RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

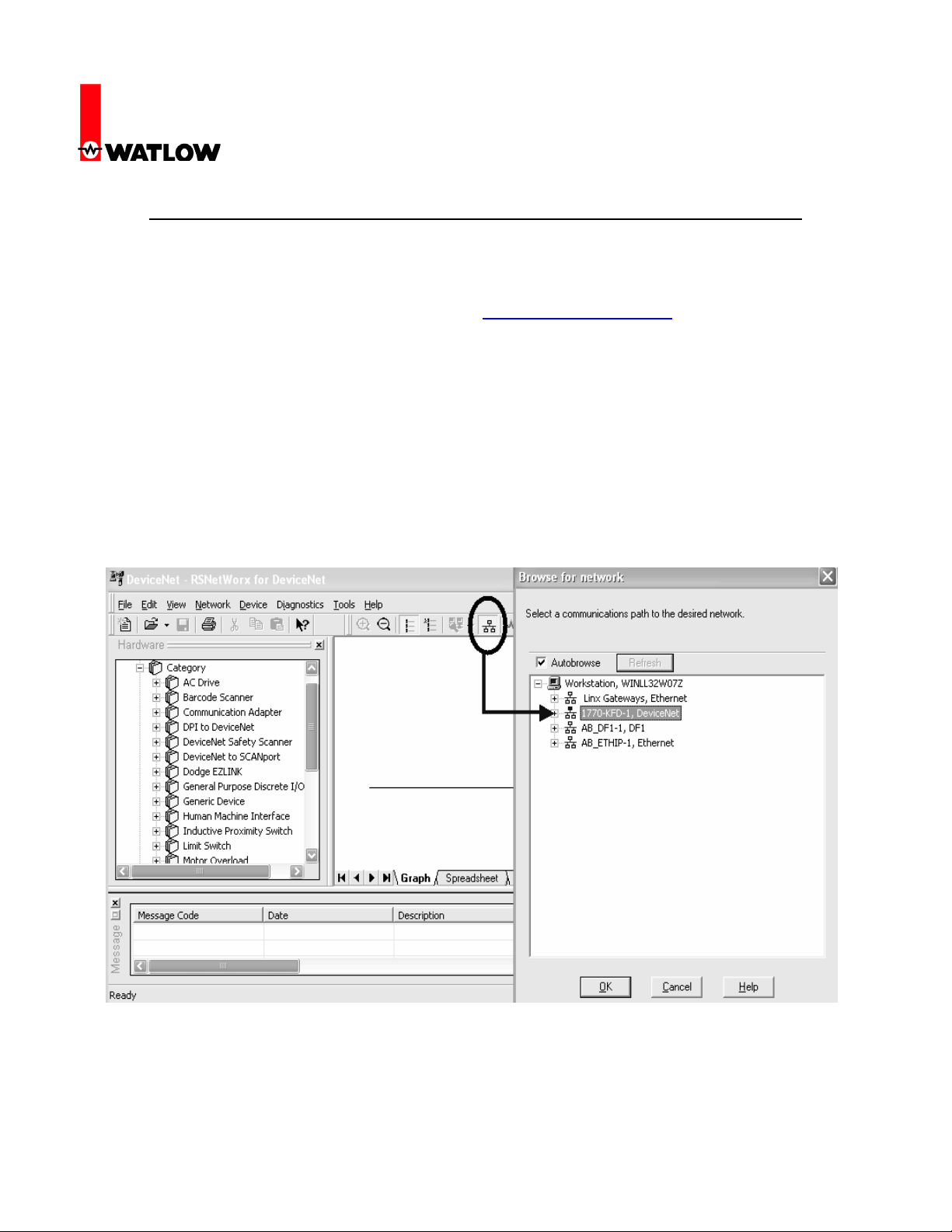

Using an Allen-Bradley CompactLogix PLC

Configuring the RUI/Gateway on DeviceNet

1. Prior to making the physical connections on the network setup the gateway DeviceNetTM

communications parameters per your network requirements, i.e., baud rate and node

address. If your not sure how to do this go to http://www.watlow.com and download the EZ-

ZONE

chapter.

2. Once the gateway communications parameters for DeviceNet

network requirements connect the gateway into the network and do the following:

a. Run RSLinx software and configure the driver of choice

b. Run RSNetWorx software.

3. As shown below (within RSNetWorx software), click on the online command from the tools

toolbar and then select the appropriate communications path to browse the DeviceNetTM

network. Set up in previous step using RSLinx software.

4. After successfully browsing the network all nodes on the network will appear in the graphical

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 1 4/08

®

PM Communications Manual and follow the procedure defined in the DeviceNet

TM

Using RSNetWorx

TM

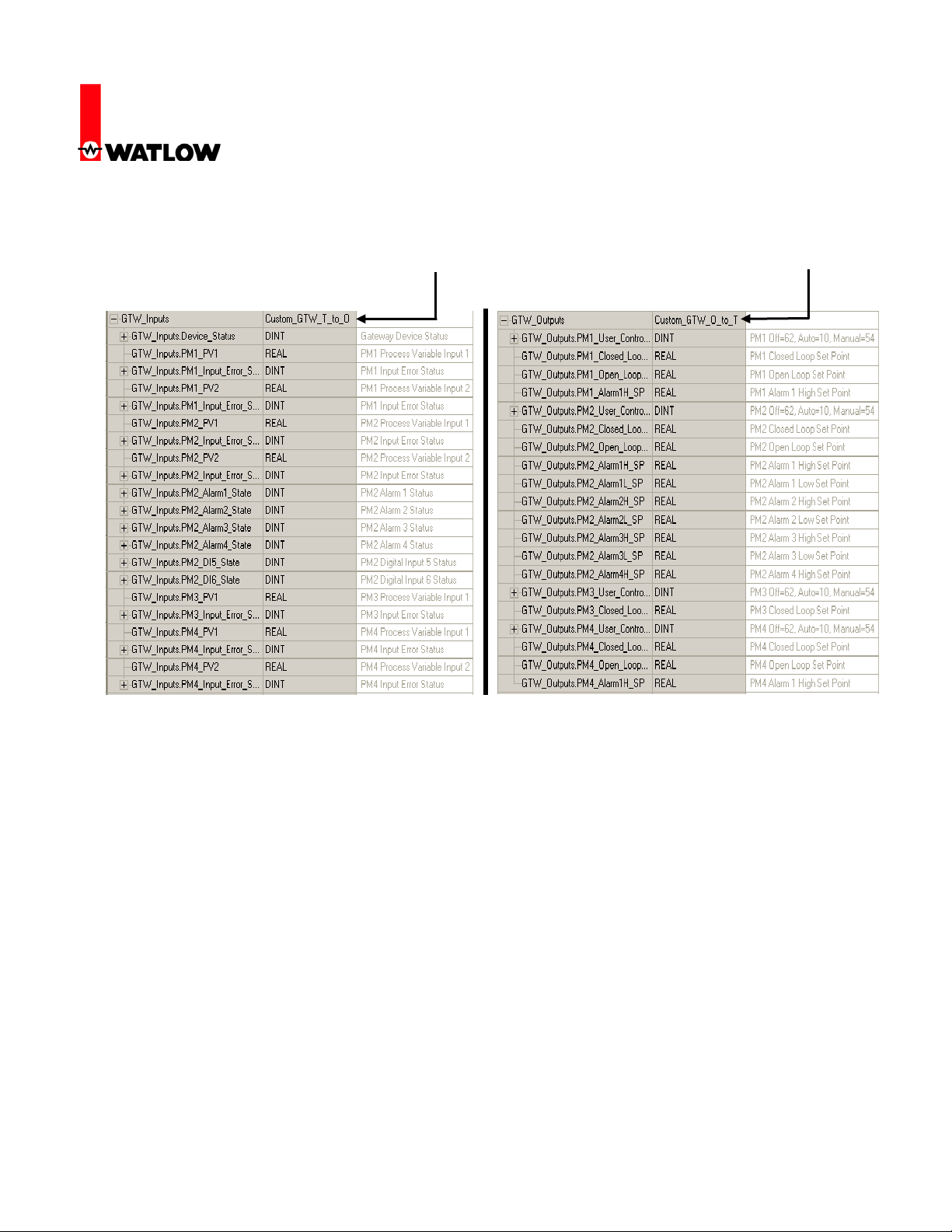

are set according to your

TM

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

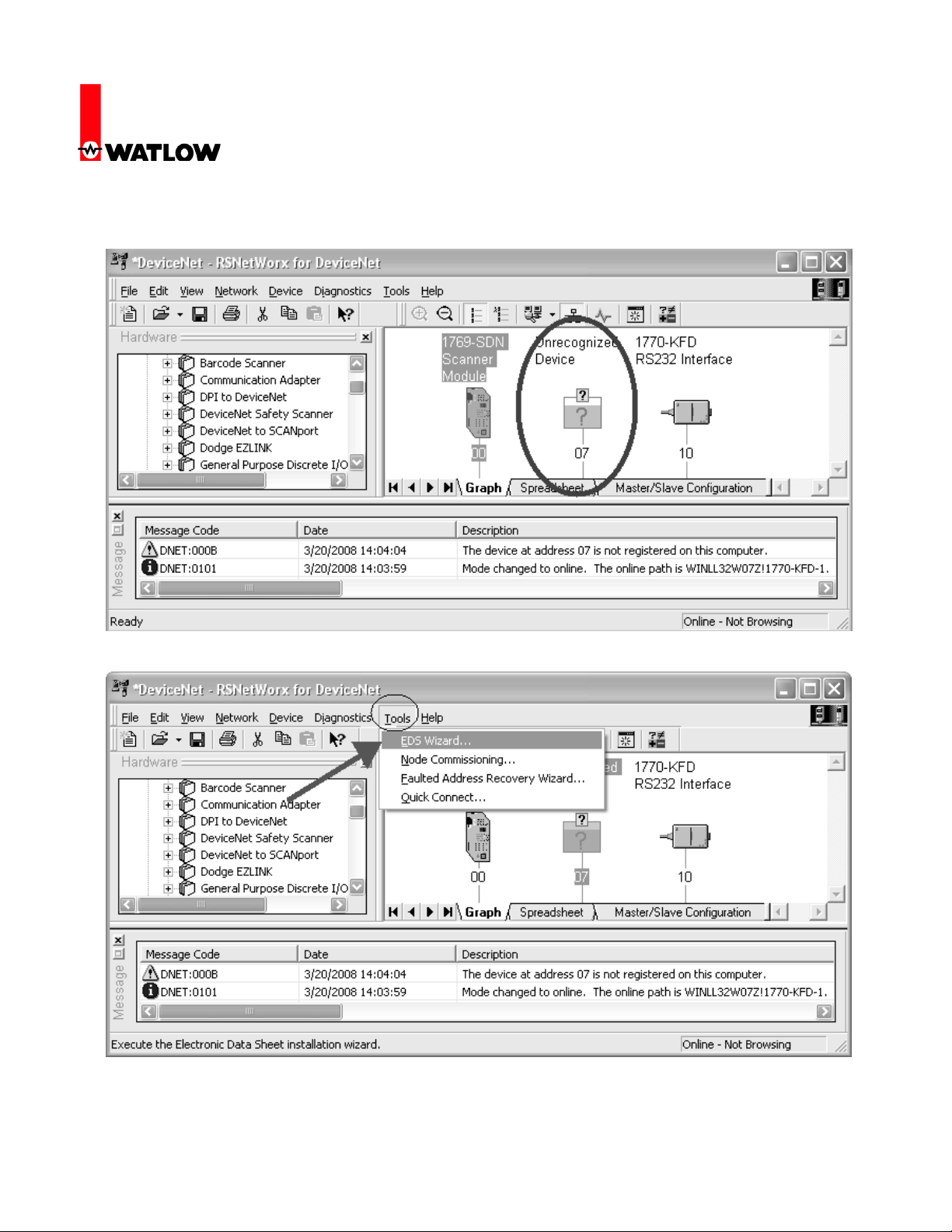

display as shown below. In this particular case, node 7 (RUI/Gateway) appears with a

question mark because it has not yet been registered on the network.

5. To register any given node on the network click on Tools and then EDS Wizard.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 2 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

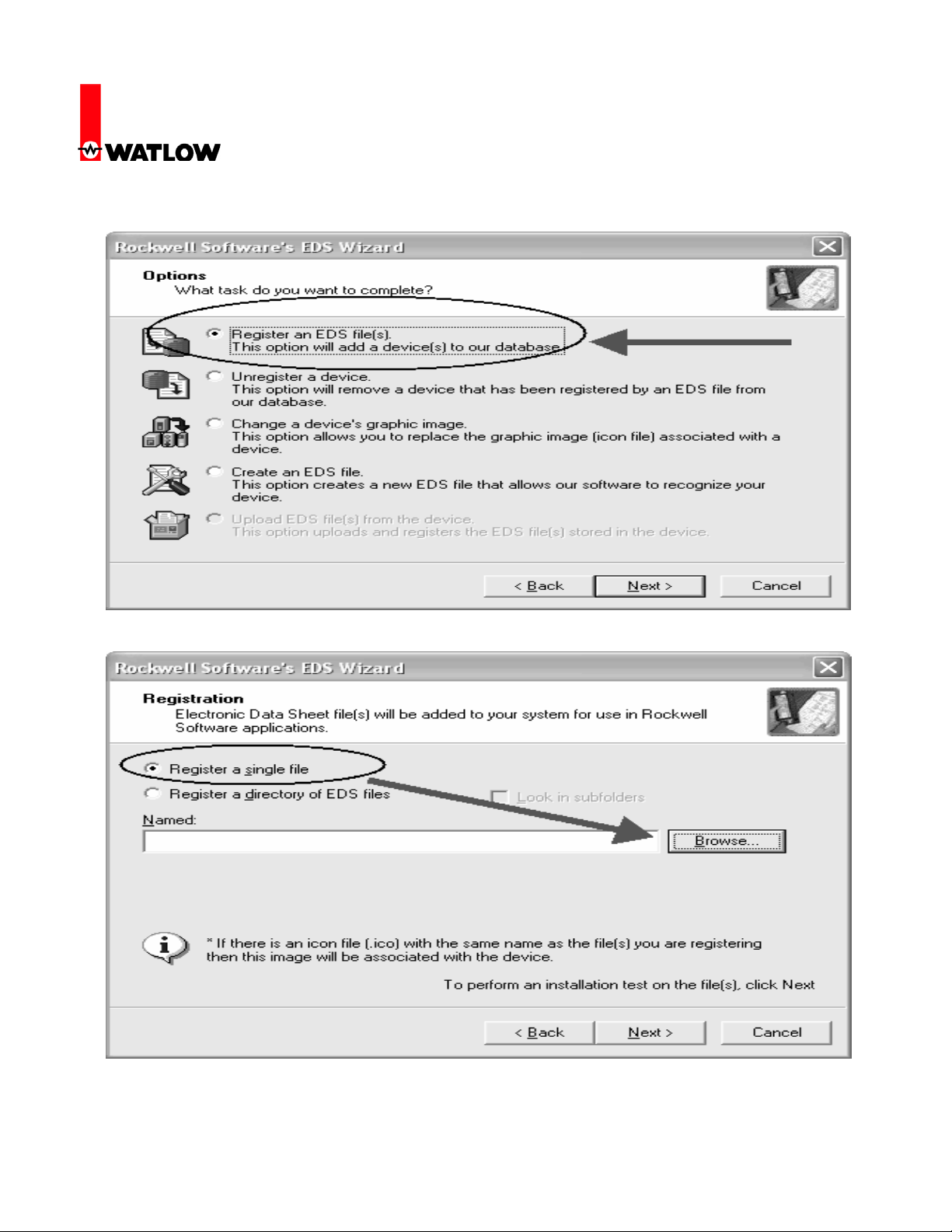

6. Select Register an EDS file.

7. Register a single file and then click browse to locate its location.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 3 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

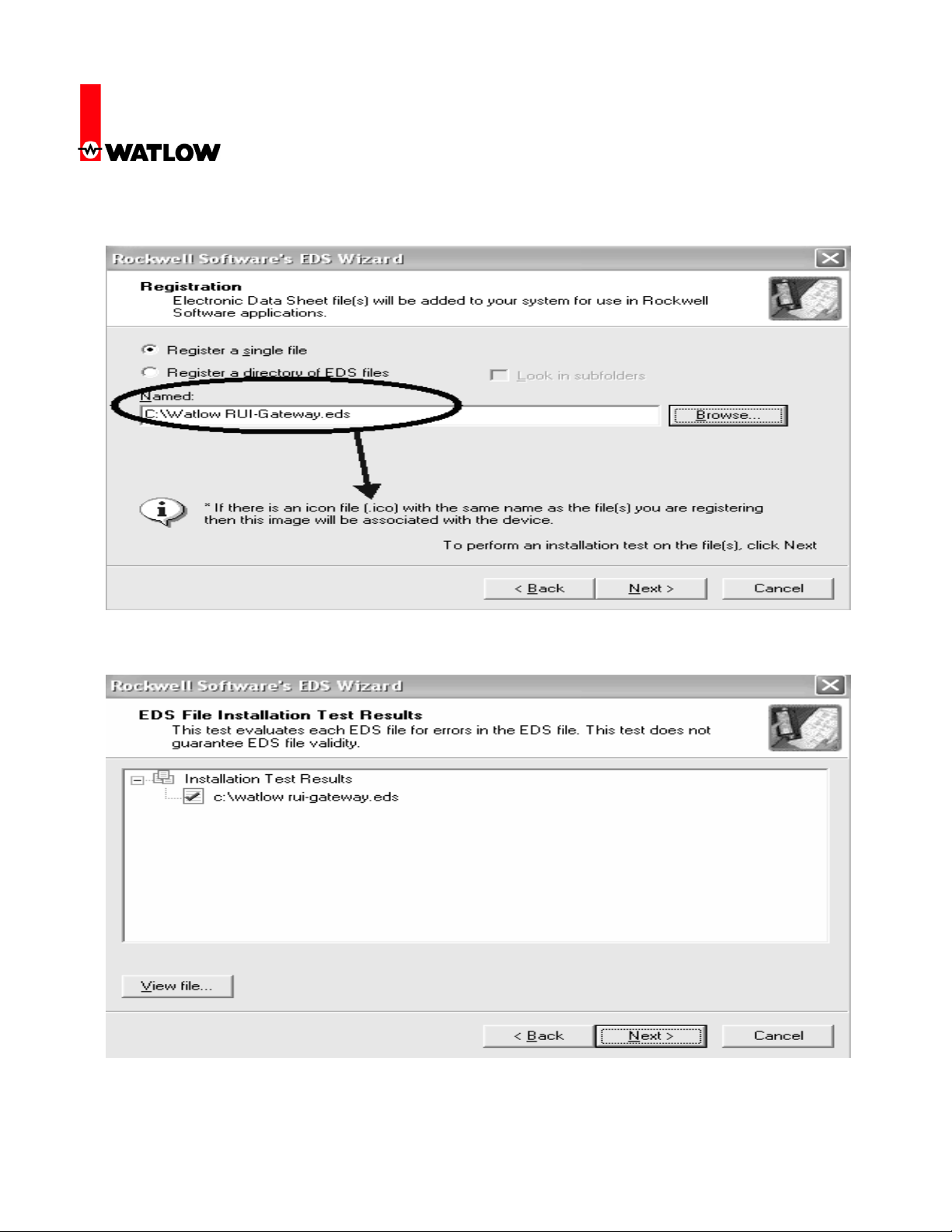

8. When found notice that if there is an icon with the same name the software will register it

along with the EDS file. Click next to proceed with the registration.

9. The next step verifies that there are no errors in the EDS file; a green check should be

displayed next to the file as shown below.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 4 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

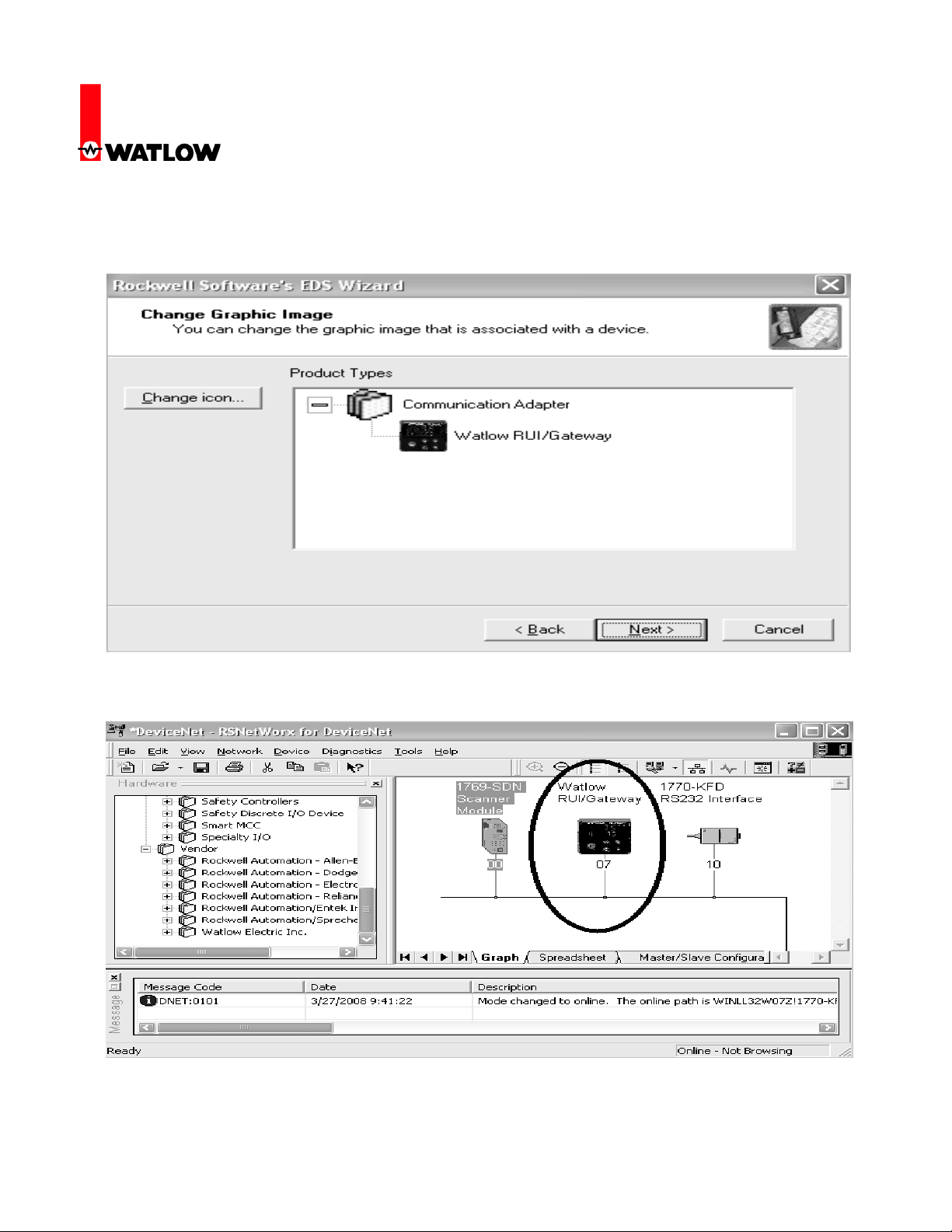

10. After clicking next above, the software will associate an icon to this device, if there was none

found in the previous step it will use a default icon to graphically represent this node. Click

next to proceed.

11. Clicking next above completes the registration process where the question mark is removed

and replaced with the icon of choice for node 7 (Watlow RUI/Gateway).

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 5 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

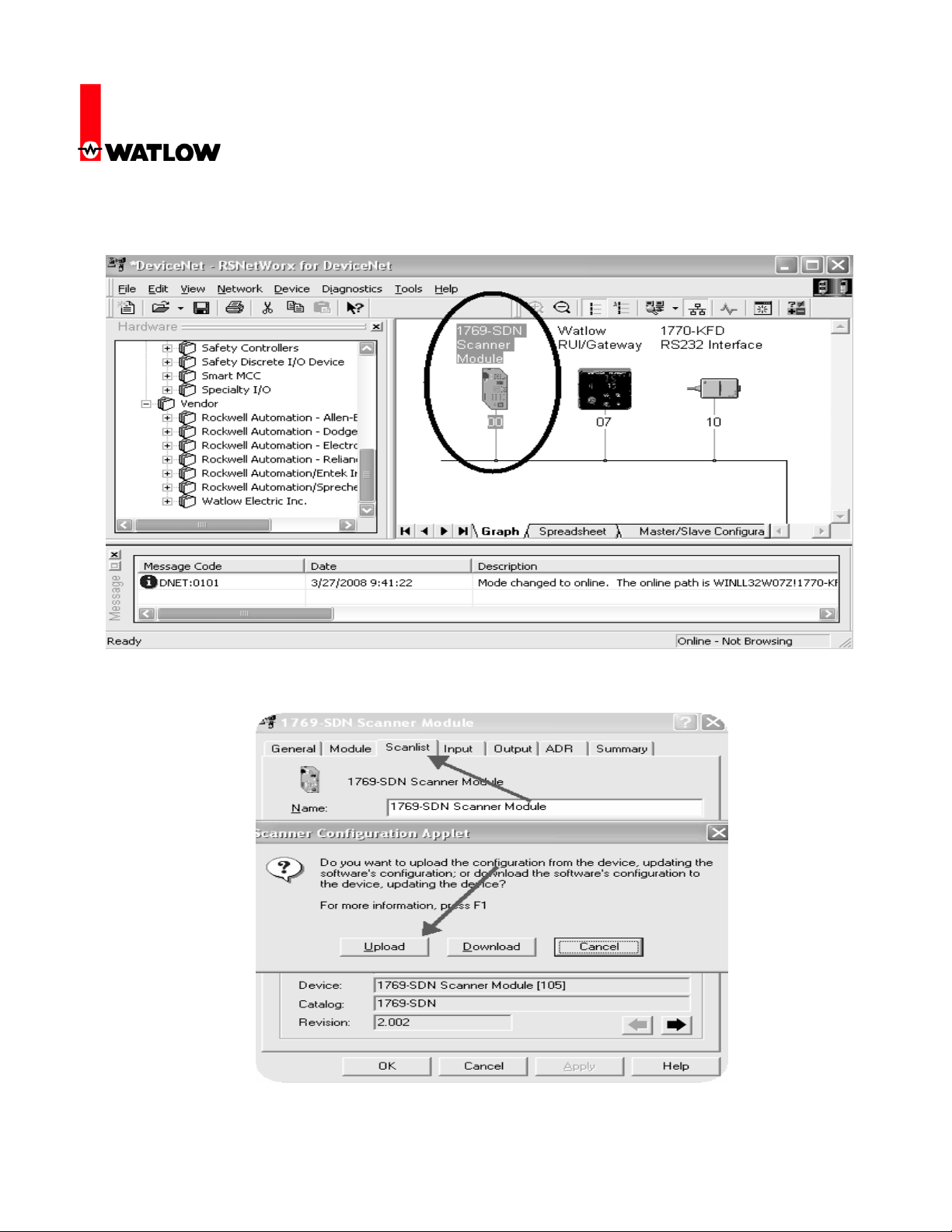

12. The next series of steps involves mapping the available RUI/Gateway input (84) and output

(80) bytes via the scanner into the PLC memory. Double click on the scanner module to

proceed.

13. Click on the scanlist tab where the next dialogue will suggest an upload or a download. Click

on the upload button to allow the scanner to see what is available on the network.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 6 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

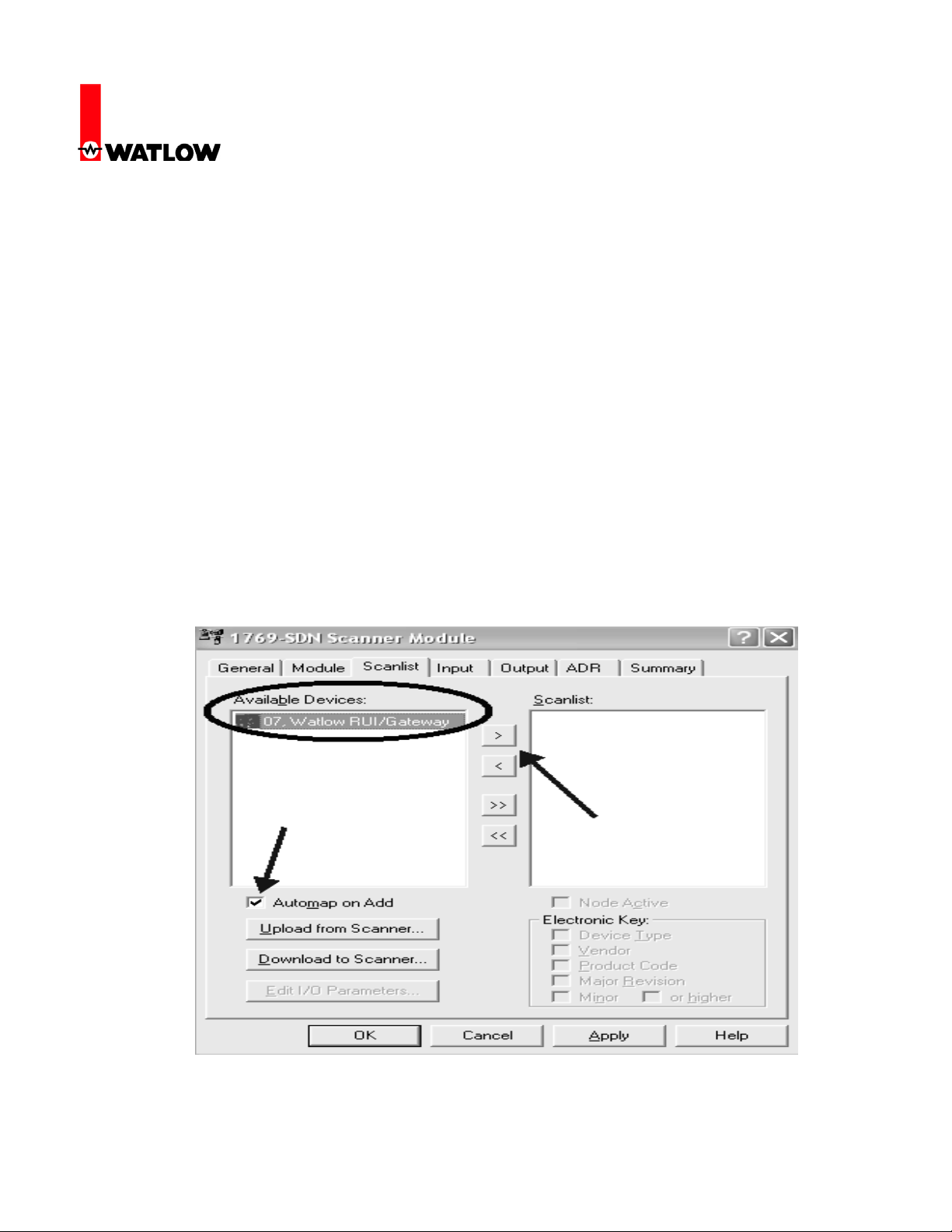

14. After the scanner recognizes the RUI/Gateway on the network it will then appear as an

Available Device as shown below. Before clicking on the right arrow to add it in the scanners

scan list consider the effect of the Automap on Add check box. If this box is checked and

there are other currently existing nodes on the network where they may not be using

complete words (less than 32 bits) the scanner will not consider word boundaries when

adding a new node and will attempt to utilize every available bit in the PLC. As an example, if

a given device has only 9 bytes of information it will use 2¼ 32 bit words (3 bytes not used in

the last word). Now, when adding a new node like the RU/Gateway that utilizes 80 bytes (2032 bit words with each being a separate entity, i.e., 32 bit Set Point) ¾ of the first word will be

placed in the last word of the node mentioned above. The impact of this action would then

break up all of the 20 words sent to and received from the RUI/Gateway in a convoluted way.

For this reason, it is suggested that this box be unchecked (if there are other devices on the

network) allowing the individual doing the configuration to select the appropriate word

boundaries manually.

In this case, there are no other devices on the network so leaving the Automap on Add box

checked will not have a negative impact on the gateway configuration.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 7 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

15. Once the available device (RUI/Gateway in this case) is moved over to the Scanlist the next

step will be to map the RUI/Gateway input and output bytes to PLC addresses; first the

inputs. In this particular case the Automap on Add box was checked and the result of that now

becomes apparent. Since there were no other devices on the network the software simply

took all of the available RUI/Gateway input bytes (84) and allocated them to the first available

PLC input bytes. Although we can’t see in the graphic below all of the addresses assigned

you can trust that what was assigned are addresses 1:I.Data[0] through 1:I.Data[20]. If there

were other devices on the network and the Automap on Add box was not checked the

address field below would not be populated. Clicking on the Advanced button would then

allow for manual configuration.

16. Likewise, all of what was said above regarding the inputs also applies to the outputs as well.

Notice in the graphic below that for the outputs the size changes to 80 bytes or 20-32 bit

words and addresses given would be 1:O.Data[0] through 1:O.Data[19]. Click on the OK

button where you will then be prompted to write this configuration to the scanner memory.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 8 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

The PLC will need to be in the program or remote program mode for this to occur. When

written this completes the configuration of the RUI/Gateway using RSNetWorx.

Configuration of the RUI/Gateway

17. Prior to looking at the PLC side of things let’s first take a look at a possible network

configuration. The graphic below depicts a network consisting of an RUI/ Gateway with a PLC

on one side talking DeviceNet

®

ZONE

PM controls talking Standard Bus. Now, seeing the network layout, the next step is to

configure the RUI/Gateway.

TM

where on the other side of the gateway we see four EZ-

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 9 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

18. The table below does not represent all of the RUI/Gateway prompts that need configuration

but they do represent those that are pertinent to this discussion. (For further information on

the RUI/Gateway configuration go to the Watlow website and download the RUI/Gateway

User Manual)

Gateway

Instance

Gtw = 1 Du;en = Yes ost = 0

Gtw = 2 Du;en = Yes ost = 4

Gtw = 3 Du;en = Yes ost = 8

Gtw = 4 Du;en = Yes ost = 12

Enable

Gateway

Instance

CIP

Offset

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 10 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

19. The gateway instance represents the EZ-ZONE

®

control, in this case, PM 1-4. The enable

gateway instance simply turns on that particular gateway where there is a direct correlation

®

between gateway instance 1 and EZ-ZONE

continues through gateway instance 16 and EZ-ZONE

PM controller 1. Likewise, that relationship

®

PM controller 16. The gateway

instance will always equate to the Standard Bus controller with the same address 1-16.

The CIP offset allows for the PLC or any master on the DeviceNetTM side to read or write the

same member from any of the four controllers on the Standard Bus network via an explicit

message.

Configuring the DeviceNetTM Scanner (1769-SDN) Using RSLogix 5000

20. In the examples that follow please note that the PLC being used is a CompactLogix L32E. If

using other PLCs the steps will vary slightly but the overall concepts will be the same. As you

might guess some configuration is required on the PLC side prior to getting started with the

programming.

21. Insert a DeviceNetTM scanner into the I/O structure of the PLC. Notice below the input and

output size correlates directly to what was configured in RSNetWorx (step 15).

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 11 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

22. Notice too, the slot number, in this case “1”. This is the physical slot in which the scanner

resides. After the scanner is configured two tags will be automatically generated reflecting the

existence of the scanner in slot 1 of the I/O structure. These tags will be used to move the

implicit input and output assemblies (more on this to follow) to and from the RUI/Gateway and

then ultimately to the destination EZ-ZONE

®

PM controls that exist on Standard Bus.

EZ-ZONE® EEPROM

23. Before we get started with the programming examples it is important to note that the EZ-

ZONE® family of controls has an on-board EEPROM to back up user settings in the event of

a power loss. By default, the non-volatile save parameter is enabled, therefore changes made

over the network as well as any changes made from the RUI are saved to the EEPROM. If

®

the implicit output (PLC to EZ-ZONE

exchanged implicitly (continuously after the connection is established) the rate at which writes

to EEPROM occur could be very fast. With this being said, it should be considered carefully

as to whether or not this parameter should remain enabled. To avoid premature EEPROM

failure (~1,000,000 writes) it is recommended that the user disable the non-volatile write

parameter in the destination nodes residing on the Standard Bus side of the RUI/Gateway. An

example will follow showing how to read and write to this parameter.

Control) assembly is in use, where information is

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 12 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

Reading and Writing to/from RUI/Gateway Using RSLogix 5000

24. The rung of logic below when enabled, will execute an explicit message sent to the gateway

where it will then be routed out over Standard Bus to the EZ-ZONE

the instance (oSt prompt). Because the CIP offset is set to 12 for gateway instance 4 this

message will be routed to PM4. When done, the destination tag identified under the

configuration tab “EEPROM _Status” (see below) will contain the value of either 106 being

enabled or 59 being disabled.

®

PM control defined by

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 13 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

25. Notice above that there are screen shots for the configuration and communication tabs.

Within the configuration, the programmer will need to specify whether this is a read (Get) or a

write (Set) operation as well as the class, instance, and attribute (CIA) of interest. The CIA for

all PM controls is 150, 2, 8 respectively. The CIA shown above in hexadecimal represents the

Non-Volatile Save parameter for node 4 going through the RUI/Gateway (see step 24 for

explanation). The communication tab allows the programmer to select a configured I/O

module to send or receive the message where the port number and node address need to be

identified. Again, as can be seen above the module is defined in the I/O structure as

DNet_Scanner.

26. If it is desired to write a new value to the member above simply change the service type to set

attribute and define the source element with the new value.

Note:

If attempting to read or write to this parameter (Non-Volatile Save) in the EZ-ZONE® ST the

class, instance, and attribute is different from what is shown above in step 24. For the ST, the

Class = 117, Instance = 1, Attribute = 51. The numbers shown are in decimal where the class

and the attribute will need to be converted to hexadecimal for the message instruction.

27. As another example of explicit messaging, to read a specific member such as PV1 of PM1 as

shown in the graphic above (step 17) the MSG instruction in the PLC would be configured

with the class equal to 104, instance would be 1, and the attribute would be 1 as found in the

EZ-ZONE

network, if it were desired to read the same member from PM3, the MSG instruction would

be configured with the class equal to 104, instance would be 9, and the attribute would be 1.

Because the CIP offset is equal to 8 for gateway instance 3 the gateway will route the

message to PM3, retrieve the first instance of the Analog Input in this case PV1, and then

send it back out to the PLC.

28. As stated in step 22 the RUI/Gateway is equipped with implicit I/O assemblies. The graphics

below represent the I/O default assemblies as shipped from the factory. The T to O input

assembly (Target - Gateway) to (Originator - PLC) consists of twenty one members and the O

to T (Originator - PLC) to (Target - Gateway) consists of twenty members. Again, these

graphics represent the factory defaults for the implicit I/O assemblies. With one exception,

any of the individual members in either assembly can be user programmed. The exception

can be found as the first member of the T to O assembly “Device Status” (more on this to

follow).

®

PM Communications Manual under the Operations Page. On the other end of the

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 14 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 15 4/08

Default Target to Originator (T to O) Assembly

Default Originator to Target (O to T) Assembly

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

29. Each of the members shown above are passed implicitly to and from the gateway to the PLC

with little to no programming.

Note:

If you are interested in learning more about how to change either of the implicit assemblies

download the PM Communications manual from the Watlow website. Refer to step one for the

link to Watlow’s website.

30. For ease in programming it is suggested (but not necessary) that two user defined data types

be created reflecting the default assembly structures (or the user defined structure) as shown

below. In the examples that follow two user defined data types will be used which correspond

with the network architecture as shown in step 17 for both T to O and O to T assemblies.

Custom O to T Data Type Custom T to O Data Type

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 16 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

31. Once the user defined data types have been created for the T to O and O to T assemblies

right click on the controller tags folder and add new tags using the T to O and O to T data

types just created; in this case, “Custom_GTW_T_to_O” and “Custom_GTW_O_to_T”.

Controller Tag (T to O)

32. Using the same network architecture as shown in step 17, let’s look closer at the use

of these implicit assemblies. As can be seen above the available 20 members for inputs

and outputs are being distributed across PM1 - PM4 disproportionally. Keep in mind, that the

maximum number of modifiable members for the T to O and O to T assemblies is 20 where

the user can dedicate all of them to one EZ-ZONE

®

PM (*ST excluded) control or distribute

them in any manner across the network. The distribution of the assemblies is determined by

the CIP Assembly size a;nb prompt within the RUI.

* The EZ-ZONE® ST allows for explicit messaging only, it does not allow for implicit

messaging (communications via the I/O assemblies).

33. Look closely at the names and the descriptions of the assemblies in step 31; the assembly

distribution across the four controls on Standard Bus can be seen clearly. Hopefully it is now

clear as to why it is recommended that user defined data types be created and then the

controller tags to utilize those data types. Simply stated, the purpose is to enable easier

Controller Tag (O to T)

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 17 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

transfer of data to and from the PLC and EZ-ZONE

in the PLC. The copy instruction also works nicely when all of the data types are not the same

such as when working with 8 bit, 16 bit, and 32 bit members. The copy instruction copies the

source to the destination byte for byte so there is no further conversion needed.

34. Because there are 4 entries for PM1 in the custom T to O and O to T assemblies above, that

must mean that the CIP Assembly Size for gateway instance 1 is equal to four. Using the

same logic, PM2 has 10 entries so the Assembly Size must be equal to 10, etc…

Gateway

Instance

CIP

Assembly

Size

Gtw = 1 A;nb = 4

Gtw = 2 A;nb = 10

Gtw = 3 A;nb = 2

Gtw = 4 A;nb = 4

As can be seen above, unless changed, the members that occupy any one of the 20 member

locations (or wherever the gateway instance changes) will be according to the factory

defaults. So, the first member of the T to O for any given gateway instance will always be

PV1 regardless of where it is placed in the assembly.

35. The first member of the T to O assembly above is identified as “Device Status “. This member

will always be present and explains why in step 15 that the input assembly size is shown as

84 bytes (21-32 bit words) different from the output assembly being 80 bytes (20-32 bit

words).

To better understand the above status word a couple of important facts related to Standard

Bus addressing must be explained. Lets first look at valid addresses (physical & logical) for

computers, RUIs, Communication cards (Masters, 0-15), and lastly, EZ-ZONE

(Slaves, 16-31). The logical addresses are set by the user. Look at the table below.

®

controllers via simple copy instructions

®

controllers

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 18 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

Device Physical Address Logical Address (Set by User)

Personal Computers 0-3 1-4

RUI 4-11 1-8

Communication Cards 12-15 1-4 (indirectly set by user)

EZ-ZONE

®

Controllers 16-31 1-16

The first graphic in step 35 shows the first member of the custom T to O assembly

“GTW_Inputs.Device_Status”. Interpreting the bits…bit 0 is shown on the far right where bit

31 is on the far left. The bits that are shown as being set to a “1” represent those devices that

the RUI/Gateway is enabled to speak to (Gateway instance). So, bit 16 through 19 represents

the PM controls on the Standard Bus side of the RUI/Gateway (1 - 4, as seen in step 17)

where bit 12 represents the physical address for the DeviceNetTM card in the RUI/Gateway.

Each of these bits can be monitored in the PLC where an alarm can be driven if communications with any enabled PM control fails.

36. Note that in the table above (step 35) showing both logical and physical addresses (logical

addresses are set by the user) that the communications card addressing is not set directly by

the user. To relieve the burden of having to set multiple Standard Bus addresses in the

RUI/Gateway the communication card picks up its address through the RUI/Gateway firmware. If the RUI/Gateway Standard Bus address (with a comms card installed) is set to logical

address 1 the communications card Standard Bus physical address will automatically be set

12. See table below for valid communications card addressing. As can be seen below, if the

communications card is to be given a valid address the RUI/Gateway logical address must be

set to a value ranging from 1-4.

RUI/Gateway Addressing Communications Card

Standard Bus

Physical Address

Logical Address

(Set by User)

Physical Address

4 1 12

5 2 13

6 3 14

7 4 15

8 5 Not Valid

9 6 Not Valid

10 7 Not Valid

11 8 Not Valid

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 19 4/08

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

37. In step 30 it was suggested that the user may want to create user defined data types.

Likewise, in step 31 it was also suggested that the user should create controller tags utilizing

those same user defined data types. The reasoning for this may become more obvious in the

following example. Below, two copy instructions are programmed to send and receive the

implicit assemblies to/from the PLC to the desired EZ-ZONE

38. As can be seen above the controller tags created for inputs from the EZ-ZONE

the PLC was defined as “GTW_Inputs” where the tag created for the outputs from PLC to EZZONE

®

controls was named “GTW_Outputs”. The ease in programming should now be

apparent. Due to the fact that the user defined data types for both T to O and O to T

assemblies where defined to correlate directly to the specific EZ-ZONE

the transfer of data between EZ-ZONE

®

controls and the PLC is done without a lot of effort.

Below the two graphics represent both the T to O and O to T assemblies with live data.

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 20 4/08

®

controls.

®

controls to

®

members of choice

RUI/Gateway & DeviceNet

TM

Configuration & Ladder Logic Example

Using an Allen-Bradley CompactLogix PLC

Custom T to O Assembly

Custom O to T Assembly

Watlow

1241 Bundy Blvd

Winona, MN 55987

Telephone: 507-494-5656

© 2007 Watlow Electric Mfg Co 21 4/08

Loading...

Loading...