Page 1

”S” CHASSIS(NTSC)

”S” CHASSIS(NTSC)

Page 2

MANUALSERVICE

CONTENTS

SAFETY PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

X-RAY radiation Precaution . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Product Safety notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

DIRCETION FOR GENERAL USE . . . . . . . . . . . . . . . . . . . . . .4

Automatic degaussing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

High Voltage Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Color - Purity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Center Convergence Adjustment . . . . . . . . . . . . . . . . . . . .5

Circumference convergence adjustment . . . . . . . . . . . . . .6

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

LOCATION & FUNCTION OF CONTROLS . . . . . . . . . . . . . .9

REMOTE CONTROL OPERATION . . . . . . . . . . . . . . . . . . . .10

GENERAL FEATURES AND ADJUSTMENTS . . . . . . . . . .11

FACTORY/SERVICE ADJUSTMENTS . . . . . . . . . . . . . . . . .12

TECHNICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . 16

1.Micro-Controller & Main Processor . . . . . . . . . . .16

2.Saw filter(Z101, Z102) . . . . . . . . . . . . . . . . . . . . . . . 19

3.Tuner(H001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3-Input video switch(QV02) . . . . . . . . . . . . . . . . . . 24

5.PIP(QP01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.Triple video output amplifier(Q901) . . . . . . . . . . . . . . . . .30

7.Power Switching Regulator(Q801) . . . . . . . . . . . . . . . . . . 32

8.Vertical delection output IC(Q301) . . . . . . . . . . . . . . . . . . 33

9.Horizontal deflection output transistor(Q404) . . . . . . . .34

10.Universal hi-fi audio processor (QA01) . . . . . . . . . . . . 35

11.

Quasi Split-Sound circuit and AM demodulator (QS02)

. . . . . 37

12.Multi-Standard Sound Processor(QS01) . . . . . . . . . . . 38

13.

6W Mono Bridge Tied Load audio amplifier(Q606)

. . 42

14.

2 7W Stereo Bridge Tied Load audio amplifier(Q606)

. . . . 43

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

No Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

No Raster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

No Picture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

No Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Vertical Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

No PIP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

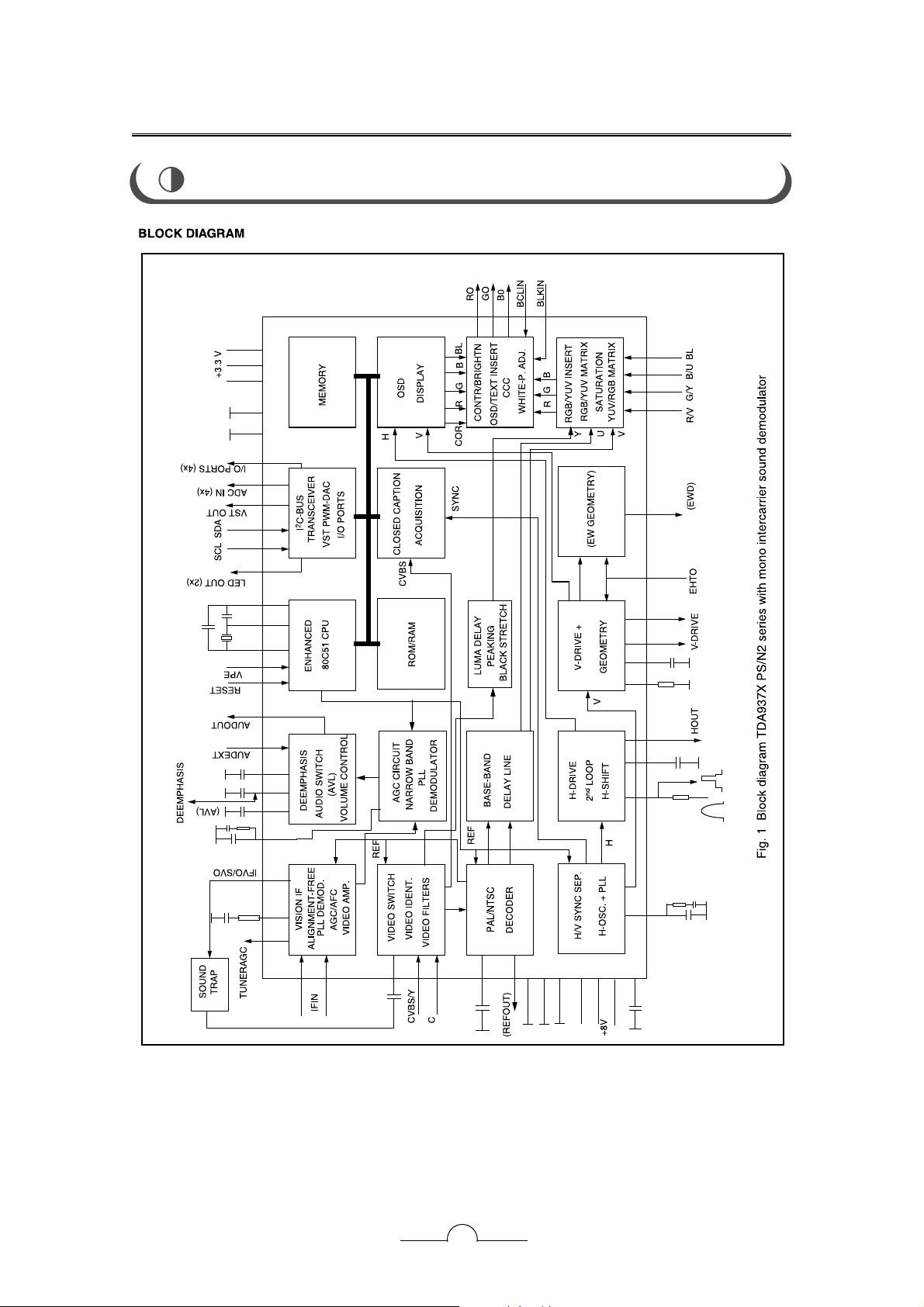

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

PCB LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

OPTION LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

CRICUIT DIAGRAM

2

Page 3

MANUALSERVICE

3

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid

such hazards, the high voltage must not be above the specified limit. The normal value of

the high voltage in this receiver is 30KV. The high voltage must not exceed 35KV. Each

time a receiver requires servicing, the high voltage should be checked according to the high

voltage check procedure on this manual. It is recommended that the reading of the high

voltage be recorded as a part of the service record. It is important to use an accurate and

reliable high voltage meter.

2. The only source of X-RAY RADIATION in this television is the picture tube. For continued

X-RAY RADIATION protection, the replacement of tube must be exactly the same type tube

as specified in the parts list.

3. Some parts in this television have special safety-related characteristics for X-RAY

RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NOTICE below.

4. Serviceman - WARNING : To Reduce the Risk of Possible Exposure to X-Radiation, take

X-Radiation Protective Measures(See Service Manual) For Personnel During Servicing.

CAUTION : SHORT ANODE LEAD ONLY TO CHASSIS.

DO NOT PLACE THIS PRODUCT ON AN UNSTABLE CART, STAND, TRIPOD, BRACKET, OR

TABLE. THE PRODUCT MAY FALL, CAUSING SERIOUS PERSONAL INJURY AND

SERIOUS DAMAGE TO THE PRODUCT. USE ONLY WITH A CART, STAND, TRIPOD,

BRACKET, OR TABLE RECOMMENDED BY THE MANUFACTURER, OR SOLD WITH THE

PRODUCT. FOLLOW THE MANUFACTURER’S INSTRUCTIONS WHEN INSTALLING THE

PRODUCT AND USE MOUNTING ACCESSORIES RECOMMENDED BY THE NUFACTURER.

A PRODUCT AND CART COMBINATION SHOULD BE MOVED WITH CARE. QUICK

STOPS, EXCESSIVE FORCE, AND UNEVEN SURFACES MAY CAUSE THE PRODUCT

AND CART COMBINATION TO OVERTURN.

SAFETY PRECAUTION

WARNING : Service should not be attempted by anyone unfamiliar with the necessary

precautions on this television. The followings are the necessary precautions to be

observed before servicing.

1. Since the chassis of this television is directly connected to the AC power line (Hot chassis),an

isolation transformer should be used during any dynamic service to avoid possible shock hazard.

2. Always discharge the picture tube anode to the CRT conductive coating before handing the

picture tube. The picture tube is highly evacuated and, if broken, glass fragments will beviolently

expelled. Use shatterproof goggles and keep picture tube away from the body while handing.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are

put back in place, such as non-metallic control knobs, insulating covers, shields isolation

resistor-capacitor network, etc.

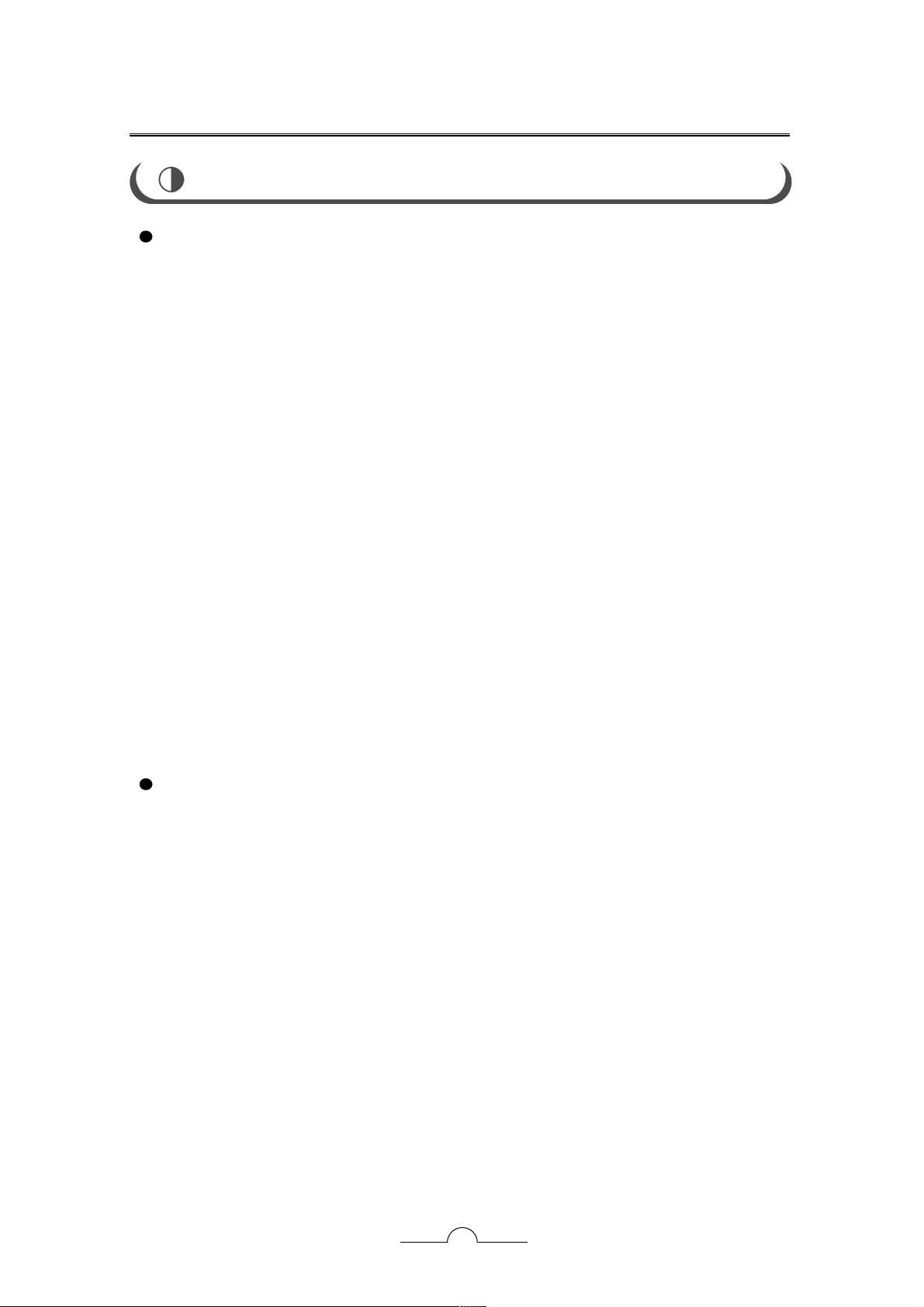

4. Before returning the set to the customer, always perform an AC leakage current check on the

exposed metallic parts of the cabinet such as terminals, screwheads, metal overlays control

shafts, etc. to insure that the set is safe to operate without danger of electrical shock.

5. Plug the AC line cord directly into a AC 120V AC outlet. (do not use a line isolation

transformer during this check) Use an AC voltmeter having 5,000 ohm per volt or more sensitivity

in the following manner, Connect a 1,500 ohm 10 watts resistor, paralleled by a 0.15uF, AC type

capacitor, between a known good earth ground (water pipe, conduit, etc.) and the exposed

metallic parts, one at a time.

SAFETY PRECAUTION

Page 4

Measure the AC voltage across the combination of 1,500 ohm resistor and 0.15uF capacitor.

Reverse the AC plug at the AC outlet and repeat. AC voltage measurements for each

exposed metallic part.

Voltage measured must not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp AC.

Any value exceeding this limit constitutes a potential shock hazard and must be corrected

immediately.

PRODUCT SAFETY NOTICE

Many electrical parts in this chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection and the protection afforded by

them cannot necessarily be obtained by using replacement, rated for higher voltage, wattage,

etc. Replacement parts which have these special safety characteristics are identified in this

manual and its parts list. Before replacing any of these components, read the parts list in this

manual carefully. The use of substitute replacement parts which do not have the same safety

characteristics as specified in the parts list may create shock, fire, x-ray radiation or other

hazards.

1. In the majority of cases, a color television receiver will need only slight touch-up adjustment

upon installation.

Check the basic characteristics such as height, vertical sync, horizontal sync and focus.

Observe the picture for good black and white objectionable color shading. If color shading is

evident, demagnetize the receiver. If color shading still persists, perform purity and

convergence adjustments.

This should be all that is necessary for optimum receiver performance.

2. THIS RECEIVER TRANSISTORIZED AND SPECIAL CARE MUST BE TAKEN. READ THE

FOLLOWING NOTES BEFORE ATTEMPTING ALIGNMENT.

1) Alignment requires an exacting procedure and should be undertaken only when necessary.

2) An isolation transformer must be used to prevent a shock hazard.

3) The test equipment specified or its equivalent is required to perform the alignment properly.

Any use of equipment which does not meet these requirements may result in an improper

alignment.

4) A correct matching of the equipment is essential. A failure to use proper matching will result

in responses which cannot represent the true operation of the receiver.

5) An use of excessive signal from a sweep generator can cause overloading of receiver circuit.

It should be avoided to obtain a true response curve. Insertion of markers from the maker

generator should not cause distortion of the responses.

6) Connect the TV only to an AC power source with voltage and frequency as specified on the

backcover nameplate.

7) Do not attempt to connect or disconnect any wire while the receiver is in operation. Make sure

the power cord is disconnected before replacing any part in the receiver.

3. REFER TO FIGURES IN PAGE 8 FOR ALIGNMENT POINTS.

MANUALSERVICE

AC VOLTMETER

0.15uF

Place this probe

on each exposed

metal part

Good earth ground

such as a water

pipe, conduit etc

1500 ohm

10 watt

4

DIRECTION FOR GENERAL USE

Page 5

AUTOMATIC DEGAUSSING

A degaussing coil is mounted around the picture tube so that external degaussing after moving

the TV should be unnecessary. But the receiver must be properly degaussed upon installation.

The degaussing coil operates for about 1 second after the power is switched ON. If the set is

moved or turned in a different direction, the power should be OFF for at least 15 minutes.

If the chassis or parts of the cabinet become magnetized, it will result in a poor color purity. If

this happens, use an external degaussing coil. Slowly move the degaussing coil around the

faceplate of the picture tube and the sides and front of the receiver. Slowly withdraw the coil to

a distance of about 6 feet before turning power OFF.

If color shading persists, perform the following Color Purity and Convergence adjustments.

HIGH VOLTAGE CHECK

CAUTION : There is no high voltage adjustment on this chassis. The +B power supply should

be +120 volts (with full color-bar input and normal picture level).

1. Connect an accurate high voltage meter to the second anode of the picture tube.

2. Turn on the receiver. Set bright and contrast controls to the minimum (zero beam current).

3. The high voltage must be measured below 34KV under any conditions.

4. Set sub-Bright DATA(SBR) minimum in FACTORY 1 MODE to ensure that the high voltage

does not exceed the limit under any conditions.

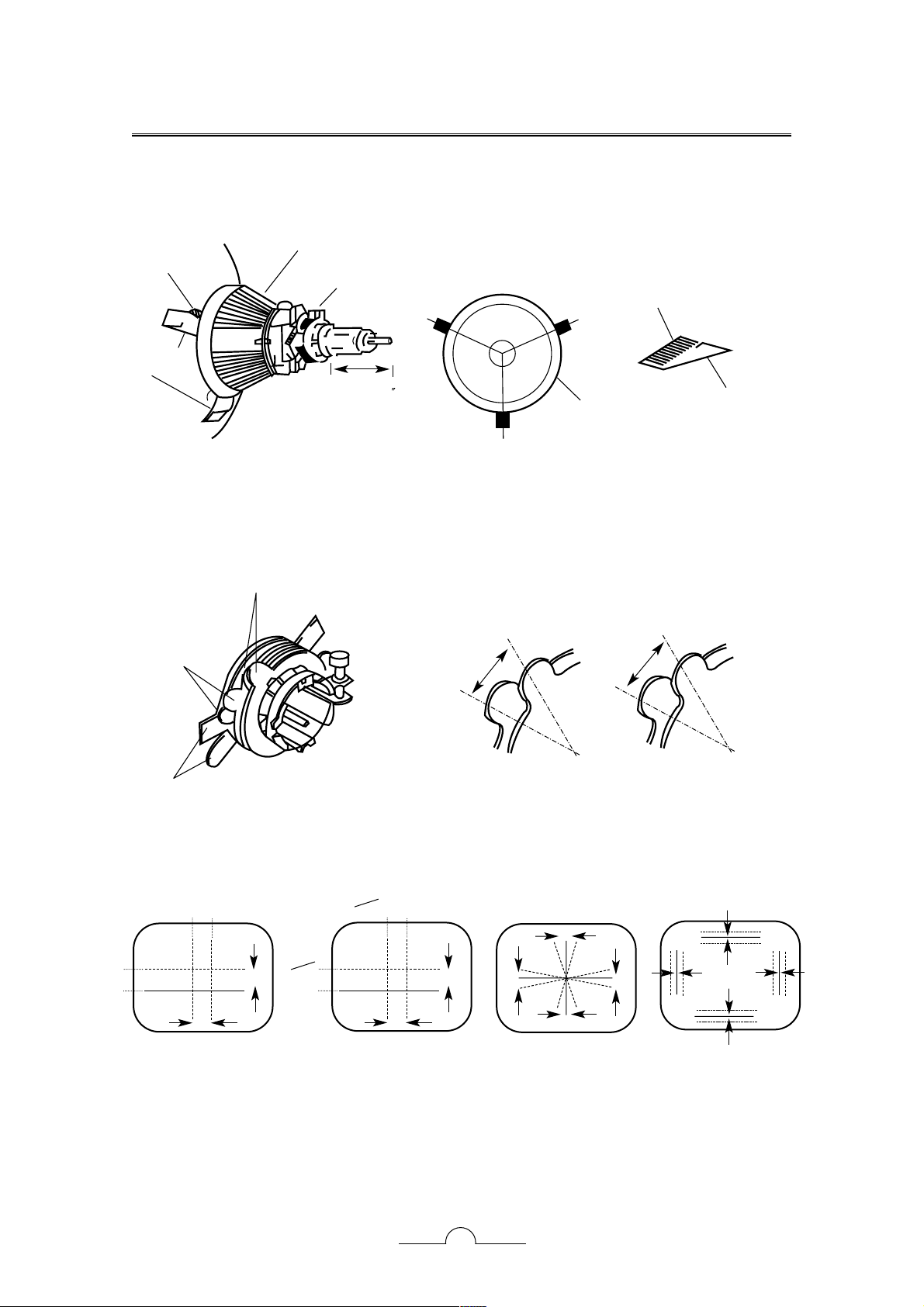

COLOR-PURITY ADJUSTMENT

NOTE : Before attempting any convergence adjustments, the TV set should be operated for at

least fifteen minutes.

1. Demagnetize the picture tube and cabinet using a degaussing coil.

2. Set the Contrast and Bright controls to the maximum.

3. Adjust RCUT and BCUT data in service mode to provide only a green raster. Advance GCUT

data if necessary.

4. Loosen the clamp screw holding the yoke and slide the yoke backward to provide vertical

green belt (zone) in the picture tube. (See Figure 1)

5. Remove the Rubber Wedges.

6. Rotate and spread the tabs of the purity magnet ( See Figure 2 ) around the neck of the picture

tube until the ground belt is in the center of the screen. At the same time, center the raster

vertically.

7. Move the yoke slowly until a forward uniform green screen is obtained. Tighten the clamp

screw of the yoke temporarily.

8. Check the purity of the red and blue raster by adjusting the R/G/B cut and GDV/BDV data.

9. Obtain a white raster, referring to "WHITE BALANCE ADJUSTMENT".

10. Proceed with the convergence adjustment.

CENTER CONVERGENCE ADJUSTMENT

1. Receive a crosshatch pattern from a color bar signal generator.

2. Adjust the Contrast and Bright controls for well defined pattern.

3. Adjust two tabs of the 4-pole magnets to change the angle between them ( See Figure 2 )

and superimpose red and blue vertical lines in the center area of the picture screen.

( See Figure 2)

4. Turn both tabs at the same line keeping constant the angle to superimpose the red and blue

horizontal lines at the center of the screen. ( See Figure 2 )

MANUALSERVICE

5

Page 6

5. Adjust two tabs of 6-pole magnets to superimpose the red and blue lines with green one.

Adjusting the angle affects the vertical lines and rotating both magnets affects the horizontal

lines.

6. Repeat adjustments 3, 4, 5 keeping in mind red, green and blue movements, because

4-pole magnets and 6-pole magnets interact and make dot movement complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

This adjustment requires 3 rubber wedges and 3 glass cloth tapes.

1. Loosen the clamping screw of deflection yoke to allow the yoke to tilt.

2. Place a wedge as shown in Figure 1 temporarily.

(Do not remove cover paper on adhesive part of the wedge.)

3. Tilt the front of the deflection yoke up or down to obtain better convergence in circumference.

(See Figure 2) Push the mounted wedge into the space between picture tube and the yoke

to hold the yoke temporarily.

4. Place other wedge into bottom space and remove the cover paper to stick.

5. Tilt the front of the yoke right or left to obtain better convergence in circumference. ( See Figure 2 )

6. Hold the yoke position and put another wedge in either upper space. Remove cover paper

and stick the wedge on picture tube to hold the yoke.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture

tube to fix the yoke.

8. After placing three wedges, recheck overall convergence. Tighten the screw firmly to hold

the yoke tightly in place.

9. Stick the grass cloth tapes on 3 wedges as shown in Figure 1.

MANUALSERVICE

6

Page 7

MANUALSERVICE

ADHESIVE

BLU RED

BLU

RED

31mm(1-3/16

)

FIGURE 1. COLOR PURITY ADJUSTMENT

FIGURE 2. CONVERGENCE ADJUSTMENT

DEFLECTION TOKE

RUBBER WEDGE

ADHE SIVE

FIXED

CONVERGENCE

MAGNET ASS’Y

RUBBER WEDGES

LOCATION

ADJUST THE ANGLE

(VERTICAL LINES)

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

DEFLECTION TOKE

RUBBER

WEDGES

6-POLE

MAGNET

4-POLE

MAGNET

PURITY

MAGNET

4-Pole Magnets Movement 6-Pole Magnets Movement Incline the Yoke up(or down) In cline the Yoke right (or left)

BLU GRN

BGR

RGB

BGR

B

G

R

R

G

B

R

G

B

B

G

R

RED

RED

BLU

GRN

Center Convergence by convergence Magnets Circumference Convergence by DEF. Yoke

7

Page 8

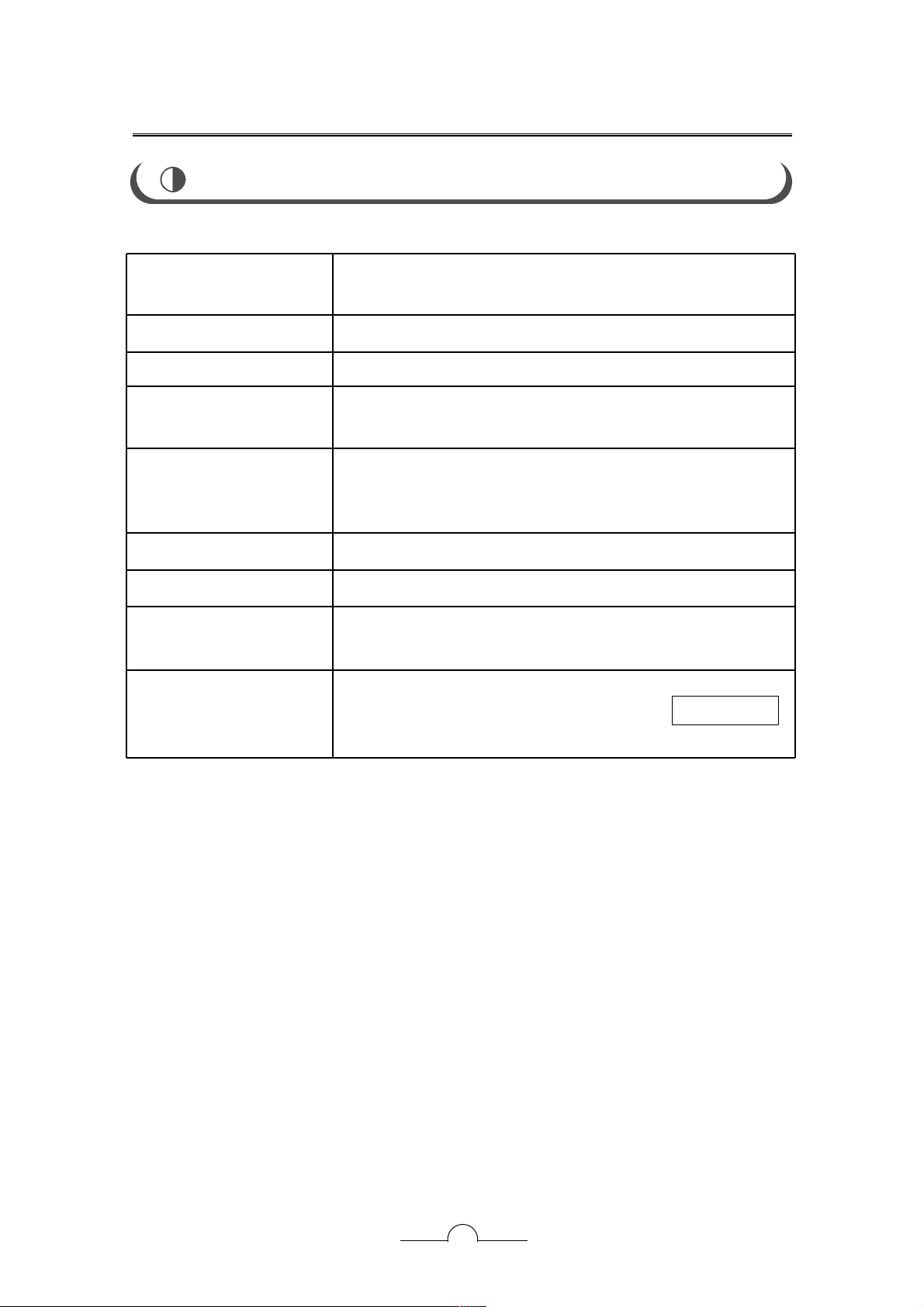

MANUALSERVICE

RECEPTION SYSTEM

POWER REQUIREMENTS AC 90~250V 50/60Hz(AUTO

)

POWER CONSUMPTION

14" : 55W , 20" : 78W, 21" : 86W

SOUND OUTPUT POWER

MONO : 4.5W

ANTENNA IMPEDANCE 75 OHM UNBALANCED TYPE

SCREEN SIZE 50.8 Cm (DIAGONAL 21 INCH

)

OPERATING FREQUENCIES

VIDEO IF 45.75MHz

SOUND IF 41.25MHz

RECEIVING

CHANNELS

VHF CH : 2 TO 13

UHF CH : 14 TO 69

CATV CH : 1, 14 TO 125

NTSC-M : TDA9377

NTSC-M, PAL-M, PAL-N : TDA9370

STEREO

AV : PSEUDO RF STEREO

RF : ZENITH

TOTAL 181CH

8

SPECIFICATIONS

AV STEREO : 5W(R) + 5W

RF STEREO : 6.3W + 6.3W AT 10%, 1KHz

Page 9

MANUALSERVICE

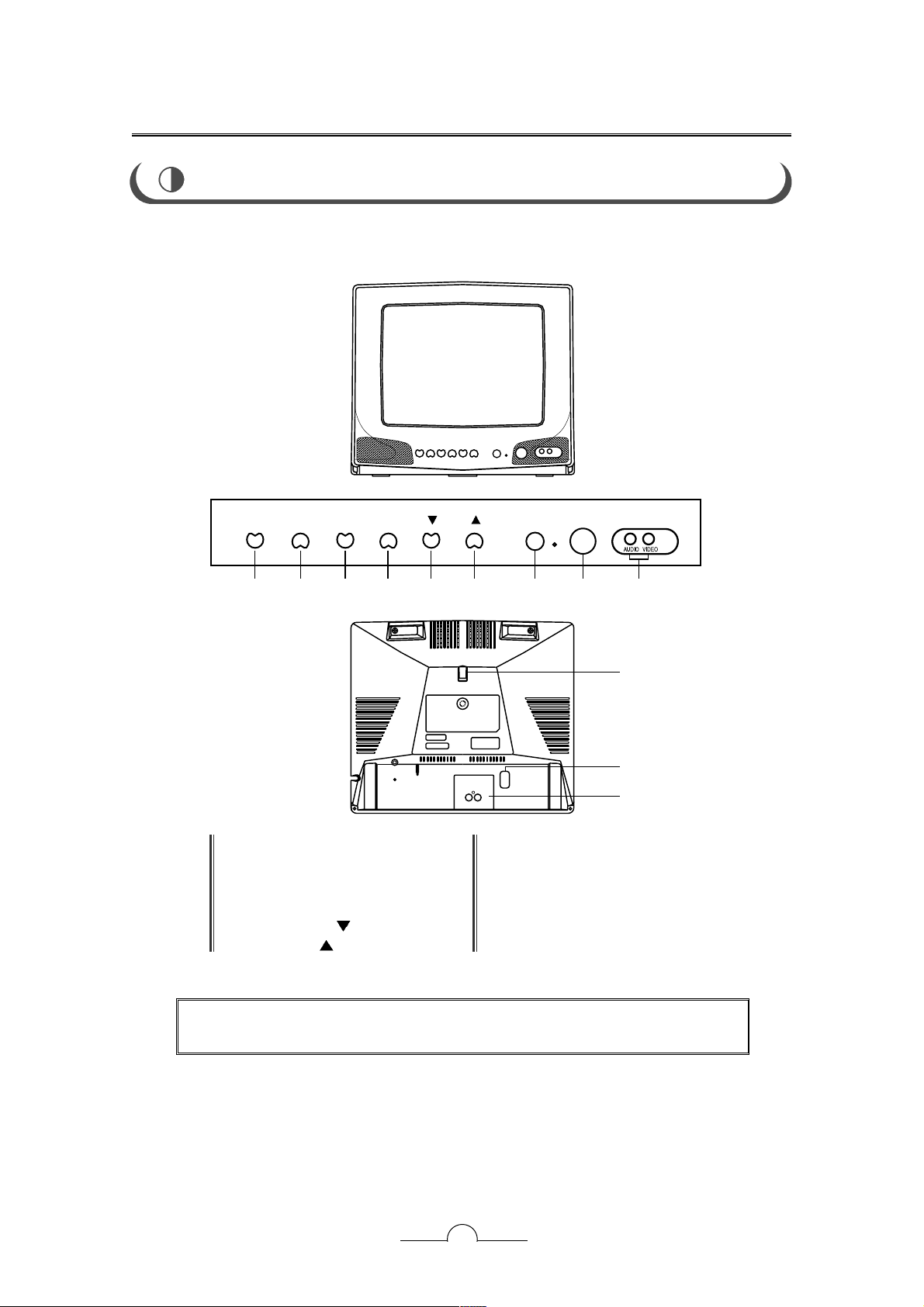

9

LOCATION AND FUNCTION OF CONTROLS

WARNING : TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS

TELEVISION TO RAIN OR MOISTURE.

1. TV/Video Key

2. Menu Key

3. Volume Down (-) Key

4. Volume Up (+) Key

5. Channel Down (

) Key

6. Channel Up (

) Key

7. Remote Control Sensor

8. Main Power Key

9. Audio/Video 2 In Jacks

10. Antenna Holder

11. Antenna Jack (75 ohm)

12. Audio/Video In Jacks

TV/VIDEO

MENU

POWER

_

VOL +

CH

29876543

11

10

12

1

REAR

FRONT

Page 10

MANUALSERVICE

10

BA TTERY INSTALLATION

Replace two batteries in the battery compartment at the same time.

lnsert "AAA" batteries, observing the polarity ( or ) marked on the unit.

Batteries should last about a year under normal use. lf the operation is unstable(either

channel or volume does not change), replace the batteries. When the hand unit is not used

for a long, or when the batteries are used up, take out the batteries to prevent possible

leakage. To avoid any malfunction of the remote control, press only one button at a time.

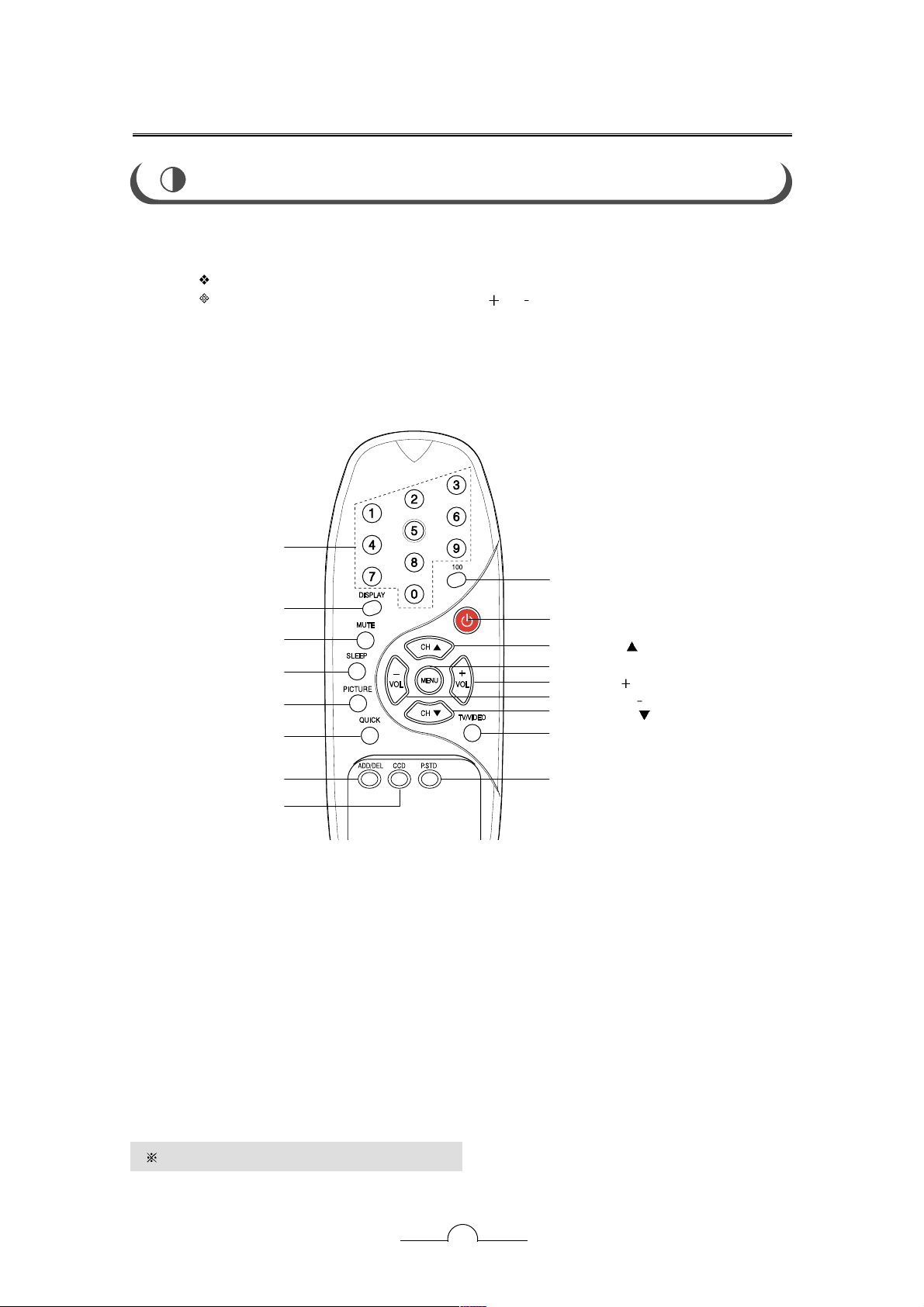

REMOTE CONTROL OPERATION

Remocon depends on the option of model

Direct channel

selection Button

Display Button

Mute Button

Sleep Button

Picture Button

Quick View Button

Add/Delete Button

CCD Button

100 Button

Power Button

Channel Up (

) Button

Menu Button

Volume Up (

)Button

Volume Down (

)Button

Channel Down( )Button

TV/Video Button

Picture Standard Button

Page 11

MANUALSERVICE

11

1. NOTE

Because this is not a hot chassis, it is not necessary to use an isolation transfromer.

However, the use of isolation transformer will help protect test instrunents.

Adjustment must be done in the correct order.

Supply AC 90~260V, 50/60Hz in general.

Most of this chassis is designed to operate in the wide range of power supply.

Automatic degaussing

The degaussing circuit operates for about 1 secord after the power is switched on.

If you change the direction of the TV set in a state of Power-On, any color-blur may happen.

In that case, plug it off and plug it on after 1 more hour.

If color shading still persists, perform purity and convergence adjustments.

2. EEPROM(Q002) REPLACEMENT

When Q002 is replaced, all values are reset to INITAL MICRO-CONTROLLER DATA.

Because the pre-set data is reset after the replacement, above all, select factory

mode and write down all the pre-set data befote the replacement.

After the replacement, select factory mode and set the initial data referring to the

written-down data.

If you fogot to write down all the pre-set data or you can t turn on TV, re-adjust the initial

data according to the adjustment manual, follow the below procedure.

Roplace the defective Q002 with a new one.

In the Stand-by mode, Press DISPLAY + MENU + 3 + 8 + POWER(ON) button

on the romote controller in sequence.

And then, factory mode will be displayed on the screen.

Input the signal like a color-bar pattern into antenna terminal, or input the current

broadcasting signal into antenna terminal.

3. WHEN CRT IS REPLACED

Do the following adjustments in the factory made.

SCREEN adjustment(SCREEN VOLTAGE)

W.BAL adjustment (R-Cut, G-Cut, R-DRV, G-DRV, B-DRV)

PICTURE adjustment (HRS(50), HRS(60), HEIGHT)

NOTE

You don

t need to select 8.EEPROM Rest and 9.UOC Control.

Two items are critical to the system operation.

Press TV/VIDEO or MTS button when you want to finish the factory adjustments.

TV/VIDEO button:the early state that you bought TV sets.

MTS button:the previous state before you enter the factory mode.

4.SIF VCO VOLTAGE CHECK

Connect the (+) terminal of multi-meter to TP60(LS06) and check the

SIF VCO Voltage within DC1.8

0.5V.

GENERAL FEATURES AND ADJUSTMENTS

Page 12

MANUALSERVICE

12

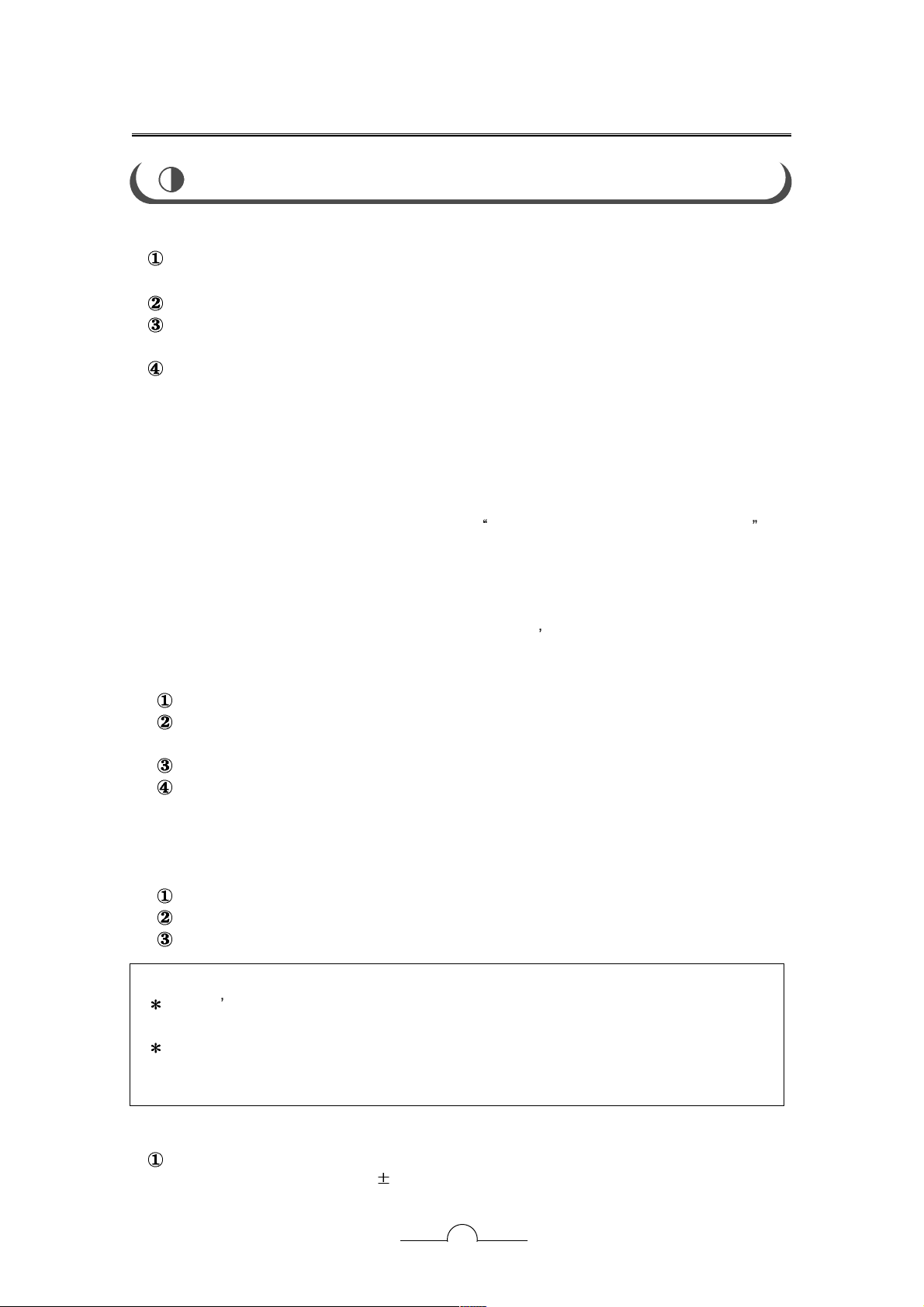

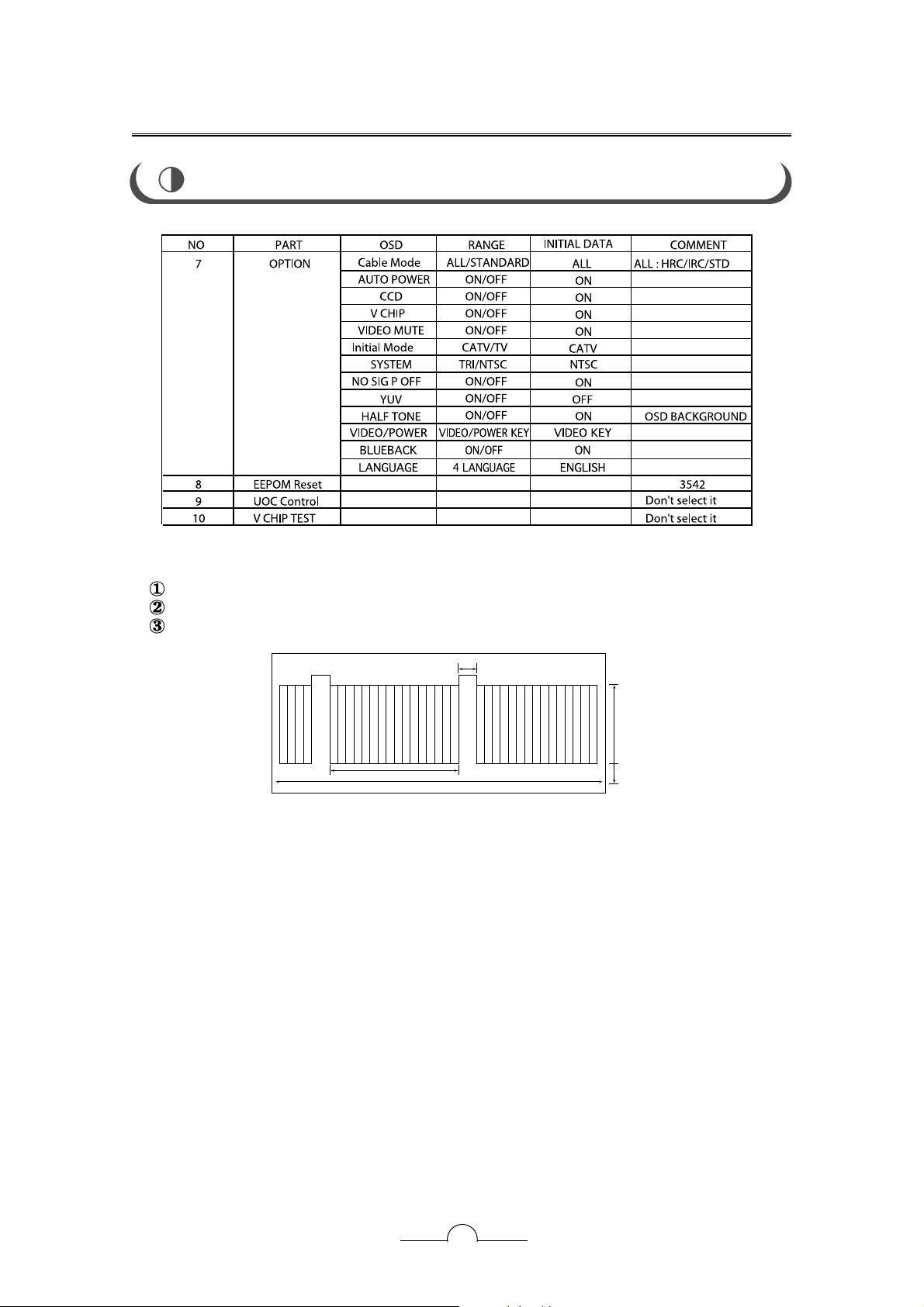

1. Procedure for the factory adjustment mode

In the Stand-By mode, the factory(Service) mode is activated by pressing the

DISPLAY + MENU + 3 + 8 + POWER(ON) button in sequence on the remote controller.

The menu of the factory mode will be displayed.

The factory mode consists of 9 componets:

1. SCREEN

2. W.BAL

3. PICTURE

4. SERVICE1 ;You do not need to Select it.

5. VOLUME TEST ;You do not need to Select it.

6. Device Check ;You do not need to Select it.

7. OPTION

8. EEPROM Reset ;You do not neet to Select it

9. UOC Control ;You do not need to Select it.

10. V-CHIP TEST ;You do not need to Select it.

Select each adjustment mode by pressing CH up( )or CH down( ) button.

And access it by pressing vol up(+)or vol down(-) button.

FACTORY/SERVICE ADJUSTMENTS

Page 13

MANUALSERVICE

13

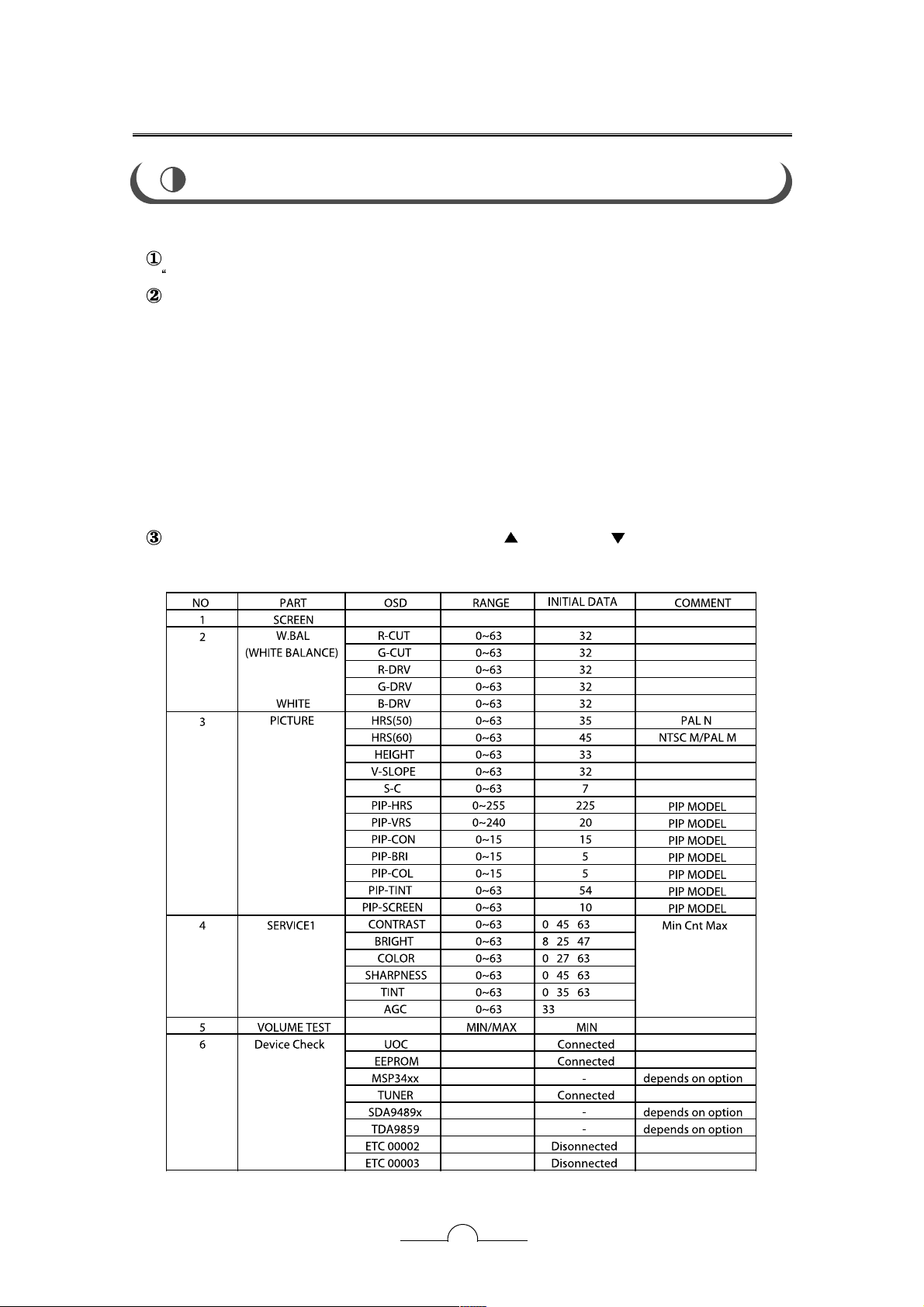

2. SCREEN Voltage Adjustment

Turn the TV set to receive a color bar pattern.(Standard picture)

Connect the probe of oscilloscope to the RK (Red Cathode) of CPT Board.

Adjust Screen Volume of FBT so that the waveform is the same as below figure.

FACTORY/SERVICE ADJUSTMENTS

P/W:

1H-LINE

Horizontal

FlyBack Time

Black level

145Vp-p

White level

GND for dc

The waveform of RK(Red Cathode) of CPT Board

Page 14

MANUALSERVICE

14

3. Deflection Adjustments

HRS(50) adjustment : Tune the TV set to a LION HEAD

pattern signal with 50Hz of

vertical frequency.

HRS(60) adjustment : Tune the TV set to a LION HEAD

pattern

Signal with 60Hz of vertical ferquency.

HEIGHT adjustment : Tune the TV set to a LION HEAD pattern

Signal and adjust the vertical amplitude to

4 bars both the Top and the bottom.

4. WHITE BALANCE Adjustments(manual)

Input PURE WHITE pattern into antenna terminal or into

Video input terminal.

Keep TV on for about 30 minutes prior to white balance adjustment.

Screen Voltage Adjustment (page 13)

Place the probe of CRT Analyzer at the center Position of picture screen.

Adjust CONTRAST & BRIGHTNESS until

Y value of CRT analyzer

becomes 35FL above roughly.

Select 2.W.BAL and press Vol(+) button.

And then

R-CUT 32 will be displayed.

1 button : R-CUT

5 button : G-CUT

9 button : R-DRV

0 button : G-DRV

100 button : B-DRV

Select R-DRV & G-DRV and adjust them to get the

color coordinates below in the high light state.

In this case, fix the reference color(B-DRV) as possible as.

X COORDINATE Y COORDINATE

0.261 0.268

FACTORY/SERVICE ADJUSTMENTS

Page 15

MANUALSERVICE

15

5. Focus ADJUSTMENT

Input CROSS DOT pattern into antenna terminal on video input terminal.

Rotate the variable resistor of FOCUS terminal on the flyback

transformer until the horizontal and vertical line becomes slim.

Check the surrounding FOCUS in the lion head pattern.

FACTORY/SERVICE ADJUSTMENTS

Page 16

MANUALSERVICE

16

TECHNICAL INFORMATION

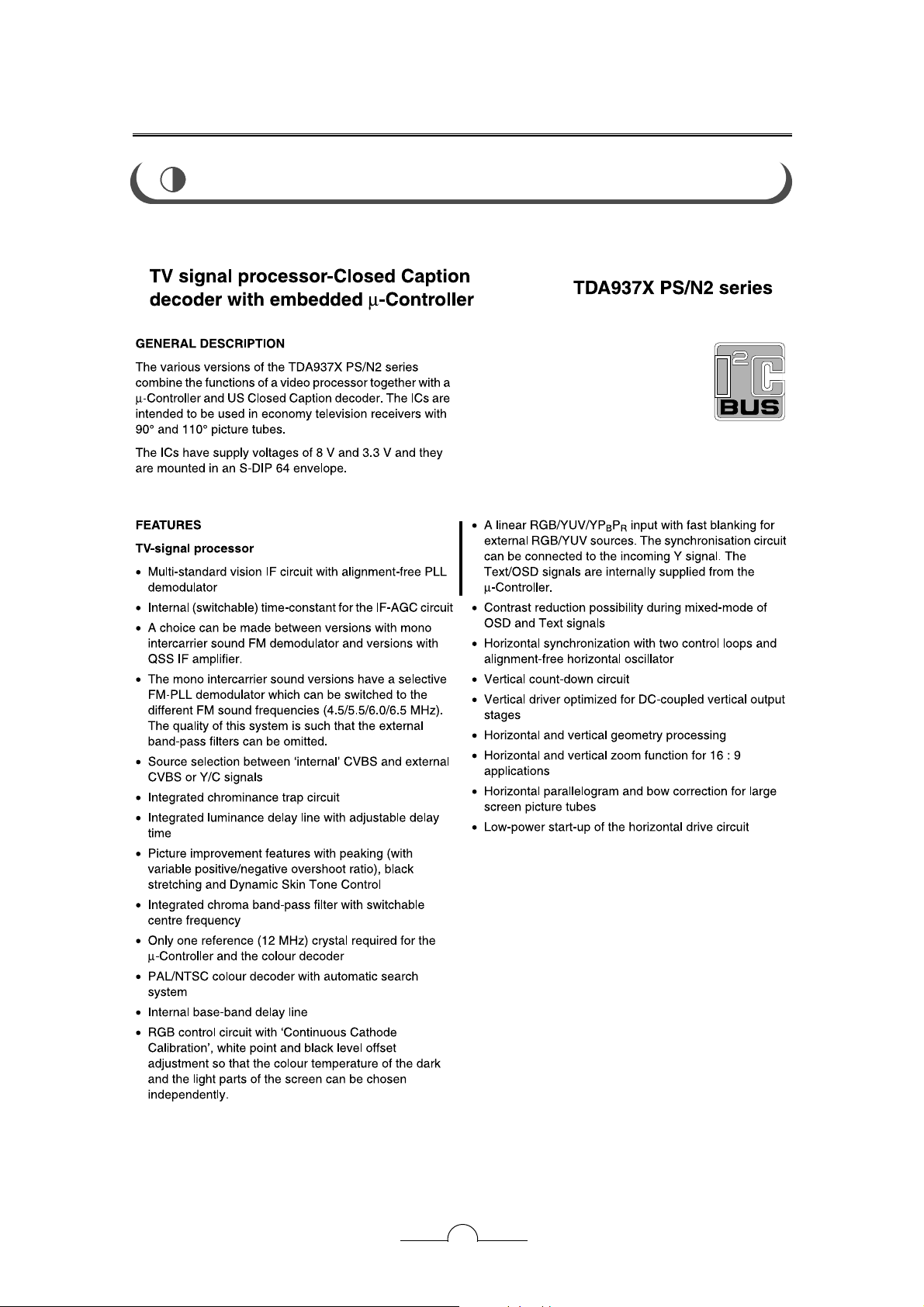

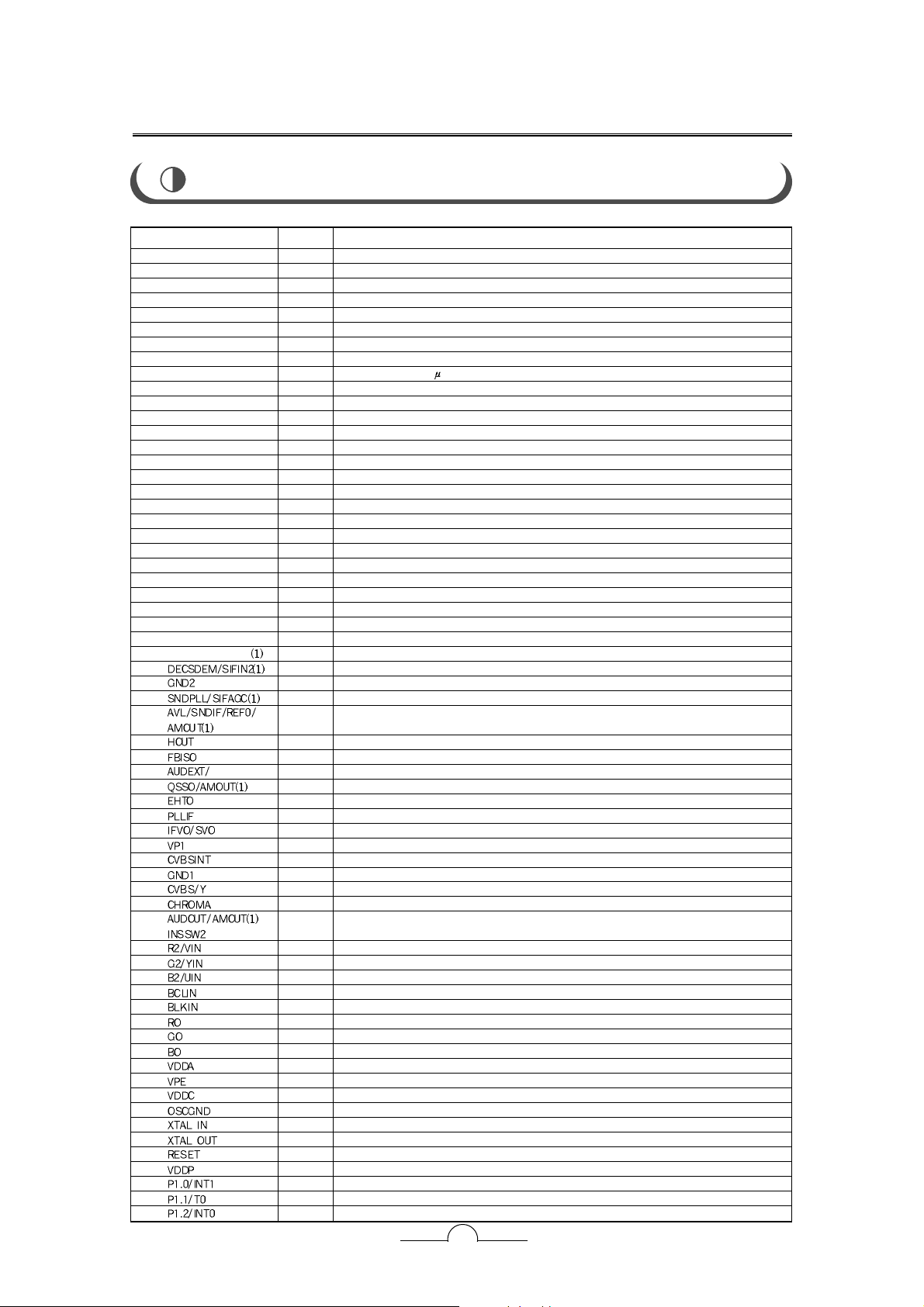

1. MICRO-CONTROLLER & MAIN PROCESSOR

Page 17

MANUALSERVICE

17

TECHNICAL INFORMATION

TDA937X PS/N2 series

Page 18

MANUALSERVICE

18

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

SYMBOL

P1.3/T1

P1.6/SCL

P1.7/SDA

P2.0/TPWN

P3.0/ADC0

P3.1/ADC1

P3.2/ADC2

P3.3/ADC3

VSSC/P

P0.5

P0.6

VSSA

SECPLL

VP2

DECDIG

PH2LF

PH1LF

GND3

DECBG

AVL/EWD(1)

VDRB

VDRA

IFIN1

IFIN2

IREF

VSC

TUNERAGC

AUDEEM/SIFIN1

DESCRIPTION

Power(ACTINE LOW) ON:LOW, STAND-BT:HIGH

Serial CLOCK

Serial DATA

SVHS MODE DETECTION INPUT(ACTIVE LOW)

NTSC SYSTEM CONVERSION OUTPUT(ACTIVE LOW)

AUDIO/VIDEO MODE SWITCH 1

CONTROL BUTTON KEY INPUT 1

CONTROL BUTTON KEY INPUT 2

digital ground for

-Controller core and periphery

AUDIO/VIDEO MODE SWITH 2

Swith Signal Video (status) input

analog ground of Teletext decoder and digital ground of TV-Processor

SECAM PLL decoupling

2

nd

supply voltage TV-processor(+8V)

decoupling digital supply of TV-processor

phase-2 filter

phase-1filter

ground 3 for TV-processor

bandgap decoupling

Automatic Volume Levelling/East-West drive output

vertical drive B output

vertical drive A output

IF input 1

IF input 2

reference current input

vertical sawtooth capacitor

tuner AGC output

audio deemphasis of SIF input 1

decoupling sound demodulator of SIF input 2

ground 2 for TV processor

narrow band PLL filter/AGC sound IF

Automatic Volume Levelling/sound IF input/subcarrier reference output/AM output

(non controlled)

horizontal output

flyback input/sandcastle output

external audio input/QSS intercarrier out/AM audio output(non controlled)

EHT/overvoltage protection input

IF-PLL loop filter

IF video output/selected CVBS output

main supply voltage TV-processor(+8V)

internal CVBS input

ground 1 for TV-processor

external CVBS/Y input

chrominance input (SVHS)

audio output /AM audio output(volume controlled)

2

nd

RGB/YUV insertion input

2

nd

R input /V(R-Y)input

2

nd

G input/Y input

2

nd

B input/U(B-Y)input

beam current limiter input/(V-guard input, note 2)

black current input/(V-guard input, note2)

Red output

Green output

Blue output

analog supply of Teletext decoder and digital suppply of TV-processor(3.3V)

OTP Programming Voltage

digital supply to core(3.3V)

oscillator gorund supply

crystal oscillator input

crystal oscillator output

reset

digital supply to periphery(+3.3V)

Remote key matrix input

I

2

C BUS STOP CONTROL PIN(LOW:BUS STOP)

MUTE OUTPUT(ACTIVE LOW)

PINNING

TECHNICAL INFORMATION

Page 19

MANUALSERVICE

19

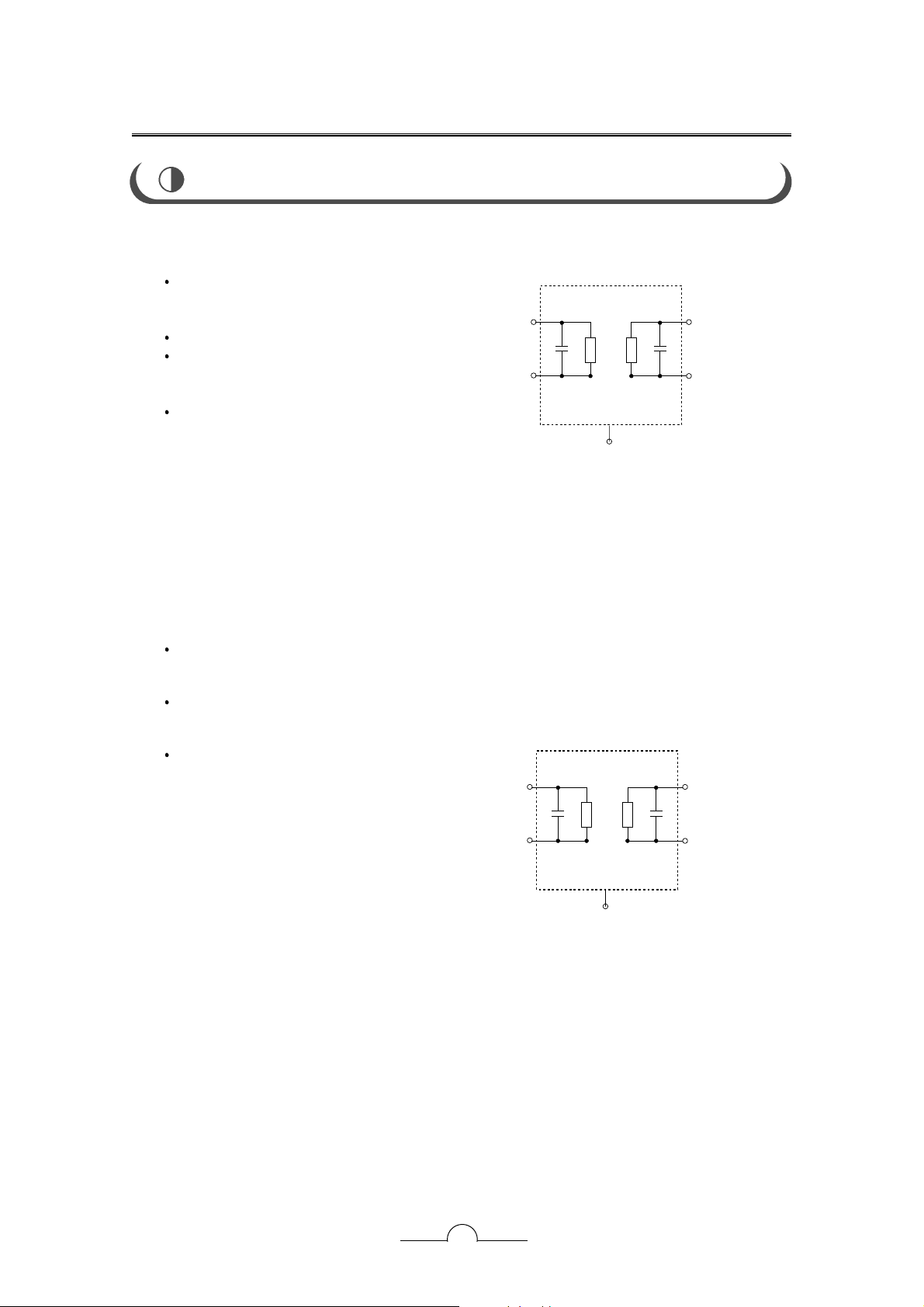

2.Saw filter(Z101) : IF filter for Intercarrier / Multe-standard Application

Standard

M/N-FCC

USA

Features

TV IF filter with Nyquist slope and sound shelf

Constant group delay

Terminals

CuFe, tinned

Pin configuration

1 Input

2 Input-ground

3 Chip carrier-ground

4 Output

5 Output

Standard

M/N

Features

TV IF audio filter with pass bands for picture carrier at 45.75MHz and sound carrier at 41.25MHz

Terminals

Tinned CuFe alloy

Pin configuration

1 Input

2 Input-ground

3 Chip carrier-ground

4 Output

5 Output

Saw filter(Z102) :

IF filter for Audio Applications (RF STEREO ONLY)

3

2

1

4

5

3

2

1

4

5

TECHNICAL INFORMATION

Page 20

MANUALSERVICE

20

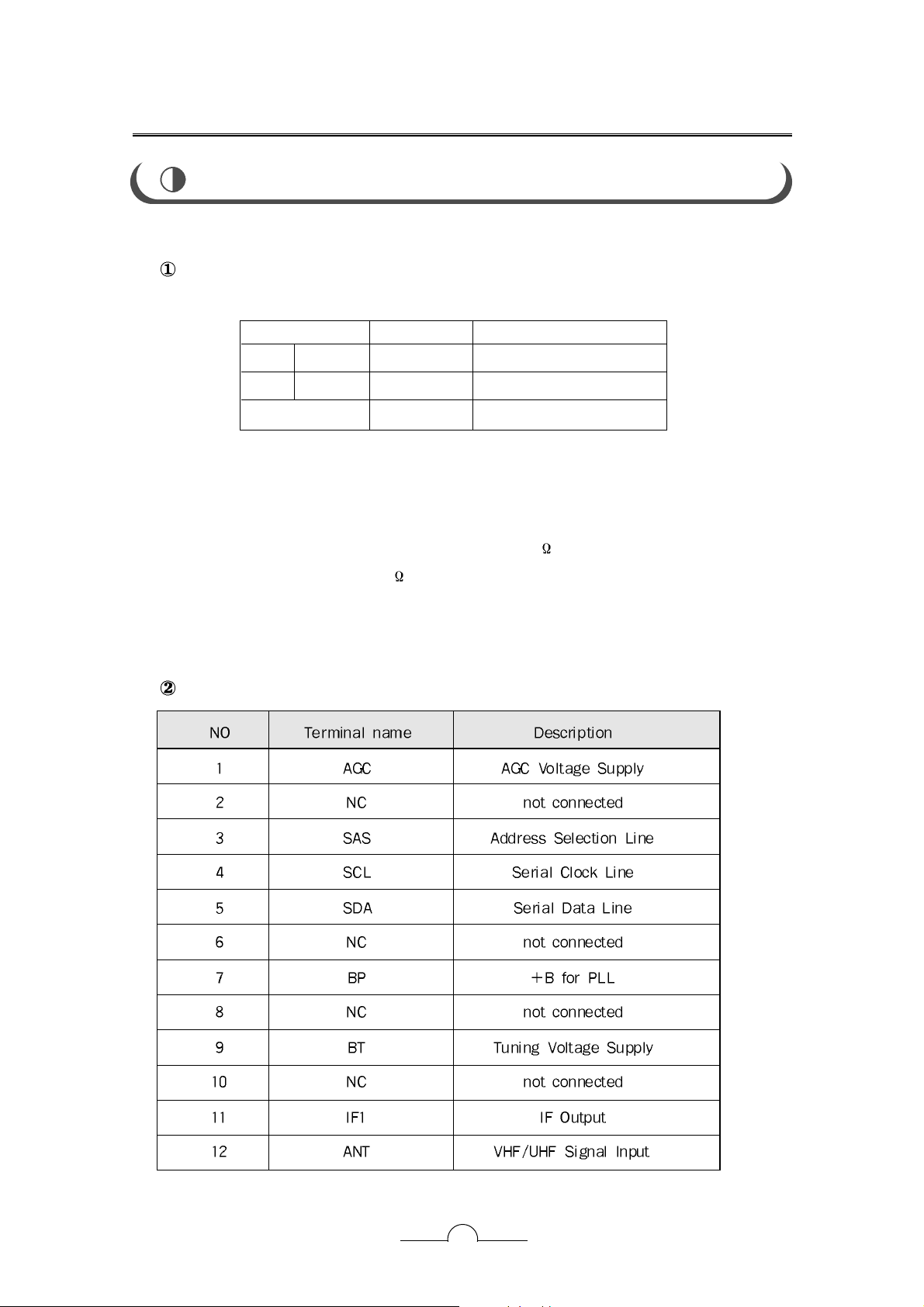

3. Tuner(H001)

features

Receiving System : NTSC M, PAL M/N

Channel :

Intermediate Frequency PIF : (45.75)MHz

CIF : (42.17)MHz

SIF : (41.25)MHz

Input Impendance : UHF/VHF Terminal (75) , Unbalanced

Output Impendance : 75 , Un Balanced

Band Change Over System : (PLL Control System)

Tuning System : (Electronic Tuning System with PLL)

Terminal For External Connection

TECHNICAL INFORMATION

Air CATV

VHF Low 2~6ch (A-8) A-5~Bch

High 7~13ch C~W+11ch

UHF 14~69ch W+12~W+84ch

Page 21

MANUALSERVICE

21

RECEIVING CHANNEL FREQUENCY TABLE

TECHNICAL INFORMATION

Page 22

MANUALSERVICE

22

TECHNICAL INFORMATION

Page 23

MANUALSERVICE

23

TECHNICAL INFORMATION

Page 24

MANUALSERVICE

24

4. 3-INPUT VIDEO SWITCH,NJM2235L(QV02)

GENERAL DESCRIPTION

The NJM2235 is 3-input video switch for video and audio signal. It has clamp

function and so is applied to fixed DC level of video signal. Its operating supply

voltage range is 5 to 12V and bandwidth is 10MHz. Crosstalk is 70dB(at

4.43MHz).

FEATURES

Operating Voltage (+4.75 ~ +13V)

3 Input-1 Output

Internal Clamp Function

Wide Operating Supply Voltage Range 4.75 ~ 13V

Cross-talk 70dB (at 4.43MHz)

Wide Frequency Range 10MHz

Muting Function available

Packange Outline DIP-8, DMP-8, SIP-8, SSOP-8

Bipolar Technology

PIN CONFIGURATION

BLOCK DIAGRAM

INPUT CONTROL SIGNAL-OUTPUT SIGNAL

SW1

L

H

L/H

OUTPUT SIGNAL

VIN1

VIN2

VIN3

SW2

L

L

H

PIN FUNCTION

1. VIN1

2. SW1

3. VIN2

4. SW2

5. V

IN

3

6. V

+

7. Vout

8. GND

NJM2235L

TECHNICAL INFORMATION

Page 25

MANUALSERVICE

25

5. PICTURE-IN-PICTURE IC(QP01)

General Description

SDA 9489X PIP IV Advanced and SDA 9589X SOPHISTICUS belong to a new

generation of Picture-in Picture(PiP) processors that combine high-quality digital PIP signal

processing, digital multistandard color decoding and AD/DA conversion on a single chip.Both

devices are equipped with CVBS and Y/C input interfaces in addition the SDA SDA 9589X is

also able to process YUV input signals for displaying high quality video signals e.g. coming

from a DVD source.

The integrated digital color decoder is able to decode all analog TV standards(PAL, NTSC

and SECAM) and detects the standard automatically. Therefore the IC is suited for world-wide

use.

A picture reduciton from 1/4 to 1/81 of original size selectable in fine steps is possible. The

transfer function of the decimation filters are optimally matched to the selected picture size

reduction and can furthermore be adjusted to the viewer s requirements by a selectable

peaking. A maximum of 324 luminance and 2x81 chrominance pixels per line are stored in the

memory. The PIP supports split-screen applications as well as multi-PiP display

Features

Single chip solution:

-AD-conversion for CVBS or Y/C or YUV?, multistandard color decoding PLL for

synchronization of inset channal decimation filtering embedded memory RGBmatrix, DA-conversion, RGB/YUV switch, data-slicer and clock generation

integrated on chip

Analog inputs:

-3x CVBS or 1x CVBS and 1x Y/C or 1xYUV alternatively

-Clamping of each input

-All ADCs with 8bit amplitude resolution

-Automatic Gain Control (AGC) for Y and CVBS

Inset Synchronization

-Multiple time constants for reliable synchronization

-Automatic recognition of 625 lines/525 lines standard

Color Decoder

-PAL-B/G, PAL-M, PAL-N(Argentina), PAL60, NTSC-M, NTSC4.4 and SECAM

-Adjustable color saturation

-Hue control for NTSC

-Automatic Chroma Control(-24dB...+6dB)

-Automatic recognition of chroma standards: different search strategies selectable

-Single crystal for all standards

-IF-characteristic compensation filter

Decimation

-PIP sizes between 1/81 and 1/4 adjustable with steps of 2 lines and 4 pixel

-Resolution up to 324 luminance and 2x81 chrominance pixels per inset line

-Horizontal and vertical filtering dependent on picture size

-Automatic zoom in/out possible with three speeds

TECHNICAL INFORMATION

PIP ONLYPIP ONLY

Page 26

MANUALSERVICE

26

Display Features:

-7bit per pixel stored in memory

-Field and joint-line free frame mode display(even at 100/120Hz AABB with picture

sizes<=1/9)

-Two split-screen modes with horizontal decimation of 2 and vertical fo 1.5 or 1.0

-POP display

-Up to 12 pictures of 1/36th size(11 still and 1 moving)

-Up to 6 pictures of 1/16th size(5 still and 1 moving)

-Up to 3 Pictures of 1/9th size (2 still and 1 moving)

-Display on VGA and SVGA screen(fH limited to 40kHZ)

-8 different read frequencies for 16:9 compatibility

-Line doubling mode for progressive scan applications

-Freeze picture

-Coarse positioning at 4 corners of the parent picture

-Fine positioning at steps of 4 pixels and 2 lines

-Wipe in/out programmable with 3 time periods

Output signal processing:

-7Bit DAC

-RGB or YUV switch:insertion of an external source without PIP processing

-Digital interpolation for anti-imaging

-Adjustable transient improvement for luma(peaking)

-Contrast, Brightness and Pedestal Level Adjustable

-Analog outputs:Y, +(B-Y), +(R-Y), or Y, -(B-y), -(R-Y) or RGB

-Three RGB matrices available:NTSC(Japan), NTSC(USA) or EBU

-64 different background colors and 4096 different frame colors

-Plain or 3D frame with variable width and height

Data Slicing:

-Slicing of closed-caption(CC)or wide-screen-signaling(WSS)data

-Violence Blocking capability(V-chip)

-Several filter for XDS data extraction

On-screen display:

-64 characters programmable

-5 characters displayed in eyery PIP picture or 3 rows of 20 characters each

-4 different character luminance values or frame color

-4 background luminance values or (Semi-)transparent mode

I2C-BUS control(400kHz)

High stability clock generation

PDSO 28-1 package(SMD)

Full SDA 9488X and SDA 9588X backward compatibility

SDA 9388X/SDA 9389X pinout compatibility

3.3V supply voltage(5V input capable)

TECHNICAL INFORMATION

Page 27

MANUALSERVICE

27

Block Diagram

Pin Configuration

TECHNICAL INFORMATION

Page 28

MANUALSERVICE

28

SDA 9489X Preliminary Data Sheet

Pin Configuration

Description

crystal oscillator (input) or external clock input

ctystal oscillator (output)

horizontal sync for parent channel

vertical sync for parent channel

I

2

C-bus data

I

2

C-bus clock

digital supply voltage

digital ground

I

2

C Address

interrupt

V/R input for external YUV/RGB source

Y/G input for external YUV/RGB source

U/B input for external YUV/RGB source

fast switch input for YUV/RGB switch

fast blanking output for PIP

analog output : chrominance signal +(B-Y) or -(B-Y) or B

analog output : luminance singnal Y or G

analog output : chrominance signal +(R-Y) or -(R-Y) or R

analog supply voltage for DAC

analog ground for DAC

upper reference voltage for ADC and DAC

analog supply voltage for ADC

analog ground for ADC

CVBS3or V (SDA 9589X) or C Input

lower reference voltage for ADC

CVBS2 or U (SDA 9589X) or Y (from Y/C) Input

mid-level reference voltage for ADC

CVBS1 or Y (from YUV, SDA 9589X) Input

I=Input / ana=analog / O=Output / TTL=Digital(TTL) / S=Supply voltage

Type

I

O

I/TTL

I/TTL

I/O

I

S

S

I

O/TTL

I/ana

I/ana

I/ana

I

O

O/ana

O/ana

O/ana

S

S

I/ana

S

S

I/ana

I/O

I/ana

I/O

I/ana

Name

XIN

XQ

HSP

VSP

SDA

SCL

VDD

VSS

12C

INT

IN1

IN2

IN3

FSW

SEL

OUT3

OUT2

OUT1

VDDA2

VSSA2

VREFH

VDDA1

VSSA1

CVBS3

VREFL

CVBS2

VREFM

CVBS1

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Page 29

MANUALSERVICE

29

Input Selection

An analog inset CVBS signal can be fed to inputs CVBS1-3 of SDA 9589X / SDA 9489X. Each

of these sources is selectable via I2C bus (CVBSEL). CVBS2 and CVBS3 can be used as

separate Y/C inputs. At SDA 9589X YUV sources can be connected to CVBS1, CVBS2 and

CVBS3 provided YUV operation being enabled (YUVSEL). Using an external switch SDA

9589X can operate in applications with both YUV and CVBS signals.

CVBSEL

D1 D0

0 0

0 1

1 0

1 1

X X

YUVSEL

0

0

0

0

1

CVBS1

CVBS

Y(VBS)

Input

CVBS2

CVBS

Y(VBS)

U(CB)

CVBS3

C

CVBS

U(CR)

Remark

Y/C mode

YUV mode

(only SDA 9589X)

TECHNICAL INFORMATION

Page 30

MANUALSERVICE

30

6. TRIPLE Video output amplifier, TDA6107Q(Q901)

GENERAL DESCRIPTION

The TDA6107Q includes three video output amplifiers in one plastic DIL-bent-SIL9-pin

medium power(DBS9MPF) package (SOT111-1), using high-voltage DMOS technology, and

is intended to drive the three cathodes of a colour CRT directly. To obtain maximum

performance, the amplifier should be used with black-current control.

FEATURES

Typical bandwidth of 5.5 MHz for an output signal of 60V (p-p)

High slew rate of 900 V/

No external components required

Very simple application

Single supply voltage of 200 V

Internal reference voltage of 2.5V

Fixed gain of 50

Black-Current Stabilization (BCS) circuit

Thermal protection

BLOCK DIAGRAM

handbook, full pagewidth

MGK278

TDA6107Q

V

DD

6

1, 2, 3

4

9, 8, 7

V

oc(3),

V

oc(2),

V

oc(1)

5

I

o(m)

R

f

MIRROR 5

DIFFERENTIAL

STAGE

VIP

REFERENCE

CURRENT

SOURCE

R

i

V

i(1)

,

V

i(2)

,

V

i(3)

R

a

3×

3×

CASCODE 1

CASCODE 2

MIRROR 2

1×

MIRROR 4

MIRROR 3

MIRROR 1

THERMAL

PROTECTION

CIRCUIT

1×

TECHNICAL INFORMATION

Page 31

MANUALSERVICE

31

SYMBOL

Vi(1)

Vi(2)

Vi(3)

GND

Iom

VDD

Voc(3)

Voc(2)

Voc(1)

PIN

1

2

3

4

5

6

7

8

9

DESCRIPTION

incerting input 1

incerting input 2

incerting input 3

ground (fin)

black-current measurement output

supply voltage

cathode output3

cathode output2

cathode output1

TECHNICAL INFORMATION

Page 32

MANUALSERVICE

32

7. POWER SWITCHING REGULATOR, STR-G 5653(Q801)

DESCRIPTION

STR-G 5653 is a hybrid IC with a built-in MOS FET and control IC,

designed for a primary side regulation.

MANY PROTECTION FUNCTIONS

OVP(over voltage protection circuit)

OCP(over current protection circuit)

TSD(Thermal shutdown circuit)

BLOCK DIAGRAM

PIN CONFIGURATION

PIN

1

2

3

4

5

SYMBOL

D

S

GND

VIN

O.C.P / F.B

Description

Drain Terminal

Source Terminal

Ground Terminal

Power supply Terminal

over current /

Feedback terminal

Functions

MOS FET DRAIN

MOS FET SOURCE

GROUND

Input of power supply for control circuit

Input of over current detection signal and

constant voltage control signals

TECHNICAL INFORMATION

Page 33

MANUALSERVICE

33

8. Vertical Delection Output IC, LA78040(Q301)

Description

The LA78040 is a Vertical deflection output IC for TVs and CRT displays with

excellent image quality.

This IC Can drive the direct(even including a DC component)

deflection yoke with the sawtooth wave output.

Because the maximum deflection current is 1.8App, the LA78040 is suited for

small and medium screen sets.

Features

Low power dissipation due to built-in pump-up circuit

Vertical output circuit

Thermal protection circuit built in

Excellent crossover characteristics

DC coupling possible

BLOCK DIAGRAM

TECHNICAL INFORMATION

Page 34

MANUALSERVICE

34

9.

HORIZONTAL DEFLECTION OUTPUT TRANSISTOR, KTD2499(Q404)

It is a horizontal deflection output transistor for color TV application.

FEATURES

High Voltage : VCBO 1500V

Low Saturation Voltage : V

CE(SAT)=5V(Max.) (IC=4A, IB=0.8A)

High Sheed : tf=0.3 (Typ.)

Built-in Damper Diode.

Collector Metal (Fin) is Fully Covered with Mold Resin.

MAXIMUM RATINGS (TC=25 )

CHARACTERISTIC

Collector-Base Voltage

Collector-Emitter Voltage

Emitter-Base Voltage

Collector Current DC

Pulse

Base Current

Collector Power Dissipation

Junction Temperature

Storage Temperature

SYMBOL

VCBO

VCEO

VEBO

IC

ICP

IB

PC

TI

TSTG

RATING

1500

600

5

6

12

3

50

150

-55~150

UNIT

V

V

V

A

A

W

TECHNICAL INFORMATION

Page 35

MANUALSERVICE

35

10. Universal hi-fi audio processor for TV TDA9859(QA01)

PIN CONFIGURATION

GENERAL DESCRIPTION

The TDA9859 provides control facilities for the main and the SCART channel

of a TV set. Due to extended switching possibilities, signals from three

stereo sources can be handled.

FEATURES

Multi-source selector switches six AF inputs

(three stereo sources or six mono sources)

Each of the input signals can be switched to each of the outputs

(crossbar switch)

Outputs for loudspeaker channel and peri-TV connector(SCART)

Switchable spatial stereo and pseudo stereo effects

Audio surround decoder can be added externally

Two general purpose logic output ports

I2C-bus control of all functions.

FUNCTIONAL DESCRIPTION

The TDA9859 consists of the following functions:

Source select switching block

Loudspeaker channel with effect controls

Two port outputs for general purpose

I2C-bus control.

TECHNICAL INFORMATION

AV STEREO ONLY

Page 36

MANUALSERVICE

36

BLOCK DIAGRAM

TECHNICAL INFORMATION

Page 37

MANUALSERVICE

37

11. Quasi split-sound circuit and AM demodulator,

TDA 3845(QS02)

GENERAl DESCRIPTION

The TDA3845 is a quasi split-sound IF circuit which is designed to provide high

performance television FM/AM sound.

FEATURES

Power supply from 5V(200mW) to 8V source also an alternative 12V source

(12V not for TDA3845T)

Gain controlled wideband IF amplifier(AC coupled with three stages)

High precision internal 90ophase shifter for quadrature demodulator

Amplitude detector for gain control which operates as a peak detector for FM sound o

and as a mean level detector for AM sound(switchable)

In-phase wideband synchronous demodulator for AM detection

Stabilizer circuit for ripple rejection and constant output signals

ESD protection for all pins

Suitable for all FM standards and L as well as L-accent standard

NICAM compatible.

SYMBOL PIN DESCRIPTION

IF2 1 IF amplifier input 2

n.c 2 not connected

AGC 3 AGC control capacitor

OPT 4

optional capacitor(see note 10 to

the characteristics)

PMD 5 peak/mean detector capacitor

AM 6 AM output

SW 7 FM/AM switch

LC

REF 8 LC reference circuit for the

picture carrier

LC

REF 9 LC reference circuit for the

picture carrier

n.c 10 not connected

Vp2 11

positive supply voltage 2

(+12V);note 1

ICO 12 intercarrier output

GND 13 ground(0V)

Vp1 14 positive supply voltage 1(+5V)

n.c 15 not connected

IF1 16 IF amplifier input 1

PIN configuration

TECHNICAL INFORMATION

RF STEREO ONLY

Page 38

MANUALSERVICE

38

12. Multi-Standard sound processor, MSP3410G(QS01)

Description

The MSP 34x0G family of single-chip Multistandard Sound Processors covers the sound

processing of all analog TV-Standards worldwide, as well as the NICAM digital sound

standards. The full TV sound processing, starting with analog sound IF signal-in down to

processed analog AF-out, is performed on a single chip.

BLOCK DIAGRAM

Application

TECHNICAL INFORMATION

RF STEREO ONLYRF STEREO ONLY

Page 39

MANUALSERVICE

39

PIN configuration

Pin No. Pin Name Type Connection Short description

PSDIP

52-pin

14 ADR_WS OUT LV ADRword strobe

- NC LV Not connected

13 ADR_DA OUT LV ADR data output

12 I2S_DA_IN1 IN LV I2S1 data input

11 I2S_DA_OUT OUT LV I2S data output

10 I2S_WS IN/OUT LV I2S word strobe

9 I2S_CL IN/OUT LV I2S clock

8 I2C_DA IN/OUT OBL I2C data

7 I2C-CL IN/OUT OBL I2C clock

- NC LV Not connected

6 STANDBYQ IN OBL Stand-by(low-active)

5 ADR_SEL IN OBL I2C Bus address select

4 D_CTR_I/O_0 IN/OUT LV D_CTR_I/O_0

3 D_CTR_I/O_1 IN/OUT LV D_CTR_I/O_1

- NC LV Not connected

- NC LV Not connected

- NC LV Not connected

2 AUD_CL_OUT OUT LV Audio clock output

(18.432 MHz)

1 TP LV Test pin

52 XTAL_OUT OUT OBL Crystal oscillator

51 XTAL_IN IN OBL Crystal oscillator

50 TESTEN IN OBL Test Pin

49 ANA_IN2+ IN AVSSvia IF input2(can be left

56 pF/LV

vacant, only if IF input 1 is

also not in use)

48 ANA_IN- IN AVSS via IF common(can be left

56pF/LV vacant, only if IF input 1

is also not in use)

TECHNICAL INFORMATION

Page 40

Pin No. Pin Name Type Connection Short description

PSDIP

52-pin

47 ANA_IN1+ IN LV IF Input 1

46 AVSUP OBL Analog Power supply 5 V

- AVSUP OBL Analog Power supply 5 V

- NC LV Not connected

- NC LV Not connected

45 AVSS OBL Analog ground

- AVSS OBL Analog ground

44 MONO_IN IN LV Mono input

- NC LV Not connected

43 VREFTOP OBL

Reference voltage IF A/D converter

42 SC1_IN_R IN LV SCART 1 input, right

41 SC1_IN_L IN LV SCART 1 input, left

- ASG1 AHVSS Analog Shield Ground1

40 SC2_IN_R IN LV SCART2 input, right

39 SC2_IN_L IN LV SCART2 input, left

- ASG2 AHVSS Analog Shield Ground 2

38 SC3_IN_R IN LV SCART 3 input, right

37 SC3_IN_R IN LV SCART 3 input, left

- ASG4 AHVSS Analong Shield Ground 4

- SC4_IN_R IN LV SCART 1 INPUT, right

- SC4_IN_L IN LV SCART 1 INPUT, left

-NC

LV or AHVSS

Not connected

36 AGNDC OBL Analog reference voltage

35 AHVSS OBL Analog ground

- AHVSS OBL Analog ground

- NC LV Not connected

- NC LV Not connected

34 CAPL_M OBL Volume capacitor MAIN

33 AHVSUP OBL Analog power supply 8V

32 CAPL_A OBL Volume capacitor AUX

MANUALSERVICE

40

TECHNICAL INFORMATION

Page 41

MANUALSERVICE

41

Pin No. Pin Name Type Connection Short description

PSDIP

52-pin

31 SC1_OUT_L OUT LV SCART output 1, left

30 SC1_OUT_R OUT LV SCART output 1, right

29 VREF1 OBL Reference ground 1

28 SC2_OUT_L OUT LV SCART output 2, left

27 SC2_OUT_R OUT LV SCART output 2, right

- NC LV Not connected

- NC LV Not connected

26 DACM_SUB OUT LV Subwoofer output

- NC LV Not connected

25 DACM_L OUT LV Loudspeaker out, left

24 DACM_R OUT LV Loudspeaker out, right

23 VREF2 OBL Reference ground 2

22 DACA_L OUT LV Headphone out, left

21 DACA_R OUT LV Headphone out, right

- NC LV Not connected

- NC LV Not connected

20 RESETQ IN OBL Power-on-reset

- NC LV Not connected

- NC LV Not connected

19 NC LV Not connected

18 I2S_DA_IN2 IN LV I2S2-data input

17 DVSS OBL Digital ground

- DVSS OBL Digital ground

- DVSS OBL Digital ground

16 DVSUP OBL Digital power supply 5V

- DVSUP OBL Digital power supply 5V

- DVSUP OBL Digital power supply 5V

15 ADR_CL OUT LV ADR clock

TECHNICAL INFORMATION

Page 42

MANUALSERVICE

42

13. 6W Mono Bridge Tied Load(BTL) audio amplifier, TDA 8943SF(Q606)

1. General description

The TDA8643SF is a single-channel audio power amplifier with an output power of 6W at an 8 load

and a 12V supply. The circuit contains a Bridge Tied Load (BTL) amplifier with an all-NPN output stage

and standby/mute logic. The TDA8943SF comes in a 9-lead single in-ine(SIL)medium power package.

The TDA8943SF is printed-circuit board(PCB) compatible with all other types in the TDA894x family One

PCB footprint accommodates both the mono and the stereo products.

2. Features

Few external componets

Fixed gain

Standby and mute mode

No on/off switching plops

Low standby current

High supply voltage ripple rejection

Outputs short-circuit Protected to ground supply and across the load

Thermally Protected

Printed-circuit board compatible

3. BLOCK DIAGRAM

4. PIN configuration

Symbol Pin Description

OUT- 1 Negative loudspeaker terminal

Vcc 2 supply voltage

OUT+ 3 Positive loudspeaker terminal

IN+ 4 Positive input

IN- 5 Negative input

SVR 6 Half supply voltage decoupling(ripple rejection)

MODE 7 mode selection input(standby, mute, operating)

GND 8 ground

n.c 9 not connented

TECHNICAL INFORMATION

FM MONO ONLY

Page 43

MANUALSERVICE

43

14. 2x7W stereo Bridge Tied Load(BTL)audio amplifier,

TDA 8944J(Q606)

1. General description

The TDA8944J is a dual-channel audio power amplifier with an output power of 2x7W at an

8

load and a 12V supply. The circuit contains a Bridge Tied Load (BTL) amplifiers with an

all-NPN output stage and standby/mute logic. The TDA8944J comes in a 17-pin DIL-bentSIL(DBS) power package. The TDA8944J is printed-circuit board(PCB) compatible with all

other types in TDA894x family. One PCB footprint accommodates both the mono and the

stereo products

2. Features

Few external componets

Fixed gain

Standby and mute mode

No on/off switching plops

Low standby current

High supply voltage ripple rejection

Outputs short-circuit Protected to ground, supply and across the load

Thermally Protected

Printed-circuit board compatible

3. BLOCK DIAGRAM

TECHNICAL INFORMATION

Page 44

MANUALSERVICE

44

4.PIN configuration

Symbol Pin Description

OUT1- 1 negative loudspeaker terminal 1

GND1 2 ground channel 1

Vcc1 3 supply voltage channel 1

OUT1+ 4 positive loudspeaker terminal1

n.c 5 cot connected

IN1+ 6 positive input 1

n.c 7 not cnonnected

IN1- 8 negative input 1

IN2- 9 negative input 2

MODE 10 mode selection input(standby, mute, operating)

SVR 11 half supply voltage decoupling(ripple rejection)

IN2+ 12 positive input 2

n.c. 13 not connected

OUT2- 14 negative loudspeaker terminal 2

GND2 15 ground channel 2

Vcc2 16 supply voltage channel 2

OUT2+ 17 positive loudspeaker terminal 2

TECHNICAL INFORMATION

Page 45

MANUALSERVICE

45

1. NO POWER (The secondary of the SMPS transformer)

START

END

Check the output voltage of

Q080, Q082, and Q081.

Check the cathode voltage of

D823 and D820.

OK?

Check the pin 4 voltage of

Q801.

Check the waveform between

pin 5 and GROUND.

Check the voltage of C807.

OK?

Check all the electric leakage in

each voltage with multi-meter.

OK?

Check the short circuits of D801,

D802, D803 and D804.

Check the open circuits of R801

OK?

Fix all the short circuits. Is there low

or abnormal voltage nevertheless?

Check F801(fuse).

In AC 90~250V INPUT, replace it with

250V 5A

NO

YES

YES

NO

YES

NO

NO

NO

STAND-BY

3.3V

0.5V

4.99V

110.3V

15.2V

11.5V

ON

3.3V

8.0V

4.9V

107V

16V

12V

MAIN PCB

Q080

Q081

Q082

D820

D823

D824

MAIN PCB

pin 4 of Q801

pin 5 of Q801

C807

STAND-BY

32V

1.19V

301V

ON

32V

1.93V

296V

TROUBLE SHOOTING

Page 46

MANUALSERVICE

46

2. NO RASTER (The power is normal but the heater voltage is “LOW”)

START

END

Check the voltage between pin 1

and GROUND.

Is it

Low ?

Check the COLLECTOR waveform

of Q404.

OK?

Check the waveform of pin

33 (Hout)of Q501.

OK?

Check the open circuits of R911

in CPT PCB.

Is there No Picture?

Check the BASE waveform of Q404.

OK?

Check the pin 1,2,3 waveforms

of Q901 in CPT PCB!

Check the pin 7,8,9 waveforms

of Q901.

Check the pin 6 voltage of Q901.

OK?

Check the output voltage of

Q080, Q081 and Q082.

Check the waveform

of X001(12MHZ).

Check the voltage of C403 +

(ST-BY:11.5V, ON:5.9V).

Check the open circuit of R402

and R404.

Check the short circuit of Q402.

Replace Q901 with new one.

Replace C907 with new one.

Check the short circuits of

D281 and Q902.

Check the open circuits of

R281.

Replace it with new one!

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

2.5Vpp

TROUBLE SHOOTING

HOUT

Page 47

MANUALSERVICE

47

3. NO PICTURE (SOUND is OK)

START

END

Check pin 7,8,9 of

Q901 in CPT PCB.

Check the pin 1,2,3

of Q901.

OK?

Check pin 53,52,51

waveforms of Q501.

OK?

Check pin 1,4,5

waveforms of Z101.

OK?

Check pin 38 waveforms

of Q501.

Check the pin 40 waveforms

of Q501.

Check the logic of QN01.

OK?

Check the waveform of

IF pin of H001.

OK?

Replace H001 with new one.

NO

NO

NO

NO

YES

NO

TROUBLE SHOOTING

Page 48

MANUALSERVICE

48

4. NO SOUND (PICTURE is “OK”)

Replace Q606 with new one.

NO

NO

NO

AV STEREO(TDA9859) RE STEREO(MSP3410G)

FIM MONO

NO

START

END END

Check the waveform between

pin 17 and 14 of Q606.

See that the mode state

(

pin 10 of Q606)is LOW .

(MUTE:high, normal:low)

OK?

Check the waveform of R,L Sound

output at pin 15 and 18 of QA01.

Check the waveform of SDA(Pin 17)

and SCL(Pin16).

Check the supply voltage at

pin 60 of QA01.

Check the waveform of MAIN Input

at pin 3 and 5 of QA01 in case

of TV mode.

OK?

Check the waveform of R,L sound

output at pin 24 and 25 of QS01.

Check the waveform of SDA(Pin8)

and SCL(pin7).

Check the supply voltage at pin

16, 46 and 33.

Check the voltage at pin 6 and 20.

Check the waveform of SIF at

pin 47 of QS01.

OK?

See that the sound state is MUTE

Check the voltage between pin 3(16)

and GROUND.

Check the waveform between

pin 14 and 17 of Q606.

OK?

Check the waveform of Aout at

pin 44 of Q501.

See that C528, C529, R531, C531

and C532 is inserted!

See that there is no signal in the IF

output of H001.

Check the voltage at pin 12

of QS02(1.8

0.5Vrms).

Check the supply voltage

at pin 14 of QS02.

See that there is no signal

in the IF output of H001.

NO

YES

TROUBLE SHOOTING

NO

Page 49

MANUALSERVICE

49

5. Vertical Line

START

END

Check the Supply voltage

at pin 2 of Q301

OK?

Check R381 and D381.

Check Q301 and Peripheral

parts.

NO

V2=DC20.8V

YES

YES

NO

NO

Check the waveform at pin 5

of Q301.

OK?

Check the waveform of the posive

sawtooth(pin7) and negative

sawtooth(pin1) of Q301.

OK?

Check the waveform at pin

21 and 22 of Q501.

TROUBLE SHOOTING

Page 50

MANUALSERVICE

50

6. NO PIP(Option)

START

END

Check the input and output voltage

of QP02.

Check the waveform at pin 46, 47

and 48 of Q501.

See that the voltage of pin 45 of Q501

is not

LOW (Low may be short-circuit).

OK?

Check the waveform of SDA(pin5)

and SCL(pin6) of QP01.

Check the frequency of XP01.

OK?

See that the waveform of HD and VD

is normal.

OK?

See that the input signals are OK

(TV-in, V

1-in, Y-in, C-in)

NO

YES

NO

VIN of QP02=8V

VOUT of QP02=3.3V

YES

HD=15.625 or

15.734KHz

VD=50 or 60Hz

YES

fx-tal=20.25MHz

TROUBLE SHOOTING

Page 51

MANUALSERVICE

51

BLOCK DIAGRAM(AV STEREO)

Page 52

MANUALSERVICE

52

BLOCK DIAGRAM(RF STEREO)

Page 53

MANUALSERVICE

53

PCB LAYOUT(MAIN)

Page 54

MANUALSERVICE

54

1. MAIN

OPTION LIST

Part No. ITEM-CODE Description 14" 20" 21"

C306 12085055T

CHEMICON,50V 0.47MF LL 85C(5*11) 100

12085056T

CHEMICON,50V 1MF LL 85C(5*11) 001

C306V1 12085055T

CHEMICON,50V 0.47MF LL 85C(5*11) 010

C404 12828274B

P/ CAP, T 200V 0.27MF J PFU 101

C404V1 12828244B

P/ CAP, T 200V 0.24MF J PFU 010

C421 12094216T

CERA-CAPA, DG3DHR471K825 (2KV470) 110

C422V1 12094216T

CERA-CAPA, DG3DHR471K825 (2KV470) 010

EL08 11061303

EYELET, HTR 2.80*2.9 SNI 011

EL09 11061303

EYELET, HTR 2.80*2.9 SNI 011

ES20 11061202

EYELET, HTR 2.11*2.8 SNI 011

ES27 11061202

EYELET, HTR 2.11*2.8 SNI 100

L401RA 11222140A

COIL, LINEARITY KLN-5167A(310MH) 001

L401RB C1222020

COIL, LIN CKLN2045 125UH (DR 10*10) 100

M902 300924035C

HARNESS, 9P 350MM (5264-5395) 100

E00924045E

HARNESS, 9P 450MM (5264-5395) ETL 011

Q404A 11865775

HEAT SINK, 29HG (55MM) 011

Q404B 11032382

SCREW, TTB 3*10 SZN 011

Q404C 11971010

COMPOUND SILICON, YG6260 0 0.025 0.025

Q404Z 150500542

HEAT SINK, ASS Y KTD2499 20US500 011

R309 12321109T

OXIDE RESISTOR, B 1/2W 1 OHM J 001

12321159T

OXIDE RESISTOR, B 1/2W 1.5 OHM J 100

R309V1 12321129T

OXIDE RESISTOR, B 1/2W 1.2 OHM J 010

R326 12321101T

OXIDE RESISTOR, B 1/2W 100 OHM J 100

12321271T

OXIDE RESISTOR, B 1/2W 270 OHM J 011

R402 12322270S

OXIDE RESISTOR, B 1W 27 OHM J 011

12322390S

OXIDE RESISTOR, B 1W 39 OHM J 100

R404 12322270S

OXIDE RESISTOR, B 1W 27 OHM J 011

12322390S

OXIDE RESISTOR, B 1W 39 OHM J 100

R409 12321221T

OXIDE RESISTOR, B 1/2W 220 OHM J 100

12323561S

OXIDE RESISTOR, B 2W 560 OHM J 011

R485 12321123T

OXIDE RESISTOR, B 1/2W 12K OHM J 100

12321822T

OXIDE RESISTOR, B 1/2W 8.2K OHM J 011

R486 12321159T

OXIDE RESISTOR, B 1/2W 1.5 OHM J 100

12323159S

OXIDE RESISTOR, B 2W 1.5 OHM J 001

R486V1 12323159S

OXIDE RESISTOR, B 2W 1.5 OHM J 010

R902 12368101T

CARBON RESISTOR, SB 1/6W 100 OHM J 011

R903 12368101T

CARBON RESISTOR, SB 1/6W 100 OHM J 011

R914 12368101T

CARBON RESISTOR, SB 1/6W 100 OHM J 100

R915 12368101T

CARBON RESISTOR, SB 1/6W 100 OHM J 100

V901A C1116435

SOCKET CRT, GZS 10-2-5 20 28MM 011

C1116436

SOCKET CRT, GZS 8-6-8 14 22MM 100

Page 55

MANUALSERVICE

55

2. SOUND

OPTION LIST

Part No. ITEM-CODE Description

A/V STEREO MTS STEREO

MONO

C528 12692222T “PLASTIC CAPACITOR, M 50V 2200PF J” 1 0 1

C529 12797100T “CHEMICON, 50V 10MF 85C 5*11” 1 0 1

C531 12692122T “PLASTIC CAPACITOR, M 50V 1200PF J” 1 0 1

C532 12436331T “CERAMIC CAPACITOR, SL 50V 330PF J” 1 0 1

C535 12797229T “CHEMICON, 50V 2.2MF 85C 5*11” 0 0 1

C619 12692224T “PLASTIC CAPACITOR, M 50V 0.22MF J” 1 1 0

C620 12692224T “PLASTIC CAPACITOR, M 50V 0.22MF J” 1 1 0

C622 12692272T “PLASTIC CAPACITOR, M 50V 2700PF J” 1 1 0

C651 12692682T “PLASTIC CAPACITOR, M 50V 6800PF J” 1 1 0

C677 12797109T “CHEMICON, 50V 1MF 85C 5*11” 1 1 0

C825 12087017T “CHEMICON, 25V 2200UF SMG(12.5*25)” 1 1 0

CA01 12692224T “PLASTIC CAPACITOR, M 50V 0.22MF J” 1 0 0

CA02 12692224T “PLASTIC CAPACITOR, M 50V 0.22MF J” 1 0 0

CA03 12794101T “CHEMICON, 16V 100MF 85C 6.3*11” 1 0 0

CA04 12794470T “CHEMICON, 16V 47MF 85C 5*11” 1 0 0

CA05 12692223T “PLASTIC CAPACITOR, M 50V 0.022MF J” 1 0 0

CA06 12692683T “PLASTIC CAPACITOR, M 50V 0.068MF J” 1 0 0

CA07 12692154T “PLASTIC CAPACITOR, M 50V 0.15MF J” 1 0 0

CA08 12692562T “PLASTIC CAPACITOR, M 50V 5600PF J” 1 0 0

CA09 12797479T “CHEMICON, 50V 4.7MF 85C 5*11” 1 0 0

CA10 12797479T “CHEMICON, 50V 4.7MF 85C 5*11” 1 0 0

CA11 12692562T “PLASTIC CAPACITOR, M 50V 5600PF J” 1 0 0

CA12 12692154T “PLASTIC CAPACITOR, M 50V 0.15MF J” 1 0 0

CA13 12692683T “PLASTIC CAPACITOR, M 50V 0.068MF J” 1 0 0

CA14 12692562T “PLASTIC CAPACITOR, M 50V 5600PF J” 1 0 0

CA16 12692473T “PLASTIC CAPACITOR, M 50V 0.047MF J” 1 0 0

CA18 12692224T “PLASTIC CAPACITOR, M 50V 0.22MF J” 1 0 0

CS01 12353180T “CERAMIC CAPACITOR, CH 50V 18PF J” 0 1 0

CS02 12353180T “CERAMIC CAPACITOR, CH 50V 18PF J” 0 1 0

CS03 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS04 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS05 12473470T “CERAMIC CAP, SL 50V 47PF J AXIAL” 0 1 0

CS06 12474101T “CERAMIC CAP, B 50V 100PF K AXIAL” 0 1 0

CS07 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS09 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS10 12797109T “CHEMICON, 50V 1MF 85C 5*11” 0 1 0

CS11 12797109T “CHEMICON, 50V 1MF 85C 5*11” 0 1 0

CS12 12797109T “CHEMICON, 50V 1MF 85C 5*11” 0 1 0

CS19 12797339T “CHEMICON, 50V 3.3MF 85C 5*11” 0 1 0

CS20 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS21 12797100T “CHEMICON, 50V 10MF 85C 5*11” 0 1 0

CS22 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS23 12683471T “CHEMICON, 16V 470MF SHL,SD (8*11.5)” 0 1 0

Page 56

MANUALSERVICE

56

Part No. ITEM-CODE Description

A/V STEREO MTS STEREO

MONO

CS31 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL” 0 1 0

CS32 12794220T “CHEMICON, 16V 22MF 85C 5*11” 0 1 0

CS33 12692103T “PLASTIC CAPACITOR, M 50V 0.01MF J” 0 1 0

CS34 12797479T “CHEMICON, 50V 4.7MF 85C 5*11” 0 1 0

CS35 12797100T “CHEMICON, 50V 10MF 85C 5*11” 0 1 0

CS37 12353270T “CERAMIC CAPACITOR, CH 50V 27PF J” 0 1 0

CS41 12797229T “CHEMICON, 50V 2.2MF 85C 5*11” 0 1 0

CS42 12793331T “CHEMICON, 10V 330MF 85C 8*12” 0 1 0

CS61 12497223T “CERAMIC CAP, F 25V 0.022MF Z AXIAL” 0 1 0

CS62 12497223T “CERAMIC CAP, F 25V 0.022MF Z AXIAL” 0 1 0

CS63 12797478T “CHEMICON, 50V 0.47MF 85C 5*11” 0 1 0

CS64 12797478T “CHEMICON, 50V 0.47MF 85C 5*11” 0 1 0

D632 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W” 1 1 0

D651 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W” 1 1 0

D652 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W” 1 1 0

D823 11115788 “DIODE, F-REC SF-54 (FOR-20MM SH)” 1 1 0

DA01 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W” 1 0 0

DS01 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W” 0 1 0

EL18 11061303 “EYELET, HTR 2.80*2.9 SNI” 1 1 0

EL19 11061303 “EYELET, HTR 2.80*2.9 SNI” 1 1 0

EL20 11061303 “EYELET, HTR 2.80*2.9 SNI” 1 1 0

EL21 11061303 “EYELET, HTR 2.80*2.9 SNI” 1 1 0

ES12 11061202 “EYELET, HTR 2.11*2.8 SNI” 1 1 0

ES13 11061202 “EYELET, HTR 2.11*2.8 SNI” 1 1 0

ES39 11061202 “EYELET, HTR 2.11*2.8 SNI” 0 0 1

ES40 11061202 “EYELET, HTR 2.11*2.8 SNI” 0 0 1

J007 11183004 “PLATING WIRE, 0.6MM” 1 0 0

J010 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J011 11183004 “PLATING WIRE, 0.6MM” 0 0 1

J012 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J013 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J014 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J016 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J017 11183004 “PLATING WIRE, 0.6MM” 1 0 1

J018 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J019 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J021 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J024 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J025 11183004 “PLATING WIRE, 0.6MM” 1 0 1

J030 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J032 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J033 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J043 11183004 “PLATING WIRE, 0.6MM” 1 1 0

OPTION LIST

Page 57

MANUALSERVICE

57

OPTION LIST

Part No. ITEM-CODE Description

A/V STEREO MTS STEREO

MONO

J049 11183004 “PLATING WIRE, 0.6MM” 0 0 1

J065 11183004 “PLATING WIRE, 0.6MM” 0 0 1

J070 11183004 “PLATING WIRE, 0.6MM” 0 0 1

J075 11183004 “PLATING WIRE, 0.6MM” 0 0 1

J086 11183004 “PLATING WIRE, 0.6MM” 0 1 0

J112 11183004 “PLATING WIRE, 0.6MM” 1 0 1

J134 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J148 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J149 11183004 “PLATING WIRE, 0.6MM” 1 1 0

J156 11183004 “PLATING WIRE, 0.6MM” 1 0 1

J721 11183004 “PLATING WIRE, 0.6MM” 1 1 0

JS12 11183004 “PLATING WIRE, 0.6MM” 0 1 0

JV01 11163140 “JACK,PJ6037B 6P YL-RDS-WH/YL-RDS-WH” 1 1 0

11163212 “JACK, PPJ145-01 2P (L CHASSIS)” 0 0 1

JV02 11163163 “JACK, RCA S-456G 2P” 0 0 1

11163164 “JACK, S-456K 3P” 1 1 0

L801RA C1211003A “COIL,LINEFILTER CKRF3004H 1.2MH MIN” 0 0 1

L801RB 11211003A “COIL,LINE FILTER KRF3004H 1.2MH MIN” 1 1 0

L825 11103049T “B-CORE, ZBF503M-00TA-(K)-02” 1 1 0

LA01 11237100T “COIL, AXIAL LAL02TB 10UH K” 1 0 0

LS01 11237330T “COIL, AXIAL LAL02TB 33UH K” 0 1 0

LS06 11183004 “PLATING WIRE, 0.6MM” 0 1 0

LS07 11237100T “COIL, AXIAL LAL02TB 10UH K” 0 1 0

LS15 11237109T “COIL, AXIAL LAL02TB 1UH K” 0 1 0

LS20 11262136 “COIL, KRF-A543 SIF” 0 1 0

LV80 11183004 “PLATING WIRE, 0.6MM” 0 1 0

MV03 E00524020 “HARNESS, 5P 200MM (5264-5395) ETL” 0 0 1

E00724020A “HARNESS, 7P 200MM (5264-5395) ETL” 1 1 0

P601 11164121 “PLUG, 2P 5267-02AX” 0 0 1

11164123 “PLUG, 4P 5267-04AX” 1 1 0

PV03 11164124 “PLUG, 5P 5267-05AX” 0 0 1

11164126 “PLUG, 7P 5267-07AX” 1 1 0

Q606 11118469 IC. TDA8943SF/N1 MONO AMP 0 0 1

11118470 IC. TDA8944J/N1 STEREO AMP 1 1 0

Q606A 11865542 “HEAT SINK,(PLATE) (55MM)” 0 0 1

11865882 “HEAT SINK, 20A1L (45MM)” 1 1 0

Q606B 11032381 “SCREW, TTB 3*8 SZN” 0 0 1

11032388 “SCREW, TTBW 3*10 SZN” 2 2 0

Q606Z 150500480 “HEAT SINK, ASS’Y TDA8943SF 14A1L” 0 0 1

150500482 “HEAT SINK, ASS’Y TDA8944 21QL” 1 1 0

QA01 11118471 IC. S.PROC. TDA9859/V2 1 0 0

QS01 11118436A “IC,MSP3420G-PO-B8-V3.IC PSDIP52P” 0 1 0

QS02 11118473 IC. QSSIC TDA3845/V3 0 1 0

Page 58

MANUALSERVICE

58

OPTION LIST

Part No. ITEM-CODE Description

A/V STEREO MTS STEREO

MONO

QS10 11119282 “IC, REGU. 1[A] KIA7805PI(7805API)” 0 1 0

QS20 11119699T “IC, VOLTAGE DETECTOR KIA7042AP” 0 1 0

R006 12368101T “CARBON RESISTOR, SB 1/6W 100 OHM J” 0 0 1

R009 12368101T “CARBON RESISTOR, SB 1/6W 100 OHM J” 0 0 1

R016 12368332T “CARBON RESISTOR, SB 1/6W 3.3K OHM J” 0 0 1

R019 12368332T “CARBON RESISTOR, SB 1/6W 3.3K OHM J” 0 0 1

R309 12321129T “OXIDE RESISTOR, B 1/2W 1.2 OHM J” 1 1 0

R309V1 12321129T “OXIDE RESISTOR, B 1/2W 1.2 OHM J” 0 0 1

R325 12321331T “OXIDE RESISTOR, B 1/2W 330 OHM J” 0 0 1

12321391T “OXIDE RESISTOR, B 1/2W 390 OHM J” 1 1 0

R486 12323109S “OXIDE RESISTOR, B 2W 1 OHM J” 1 1 0

R486V1 12323159S “OXIDE RESISTOR, B 2W 1.5 OHM J” 0 0 1

R531 12368392T “CARBON RESISTOR, SB 1/6W 3.9K OHM J” 1 0 1

R534 12368201T “CARBON RESISTOR, SB 1/6W 200 OHM J” 0 0 1

R544 12061633T “CARBON-VR, 0.2W B 5K OHM FB” 0 0 1

12368101T “CARBON RESISTOR, SB 1/6W 100 OHM J” 1 0 0

R611 12368201T “CARBON RESISTOR, SB 1/6W 200 OHM J” 1 0 0

12368271T “CARBON RESISTOR, SB 1/6W 270 OHM J” 0 0 1

12368272T “CARBON RESISTOR, SB 1/6W 2.7K OHM J” 0 1 0

R612 12368201T “CARBON RESISTOR, SB 1/6W 200 OHM J” 1 0 0

12368272T “CARBON RESISTOR, SB 1/6W 2.7K OHM J” 0 1 0

12368561T “CARBON RESISTOR, SB 1/6W 560 OHM J” 0 0 1

R651 12368102T “CARBON RESISTOR, SB 1/6W 1K OHM J” 1 1 0

R652 12368224T “CARBON RESISTOR, SB 1/6W 220K OHM J” 1 1 0

R691 12323159S “OXIDE RESISTOR, B 2W 1.5 OHM J” 1 1 0

12323229S “OXIDE RESISTOR, B 2W 2.2 OHM J” 0 0 1

RA01 12368133T “CARBON RESISTOR, SB 1/6W 13K OHM J” 1 0 0

RA02 12368391T “CARBON RESISTOR, SB 1/6W 390 OHM J” 1 0 0

RA03 12368391T “CARBON RESISTOR, SB 1/6W 390 OHM J” 1 0 0

RA04 12368133T “CARBON RESISTOR, SB 1/6W 13K OHM J” 1 0 0

RS01 12368101T “CARBON RESISTOR, SB 1/6W 100 OHM J” 0 1 0

RS02 12368101T “CARBON RESISTOR, SB 1/6W 100 OHM J” 0 1 0

RS10 11183004T “PLATING WIRE,(TAPPING) 0.6MM 52MM” 0 1 0

RS21 12368102T “CARBON RESISTOR, SB 1/6W 1K OHM J” 0 1 0

RS61 12368102T “CARBON RESISTOR, SB 1/6W 1K OHM J” 0 1 0

RS62 12368102T “CARBON RESISTOR, SB 1/6W 1K OHM J” 0 1 0

RV54 12368102T “CARBON RESISTOR, SB 1/6W 1K OHM J” 1 1 0

RV55 12368224T “CARBON RESISTOR, SB 1/6W 220K OHM J” 1 1 0

RV71 12368102T “CARBON RESISTOR, SB 1/6W 1K OHM J” 0 0 1

RV72 12368221T “CARBON RESISTOR, SB 1/6W 220 OHM J” 0 0 1

RV73 12368681T “CARBON RESISTOR, SB 1/6W 680 OHM J” 0 0 1

XS01 11153276 “CRYSTAL,18.43200MHZ 16PF HC-49U 4.5” 0 1 0

Z101 C1107310 “SAW FILTER, HDIF45A4M NTSC” 1 0 1

C1107313 “SAW FILTER, HDIF45A12M NT” 0 1 0

Z102 C1107312 “SAW FILTER, HDAF45A1M NT” 0 1 0

Page 59

MANUALSERVICE

59

ELECTRICAL PARTS LIST

P / No.

ITEM No. ITEM NAME P / No. ITEM No. ITEM NAME

A001 150012944 “MAIN, NTSC PTSM02 21ES200”

A001A 150012945 “MAIN, NTSC PTSM02-1 21ES200”

AA01R 150610801 “MAIN, RHU PTSM02-1 21ES200”

AA01U 150111396 “MAIN, AUTO PTSM02-1 21ES200”

AA01A 150211514 “MAIN, AXIAL PTSM02-1 21ES200”

C054 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL”

C060 12474102T “CERAMIC CAP, B 50V 1000PF K AXIAL”

C061 12474102T “CERAMIC CAP, B 50V 1000PF K AXIAL”

C062 12474102T “CERAMIC CAP, B 50V 1000PF K AXIAL”

C161 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL”

C162 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL”

C163 12497103T “CERAMIC CAP, F 25V 0.01MF Z AXIAL”

C521 12477104T “CERAMIC CAP, F 50V 0.1MF Z AXIAL”

C522 12477104T “CERAMIC CAP, F 50V 0.1MF Z AXIAL”

C525 12477104T “CERAMIC CAP, F 50V 0.1MF Z AXIAL”

C536 12477104T “CERAMIC CAP, F 50V 0.1MF Z AXIAL”

C569 12497223T “CERAMIC CAP, F 25V 0.022MF Z AXIAL”

D050 11115623T “ZD, MTZJ5.1B (VZ4.94-5.20) 0.5W”

D052 11115686T “ZD, MTZJ33B (VZ30.32-31.88) 0.5W”

D063 11115623T “ZD, MTZJ5.1B (VZ4.94-5.20) 0.5W”

D111 11115024T “SILICON DIODE, 1N4148”

D231 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

D232 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

D281 11115790T “DIODE, F-REC RGP15J (SH)”

D301 11115003T “SILICON DIODE, 1N4004”

D354 11115686T “ZD, MTZJ33B (VZ30.32-31.88) 0.5W”

D355 11115686T “ZD, MTZJ33B (VZ30.32-31.88) 0.5W”

D356 11115686T “ZD, MTZJ33B (VZ30.32-31.88) 0.5W”

D381 11115458T “DIODE, FAST RECOVERY UF-156”

D433 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W”

D482 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W”

D483 11115790T “DIODE, F-REC RGP15J (SH)”

D514 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W”

D522 11115024T “SILICON DIODE, 1N4148”

D534 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W”

D539 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W”

D550 11115635T “ZD, MTZJ7.5B (VZ7.07-7.45) 0.5W”

D570 11115024T “SILICON DIODE, 1N4148”

D631 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

D632 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

D651 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

D652 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

D681 11115024T “SILICON DIODE, 1N4148”

D801 11115464T “DIODE, RECTIFIER 1N5398E”

D802 11115464T “DIODE, RECTIFIER 1N5398E”

D803 11115464T “DIODE, RECTIFIER 1N5398E”

D804 11115464T “DIODE, RECTIFIER 1N5398E”

D805 11115003T “SILICON DIODE, 1N4004”

D811 11115787T “DIODE, F-REC SF-14 (SH)”

D812 11115787T “DIODE, F-REC SF-14 (SH)”

D813 11115787T “DIODE, F-REC SF-14 (SH)”

DA01 11115638T “ZD, MTZJ8.2B (VZ7.78-8.19) 0.5W”

DV51 11115641T “ZD, MTZJ9.1B (VZ8.57-9.01) 0.5W”

EL01 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL02 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL03 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL04 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL05 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL06 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL07 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL08 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL09 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL12 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL13 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL14 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL15 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL18 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL19 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL20 11061303 “EYELET, HTR 2.80*2.9 SNI”

EL21 11061303 “EYELET, HTR 2.80*2.9 SNI”

ES01 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES02 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES03 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES04 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES05 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES06 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES07 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES08 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES09 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES10 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES11 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES12 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES13 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES14 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES15 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES16 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES17 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES18 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES19 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES20 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES21 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES22 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES23 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES24 11061202 “EYELET, HTR 2.11*2.8 SNI”

ES25 11061202 “EYELET, HTR 2.11*2.8 SNI”