Page 1

Technical Bulletin

3

4

1

2

5

6

CLOSES VALVE

OPENS VALVE

FLOW

ES-ACV-116FM

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

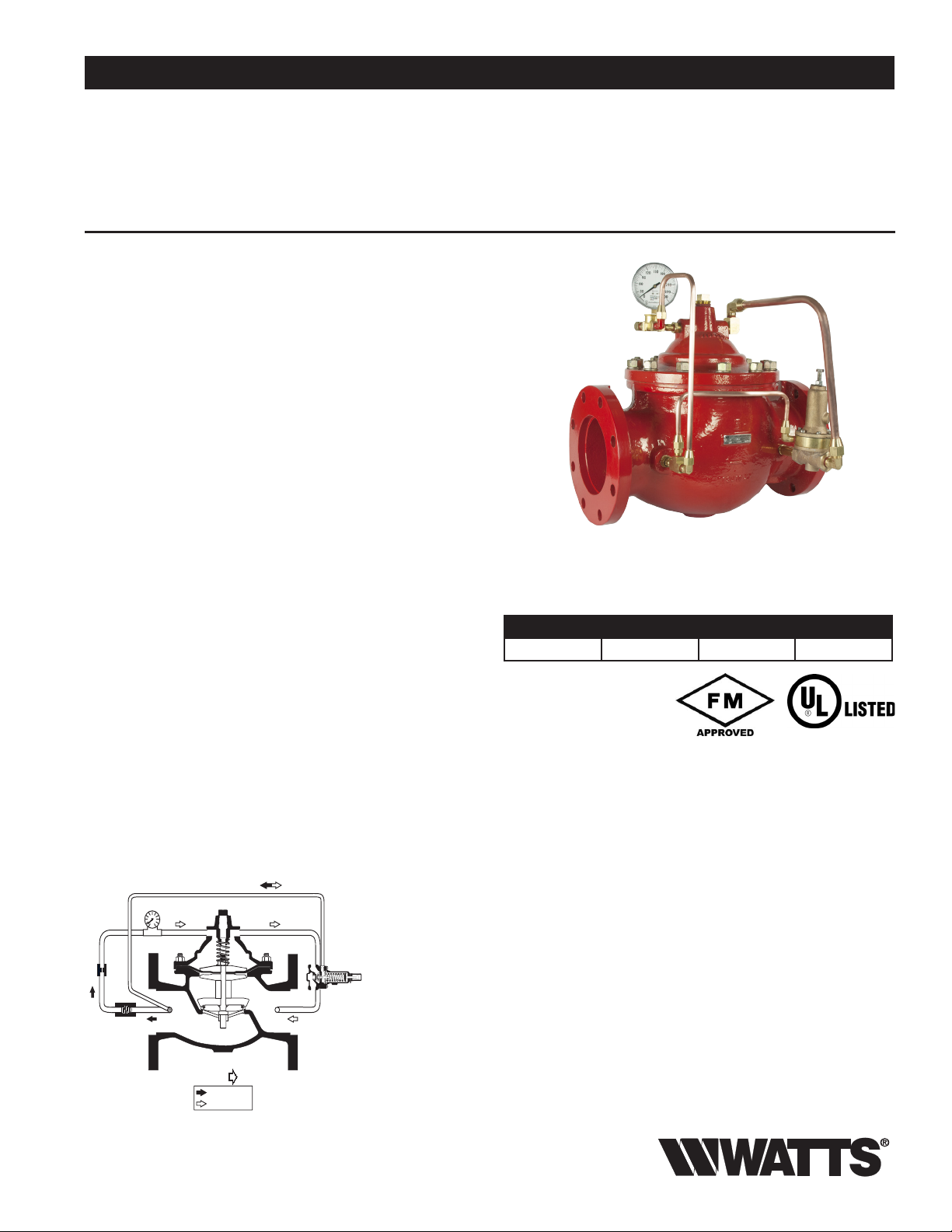

Series 116FM Globe

Fire Pump Relief Valve

Function

Automatically maintains a constant pressure in the fire protection

system by relieving excess pressure.

Features

The WATTS ACV 116FM (Globe) Relief Valve meets all requirements for UL listed, FM Approved fire protection service. The

design and features incorporated in the WATTS ACV Valves

assure accurate control, dependable performance, and long life.

Models

Model 116FM: Globe Pattern Single Chamber Relief Valve

Also Available:

Model 1116FM: Angle Pattern Single Chamber Relief Valve

Materials

Body & Cover: Ductile Iron ASTM A536

Seat (Trim): Stainless Steel CF8M - Xylan Coated

Internals: Stainless Steel S30400 or Ductile Iron

ASTM A536 Fusion Bonded Epoxy

Coated

Stem: Stainless Steel S30400 - Xylan Coated

Spring: Stainless Steel AISI S30200

Elastomers: Buna-N

Control Tubing: Copper

Fittings: Brass

Pressure Relief

Control Body:

Bronze

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

116FM Globe

Valve Sizes Available in Angle and Globe

3” 4” 6” 8”

UL UL/FM UL/FM UL/FM

Sizes / Approvals

20 - 175 PSI Relief Service

100-300 PSI Relief Service

ANSI End Connections 150, 300, and 300 x 150

Operation

The WATTS ACV Model 116FM PRESSURE RELIEF VALVE

is controlled by a Pressure Relief Control. The Pressure Relief

Control is normally closed, held closed by an adjustable spring

setting to maintain a constant inlet pressure to the main valve.

When upstream pressure increases above the relief set-point,

the Relief Control throttles open, increasing flow through the

control tubing. Pressure is decreased in the main valve cover

chamber, causing the main valve to modulate towards open,

relieving excess upstream pressure. The desired system pressure is maintained.

Components

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

1 - Main Valve

2 - PV20C Relief Control

3 - Pressure Gauge

4 - Fixed Orifice

5 - Check Valve

6 - Flo-Clean Strainer

As the upstream pressure decreases below the relief set-point,

the Relief Control throttles closed, restricting flow through the

control tubing. Pressure is increased in the main valve cover

chamber, causing the main valve to modulate towards closed,

maintaining the desired upstream pressure. Should upstream

pressure drop below and remain below the set-point, the main

valve closes drip tight.

Page 2

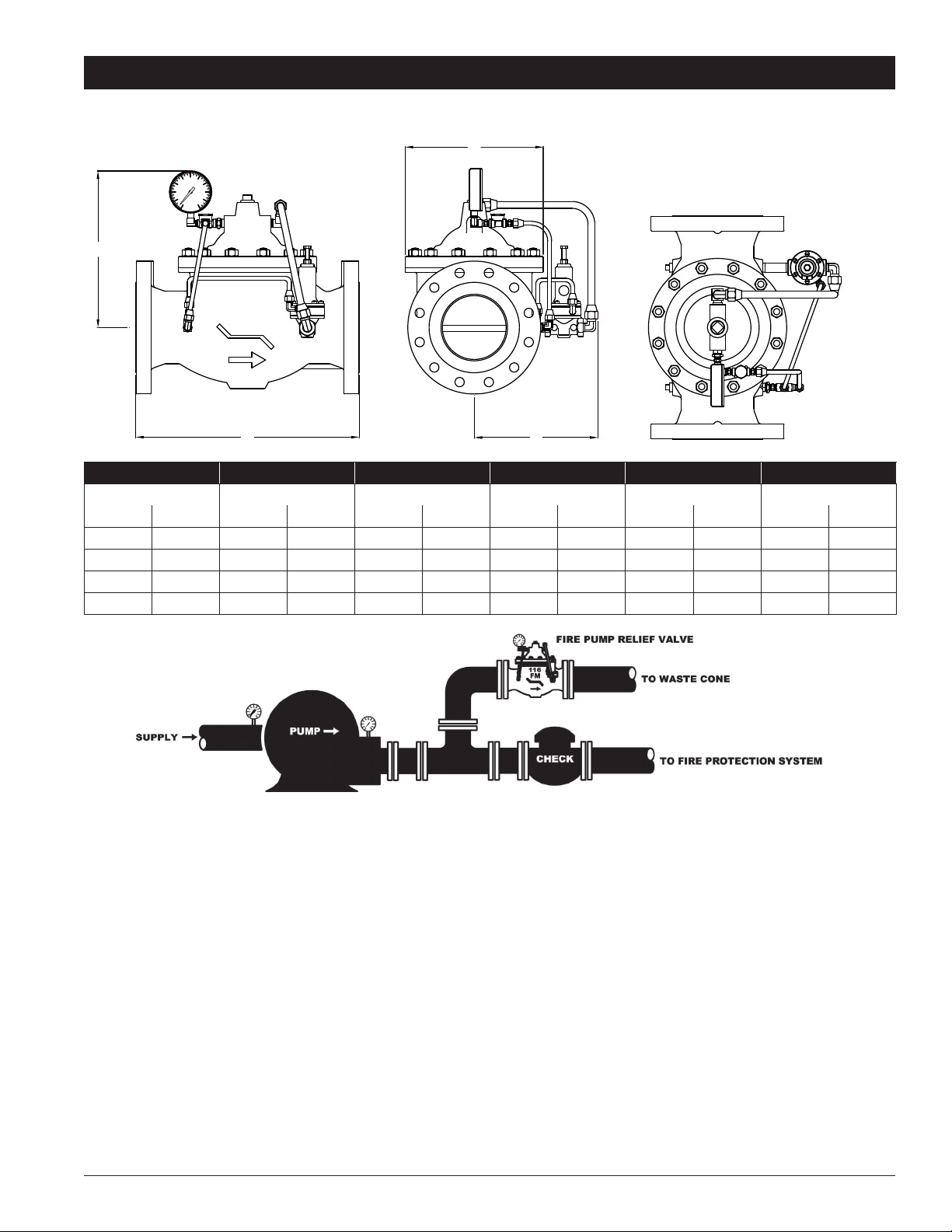

VALVE SIZE

INCH - MM

3 80

6 150

A

150

300

B

C

D

7.875

13.2221.00

12.00

20.00

13.25

10.125

15.00

9.75

11.50

4 100

8 200

9.97

16.00

25.38

15.63

26.38

15.00

10.50

18.50

10.00

13.00

116FM (Globe) - Pressure Relief Valve

DIMENSIONS - ACV 116FM (Globe)

150

120

180

90

210

60

240

270

30

0

300

B

INLET

OUTLET

C

X

WATTS

ACV

XX

A

D

Valve Size 150 Outlet 300 Outlet

A A B C D

in. mm in. mm in. mm in. mm in. mm in. mm

3 80 12 305 131⁄

4 100 15 381 155⁄

4

8

6 150 20 508 21 533 15 381 131⁄

8 800 253⁄

Installation and Start-up

Start-up of an Automatic Control Valve requires following proper procedures. Time must be allowed for the valve to react

to adjustments and the system to stabilize. The objective is to bring the valve into service in a controlled manner to protect

the system from damaging overpressure.

8

645 263⁄

8

337 101⁄

397 101⁄

670 181⁄

8

2

2

257 77⁄

267 915⁄

8

16

4

470 16 406 13 330

200 93⁄

4

248

252 10 254

337 111⁄

2

292

NOTICE: Avoid mounting valves in a vertical discharge postion (valve stem horizontal or cover pointed sideways.) Valves mounted in

this position may not perform as tested and approved.

• Clear the line of slag and other debris.

• Install the valve so that the FLOW ARROW marked on the valve body matches the flow through the line.

• Install pressure gauge (supplied) in the fitting on valve tubing.

1. Turn the Relief Control adjustment screw counterclockwise (out). This lowers the initial relief set-point, allowing the set-point to be

increased to the desired setting.

2. Loosen a tube fitting at a high point on the valve. This allows the cover to vent trapped air during initial filling of the valve.

3. Start the pump to supply fluid/pressure to the valve.

4. Tighten the tubing when all air is vented from the cover as indicated by continual flow of fluid.

NOTICE: THE RELIEF SET-POINT SHOULD BE LOWER THAN DESIRED AT THIS TIME.

5. Turn the Relief Control adjustment screw clockwise (in) slowly, allowing time for the pressure to gradually increase to the desired

set-point.

USA: • Tel. (713) 943-0688 • (713) 944-9445 • www.watts.com

Page 3

116FM (Globe) - Pressure Relief Valve

Cover

Cover bearing

Cover chamber

Spring

Diaphragm

Stem

Spacer

Retainer

Quad seal

retainer plate

Seat

Seat O-ring

Body

F100 Globe

Maintenance

The basic valve normally requires a minimum of maintenance, due

to a packless construction and no required lubrication. However,

it is suggested that a periodic inspection schedule be established

to determine how the fluid is affecting the efficiency of the valve.

Fluid velocity as well as any substance entrained in the fluid, such

as dissolved minerals and/or suspended particles, vary between

installations. In areas subject to freezing, remove the body cover

drain plugs for winter drain-down.

NOTICE: The following method will determine if there is a damaged diaphragm without removing the valve cover. Put pressure into the valve and close all control lines to the valve cover

chamber.Remove a fitting on the valve cover. If there is a continuous flow out of the cover chamber through this opening, the

diaphragm is damaged or the diaphragm assembly on the stem

is loose. CAUTION: The valve will be wide open during this procedure.Omit if the fully open valve could result in system damage.

Stem nut

Diaphragm

washer

Stem O-ring

Quad seal

Drain plug

(alum steel valve only)

Disassembly/Assembly

Inspection or maintenance can be accomplished without removal

from the line.

To replace the diaphragm and/or the quad ring:

1. Remove fitting nuts where necessary to release the valve

cover from the controls or control lines.

2. Remove the cover and spring.

3. Remove the diaphragm and stem assembly, taking care not

to damage the diaphragm when removing over studs.

4. With the assembly removed, examine the diaphragm and

quad ring for wear or damage. Do not disassemble unless

replacement is indicated.

5. To replace the diaphragm, quad ring and/or stem O-ring,

hold the stem in a vise or with wrench on the flats at the

bottom end of the stem. Remove the nuts.

6. Remove the diaphragm washer, diaphragm, etc., in the

proper sequence.

7. Check all surfaces, seat, O-ring grooves and diaphragm

clamping surfaces for damage and/or foreign particles.

8. To reassemble, reverse the order of disassembly. Tighten

stem nuts securely to ensure proper clamping of the diaphragm. To assure positive and even clamping of the diaphragm between the body and the cover, gradually tighten

the cover nuts diametrically opposite each other.

USA: • Tel. (713) 943-0688 • (713) 944-9445 • www.watts.com

Page 4

116FM (Globe) - Pressure Relief Valve

Maximum continuous flow based on velocity of 20 ft. per second.

M

The C

The fac

C

Q (Flow) = C

V

∆ P ∆ P (Pressure Drop) = (Q/C

V

)2

Flow Data - F100 (Globe)

3 4 6 8

Flow Rate GPM (Water) 460 800 1800 3100

Maximum Intermittent

Flow Rate GPM (Water)

Cv Factor GPM (Globe) 125 220 460 775

Cv Factor GPM (Angle) 170 280 650 1100

aximum intermittent flow based on velocity of 25 ft. per second.

Factor of a value is the flow rate in US GPM at 60° F that will cause a 1 psi drop in pressure.

V

tors stated are based upon a fully open valve.

V factor ca n be used in the following equations to determine Flow (Q) and Pressure Drop (∆ P):

Headloss

570 1000 2300 3900

100

80

60

40

20

10

8

6

Pressure Drop (psi)

4

3

2

2 3 4 5 6 789 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000

Globe

Flow Rate - Gallons per Minute (Water)

4

3

6

8

Valve Cover Chamber Capacity

Valve Size - Inches 3 4 6 8

fluid oz. 10 22 70

U.S. Gal 1-1/4

Valve Travel

Valve Size - Inches 3 4 6 8

Travel - Inches 3/4 1 1-1/2 2

A Watts Water Technologies Company

ES-ACV-116FM 1308 © 2011 Watts

USA:•Tel.(713)943-0688•(713)944-9445•www.watts.com

Loading...

Loading...