Watlow Electric Freeflex User Manual

FREEFLEX

Assures Reliable,

Efficient Heating and

Transport of Liquids

and Gases

®

Watlow’s miniature heated polymeric tubing assemblies

provide a flexible heat-up and transport system for moving

fluids in tubing as small as

diameter. FREEFLEX

maintains temperature during transfer from a reservoir to a

point of use. In some applications, the tubing can actually

serve as the reservoir for limited volumes of fluid, helping to

reduce start-up times. For higher temperatures consult the

factory.

Watlow’s innovative design places the heating element and

sensor directly in contact with the perimeter of the tubing to

produce efficient, responsive heating and temperature control

of the tube contents. The element is evenly wound to ensure

reliable, close contact for uniform heating along a portion or

the entire length of the line. A flexible, durable jacket covers

the wound element and lets the tubing flex and move in a

dynamic system. This allows for fluid delivery to multiple

locations from a single supply source. In stationary

applications, the FREEFLEX heated tubing is conveniently

routed through available space or around other system

components. This saves space and provides for an

uncomplicated retrofit in existing systems.

The superior construction employs an efficient heating

element design with the ability to incorporate optional

thermocouple, thermistor or RTD temperature sensors into

the thermal package. Users can select leads to exit one or

both ends of the assembly. Typical standard Teflon

comes in

inside diameters, although other sizes and materials

are available.

1

⁄32-, 1⁄16-, 1⁄8- or 3⁄16-inch (0.792, 1.59, 3.18, 4.76 mm)

1

⁄32 inch (0.792 mm) inside

®

heats fluids up to 100˚C (212˚F) and

®

tubing

Features and Benefits

Flexible heat-up and transport system

• Eliminates the need for heated reser

many applications

Heating element directly contacts tubing

• Provides fast, efficient more responsive heating

Three configurations a

• FREEFLEX design - allows tubing to flex, coil or bend

around system components

• Pre-for

• Molded design - provides a compact heating assembly

Integral sensors

• Maintains close control of heater and fluid temperatures

Low voltage design

• Promotes saf

Miniature siz

diameter

• Transports and heats fluids in even the smallest spaces

Con

• Allows for routing flexible tubing around system

®

UL

• Available on qualified designs by request

med design - allows longer tube length in

smaller volume

for easy installation

es as small as

venient retrofit

components and using e

recognition

ety

vailable

1

⁄32 inch (0.792 mm) inside

xisting control system

voir systems in

Applications

• Medical: automated clinical analyzers, tissue processing

equipment

• Analytical: sample preheating f

breathalyzers

• Semiconductor processing: wafer drying equipment,

DI water heating

• Printing: ink jet printers, rapid prototyping systems,

r

photolithog

• General Process: wax/paraffin processing and

non-combustib

• Water purification systems

• Precision c

• Aerospace

• Military

© 2007 Watlow Electric Manufacturing Company

aphy

le gas heating

leaning equipment

or LC and HPLC systems,

COL-FFLX-0505

2101 Pennsylvania Drive

Columbia, Missouri 65202 USA

Phone: +1 (573) 474-9402

FAX: +1 (573) 474-5859

Internet: www.watlow

e-mail: info@watlow.com

Teflon®is a registered trademark of E.I. du Pont de Nemours & Company.

®

UL

is a registered trademark of Underwriter’s Laboratories, Inc.

.com

Quote and Ordering Information

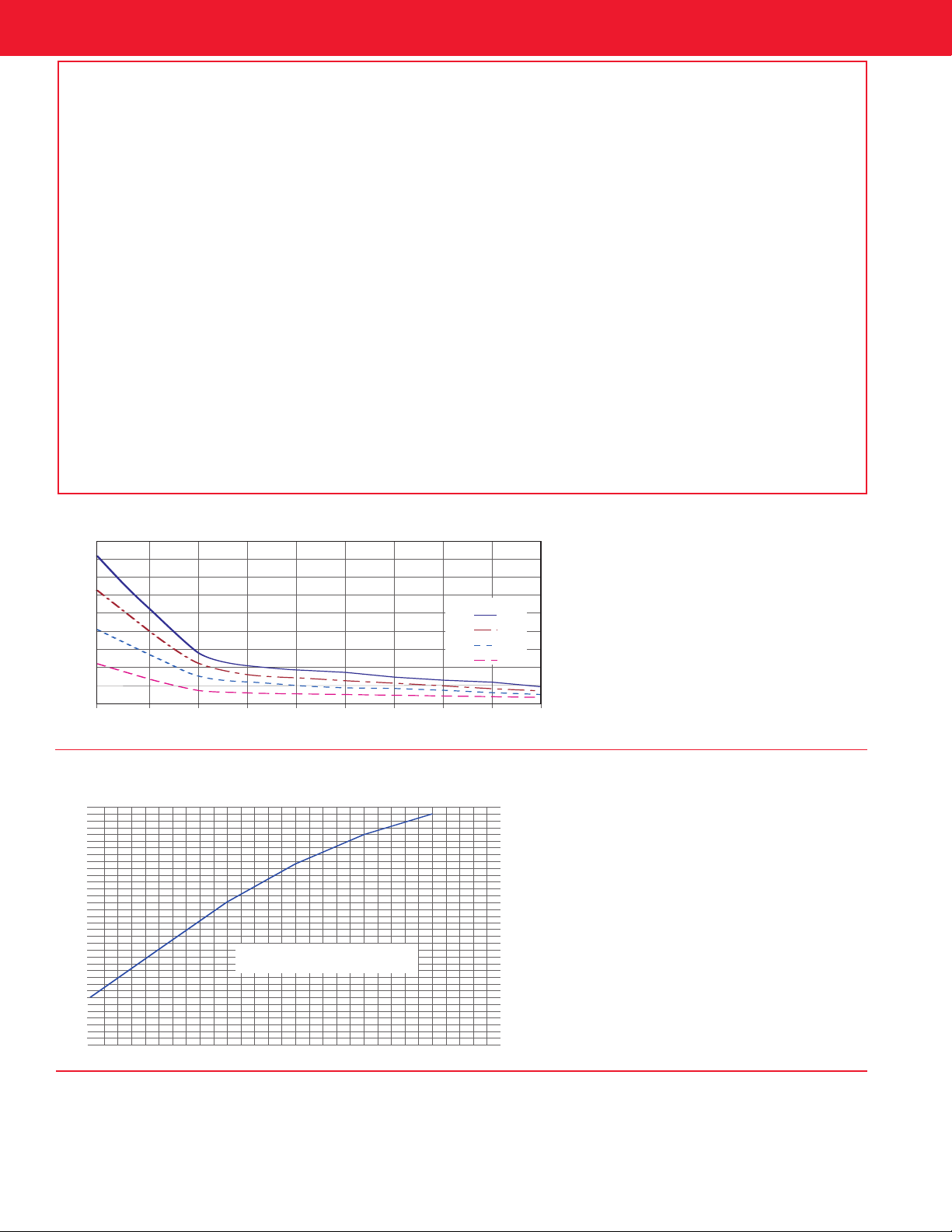

O.D. Temperature vs. Watts/Meter

O.D. Temperature (˚F)

350

300

250

200

150

100

50

0

0

5

10 15 20 25 30

O.D. Temperature vs. Watts/Foot

177

149

121

93

66

38

10

1.5

3.0

4.6

6.1

7.6

O.D. Temperature (˚C)

O.D. Temperature vs. Watts/Unit Length

Dry Tube - No Flow

Water Temperature Rise/Foot vs. Flow Rate vs. Watt Density (

1

/

16

in. (1.59 mm) I.D. Tube)

Water Temperature Rise

(˚F/Foot)

9

0

80

70

60

5

0

4

0

3

0

20

10

0

10 20 30

40 50

60

70

80 90

100

164

146

128

109

91

73

55

36

18

0

Water Temperature Rise

(˚C/Meter)

50.0

37.5

25.0

12.5

W/ft

164

123

82

41

W/m

For a quote, please request, fill out and return a FREEFLEX

application data sheet.

To order, please specify:

Fluid Type

Inlet Temperature

Outlet Temperature

Flow Rate

Voltage - Typically less than 36 volts

Watts/ft - See chart below for typical values

Maximum Allowable Outside Surface Temperature

T

ube Siz

e

1

•

⁄32 in. (0.792 mm) I.D. x 1⁄16 in. (1.59 mm) O.D.

1

•

⁄16 in. (1.59 mm) I.D. x 1⁄8 in. (3.18 mm) O.D.

1

•

⁄8 in. (3.18 mm) I.D. x 3⁄16 in. (4.76 mm) O.D.

3

•

⁄16 in. (4.76 mm) I.D. x 1⁄4 in. (6.35 mm) O.D.

• Other (specify size)

Tube Material

Tube Length - 12 to 120 in. (305 to 3048 mm) typical

T

®

• Teflon

(standard)

• Silicone rubber

• Others upon request

• T

otal

• Heated

• Unheated (specify)

ube Fittings

• No fittings (1 in.

•

Other (specify)

(25 mm) bare tubing at each end)

Tube Flexing

• Static (to route around components in system)

• Dynamic (subject to more continuous flexing)

• Occasional, frequent or continuous

Note: Minimum recommended flexing radius

1

•

⁄32

in. (0.792 mm) I.D. x

1

•

⁄16

in. (1.59 mm) I.D. x

1

•

⁄8

in. (

3.18 mm

3

•

⁄16

in. (

4.76 mm

) I.D. x

) I.D. x

1

⁄16

in. (1.59 mm) O.D. Teflon®1 in. (25 mm)

1

⁄8

in. (3.18 mm) O.D. Teflon®1

3

⁄16

in. (4.76 mm) O.D. Teflon®2 in. (51 mm)

1

⁄4

in. (6.35 mm) O.D. Teflon®3 in. (76 mm)

Heater Leads

• One at each end

• Both at one end

• Standard lead insulation (UL®Style 1180 white Teflon®)

• Other insulation (specify)

Heater Lead Length

• Standard 12 in. (305 mm) w/customer end stripped/tinned

1

⁄2 in. (13 mm)

• Other (specify)

Heater Lead Exit Direction

• Inboard/outboard

Temperature Sensor

• Standard thermocouple (#30 AWG Teflon®- Type J)

• Thermistor (specify) 10KΩ at 25˚C (72˚F) standard

• Other temperature sensors size/types (specify)

• Sense heater element or tube temperature

Sensor Lead Exit Direction

• Inboard/outboard

Temperature Sensor Lead Length

• Standard 12 in. (305 mm)

• Other (specify)

Water Temperature Rise/Length Versus Flow Rate Versus Watt Density

Water Temperature Rise °F/Foot

Flow Rate (mL/minute)

W/ft 10 30 50 100

50.0 82 29 19 10

37.5 64 22 14 7

25.0 41 16 10 5

12.5 22 8 5 3

1

⁄2

in. (38 mm)

FREEFLEX Outside Diameter Temperature Versus Watts/Length

To be automatically connected to the nearest North American Technical and Sales Office:

1-800-WATLOW2 • www.watlow.com • info@watlow.com

International Technical and Sales Offices: Australia, +61-3-9335-6449 • China, +86-21-3950-9510 • France, +33 (0) 3073-2425 •

Germany, +49 (0) 7253-9400-0 • Italy, +39 (0) 2 458-8841 • Japan, +81-3-3518-6630 • Korea, +82-2-575-9804 • Malaysia, +60-3-7980-7741 •

Mexico, +52 (442) 217-6235 • Shanghai, +86-21-3950-9504 • Singapore, +65-6777-1266 • Spain, +34 91 675 1292 • Sweden, +46 35-27-11-66 •

Taiwan, +886-7-288-5168 • United Kingdom, +44 (0) 115-964-0777

Water Temperature Rise °C/Meter

Flow Rate (mL/min

ute)

W/m 10 30 50 100

164 149 52 35 18

123 116 40 26 13

82 75 29 18 9

41 40 15 9 5

W/ft W/m O.D. Temperature

°C (°F) (Ambient)

0 0 21 (70)

5 1.5

60 (140)

10 3.0 99 (210)

15 4.6 129 (265)

20 6.1 154 (310)

25 7.6 171 (340)

Loading...

Loading...