Page 1

Installation, Maintenance, & Repair

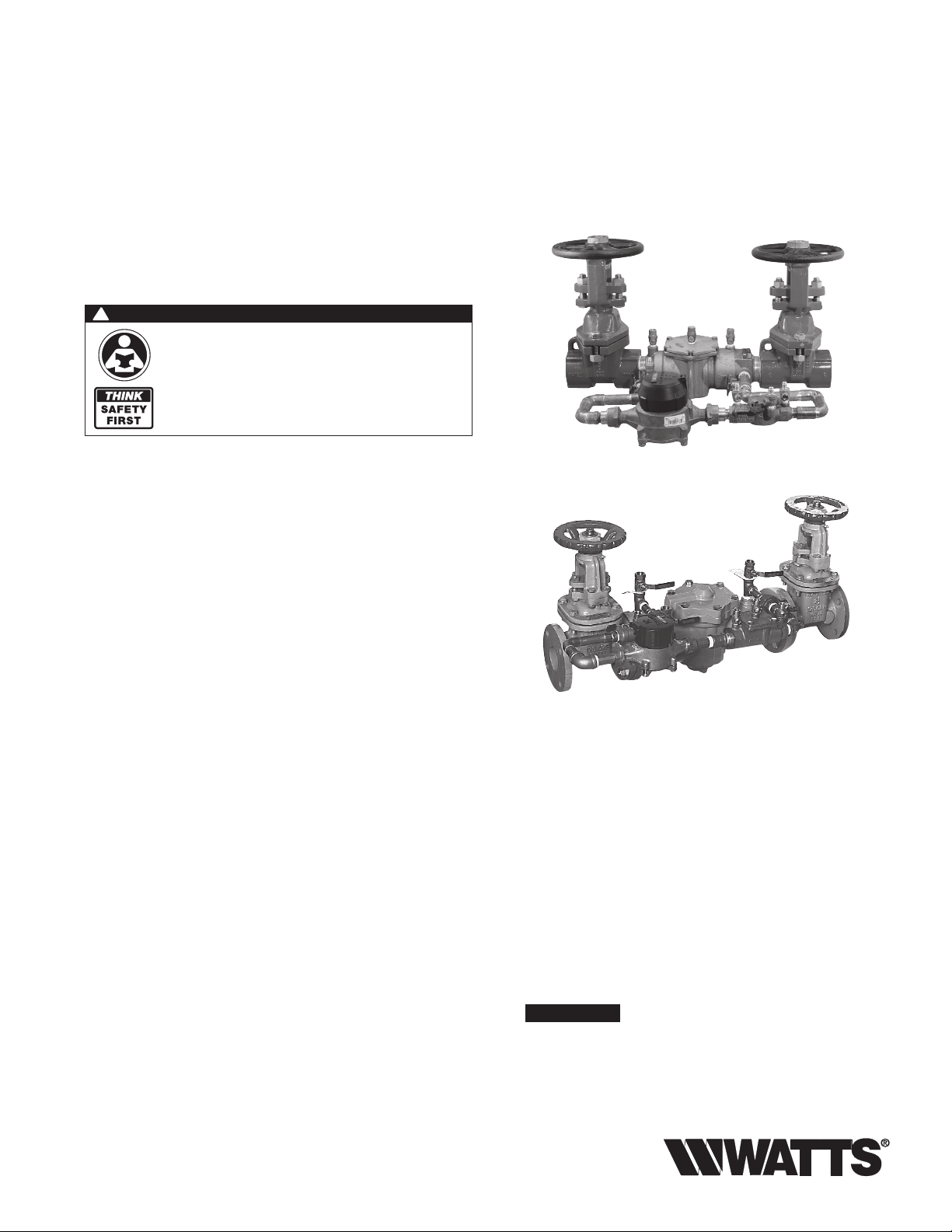

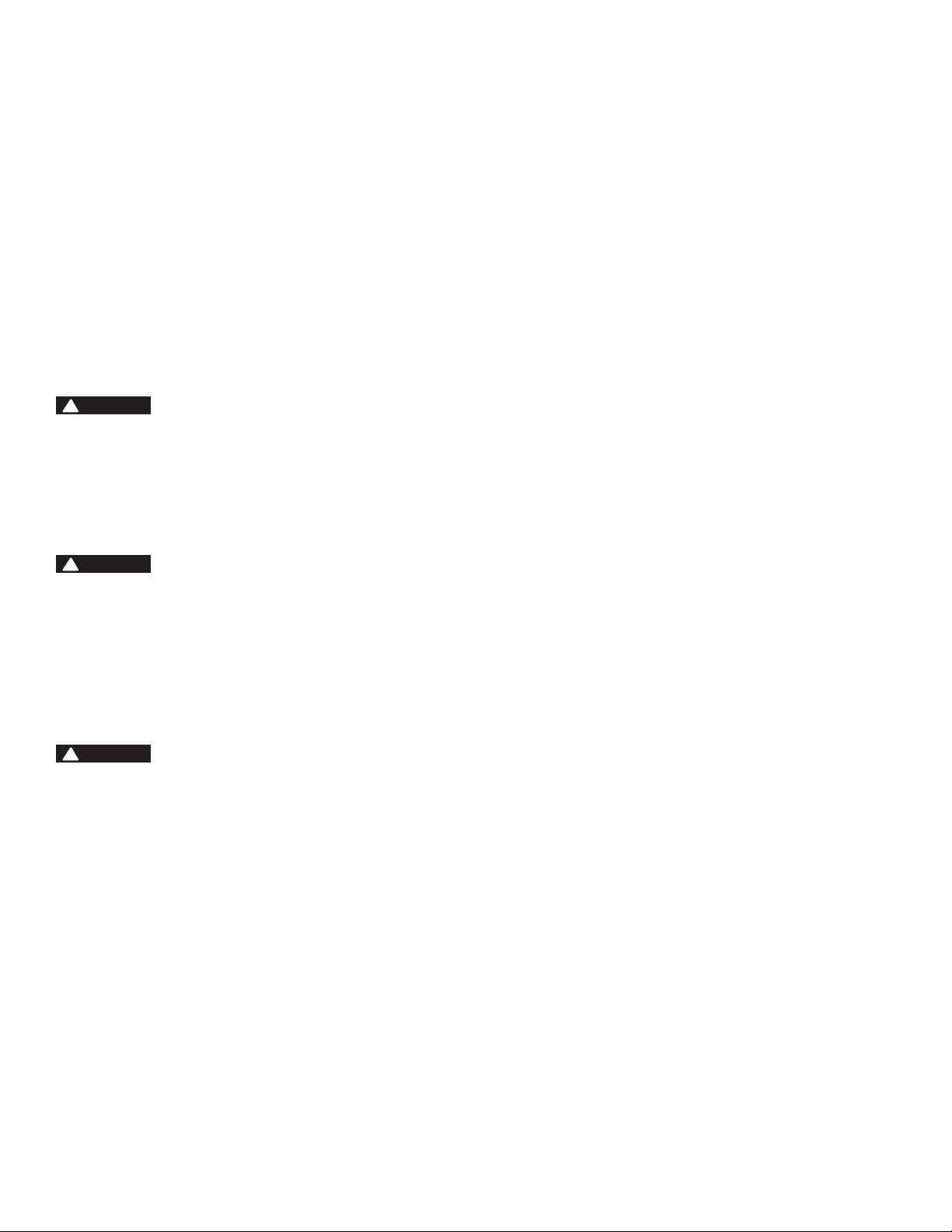

Series 007DCDA

Double Check Detector Backflow Preventer Assembly

Models & Size Included

• 007M1DCDA 2" (50mm)

• 007DCDA 2" (50mm)

• 007DCDA 2

!

WARNING

1

⁄2" & 3" (65 & 80mm)

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

RP/IS-007DCDA

Local building or plumbing codes may require modifications to

the information provided. You are required to consult the local

building and plumbing codes prior to installation. If this information is not consistent with local building or plumbing codes, the

local codes should be followed.

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes, but

at least once per year or more as service conditions warrant.

Corrosive water conditions, and/or unauthorized adjustments

or repair could render the product ineffective for the service intended. Regular checking and cleaning of the product’s internal

components helps assure maximum life and proper product

function.

The Series 007DCDA Double Check Detector Assembly is specifically designed to protect against possible backpressure and

backsiphonage conditions for non-health hazard (i.e., pollutant)

application in accordance with Local Governing Water Utility

Code. This device assembly is primarily used on potable drinking

water systems where Local Governing Code mandates protection from non-potable quality water being pumped or siphoned

back into the potable water system.

Testing

For field testing procedure, refer to Watts installation sheets

IS-TK-DP/DL, IS-TK-9A, IS-TK-99E and IS-TK-99D found on

www.watts.com.

For other repair kits and service parts, refer to our Backflow

Prevention Products Repair Kits & Service Parts price list PL-RPBPD found on www.watts.com.

For technical assistance, contact your local Watts representative.

007M1DCDA-OSY Size: 2" (50mm)

007DCDA Size: 21⁄2" (65mm)

NOTICE

Inquire with governing authorities for local installation

requirements

Page 2

Installation Instructions

Series 007DCDA

Annual inspection of all water system safety and valves is

required. Regular inspection, testing and cleaning assures

maximum life and proper product function.

The Series 007DCDA may be installed in either a horizontal or

vertical-up orientation for service on commercial potable water

or fire sprinkler systems. Supply pipe lines should be thoroughly

flushed to remove foreign material before installing the unit that

may cause unnecessary check fouling. The backflow assembly

must be installed with the arrow on the valve body pointing in the

direction of flow for proper operation.

It is recommended this device is installed downstream of a water

meter and/or main line insolation shutoff valves with installation

techniques that comply with the latest edition of the Uniform

Plumbing Code. Please consult Local Governing Code for proper

installation and agency code requirements.

!

CAUTION

Strainer Installations

The installation of a strainer upstream of the Backflow Assembles

is recommend to prevent the check modules from unnecessary fouling when used on commercial potable water systems.

DO NOT install a strainer when the Backflow Preventer is called

upon for emergency deluge or used on a fire sprinkler system

and/or individual sprinkler feed.

!

CAUTION

Fire Protection System Installations

The National Fire Protection Agency (NFPA) Guidelines require

a confirming flow test to be conducted whenever a “main line”

valve such as the shutoff valves or a backflow assembly have

been operated. A Certified Backflow Tester must conduct this

test. The trim valves located on the detector meter bypass line (if

equipped) should be fully closed during the confirming flow test

of the “main line” Backflow Assembly. Once complete, the trim

valves must be returned to a fully open position.

!

CAUTION

Flange Connections

It is recommended to inspect and retighten all flange gasket

bolts on the Backflow Assembly during installation. Flange

gasket bolts may have loosened due to storage, transport and/or

static system hydro-testing.

Indoor Installations

For indoor installation, it is important the Backflow Assembly be

easily accessible to facilitate testing, “main line” valve servicing and/or removal of the detector meter bypass line. DO NOT

install a Backflow Assembly in a concealed location.

Outdoor Installations

For outdoor installations, care must be taken to ensure the Backflow Assembly is not subjected to periods of freezing conditions.

Freezing conditions may damage the product and produce a

non-operational assembly. If the installation is subjected to freezing conditions, the use of an insulated and/or heated enclosure

(WattsBox) may be required.

Below Ground Installations

The Series 007DCDA is not recommend for below ground (burial)

installations. The most satisfactory installation is above ground

and should be installed in this manner whenever possible. If

below ground installation is required, the use of a “valve box” to

shield the Backflow Assembly from contact with soil organics

and provide adequate drainage in the event of rain-fall is recommended. Consult your Local Governing Code for proper below

ground installation and agency code requirements.

Parallel Installations

Two or more Series 007DCDA Backflow Assemblies may be

piped in parallel (where approved by Local Governing Code)

to serve a larger supply pipe main. This type of installation is

employed whenever it is vital to maintain a continuous supply

of water, where interruptions for testing and servicing would be

unacceptable. Parallel installations also provide an advantage

to increase capacity where needed beyond that provided by a

single Backflow Assembly and permits testing or servicing of an

individual assembly without shutting down the complete line. For

two valve installations, the total capacity should equal or exceed

the total requirement of the system.

2

Page 3

Horizontal Installation

Main

Vertical-Up Installation

Servicing Instructions

Series 007DCDA

1. Remove cover bolts and cover.

2. Remove the retainer from the body bore. The check valve

modules can now be removed from the valve by hand or with

Watts

StrainerMeter

2" (50mm)

007M1DCDA

a screwdriver.

3. The check seats are attached to the cage with a bayonet type

locking arrangement. Holding the cage in one hand, push the

seat inward and rotate counterclockwise against the cage.

The seat, spring cage, spring and disc assembly are now

individual components.

4. The disc assembly may now be cleaned and reassembled or

depending on its condition, may be discarded and replaced

with a new assembly from the repair kit. O-rings should be

cleaned or replaced as necessary. For more information, refer

to repair parts price list PL-RP-BPD.

5. Reassemble the Check valve modules. Check modules are

installed in the valve body with the seats facing the valve inlet.

The modules must be securely in place before the retainer can

be replaced.

NOTICE

No special tools required to service Series 007DCDA.

Outdoor Installation

WattsBox Insulated Enclosures,

for more information, send for literature ES-WB.

Parallel Installation

WattsBox

Check Assemblies — (007DCDA 21⁄2" and 3")

Seat

Seat

O-ring

Disc.

Assy.

Spring

Exploded View — (007DCDA 2

Cover

Cover O-ring

Retainer

1

⁄2" and 3")

Second Check

Service Parts Kit

Retainer

Cage/

Seat

First Check

Service Parts Kit

Body

3

Page 4

Check Module — (007M1DCDA 2") Exploded View

1st Check Assembly

Seat

Seat

O-ring

Disc.

Assy.

Spring

Cage

2nd Check Assembly

For repair kits and parts, refer to our Backflow

Prevention Products Repair Kits & Service Parts

price list PL-RP-BPD found on www.watts.com.

Cover Bolts

Cover

Cover O-ring

Retainer

1st Check

Assembly

2nd Check

Assembly

Body

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information: www.watts.com/prop65

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

RP/IS-007DCDA 1319 EDP# 1911335 © 2013 Watts

Loading...

Loading...