Page 1

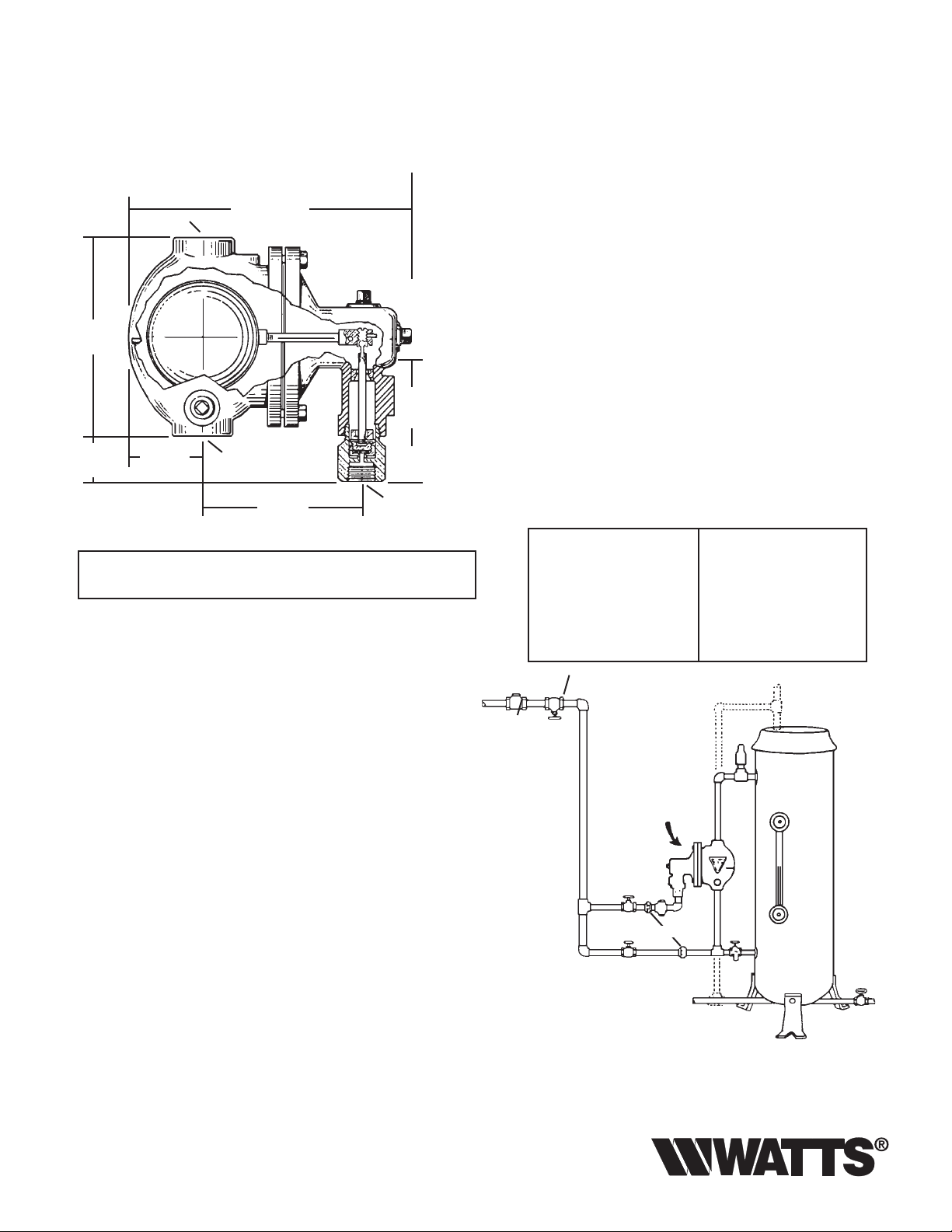

Watts No. 142

Process Boiler Water Feeder

(With Direct Feed Through Float Chamber)

▲

▲

1" N.P.T.

87⁄8" (225mm)

7

⁄8"

4

(124mm)

▲

2

(64mm)

1

⁄2" N.P.T.

1

⁄2"

6"

(152mm)

13⁄8"

(35mm)

1" N.P.T.

3

2

⁄8"

(60mm)

IS-142

Without Strainer- - - - - - - - - - - Type 142

With Strainer- - - - - - - - - - - - - Type 142S

For use on pressing machines and other small process boilers when feed through fl oat chamber is permissible.

Water is fed automatically as needed to maintain the correct

operating level in the boiler.

The entire unit is simple in design and operation, easy to

install and inexpensive to operator.

The simple construction of the feed valve permits quick and

easy cleaning should it become fouled by dirt in the water

supply.

Specifi cations

Connections: Water Feed - 1⁄2" (13mm)

N.P.T. Female

Float Chamber - 1" (25mm)

N.P.T. Female

Pressure: Steam - Max. 100 psi (6.9 bars)

Water - Max. 125 psi (8.6 bars)

Water Pressure must be at least

10 psi (69 kPa) higher than steam

pressure.

Capacity

Diff. between steam Boiler Horse Power

“ATTENTION INSTALLER: After installation, please leave this

Instruction Sheet for occupant’s information.”

and water pressure.

10 8

20 13

30 16

Installation Instructions

Install feeder as illustrated. If boiler tappings for equalizing pipes

“A” and “B” are not available, connect either one or both as

shown by dotted lines. Install with “water line” mark on fl oat

chamber on a level with the middle try-cock, or about halfway

up the gauge glass. Connect water supply line “C”. If a strainer

is used, install it in this line.

Install by-pass “D” so that boiler can be fi lled by hand, if necessary.

All valves should be tight-closing and of good quality. Leaky

valves will fl ood boiler. Blow down fl oat chamber at least once

a week by opening valve “F” and letting water run for a few

minutes.

A shutoff and check valve must be installed in the water supply

line “E”.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material

and workmanship under normal usage for a period of one year from the date of original shipment. In the event of such

defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY

WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THE

COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach

of warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including

without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does

not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign

material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has

no control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper

maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This

Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You

should consult applicable state laws to determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE

LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM

THE DATE OF ORIGINAL SHIPMENT.

40 18

50 19

Check Valve Shut-Off

E

Dotted lines indicate

method of installing

when tappings in boiler

shown in illustration are

not available

Watts type 142

C

D

union

Boiler

A

B

F

Page 2

Watts No. 144

Process Boiler Water Feeder

(With External Water Feed Connections)

1" N.P.T.

6"

(152mm)

3

2

13⁄8"

(35mm)

⁄8"

(60mm)

Installation Instructions

Install feeder as illustrated. If boiler tappings for equalizing pipes “A”

and “B” are not available, connect either one or both as shown by

dotted lines.

Install with “water line” mark on fl oat chamber on a level with the

middle try-cock, or about halfway up the gauge glass.

Connect water supply line “C”. If a strainer is used, install it in this

line. Connect feed line “D” from valve to bottom of boiler.

Install by-pass “E” so that boiler can be fi lled by hand if necessary.

All valves should be tight-closing and of good quality. Leaky valves

will fl ood boiler.

Blow down fl oat chamber at least once a week by opening valve “F”

and letting water run for a few minutes.

A shutoff and check valve must be installed in the water supply line

“G”.

▲

▲

1" N.P.T.

87⁄8" (225mm)

7

⁄8"

4

(124mm)

▲

▲

2

(64mm)

1

⁄2" N.P.T.

1

⁄2" NPT

1

⁄2"

Without Strainer- - - - - - - - - - - Type 144

With Strainer- - - - - - - - - - - - - Type 144S

For pressing machine and other small process boilers.

Water is automatically supplied to the boiler as needed

to maintain boiler water at the correct working level.

Feed valve is fl oat-operated and simply constructed.

Can be easily cleaned if fouled by dirt in the water supply.

Water is fed to the boiler through an independent connection to the bottom of the boiler.

Specifi cations

CONNECTIONS: Water Feed - 1⁄2" (13mm)

PRESSURE: Steam - Max. 100 psi (6.9 bars)

N.P.T. Female

Float Chamber - 1" (25MM)

N.P.T. Female

Water - Max. 125 psi (8.6 bars)

Water Pressure must be at least

10 psi (69 kPa) higher than steam

pressure.

Capacity

Diff. between steam Boiler Horse Power

and water pressure.

10 8

20 13

30 16

40 18

50 19

Check Valve Shut-Off

Dotted lines indicate

method of installing

G

when tappings in boiler

shown in illustration are

not available

Watts type 144

Boiler

union

D

B

C

F

Valve

By Pass

E

Water Safety & Flow Control Products

Union

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IS-142 0829 EDP# 1910214 © Watts, 2008

Loading...

Loading...