Ends Pressure Bar (Temperature)

❑ ANSI 250 Flanged 200 psig 13.8 (200°F) 93°C

SPRING RANGES

❑ 30 to 80 psig (207-552 kPa)

RATED FLOW COEFFICIENTS (Cv)

Valve Size 3 4

C

32 52

v

DIMENSIONS (inches) AND WEIGHTS (pounds)

FACE TO FACE OTHER DIMENSIONS APPROX. WEIGHT

E

SIZE ANSI ANSI ANSI A B C ANSI ANSI ANSI

IN. MM NPT 125 250 NPT 125 250

3 80 — 10 10

4 100 — 11

7

⁄8 121⁄2 65⁄8 265⁄8 111⁄4 198 225

3

⁄4 6 213⁄4 9 — 108 128

Page 2

Installation and Maintenance Instructions

(Brackets refer to item number)

Principles of Operation

When the water supply is cut in, the valve is in wide open position. Water flowing to the system creates a rising delivery pressure which feeds back through the control ports to the underside

of diaphragm (8). As the pressure on diaphragm (8) approaches

a balance with the force exerted by adjusting spring (5), disc (20)

is throttled to a position where just enough water flows to maintain the set delivery pressure.

Installation

Carefully clear inlet piping system of foreign matter and mount

regulator with the flow arrow pointing in the direction of flow.

Preferred position for 2300 valves is in a horizontal line with

spring chamber up. When so mounted, the tendency of sediment to settle in the control ports is practically eliminated.

Provide a three-valve bypass to facilitate inspection of the reducing valve without interrupting service. Avoid damaging effects of

foreign matter in the flow by using a strainer ahead of the valve.

This valve should be installed where it is accessible with sufficient

clearance for cleaning, service or adjustment.

Operation

On starting up, proceed as follows:

1. Open the inlet stop valve gradually until the reducing valve

takes control as indicated by the delivery pressure gage.

2. Turn adjusting screw (1) clockwise to increase the delivery

pressure, counterclockwise to lower it.

CAUTION: Any time a reducing valve is adjusted, the use of a

pressure gauge is recommended to verify correct pressure setting. Do not bottom out adjusting screw on spring chamber.

To examine diaphragm or stem:

1. Remove compression from spring by turning adjusting

screw (1) counterclockwise.

2. Remove diaphragm bolts (9) and lift off spring chamber

(4).

3. Lift pressure plate (7) to withdraw diaphragm and stem

from valve.

4. To examine diaphragm, disassemble coupling nut (6) and

lift off pressure plate (7).

Valve Setting

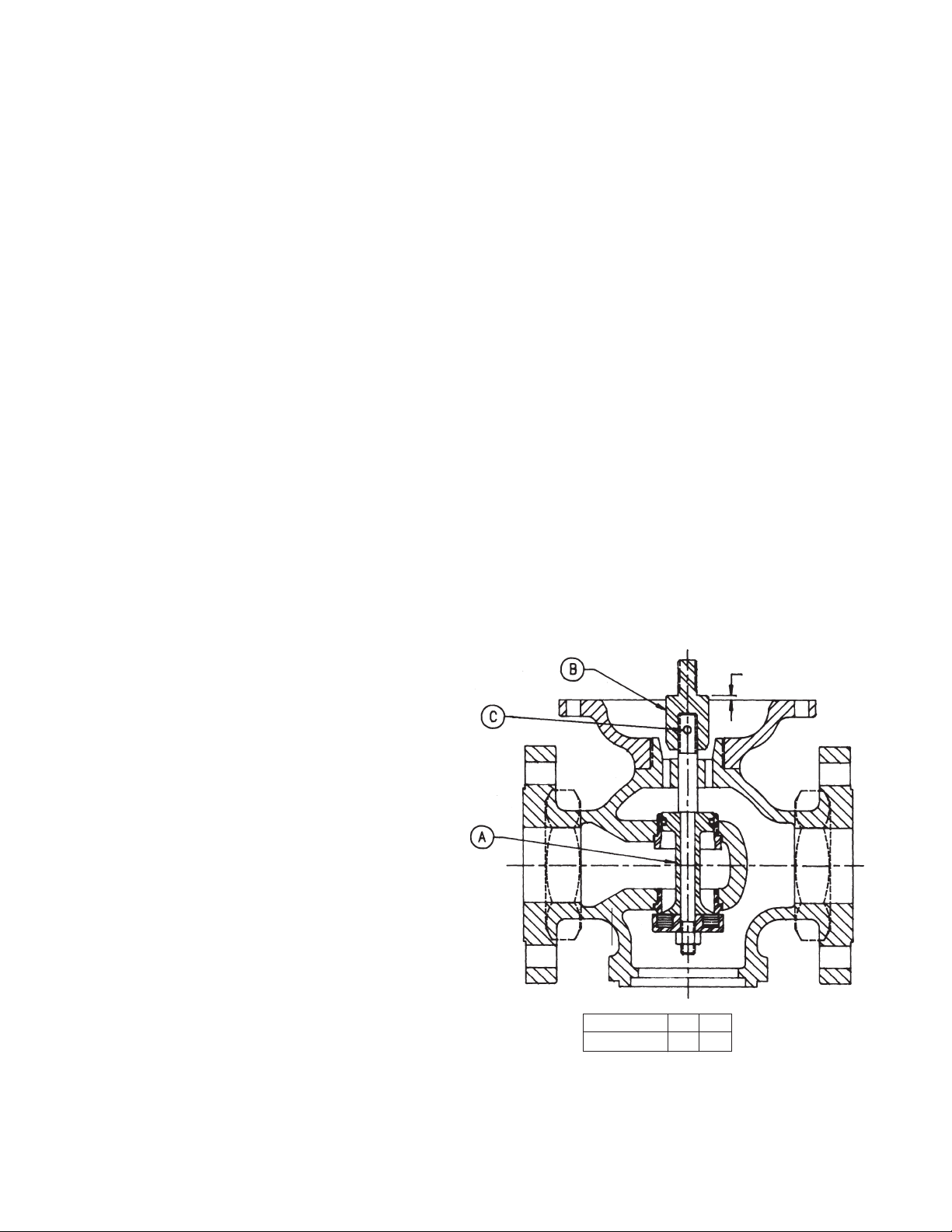

Should the threaded connection between stem coupling

(11) and stem (14) be disturbed, proceed as follows:

1. Insert stem assembly (A) and hold disc on seat ring in

closed position, as shown.

2. Screw stem coupling (B) on stem until travel setting T is

reached.

3. Remove stem assembly (A) and lock setting by drilling

hole drilling hole and inserting dowel pin (C).

NOTE: Annual inspection of the rubber components

and control parts is recommended to ensure proper

operation.

Troubleshooting

Inadequate flow or delivery pressure:

1. Check initial pressure to see if full intended line pressure is

applied at the valve inlet.

Reduced pressure builds up:

1. Foreign matter may be lodged between disc (20) and seat ring

(19). Remove blind flange (24) to inspect.

2. Diaphragm (8) may be ruptured. Remove spring chamber (4)

to inspect.

3. Sealing ring (16) may be damaged. See dismantling

instructions below to replace.

Erratic Operation

Complete dismantling is recommended.

1. Check for clogged control ports connecting body outlet with

diaphragm chamber.

2. Check for deposits causing sticking of sealing ring (16) or stem

(14) in their respective guides.

Dismantling

To change or inspect composition disc or sealing ring:

1. Remove blind flange (24).

2. Remove stem nuts (22). Keep stem from turning by inserting

screw driver in slot on end of stem.

3. Disc holder (21) will drop out. Carefully remove balance piston (18) so as not to damage sealing ring (16) as it is pulled

through seat ring (19).

Valve Size 3 4

Dimension T

3

⁄16 17⁄64

DIMENSION ‘T’

Page 3

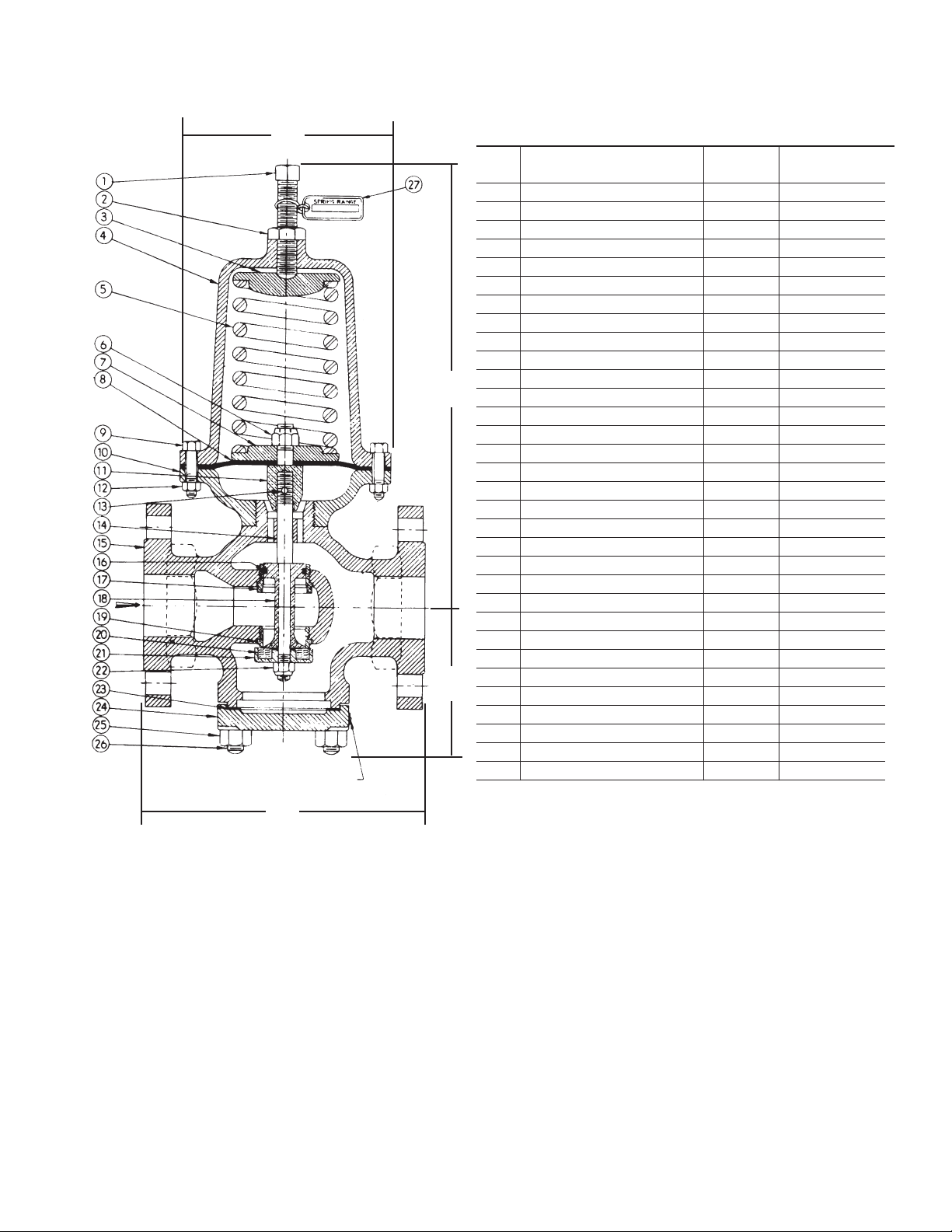

▼

▼

Serial Number Plate

C

E

▼

▼

Item

▼

No. Part Name Remarks Material

1 Adjusting Screw Steel

2 Adjusting Screw Locknut Steel

3 Spring Button Cast Iron

4 Spring Chamber Cast Iron

5 Adjusting Spring (10-40 psi) Steel

Adjusting Spring (30-80 psi) Steel

6 Coupling Nut Note 2 Steel

7 Pressure Plate Note 2 Cast Iron

8 Diaphragm Note 1,2 Hycar

9 Diaphragm Bolts Steel

10 Base Cast Iron

B

11 Stem Coupling Note 2 Stainless Steel

12 Diaphragm Nut Steel

13 Dowel Pin Note 2 Steel

14 Stem Note 2 Stainless Steel

15 Body - ANSI NPT Scr Cast Iron

Body - ANSI 125 Fig Cast Iron

Body - ANSI 250 Cast Iron

16 Sealing Ring Note 1,2 Hycar

17 Guide Ring Stainless Steel

18 Balanced Piston Stainless Steel

Balanced Piston Assembly Stainless Steel

19 Seat Ring Stainless Steel

20 Composition Disc Note 1,2 Hycar

21 Composition Disc Holder Note 2 Stainless Steel

22 Stem Nut Note 2 Steel

23 Blind Flange Gasket Note 1,2 Non-Asbestos

A

24 Blind Flange Cast Iron

25 Blind Flange Nut Steel

26 Blind Flange Studs Ledloy

▼

27 Range Tag (10-40 psi) Aluminum

Range Tag (30-80 psi) Aluminum

NOTES:

1 Recommended Spare Part

2 These parts furnished in Repair

Standard Parts

When ordering parts, it is essential that the valve type, size, service and serial

number be stated.

Select part by item number, but order by part number.

Specify complete part number when ordering.

Page 4

Part No. By Valve Size

Part 3" 4"

Adjusting Screw 05-04867-00 05-04869-00

Adjusting Screw Locknut 05-02945-00 05-02946-00

Spring Button 05-01046-00 05-01047-00

Spring Chamber 04-01414-00 04-01417-00

Adjusting Spring (10-40 psi)

Adjusting Spring (30-80 psi)

Coupling Nut 05-03019-00 05-03020-00

Pressure Plate 04-03647-00 04-03649-00

Diaphragm 05-01612-00 05-01614-00

Diaphragm Bolts 05-04777-00 05-04782-00

Base 04-00459-00 04-00461-00

Stem Coupling 04-09487-00 04-01496-01

Diaphragm Nut 05-02875-00 05-02877-00

Dowel Pin 05-03865-00 05-03867-00

Stem 04-05343-00 04-05346-00

Body - ANSI NPT Scr – –

Body - ANSI 125 Fig 04-00918-00 04-00920-00

Body - ANSI 250 Fig 04-00928-01 04-00930-00

Sealing Ring 05-04038-00 05-04045-00

Guide Ring 04-04407-00 04-04411-01

Balanced Piston 04-09481-00 –

Balanced Piston Assembly – 22445

Seat Ring 04-04177-01 04-04180-02

Composition Disc 05-01719-00 05-01721-00

Composition Disc Holder 04-09493-00 04-09494-00

Stem Nut 05-03017-00 05-03018-00

Blind Flange Gasket 05-02367-00 05-02369-00

Blind Flange 04-02183-00 04-02186-00

Blind Flange Nut 05-02862-00 05-02860-00

Blind Flange Studs 04-05448-00 04-10119-00

Range Tag (10-40 psi) 05-06221-00 05-06221-00

Range Tag (30-80 psi) 05-06222-00 05-06222-00

Repair Kits

05-05115-01 05-05155-00

05-05148-00 05-05150-00

Part 3" 4"

Repair Kit 33167 33168

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information: www.watts.com/prop65

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

IS-2300 1411 EDP# 1910867 © 2014 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Page 5

INSTRUCCIONES EN ESPAÑOL

Serie 2300

Válvula reductora de la presión del agua

Tamaños: 80-100 mm (3-4 pulg.)

!

ADVERTENCIA

Lea este manual ANTES de utilizar este equipo.

El no leer y seguir todas las medidas de seguridad y usar

la información puede causar la muerte, lesiones personales graves, daños materiales o daños en el equipo.

Guarde este manual para referencia futura.

!

ADVERTENCIA

Los códigos locales de construcción o fontanería

pueden requerir modificaciones en la información

proporcionada Es obligatorio consultar los códigos

locales de construcción y fontanería antes de comenzar

la instalación. Si la información de este manual no se

corresponde con los códigos locales de construcción y

fontanería, deberán seguirse estos últimos. Este producto

debe ser instalado por un contratista con licencia, de

acuerdo con los códigos y ordenanzas locales.

ADVERTENCIA

!

Requerimiento de inspección periódica/mantenimiento:

Este producto debe ser evaluados periódicamente de acuerdo

con los códigos locales, pero al menos una vez o más al año

según las condiciones del servicio. Todos los productos deben

volver a ser evaluados una vez se haya realizado el mantenimiento.

Condiciones de agua corrosiva y/o ajustes o reparaciones no

autorizados pueden provocar que el producto deje de funcionar

para el servicio previsto. Una inspección y limpieza regulares de

los componentes internos del producto garantizan la vida máxima

y el adecuado funcionamiento del producto.

CLASIFICACIÓN DE COEFICIENTES DE FLUJO (C

Instrucciones de instalación:

La válvula reductora de operación directa 2300 está diseñada para

servicios de agua de extremo cerrado donde el flujo es intermitente

y cambia rápidamente, como en los sistemas hidráulicos

domésticos. Es particularmente eficaz en la regulación del flujo de

agua en equipos de acción rápida como medidores de descarga.

El diseño es autocontenido, no se requiere tubo de control.

La posición preferida para la válvula 2300 es en línea horizontal

con el compartimiento del resorte hacia arriba. Cuando se instala

de esta manera, prácticamente queda eliminada la tendencia del

sedimento a depositarse en los puertos de control.

CLASIFICACIONES (condiciones de máxima entrada)

Extremos de la válvula Bares de presión (Temperatura)

❑ ANSI 250 con brida 13,8 bares (200 psig) 93 °C (200 °F)

RANGOS DEL RESORTE

❑ 207-552 kPa (30 a 80 psig)

v)

IS-2300

Series 2300

Tamaño de la válvula 3 4

C

v

TAMAÑO

3 80 —

4 100 —

27,5 Kv (32 Cv) 44,7 Kv (52 Cv)

DIMENSIONES (mm - pulgadas) Y PESOS (Kg - libras)

CARA A CARA OTRAS DIMENSIONES PESO APROX.

E

ANSI

NPT

ANSI

125

254 mm/

10 pulg.

301 mm/

7

11

⁄8 pulg.

ANSI

250PULG MM

273 mm/

3

10

⁄4 pulg.

318 mm/

121⁄2 pulg.

A B C

152 mm/

6 pulg.

168 mm/

65⁄8 pulg.

552 mm/

213⁄4 pulg.

672 mm/

265⁄8 pulg.

229 mm/

9 pulg.

286 mm/

111⁄4 pulg.

ANSI

NPT

—

ANSI

125

49 kg/

108 lb

90 kg/

198 lb

ANSI

250

58 kg/

128 lb

102 kg/

225 lb

Page 6

Instrucciones para la instalación y el mantenimiento

(los paréntesis se refieren al número de artículo)

Principios de funcionamiento

Cuando está activado el suministro de agua, la válvula está en

posición totalmente abierta. El flujo de agua al sistema crea una

mayor presión que retorna a través de los puertos de control

hasta la parte inferior del diafragma (8). A medida que la presión

en el diafragma (8) se acerca a un equilibrio con la fuerza ejercida

por el resorte de ajuste (5), el disco (20) es estrangulado hasta

una posición en la que fluye suficiente agua para mantener la

presión de suministro fijada.

Instalación

Elimine cuidadosamente los objetos extraños del sistema de la

tubería de entrada e instale el regulador con la flecha de flujo

apuntando en la dirección del flujo. La posición preferida para

las válvulas 2300 es en línea horizontal con el compartimiento

del resorte hacia arriba. Cuando se instala así, prácticamente

queda eliminada la tendencia del sedimento a depositarse en los

puertos de control.

Coloque una derivación de tres válvulas para facilitar la

inspección de la válvula reductora sin interrumpir el servicio. Evite

los efectos dañinos de los elementos extraños en el flujo usando

un filtro delante de la válvula.

Esta válvula debe instalarse en un lugar accesible con suficiente

espacio para hacer limpieza, servicio o ajustes.

Funcionamiento

Para iniciar, proceda así:

1. Abra gradualmente la válvula de retención de entrada hasta

que la válvula reductora tome el control según lo indique el

medidor de presión de suministro.

2. Gire el tornillo de ajuste (1) hacia la derecha para aumentar la

presión de suministro y hacia la izquierda para disminuirla.

PRECAUCIÓN: Siempre que ajuste una válvula reductora, se

recomienda el uso de un medidor de presión para verificar la

configuración correcta de la presión. No apriete el tornillo de

ajuste hasta el fondo del compartimiento del resorte.

Desmontaje

Para cambiar o inspeccionar el disco de composición o el

anillo obturador:

1. Quite la brida ciega (24).

2. Quite las tuercas de vástago (22). Inserte un destornillador

en la ranura del extremo del vástago para impedir que el

vástago gire.

3. Se caerá la base del disco (21). Quite cuidadosamente el

pistón de equilibrio (18) para no dañar el anillo obturador

(16) cuando se extraiga a través del anillo de asiento (19).

Para examinar el diafragma o el vástago:

1. Gire hacia la izquierda el tornillo de ajuste (1) para quitarle

compresión al resorte.

2. Quite los pernos del diafragma (9) y levante y retire el

compartimiento del resorte (4).

3. Levante la platina de presión (7) para retirar el diafragma y

el vástago de la válvula.

4. Para examinar el diafragma, desmonte la tuerca de

acoplamiento (6) y levante y retire la platina de presión (7).

Configuración de la válvula

En caso de que la conexión roscada entre el acoplamiento

del vástago (11) y el vástago (14) esté alterada, proceda de

la siguiente manera:

1. Inserte la unidad del vástago (A) y mantenga el disco en el

anillo de asiento en posición cerrada, como se muestra.

2. Atornille el acoplamiento del vástago (B) en el vástago

hasta que se alcance la configuración de recorrido T.

3. Quite la unidad del vástago (A) y taladre un orificio e

inserte el pasador guía (C) para fijar la configuración.

NOTA: Se recomienda una inspección anual de los

componentes de goma y de las piezas de control para

asegurar un funcionamiento correcto.

Resolución de problemas

Flujo o presión de suministro incorrectos:

1. Revise la presión inicial para ver si se ejerce presión completa

en la tubería indicada en la entrada de la válvula.

Se acumula presión reducida:

1. Puede haber materia extraña entre el disco (20) y el anillo de

asiento (19). Quite la brida ciega (24) e inspeccione.

2. Puede estar roto el diafragma (8). Quite el compartimiento del

resorte (4) e inspeccione.

3. Puede estar roto el anillo obturador (16). Vea las instrucciones

para desmontar que están a continuación y reemplace.

Funcionamiento errático

Se recomienda desmontar completamente.

1. Revise si hay taponamiento en los puertos de control que

conectan la salida del cuerpo con el compartimiento del

diafragma.

2. Revise si hay depósitos que ocasionan la adhesión del anillo

obturador (16) o el vástago (14) en sus respectivas guías.

DIMENSIÓN ‘T’

Tamaño de la válvula

Dimensión ‘T’ 4,76 mm (3⁄16 pulg.) 6,75 mm (17⁄64 pulg.)

80 mm (3 pulg.) 100 mm (4 pulg.)

Page 7

▼

▼

C

Placa del número de serie

E

▼

▼

Piezas estándar

N.º de

artículo Nombre de la pieza

1 Tornillo de ajuste Acero

▼

B

A

▼

2 Tuerca de seguridad del

tornillo de ajuste

3 Botón del resorte Hierro fundido

4 Compartimiento del resorte Hierro fundido

5 Resorte de ajuste 69 a

275 kPa (10 – 40 psi)

Resorte de ajuste 207 a

552 kPa (30 – 80 psi)

6 Tuerca de acoplamiento Nota 2 Acero

7 Placa de presión Nota 2 Hierro fundido

8 Diafragma Nota 1,2 Hycar

9 Pernos del diafragma Acero

10 Base Hierro fundido

11 Acoplamiento del vástago Nota 2 Acero inoxidable

12 Tuerca del diafragma Acero

13 Pasador guía Nota 2 Acero

14 Vástago Nota 2 Acero inoxidable

15 Cuerpo – Tornillo ANSI NPT Hierro fundido

Cuerpo – Con brida ANSI 125 Hierro fundido

Cuerpo – ANSI 250 Hierro fundido

16 Anillo obturador Nota 1,2 Hycar

17 Anillo guía Acero inoxidable

18 Pistón de equilibrio Acero inoxidable

Unidad del pistón de equilibrio Acero inoxidable

19 Anillo de asiento Acero inoxidable

20 Disco de composición Nota 1,2 Hycar

21 Soporte del disco de

composición

22 Tuerca de vástago Nota 2 Acero

23 Junta de la brida ciega Nota 1,2 Sin asbesto

24 Brida ciega Hierro fundido

25 Tuerca de la brida ciega Acero

26 Espárragos de la brida ciega Ledloy

27 Etiqueta de rango 69 a

275 kPa (10 – 40 psi)

Etiqueta de rango 207 a

552 kPa (30 – 80 psi)

Observa-

ciones Material

Acero

Acero

Acero

Nota 2 Acero inoxidable

Aluminio

Aluminio

Cuando se ordenen las piezas, es esencial especicar el tipo de válvula, el

tamaño, el servicio y el número de serie.

Seleccione la pieza por el número de artículo pero ordene por número de pieza.

Especique el número completo de la pieza cuando haga el pedido.

NOTAS:

1 Repuestos recomendados

2 Estas piezas se suministran en la reparación

Page 8

N.º de pieza por tamaño de válvula

Piezas 80 mm (3 pulg.) 100 mm (4 pulg.)

Tornillo de ajuste 05-04867-00 05-04869-00

Tuerca de seguridad del tornillo de ajuste 05-02945-00 05-02946-00

Botón del resorte 05-01046-00 05-01047-00

Compartimiento del resorte 04-01414-00 04-01417-00

Resorte de ajuste 69 a 275 kPa (10 a 40 psi) 05-05115-01 05-05155-00

Resorte de ajuste 207 a 552 kPa (30 a 80 psi) 05-05148-00 05-05150-00

Tuerca de acoplamiento 05-03019-00 05-03020-00

Placa de presión 04-03647-00 04-03649-00

Diafragma 05-01612-00 05-01614-00

Pernos del diafragma 05-04777-00 05-04782-00

Base 04-00459-00 04-00461-00

Acoplamiento del vástago 04-09487-00 04-01496-01

Tuerca del diafragma 05-02875-00 05-02877-00

Pasador guía 05-03865-00 05-03867-00

Vástago 04-05343-00 04-05346-00

Cuerpo – Tornillo ANSI NPT – –

Cuerpo – Con bridas ANSI 125 04-00918-00 04-00920-00

Cuerpo – Con bridas ANSI 250 04-00928-01 04-00930-00

Anillo obturador 05-04038-00 05-04045-00

Anillo guía 04-04407-00 04-04411-01

Pistón de equilibrio 04-09481-00 –

Unidad del pistón de equilibrio – 22445

Anillo de asiento 04-04177-01 04-04180-02

Disco de composición 05-01719-00 05-01721-00

Soporte del disco de composición 04-09493-00 04-09494-00

Tuerca de vástago 05-03017-00 05-03018-00

Junta de la brida ciega 05-02367-00 05-02369-00

Brida ciega 04-02183-00 04-02186-00

Tuerca de la brida ciega 05-02862-00 05-02860-00

Espárragos de la brida ciega 04-05448-00 04-10119-00

Etiqueta de rango 69 a 275 kPa (10 a 40 psi) 05-06221-00 05-06221-00

Etiqueta de rango 207 a 552 kPa (30 a 80 psi) 05-06222-00 05-06222-00

Juegos para reparación

Pieza 80 mm (3 pulg.) 100 mm (4 pulg.)

Juego para reparación 33167 33168

ADVERTENCIA: Este producto contiene sustancias químicas

que en el Estado de California se conocen como causantes de

cáncer y malformaciones u otros daños reproductivos.

Para más información: www.watts.com/prop65

Garantía limitada: Watts Regulator Co. (“la compañía") garantiza que cada producto está libre de fallas en el material y la mano de obra bajo condiciones de uso normales por un período de un año

a partir de la fecha de envío original. En caso de que dichas fallas ocurran dentro del período de garantía, la compañía, a su criterio, cambiará o reparará el producto sin costo alguno.

LA GARANTÍA AQUÍ DESCRITA SE OTORGA DE MANERA EXPRESA Y ES LA ÚNICA GARANTÍA OFRECIDA POR WATTS REGULATOR COMPANY CON RESPECTO AL PRODUCTO. LA COMPAÑÍA

NO OFRECE NINGUNA OTRA GARANTÍA, YA SEA EXPRESA O IMPLÍCITA. POR EL PRESENTE, LA COMPAÑÍA DESCONOCE ESPECÍFICAMENTE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA,

INCLUIDAS, SIN LIMITARSE A, LAS GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN O APTITUD PARA UN FIN ESPECÍFICO.

El recurso descrito en el primer párrafo de esta garantía constituirá el recurso único y exclusivo para el incumplimiento de la garantía y la compañía no será responsable por ningún daño incidental,

especial ni indirecto, lo cual incluye, sin limitación alguna, ganancias perdidas o el costo de reparar o cambiar otros bienes que se hayan dañado si este producto no funciona correctamente, otros

costos resultantes de costos de mano de obra, retrasos, vandalismo, negligencia, obstrucción por materia extraña, daños por condiciones adversas del agua, productos químicos o cualquier otra

circunstancia sobre la cual la compañía no tenga control. Esta garantía quedará anulada por maltrato, uso indebido, mal uso, instalación incorrecta o mantenimiento incorrecto o alteración del

producto.

Algunos estados no permiten limitaciones sobre la duración de las garantías implícitas y no permiten la exclusión ni la limitación de daños incidentales o consecuentes. Por lo tanto es posible que

las limitaciones anteriores no correspondan en su caso. Esta garantía limitada le proporciona derechos legales específicos, y también puede tener otros derechos que varíen de un estado a otro.

Deberá consultar las leyes estatales correspondientes para poder determinar sus derechos. SIEMPRE QUE SEA ACORDE CON LAS LEYES ESTATALES APLICABLES, LAS GARANTÍAS IMPLÍCITAS

QUE NO PUEDAN DESCONOCERSE, INCLUIDAS LAS GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN O APTITUD PARA UN FIN ESPECÍFICO, ESTÁN LIMITADAS EN SU DURACIÓN A UN AÑO

DESDE LA FECHA DEL ENVÍO ORIGINAL.

Una compañía de Watts Water Technologies

IS-2300 1411 EDP# 1910867 © 2014 Watts

EE.UU.: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canadá:: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Page 9

INSTRUCTIONS EN fRANÇAIS

Série 2300

Régulateur de pression d’eau

Tailles : 80 mm à 100 mm (3 po à 4 po)

!

AVERTISSEMENT

Lisez attentivement ce manuel avant d'utiliser cet équipement.

Négliger de lire et de suivre toutes les consignes de sécurité

et d'utilisation de l'information peut entraîner la mort, des

blessures graves ou des dégâts matériels, ou endommager

l'équipement.

Veuillez conserver ce manuel pour toute référence ultérieure.

!

AVERTISSEMENT

Les codes locaux du bâtiment ou de la plomberie peuvent

nécessiter des modifications aux renseignements

donnés. Vous êtes tenus de consulter des codes locaux

du bâtiment ou de la plomberie avant de commencer

l’installation. Si les renseignements donnés ci-dessous ne

sont pas cohérents avec les codes locaux du bâtiment ou

de la plomberie, les codes locaux doivent être respectés.

Ce produit doit être installé par un entrepreneur licencié

conformément aux codes et règlements locaux.

!

AVERTISSEMENT

Nécessité d'inspection périodique/maintenance: Ce produit

doit être testé périodiquement en conformité avec les codes

locaux, mais au moins une fois par an ou plus, comme les

conditions de service le justifient. Tous les produits doivent être

testés une fois que les opérations d'entretien ont été effectuées.

Des conditions d'admission corrosives et/ou des réglages ou des

réparations non autorisés peuvent rendre le produit inefficace

pour le service prévu. Un contrôle régulier et le nettoyage des

composants internes du produit permettent d'assurer la durée de

vie et le bon fonctionnement du produit.

COEFFICIENTS DE DÉBIT NOMINAL (C

Taille du robinet 3 4

C

v

32 52

v)

IS-2300

Series 2300

Instructions d’installation :

Le régulateur de pression 2300 actionné directement est conçu

pour le service d’eau en cul-de-sac à débit intermittent et à

changement rapide, comme pour les systèmes résidentiels.

Il est particulièrement efficace pour réguler le débit d’eau des

équipements à action rapide comme les compteurs de chasse.

La conception est autonome et aucune tuyauterie de régulation

n’est requise.

Il est préférable d’installer le régulateur de pression 2300 sur une

conduite horizontale avec la chambre d’aspiration orientée vers le

haut, pour que les sédiments n’aient pas tendance à se déposer

dans les orifices de commande.

CAPACITÉ (Conditions d’entrée maximales)

Extrémités du régulateur Barre de pression (Température)

❑ ANSI 250 à colerette 13,8 bars 200 psig 93 °C (200 °F)

AMPLITUDES DE VIVE EAU

❑ 207 à 552 kPa (30 à 80 psig)

TAILLE

PO MM

3 80 —

4 100 —

DIMENSIONS (mm/po) ET POIDS (kg/lb)

FACE À FACE AUTRES DIMENSIONS POIDS APPROX.

ANSI

NPT

E

ANSI

125

254 mm/

10 po

301 mm/

7

11

⁄8 po

ANSI

250

273 mm/

3

10

⁄4 po

318 mm/

121⁄2 po

A B C

150 mm/

6 po

168 mm/

65⁄8 po

552 mm/

213⁄4 po

672 mm/

265⁄8 po

229 mm/

9 po

286 mm/

111⁄4 po

ANSI

NPT

—

ANSI

125

49 kg/

108 lb

90 kg/

198 lb

ANSI

250

58 kg/

128 lb

102 kg/

225 lb

Page 10

Instructions d’installation et d’entretien

(Les chiffres entre parenthèses font référence au numéro d’article)

Principes de fonctionnement

Lorsque l’alimentation en eau est activée, le régulateur est en

position ouverte. L’eau qui s’écoule dans le système augmente la

pression de refoulement qui alimente les orifices de commande

sous la membrane (8). Lorsque la pression de la membrane (8)

s’approche de l’équilibre avec les forces exercées par le ressort

de réglage (5), le disque (20) se déplace pour laisser passer juste

assez d’eau pour maintenir la pression de consigne.

Installation

Enlever avec soin tout corps étranger du système de tuyauterie

d’entrée et installer le régulateur avec la flèche de débit pointant

dans la direction du débit. Il est préférable d’installer le régulateur

de pression 2300 sur une conduite horizontale avec la chambre

d’aspiration orientée vers le haut, pour que les sédiments n’aient

pas tendance à se déposer dans les orifices de commande.

Fournir une dérivation à trois valves pour faciliter l’inspection du

régulateur de pression sans interrompre le service. Pour éviter

des dommages causés par des corps étrangers, utiliser une

crépine en amont du régulateur.

Ce robinet doit être installé dans un endroit accessible avec un

dégagement suffisant pour le nettoyage, l’entretien et le réglage.

Fonctionnement

Au démarrage, procéder comme suit :

1. Ouvrir graduellement le robinet d’arrêt d’admission, jusqu’à

ce que le régulateur de pression prenne le contrôle, comme

indiqué par le manomètre de pression de consigne.

2. Tourner la vis de réglage (1) dans le sens horaire augmenter

la pression de consigne et dans le sens antihoraire pour la

diminuer.

MISE EN GARDE : Avant chaque réglage, il est recommandé

d’utiliser un manomètre pour vérifier l’exactitude du réglage de

pression. Ne pas serrer à bloc la vis de réglage au fond de la

cage à ressort.

Dépannage

Débit inadéquat de la pression de consigne :

1. Vérifier que la pression initiale est celle prévue pour la conduite

de pression et qu’elle est appliquée au niveau du robinet

d’admission.

Accumulation de réduction de pression :

1. Des corps étrangers peuvent être logés entre le disque (20)

et la bague de siège du corps (19). Enlever la bride pleine (24)

pour inspecter.

2. La membrane (8) peut être brisée. Enlever la chambre

d’aspiration (4) pour inspecter.

3. L’anneau de scellement (16) pourrait être endommagé.

Consulter les instructions de démontage ci-dessous pour

effectuer un remplacement.

Démontage

Pour changer ou inspecter le disque de clapet ou l’anneau

de scellement :

1. Enlever la bride pleine (24).

2. Enlever les carrés de manœuvre (22). Empêcher la

tige de tourner en insérant un tournevis dans la fente à

l’extrémité de la tige.

3. Le support d’anneau (21) tombera. Déposer avec

précaution le piston d’équilibrage (18) pour éviter

d’endommager l’anneau de scellement (16), car il est

extrait à travers la bague de siège du corps (19).

Pour examiner la membrane ou la tige :

1. Éliminer la compression du ressort en tournant la vis de

réglage (1) dans le sens antihoraire.

2. Enlever les boulons de la membrane (9) et soulever la

chambre d’aspiration (4).

3. Soulever la plaque de pression (7) pour retirer la

membrane et la tige du robinet.

4. Pour examiner la membrane, démonter l’écrou

d’accouplement (6) et soulever la plaque de pression (7).

Réglage du robinet

Si le raccord fileté entre le raccord de tige (11) et la tige (14)

est endommagé, procéder comme suit :

1. Insérer la tige (A) et maintenir le disque sur la bague de

siège du corps en position fermée, comme illustré.

2. Visser le raccord de tige (B) sur la tige jusqu’à ce que le

réglage de la course T soit atteint.

3. Enlever la tige (A) et verrouiller le réglage en perçant un

trou et en insérant une goupille (C).

REMARQUE : Il est recommandé d’effectuer une

inspection annuelle des composants en caoutchouc

et des pièces de contrôle pour assurer un

fonctionnement adéquat.

T DE DIMENSION

Fonctionnement irrégulier

Un démontage complet est recommandé.

1. Rechercher les orifices de commande obstrués raccordant la

sortie du corps avec la chambre de la membrane.

2. Rechercher des dépôts qui causent une adhérence de

l’anneau de scellement (16) ou de la tige (14) dans leurs

guides respectifs.

Taille du robinet

T de dimension 4,76 mm (3⁄16 po) 6,75 mm (17⁄64 po)

80 mm (3 po) 100 mm (4 po)

Page 11

▼

C

▼

B

Plaque du numéro de série

▼

Lorsque des pièces sont commandées, il est essentiel d’indiquer le

type de robinet, ses dimensions, son service et son numéro de série.

Sélectionner la pièce par numéro d’article, mais commander par

numéro de pièce.

Indiquer le numéro de pièce complet lors de la commande.

E

▼

A

▼

Pièces standard

Numéro

d’article Nom de la pièce Remarques Matériau

1 Vis de réglage Acier

▼

2 Contre-écrou de vis de

réglage

3 Bouton-ressort Fonte

4 Chambre d’aspiration Fonte

5 Ressort de réglage (69 à

275 kPa/10 à 40 psi)

Ressort de réglage (207 à

552 kPa/30 à 80 psi)

6 Écrou d’accouplement Remarque 2 Acier

7 Plaque de pression Remarque 2 Fonte

8 Membrane Remarque 1

et 2

9 Boulons de membrane Acier

10 Base Fonte

11 Raccord de tige Remarque 2 Acier inoxydable

12 Écrou de membrane Acier

13 Goupille Remarque 2 Acier

14 Tige Remarque 2 Acier inoxydable

15 Corps - vis ANSI NPT Fonte

Corps - bride ANSI 125 Fonte

Corps - ANSI 250 Fonte

16 Anneau de scellement Remarque 1

et 2

17 Bague de guidage Acier inoxydable

18 Piston équilibré Acier inoxydable

Ensemble de piston

équilibré

19 Bague de siège du corps Acier inoxydable

20 Disque de clapet Remarque 1

et 2

21 Support de disque de clapet Remarque 2 Acier inoxydable

22 Carré de manœuvre Remarque 2 Acier

23 Joint de bride pleine Remarque 1

et 2

24 Bride pleine Fonte

25 Écrou de bride pleine Acier

26 Goujons de bride pleine Alliage d’acier

27 Étiquette de plage (69 à

275 kPa/10 à 40 psi)

Étiquette de plage (207 à

552 kPa/30 à 80 psi)

Acier

Acier

Acier

Hycar

Hycar

Acier inoxydable

Hycar

Sans amiante

au carbone

Aluminium

Aluminium

REMARQUES :

1 Pièces de rechange de recommandées

2 Ces pièces sont fournies pour la réparation

Page 12

Nº de pièce selon la taille du robinet

Pièce 80 mm (3 po) 100 mm (4 po)

Vis de réglage 05-04867-00 05-04869-00

Contre-écrou de vis de réglage 05-02945-00 05-02946-00

Bouton-ressort 05-01046-00 05-01047-00

Chambre d’aspiration 04-01414-00 04-01417-00

Ressort de réglage (69 à 275 kPa/10 à 40 psi) 05-05115-01 05-05155-00

Ressort de réglage (207 à 552 kPa/30 à 80 psi) 05-05148-00 05-05150-00

Écrou d’accouplement 05-03019-00 05-03020-00

Plaque de pression 04-03647-00 04-03649-00

Membrane 05-01612-00 05-01614-00

Boulons de membrane 05-04777-00 05-04782-00

Base 04-00459-00 04-00461-00

Raccord de tige 04-09487-00 04-01496-01

Écrou de membrane 05-02875-00 05-02877-00

Goupille 05-03865-00 05-03867-00

Tige 04-05343-00 04-05346-00

Corps - vis ANSI NPT – –

Corps - bride ANSI 125 04-00918-00 04-00920-00

Corps - bride ANSI 250 04-00928-01 04-00930-00

Anneau de scellement 05-04038-00 05-04045-00

Bague de guidage 04-04407-00 04-04411-01

Piston équilibré 04-09481-00 –

Ensemble de piston équilibré – 22445

Bague de siège du corps 04-04177-01 04-04180-02

Disque de clapet 05-01719-00 05-01721-00

Support de disque de clapet 04-09493-00 04-09494-00

Carré de manœuvre 05-03017-00 05-03018-00

Joint de bride pleine 05-02367-00 05-02369-00

Bride pleine 04-02183-00 04-02186-00

Écrou de bride pleine 05-02862-00 05-02860-00

Goujons de bride pleine 04-05448-00 04-10119-00

Étiquette de plage (69 à 275 kPa/10 à 40 psi) 05-06221-00 05-06221-00

Étiquette de plage (207 à 552 kPa/30 à 80 psi) 05-06222-00 05-06222-00

Trousses de réparation

Pièce 80 mm (3 po) 100 mm (4 po)

Trousse de réparation 33167 33168

Garantie limitée : Watts Regulator Co. (la « Société ») garantit chaque produit contre tout défaut de matériau et de fabrication lors d’une utilisation normale, et ce pour une période de un (1) an à partir de la date de l’expédition d’origine. Si

une telle défaillance devait se produire au cours de la période sous garantie, la Société aura à sa discrétion l’alternative

suivante : le remplacement ou la remise en état du produit, sans frais pour le demandeur.

LA PRÉSENTE GARANTIE EXPRESSE EST LA SEULE ET UNIQUE GARANTIE, RELATIVE AU PRODUIT, FOURNIE PAR

LA SOCIÉTÉ. LA SOCIÉTÉ NE FORMULE AUCUNE AUTRE GARANTIE, EXPRESSE OU IMPLICITE. LA SOCIÉTÉ REJETTE

AUSSI FORMELLEMENT PAR LA PRÉSENTE TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, Y COMPRIS (SANS

S’Y LIMITER) LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE PARTICULIER.

Le dédommagement précisé dans le premier paragraphe de cette garantie constitue la seule et unique alternative en cas de service demandé sous cette garantie. La Société ne pourra être tenue

responsable de dommages spéciaux ou indirects, incluant, sans s’y limiter : pertes de profit, coûts de réparation ou de remplacement des autres biens ayant été endommagés si ce produit ne

fonctionne pas correctement, autres coûts afférents aux frais de main d’œuvre, de retards, de vandalisme, de négligence, d’engorgement causés par des corps étrangers, dommages causés par des

propriétés de l’eau défavorables, des produits chimiques, ou toute autre circonstance indépendante de la volonté de la Société. Cette garantie est nulle et non avenue en cas de mésusage du produit,

d’une installation ou d’un entretien inappropriés, ou de modification du produit.

Certaines juridictions ne permettent pas les limitations de durée de la garantie implicite, tandis que d’autres ne permettent pas l’exclusion ou la limitation des dommages indirects. Par conséquent,

ces restrictions pourraient ne pas s’appliquer à votre cas. Cette garantie limitée vous confère des droits spécifiques, reconnus par la loi ; vous pourriez également avoir d’autres droits, lesquels

varient selon la loi en vigueur. Vous devez consulter les lois applicables de votre État pour déterminer vos droits. LA DURÉE DE TOUTE GARANTIE IMPLICITE PRÉVUE PAR LA LOI EN APPLICATION

ET DEVANT DONC ÊTRE ASSUMÉE, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE PARTICULIER, SERA LIMITÉE À UN AN À PARTIR DE LA

DATE DE L’EXPÉDITION D’ORIGINE.

Une entreprise de Watts Water Technologies

IS-2300 1411 EDP# 1910867 © 2014 Watts

États-Unis : Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

AVERTISSEMENT: Ce produit contient des produits chimiques

reconnus par l’État de Californie comme étant cancérigènes et

pouvant provoquer des anomalies congénitales ou affecter la

capacité de reproduction.

Pour plus d'informations : www.watts.com/prop65

Canada : Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Loading...

Loading...