Page 1

For Steam, Liquid or Air Applications

ES-152A

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

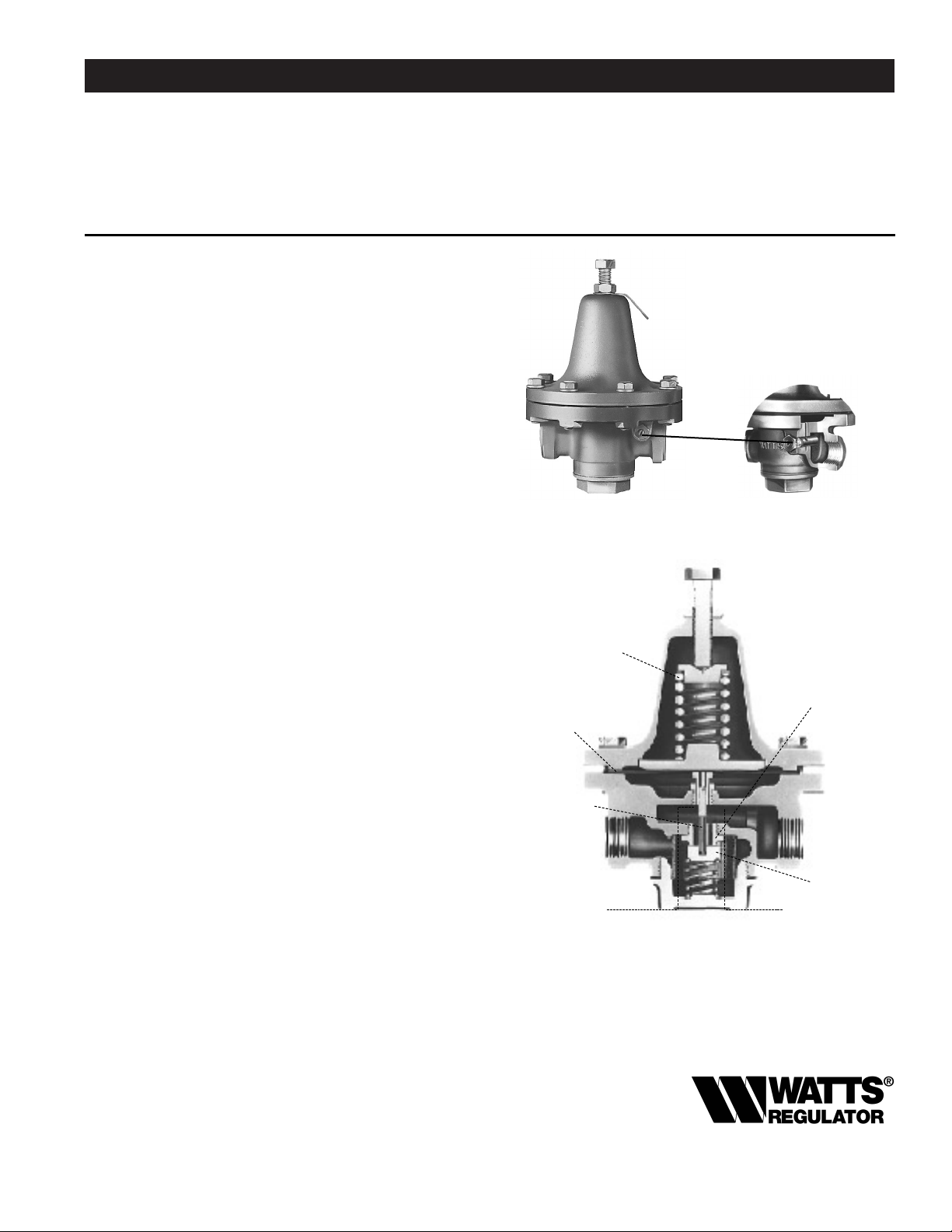

Series 152A

Stainless Steel

Strainer Screen

Replaceable

Stainless Steel

Seat and Valve

Disc.**

Stainless Steel

Disc and Stem

Guide (This

stainless steel

trim is standardly furnished at

no extra cost)

Laminated Metal

Diaphragm

Adjusting Springs

for reduced pressure

ranges between 3

and 140 psi (.21 and

9.8 bars)

Series 152A

Process Steam Pressure

Regulators

Sizes 1⁄

2" – 2" (15 - 50mm)

Series 152A Process Steam Pressure Regulators are designed to

offer highly sensitive response to reduced pressure changes and

maintain fullest possible volume without appreciable reduced

pressure drop. These regulators are ideal for use on applications

such as oil lines, testing fixtures, autoclaves, steam tables, steam

irons, single radiators, vulcanizers, sterilizers and process lines. The

series 152A features a sensitivity adjuster to eliminate any vibrating

condition that may arise from critical flow requirements.

Features

• Iron body construction

• Serviceable in line

• Standard sensitivity adjuster

Models

152A – Iron body for pressures up to 200psi (14 bars)

152AT – Tight seating for dead end and liquid service. Utilizes

Teflon

®

valve disc, maximum operating temperatures are 300°F

(204°C) at 300psi (21 bars) and 400°F (204°C) at 200psi (14 bars)

For information on

1

⁄2

" – 1" stainless steel construction, see literature

ES-152SS.

Specifications

Valve shall be manufactured out of iron and have a maximum working pressure of up to 200psi. Valve shall feature a sensitivity adjuster

to eliminate vibrating conditions. Valves shall be serviceable in line

and have stainless steel trim and strainer. Valve shall be a Watts

Regulator Company Series 152A.

Materials

Body: Iron

Trim: Stainless Steel

Strainer: Stainless Steel

Diaphragm: Laminated Metal

Seat: Replaceable Stainless Steel

Disc: Replaceable Stainless Steel

Pressure – Temperature

152A Maximum Working Pressure: 200psi (14 bars)

152AT – Maximum Temperature: 300°F (149°C)

Maximum Working Pressure: 300psi (21 bars), and

Maximum Temperature: 400°F (204°C)

Maximum Working Pressure: 200psi (14 bars)

** When utilizing a Teflon®valve disc in the 152AT, the maximum

operating temperatures are 300°F at 300psi (149°C at 21 bars)

and 400°F at 200psi (204°C at 14 bars).

A Plus Feature

Sensitivity Adjuster

Basic Design Feature

Teflon®is a registered tradename of E.I. duPont deNemours Co., Inc.

Page 2

ES-152A 0403 © Watts Regulator Co., 1996 Printed in U.S.A.

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

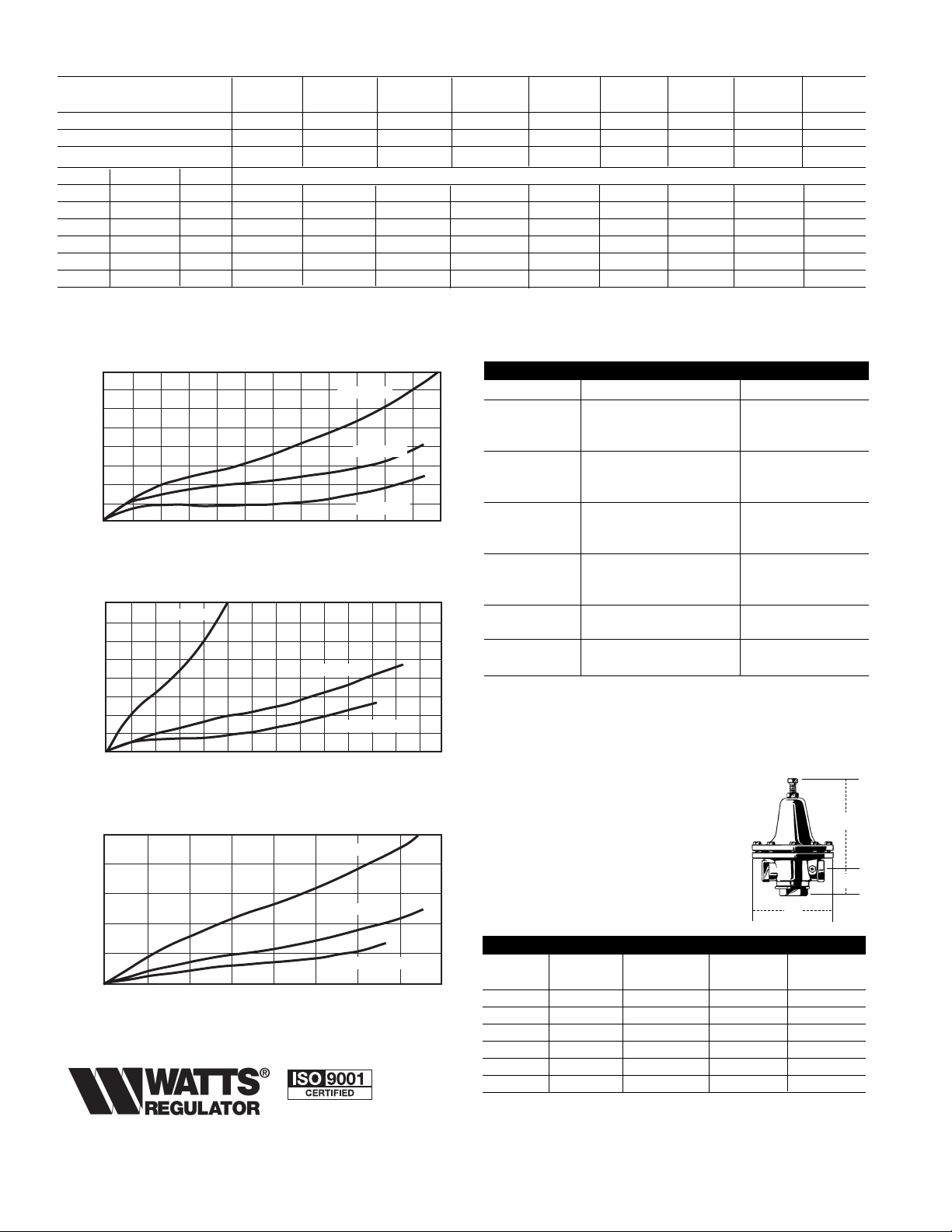

A

D

C

Flow

Flow

Flow

Pressure Drop

Pressure Drop

Pressure Drop

Series 152A

Adjusting Spring Range Chart

SIZE *ADJUSTABLE RANGES SPRING AND MODEL NO.

in. mm psi bars

1

⁄

2

15 3 – 15 .21 – 1.05 145

1

⁄

2

15 10 – 50 .70 – 3.51 146

1

⁄

2

15 30 – 140 2.11 – 9.84 141

3

⁄

4

20 3 – 15 .21 – 1.05 145

3

⁄

4

20 10 – 50 .70 – 3.51 146

3

⁄

4

20 30 – 140 2.11 – 9.84 141

1253 – 15 .21 – 1.05 146

12510 – 30 .70 – 2.11 128

12530 – 140 2.11 – 9.84 142

11⁄

4

32 3 – 15 .21 – 1.05 146

1

1

⁄

4

32 10 – 30 .70 – 2.11 128

1

1

⁄

4

32 30 – 140 2.11 – 9.84 142

11⁄

2

40 5 – 40 .35 – 2.81 276

1

1

⁄

2

40 30 – 100 2.11 – 7.03 299

2505 – 40 .35 – 2.81 276

25030 – 100 2.11 – 7.03 299

*The minimum reduced pressure ranges shown are recommended

only when very sensitive regulation service is needed for specific

requirements. However, all valves may be adjusted below the working

range minimums shown for lower regulation or complete shut off.

SIZE (DN) DIMENSIONS WEIGHT

AC D

in. mm in. mm in. mm in. mm lbs. kg.

1

⁄215 6 152 7 178 115⁄1649 11 4.99

3

⁄420 6 152 7 178 115⁄1649 11 4.99

12571⁄

2

191 7

1

⁄

2

191 2

3

⁄

16

56 20 9.07

11⁄432 71⁄2191 71⁄2191 23⁄

16

56 20 9.07

11⁄240 9 229 111⁄4286 23⁄470 40 18.14

2509229 111⁄

4

286 2

3

⁄

4

70 40 18.14

bars psi

1.4 20

1.0 15

0.7 10

0.3 5

00

24681012 gpm

7.6 15.2 22.8 30.4 38 45.6 lpm

bars psi

1.4 20

1.0 15

0.7 10

0.3 5

00

bars psi

1.7 25

1.4 20

1.0 15

0.7 10

0.3 5

00

510152025303540gpm

19 38 57 76 95 114 133 152 lpm

5101520253035gpm

19 38 57 76 95 114 133 lpm

Quick Reference Capacity Chart For Average Conditions

From From From From From From From From From

psi bar psi bar psi bar psi bar psi bar psi bar psi bar psi bar psi bar

Initial Pressure 50 3.52 75 5.27 100 7.03 125 8.79 150 10.55 175 12.3 200 14.06 225 15.82 250 17.58

Up To Up To Up To Up To Up To Up To Up To Up To Up To

Reduced Pressure 20 1.41 35 2.46 50 3.52 60 4.22 70 4.92 80 5.62 90 6.33 100 7.03 125 8.79

in. mm *Maximum Capacities in Lbs. of Steam Per Hour

152A

1

⁄2"1580111 143 175 205 237 270 299 332

152A

3

⁄

4

"20285 394 506 620 726 841 956 1060 1178

152A 1" 25 402 557 715 875 1025 1186 1349 1497 1663

152A 11⁄

4

"32442 613 786 962 1127 1305 1484 1646 1830

152A 11⁄

2

"40665 870 1120 1355 1600 1950 2230 2460 2725

152A 2" 50 765 1000 1285 1490 1840 2242 2564 2829 3134

*1 Lb. Steam Equals 970 BTU Per Hour

Capacity

152A Size 1⁄2" (15mm)

152A Size 3⁄4" (20mm)

152A Size 1" (25mm)

Range 30 - 140

Range 10 - 50

Range 3 - 15

Range 30 - 140

Range 10 - 50

Range 3 - 15

Range 30 - 140

Range 10 - 50

Range 3 - 15

Dimensions — Weights

Loading...

Loading...