Watlow Electric EZ-ZONE PM User Manual

ISO 9001

CUSTTOOMMERER

TISFAA

CTIOONN

EZ-ZONE® PM

User’s Manual

0600-0059-0000 Rev. C Made in the U.S.A.

March 2008 $15.00

Integrated Controller Models

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

TOTAL

CUS

SSAATISF

3 Year Warranty

ISO 9001

Registered Company

Winona, Minnesota USA

CTI

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to important

operational and safety information.

A “NOTE” marks a short message to alert you to

an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and performance. Be especially careful to

read and follow all cautions that apply to your

application.

A “WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very

close attention to all warnings that apply to your

application.

The safety alert symbol, ç (an exclamation

point in a triangle) precedes a general CAUTION

or WARNING statement.

The electrical hazard symbol, Ó (a lightning bolt

in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

ç CAUTION or WARNING

Ó Electrical Shock Hazard

CAUTION or WARNING

Warranty

The EZ-ZONE® PM is manufactured by ISO

9001-registered processes and is backed by a threeyear warranty to the first purchaser for use, providing that the units have not been misapplied. Since

Watlow has no control over their use, and sometimes misuse, we cannot guarantee against failure.

Watlow’s obligations hereunder, at Watlow’s option,

are limited to replacement, repair or refund of purchase price, and parts which upon examination prove

to be defective within the warranty period specified.

This warranty does not apply to damage resulting

from transportation, alteration, misuse or abuse. The

purchaser must use Watlow parts to maintain all

listed ratings.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify

that your selections are consistent with your application: inputs, outputs, alarms, limits, etc. If the problem persists, you can get technical assistance from

your local Watlow representative (see back cover), by

e-mailing your questions to wintechsupport@watlow.

com or by dialing +1 (507) 494-5656 between 7 a.m.

and 5 p.m., Central Standard Time (CST). Ask for for

an Applications Engineer. Please have the following

information available when calling:

• Complete model number

• All configuration information

• User’s Manual

• Factory Page

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300,

for a Return Material Authorization (RMA) number before returning any item for repair. If you

do not know why the product failed, contact an

Application Engineer or Product Manager. All

RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning

the product.

2. Prior approval and an RMA number from the

Customer Service Department is required when

returning any product for credit, repair or evaluation. Make sure the RMA number is on the outside of the carton and on all paperwork returned.

Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it

and try to verify the reason for returning it.

4. In cases of manufacturing defect, we will enter a

repair order, replacement order or issue credit for

material returned. In cases of customer mis-use,

we will provide repair costs and request a purchase order to proceed with the repair work.

5. To return products that are not defective, goods

must be be in new condition, in the original boxes

and they must be returned within 120 days of

receipt. A 20 percent restocking charge is applied

for all returned stock controls and accessories.

6. If the unit is unrepairable, you will receive a letter of explanation. and be given the option to have

the unit returned to you at your expense or to

have us scrap the unit.

7. Watlow reserves the right to charge for no trouble

found (NTF) returns.

The EZ-ZONE® PM User’s Manual is copyrighted

by Watlow Winona, Inc., © July 2007 with all rights

reserved.

EZ-ZONE® PM is covered by U.S. Patent No.

6,005,577 and Patents Pending

TC

Table of Contents

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Standard Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2: Install and Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Chapter 3: Keys and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Attention Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4: Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 5: Operations Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 6: Setup Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 7: Profiling Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 8: Factory Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 9: Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 10: Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Troubleshooting Alarms, Errors and Control Issues . . . . . . . . . . . . . . 66

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Ordering Information for Integrated Controller Models . . . . . . . . . . . . 71

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Watlow EZ-ZONE® PM Integrated Controller • 1 • Table of Contents

1

Chapter 1: Overview

The EZ-ZONE® PM takes the pain out of solving

your thermal loop requirements.

Watlow ’s E Z -Z ONE® PM controllers offer options

to reduce system complexity and the cost of controlloop ownership. You can order the EZ-ZONE® PM as

a PID controller or an over-under limit controller, or

you can combine both functions in the PM Integrated Limit Controller. You now have the option to integrate a high-amperage power controller output, an

over-under limit controller and a high-performance

PID controller all in space-saving, panel-mount

packages. You can also select from a number of serial communications options to help you manage system performance.

It just got a whole lot easier to solve the thermal requirements of your system. Because the EZZONE® PM controllers are highly scalable, you only

pay for what you need. So if you are looking for a

PID controller, an over-under limit controller or an

integrated controller, the EZ-ZONE® PM is the answer.

Standard Features and Benefits

Advanced PID Control Algorithm

• TRU-TUNE+® Adaptive tune provides tighter con-

trol for demanding applications.

• Auto Tune for fast, efficient start ups

Agency approvals: UL Listed, CSA, CE, RoHS,

W.E.E.E. FM

• Assures prompt product acceptance

• Reduces end product documentation costs

• FM approval on Limit Models

• Semi F47-0200

P3T Armor Sealing System

• NEMA 4X and IP66 offers water and dust resis-

tance, can be cleaned and washed down

• Backed up by UL 50 independent certification to

NEMA 4X specification

Three-year warranty

• Demonstrates Watlow’s reliability and product

support

Touch-safe Package

• IP2X increased safety for installers and operators

Removable cage clamp wiring connectors

• Reliable wiring, reduced service calls

• Simplified installation

EZ-Key

• Programmable EZ-Key enables simple one-touch

operation of repetitive user activities

High-amperage Power Control Output

• Drives 15 amp resistive loads directly

• Reduces component count

• Saves panel space and simplifies wiring

• Reduces the cost of ownership

EZ-ZONE® configuration communications and

software

• Saves time and improves the reliability of control-

ler set up

FM Approved Over-under Limit with Auxiliary

Outputs

• Increases user and equipment safety for over-

under temperature conditions

Parameter Save & Restore Memory

• Reduces service calls and down time

Watlow EZ-ZONE® PM Integrated Controller • 2 • Chapter 1 Overview

Programmable Menu System

• Reduces set up time and increases operator effi-

ciency

Full-featured Alarms

• Improves operator recognition of system faults

• Control of auxiliary devices

Heat-Cool Operation

• Provides application f lexibility with accurate tem-

perature and process control

Profile Capability

• Preprogrammed process control

• Ramp and soak programming with four files and

40 total steps

A Conceptual View of the PM

The flexibility of the PM’s software and hardware allows a large range of configurations. Acquiring a better understanding of the controller’s overall functionality and capabilities while at the same time planning out how the controller can be used will deliver

maximum effectiveness in your application.

It is useful to think of the controller in three

parts: inputs; procedures; and outputs. Information

flows from an input to a procedure to an output when

the controller is properly configured. A single PM

controller can carry out several procedures at the

same time, for instance closed-loop control, monitoring for several different alarm situations and operating switched devices, such as lights and motors.

Each process needs to be thought out carefully and

the controller’s inputs, procedures and outputs set up

properly.

Inputs

The inputs provide the information that any given

programmed procedure can act upon. In a simple

form, this information may come from an operator

pushing a button or as part of a more complex procedure it may represent a remote set point being received from another controller.

Each analog input typically uses a thermocouple

or RTD to read the temperature of something. It can

also read volts, current or resistance, allowing it to

use various devices to read humidity, air pressure,

operator inputs and others values. The settings in

the Analog Input Menu (Setup Page) for each analog

input must be configured to match the device connected to that input.

Each digital input reads whether a device is active

or inactive. A PM with digital input-output hardware

includes two sets of terminals each of which can be

used as either an input or an output. Each pair of

terminals must be configured to function as either

an input or output with the Direction parameter in

the Digital Input/Output Menu (Setup Page).

The Function or EZ Key on the front panel of the

PM also operates as a digital input by toggling the

function assigned to it in the Digital Input Function

parameter in the Function Key Menu (Setup Page).

Keep in mind that a function is a user-programmed internal process that does not execute any

action outside of the controller. To have any effect

outside of the controller, an output must be configured to respond to a function.

Outputs

Outputs can perform various functions or actions in

response to information provided by a function, such

as operating a heater; turning a light on or off; unlocking a door; or turning on a buzzer.

Assign an output to a Function in the Output

Menu or Digital Input/Output Menu. Then select

which instance of that function will drive the selected output. For example, you might assign an output

to respond to alarm 4 (instance 4) or to retransmit

the value of analog input 2 (instance 2).

You can assign more than one output to respond

to a single instance of a function. For example, alarm

2 could be used to trigger a light connected to output

1 and a siren connected to digital output 5.

Input Events and Output Events

Input events are internal states that are set by the

digital inputs. Digital input 5 provides the state of

input event 1, and digital input 6 provides the state

of input event 2. Wait for Event steps in profiles

are triggered by these events. The setting of Digital

Input Function (Setup Page, Digital Input/Output

Menu) does not change the relationship between the

input and the event, so take care not to configure the

function in a way that would conflict with a profile

that uses an input event. An input will still control

the input event state, even if Digital Input Function

is set to None.

Output events are internal states that can only be

set by profile steps. Outputs 1 through 4 can be configured to respond to output events.

Functions

Functions use input signals to calculate a value. A

function may be as simple as reading a digital input

to set a state to true or false, or reading a temperature to set an alarm state to on or off. Or, it could

compare the temperature of a process to the set point

and calculate the optimal power for a heater.

To set up a function, it’s important to tell it what

source, or instance, to use. For example, an alarm

may be set to respond to either analog input 1 or 2

(instance 1 or 2, respectively).

Watlow EZ-ZONE® PM Integrated Controller • 3 • Chapter 1 Overview

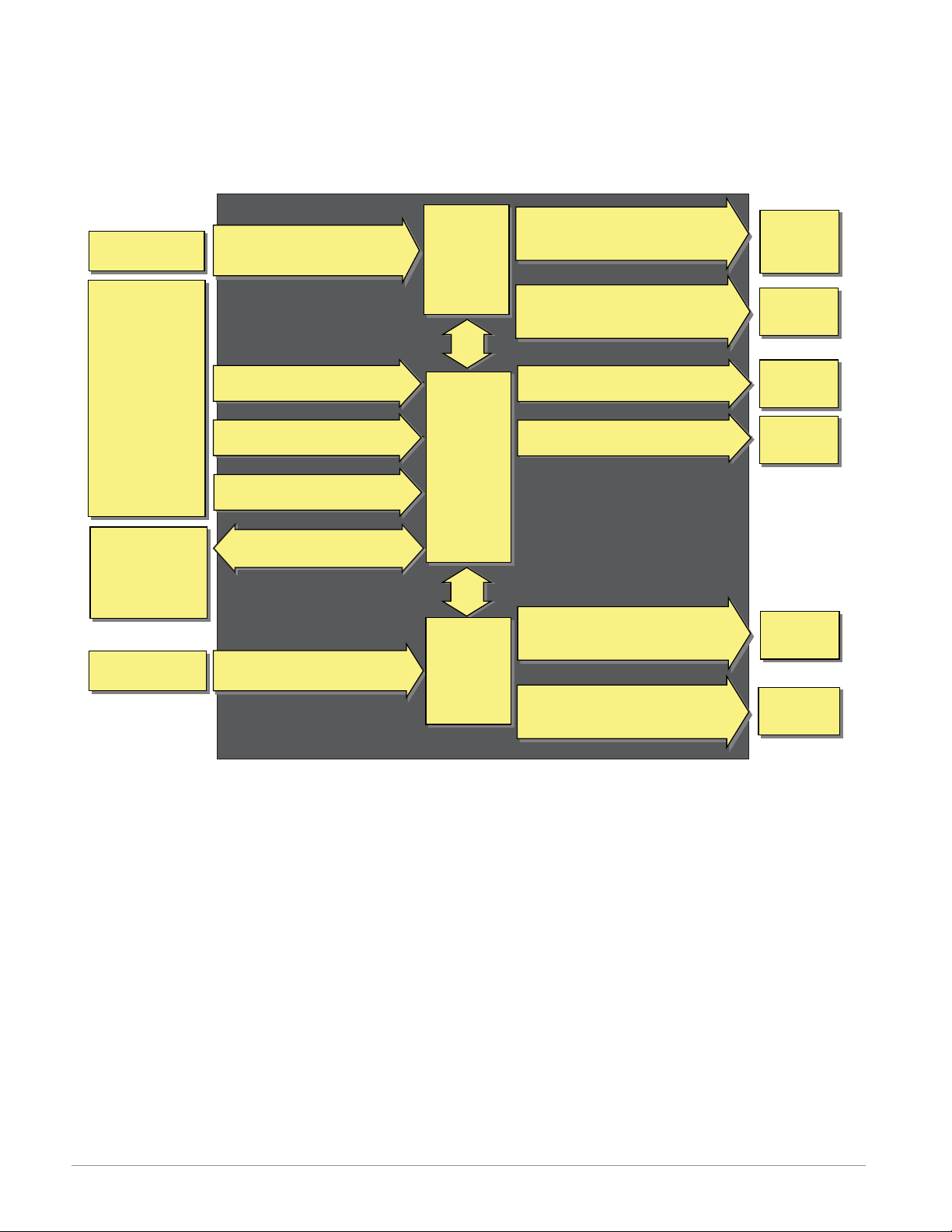

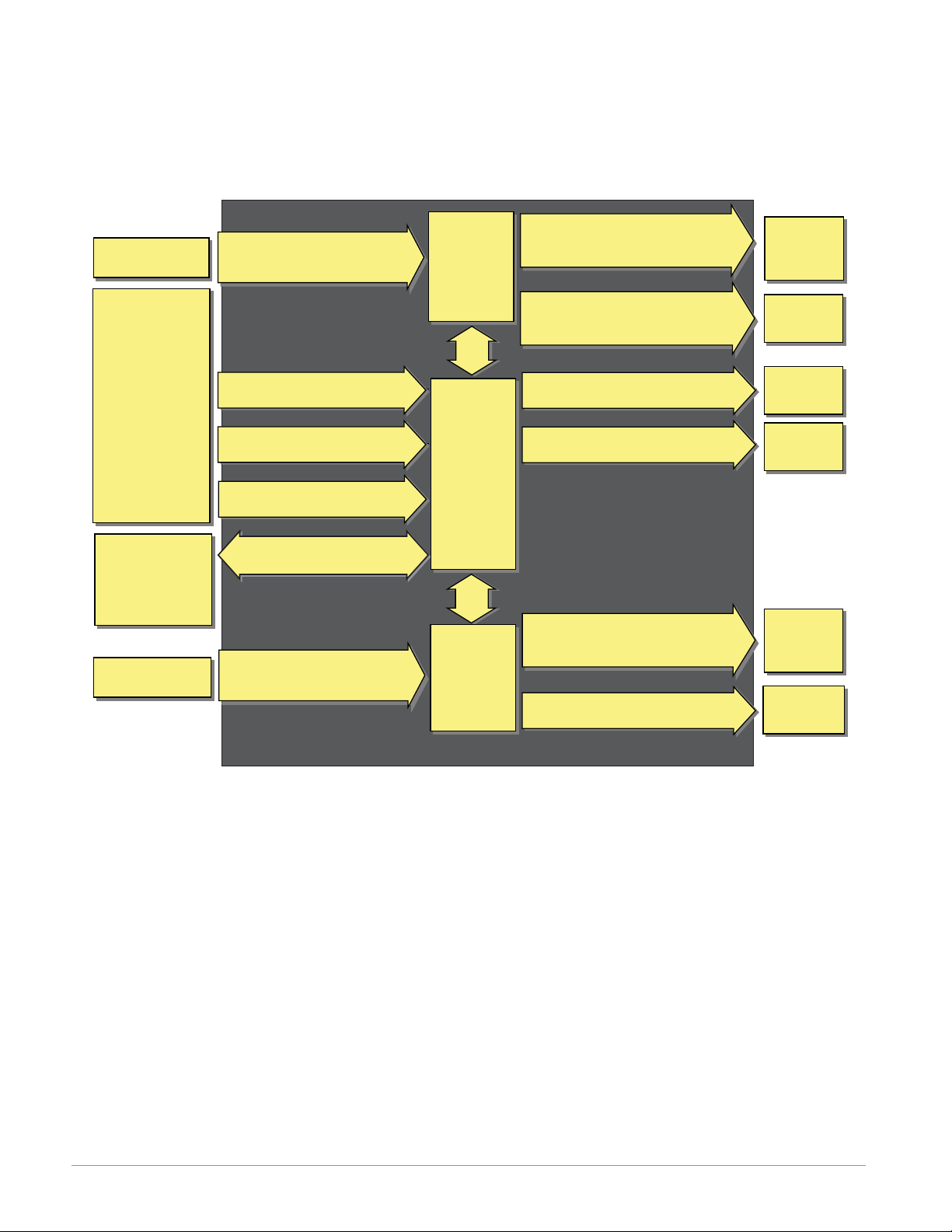

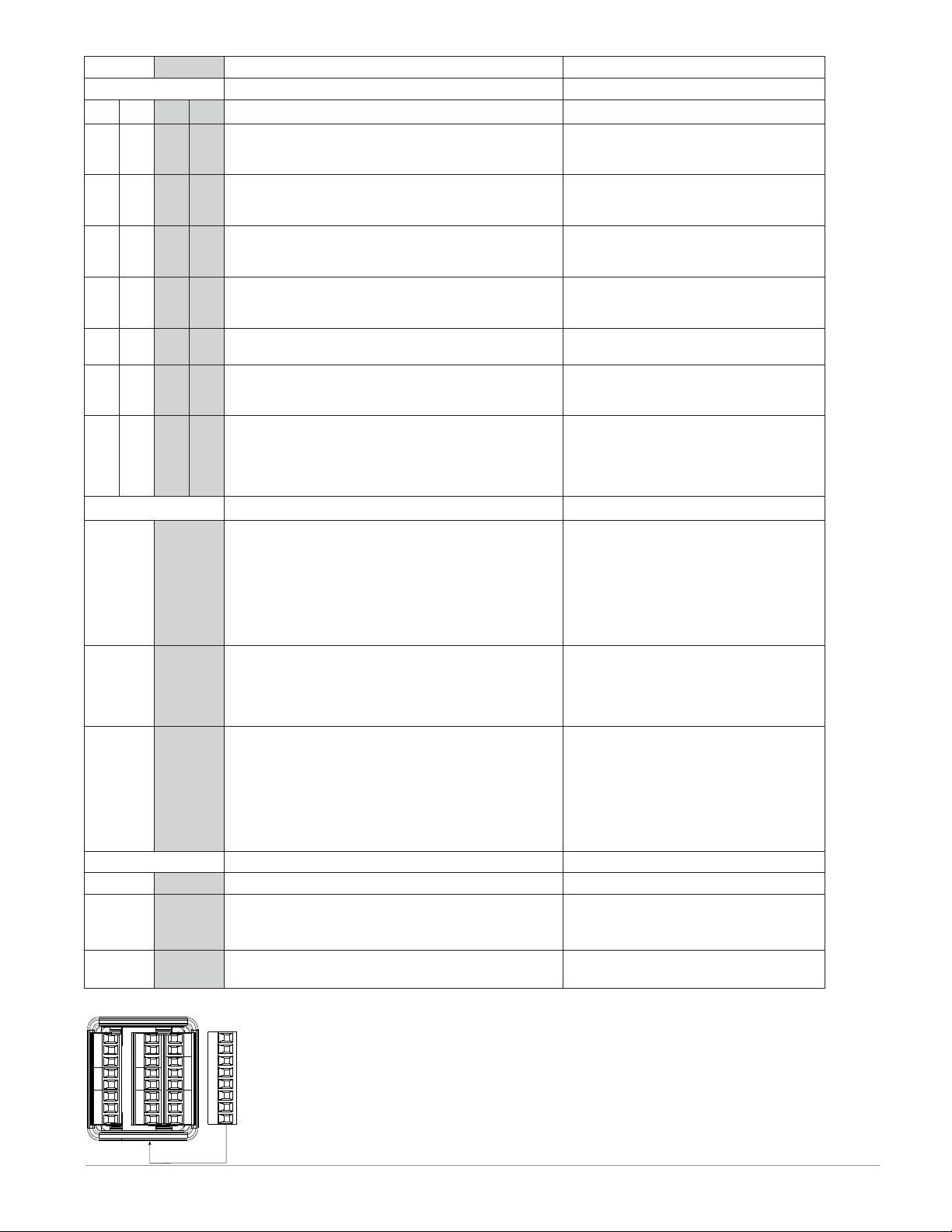

EZ-ZONE® PM Integrated Model 1/16 DIN with a Current Transformer — Input/Output

(no communications options 2 to 3)

Universal Sensor Input, Configuration Communications,

Red/Green 7-Segment Display

Input

Functions

input sensor

none,

idle set point,

alarm reset,

tune,

silence alarm,

manual/auto mode,

control outputs off,

lock keypad,

force alarm,

TRU-TUNE+

loop & alarms off,

profile disable,

profile hold/resume,

profile start,

profile start/stop,

restore user settings

Network

remote user interface,

personal computer,

programmable logic

controller, humanmachine interface

current transformer

®

disable

Analog Input 1 thermocouple,

RTD, process (V, mV, mA, 1k potentiometer)

Digital Input (or Output) 5

(optional) none, switch, volts dc

Digital Input (or Output) 6

(optional) none, switch, volts dc

EZ Key

programmable event

EIA 485 Communications

Standard Bus, Modbus RTU (optional)

Analog Input 2

current transformer

PID

Controller

Board

Slot A

ramp-soak

with 4 files

(optional)

Supervisory

&

Power

Board

Slot C

Current

Transformer

Board

(optional)

Slot B

Output 1 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 2 none, switched dc, no-arc

power control (15 A), form A mechanical

(5 A) or solid-state (0.5 A) relay

Digital Output (or Input) 5 (optional)

none, switched dc

Digital Output (or Input) 6 (optional)

none, switched dc

Output 3 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 4 none, switched dc, form A

mechanical (5 A) or solid-state (0.5 A)

relay

Output

Functions

off, heat, cool,

duplex, alarm,

retransmit,

event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event,

retransmit

off, heat, cool,

alarm, event

Current Monitoring

• detects heater current f low

• provides an alarm indication of a failed-load issue.

Watlow EZ-ZONE® PM Integrated Controller • 4 • Chapter 1 Overview

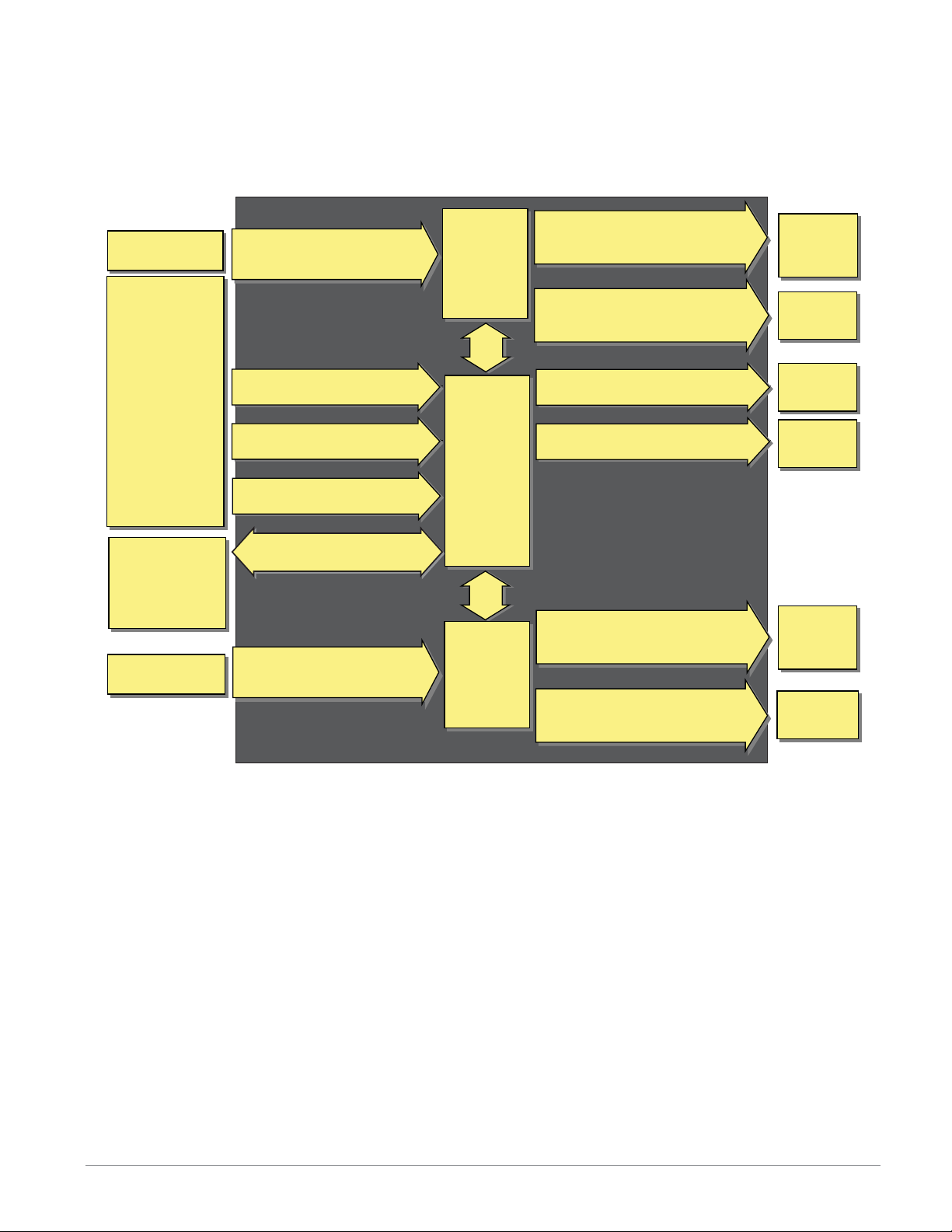

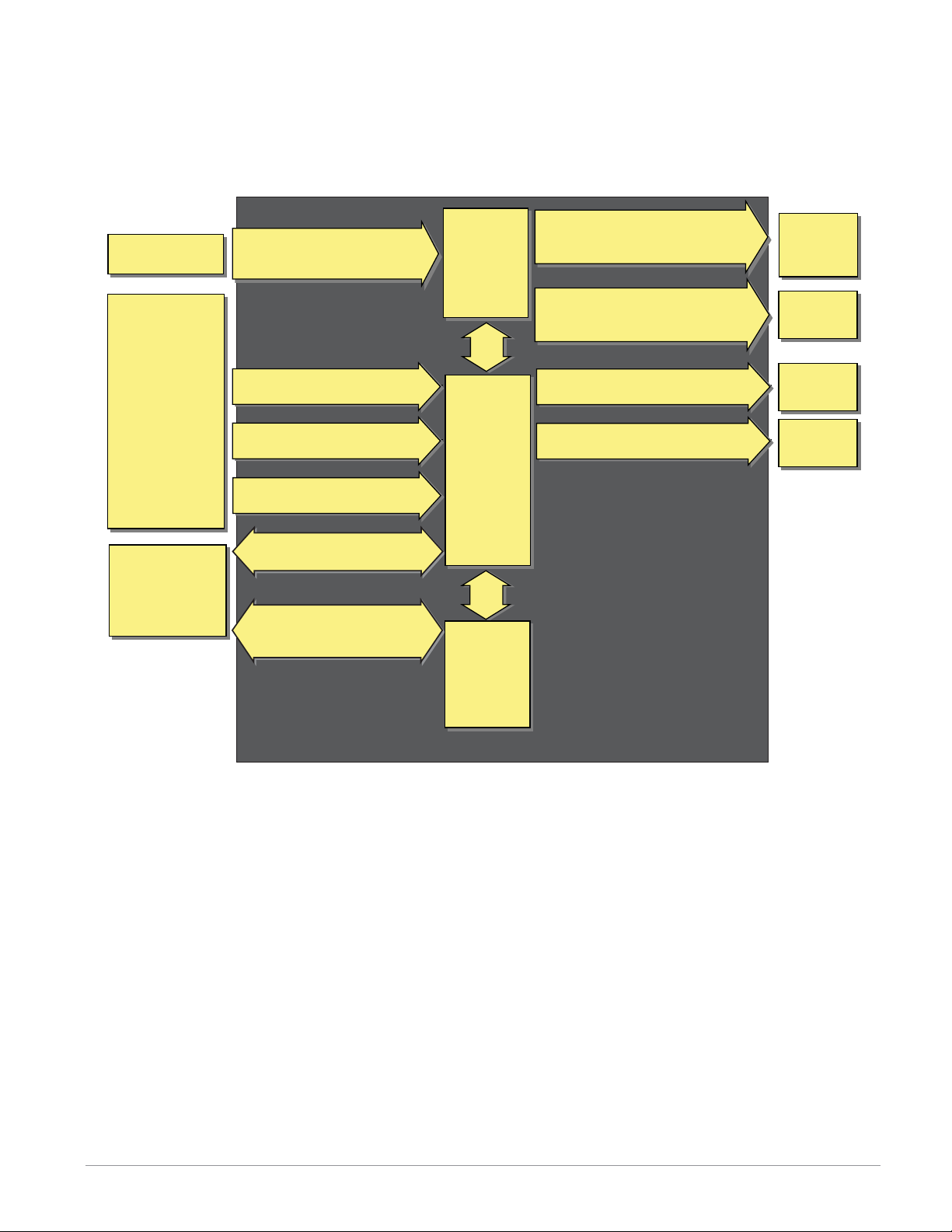

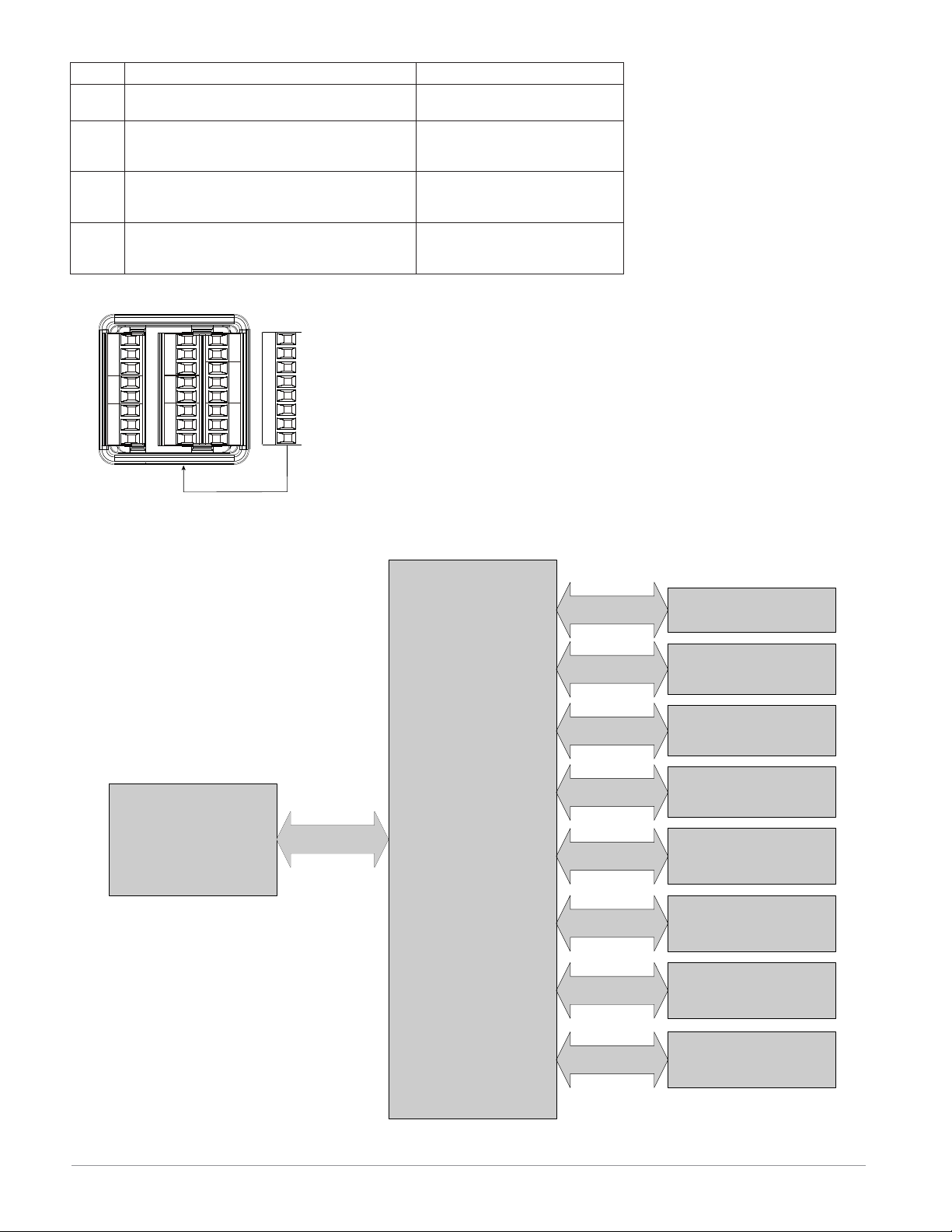

EZ-ZONE® PM Integrated Model 1/16 DIN with Remote Set Point — Input/Output

(no communications options 2 to 3)

Universal Sensor Input, Configuration Communications,

Red/Green 7-Segment Display

Input

Functions

input sensor

none,

idle set point,

alarm reset,

tune,

silence alarm,

manual/auto mode,

control outputs off,

local-remote,

lock keypad,

force alarm,

TRU-TUNE+

loop & alarms off,

profile disable,

profile hold/resume,

profile start,

profile start/stop,

restore user settings

Network

remote user interface,

personal computer,

programmable logic

controller, humanmachine interface

input sensor

®

disable

Analog Input 1 thermocouple,

RTD, process (V, mV, mA, 1k potentiometer)

Digital Input (or Output) 5

(optional) none, switch, volts dc

Digital Input (or Output) 6

(optional) none, switch, volts dc

EZ Key

programmable event

EIA 485 Communications

Standard Bus, Modbus RTU (optional)

Analog Input 2 thermocouple,

RTD, process (V, mV, mA, 1k potentiometer)

PID

Controller

Board

Slot A

ramp-soak

with 4 files

(optional)

Supervisory

&

Power

Board

Slot C

Remote Set

Point

Board

(optional)

Slot B

Output 1 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 2 none, switched dc, no-arc

power control (15 A), form A mechanical

(5 A) or solid-state (0.5 A) relay

Digital Output (or Input) 5 (optional)

none, switched dc

Digital Output (or Input) 6 (optional)

none, switched dc

Output 3 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 4 none, switched dc, form A

mechanical (5 A) or solid-state (0.5 A)

relay

Output

Functions

off, heat, cool,

duplex, alarm,

retransmit,

event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

duplex, alarm,

retransmit,

event

off, heat, cool,

alarm, event

Remote Set Point Operation

• Supports efficient set point manipulation from a remote device, such as a master control or PLC.

Watlow EZ-ZONE® PM Integrated Controller • 5 • Chapter 1 Overview

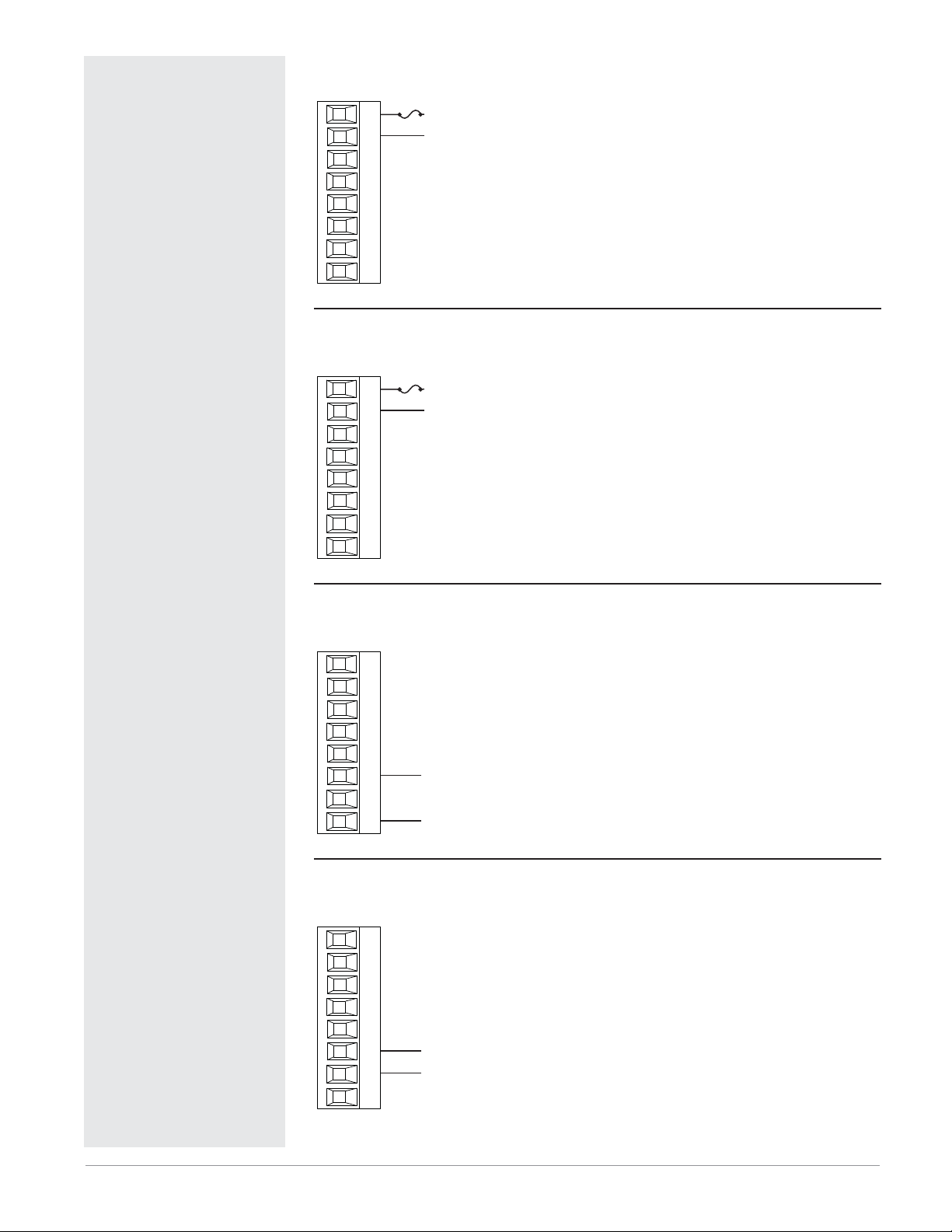

EZ-ZONE® PM Integrated Model 1/16 DIN with a Limit — Input/Output

(no communications options 2 to 3)

Universal Sensor Input, Configuration Communications,

Red/Green 7-Segment Display

Input

Functions

input sensor

none, limit reset,

idle set point,

tune,

alarm reset,

silence alarm,

manual/auto mode,

control outputs off,

lock keypad,

force alarm,

TRU-TUNE+

loop & alarms off,

profile disable,

profile hold/resume,

profile start,

profile start/stop,

restore user settings

Network

remote user interface,

personal computer,

programmable logic

controller, humanmachine interface

input sensor

®

disable

Analog Input 1 thermocouple,

RTD, process (V, mV, mA, 1k potentiometer)

Digital Input (or Output) 5

(optional) none, switch, volts dc

Digital Input (or Output) 6

(optional) none, switch, volts dc

EZ Key

programmable event

EIA 485 Communications

Standard Bus, Modbus RTU (optional)

Analog Input 2 thermocouple,

RTD, process (V, mV, mA, 1k potentiometer)

PID

Controller

Board

Slot A

ramp-soak

with 4 files

(optional)

Supervisory

&

Power

Board

Slot C

Limit

Controller

Board

(optional)

Slot B

Output 1 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 2 none, switched dc, no-arc

power control (15 A), form A mechanical

(5 A) or solid-state (0.5 A) relay

Digital Output (or Input) 5 (optional)

none, switched dc

Digital Output (or Input) 6 (optional)

none, switched dc

Output 3 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 4

form A mechanical (5 A) relay

Output

Functions

off, heat, cool,

duplex, alarm,

retransmit,

event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

duplex, alarm,

retransmit,

event, limit

limit

Integrated PID and Limit Controller

• Reduces wiring time and termination complexity compared to connecting separate products

• Reduces panel space

• Reduces installation costs

• Increases dependability with backup control sensor operation

• Increases user and equipment safety for over-under temperature conditions

Watlow EZ-ZONE® PM Integrated Controller • 6 • Chapter 1 Overview

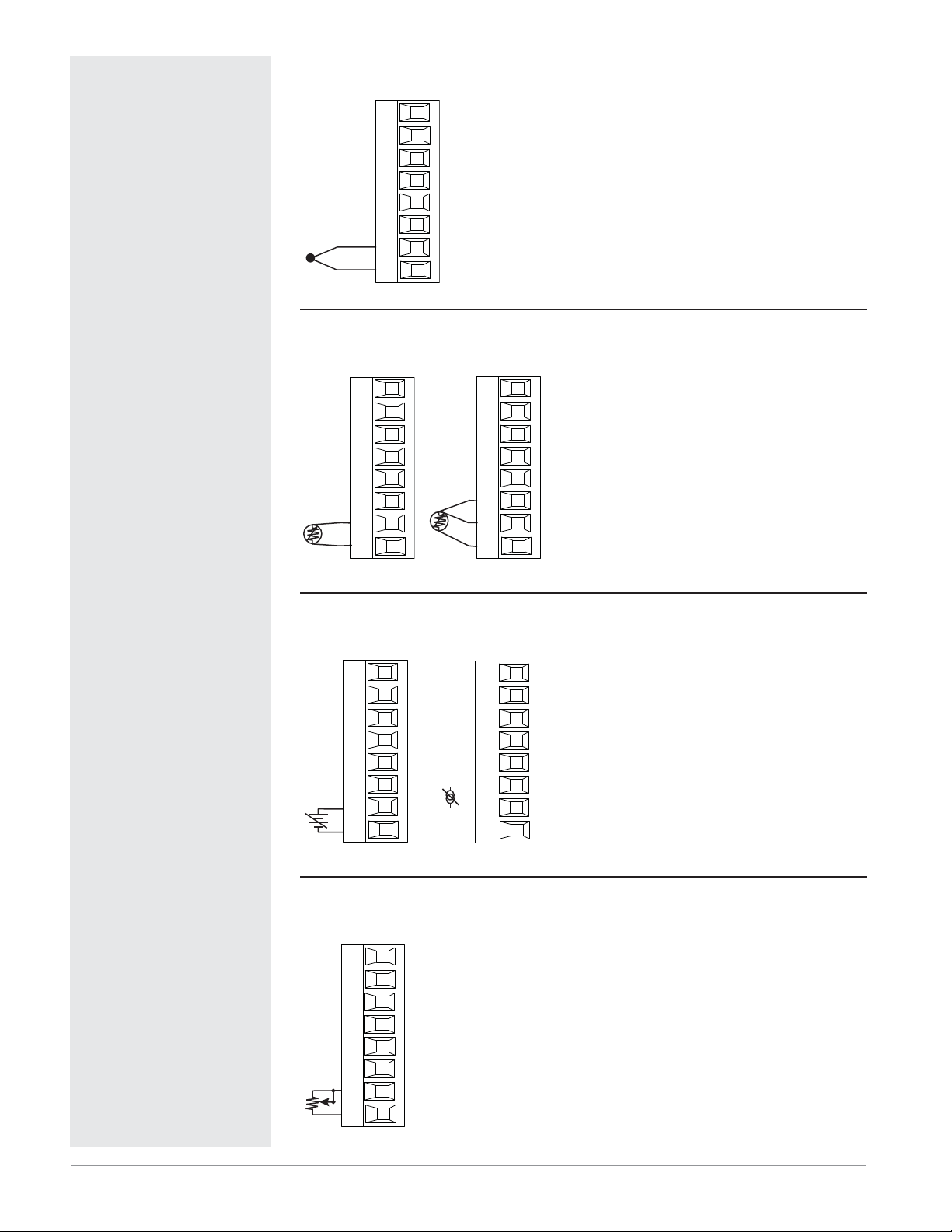

EZ-ZONE® PM Integrated Model 1/16 DIN with Expanded Communications

— Input/Output

Universal Sensor Input, Configuration Communications,

Red/Green 7-Segment Display

Input

Functions

input sensor

none,

idle set point,

tune,

alarm reset,

silence alarm,

manual/auto mode,

control outputs off,

lock keypad,

force alarm,

TRU-TUNE+

loop & alarms off,

profile disable,

profile hold/resume,

profile start,

profile start/stop,

restore user settings

Network

remote user interface,

personal computer,

programmable logic

controller, humanmachine interface

®

disable

Analog Input 1 thermocouple,

RTD, process (V, mV, mA, 1k potentiometer)

Digital Input (or Output) 5

(optional) none, switch, volts dc

Digital Input (or Output) 6

(optional) none, switch, volts dc

EZ Key

programmable event

EIA

485 Communications

Standard Bus, Modbus RTU (optional)

Communications

EIA-232/485 Modbus RTU,

EtherNet/IP

TM

, Modbus TCP

PID

Controller

Board

Slot A

ramp-soak

with 4 files

(optional)

Supervisory

&

Power

Board

Slot C

Communi-

cations

Board

(optional)

Slot B

Output 1 none, switched dc/open

collector, form C mechanical (5 A) or

solid-state (0.5 A) relay, process (V, mA)

Output 2 none, switched dc, no-arc

power control (15 A), form A mechanical

(5 A) or solid-state (0.5 A) relay

Digital Output (or Input) 5 (optional)

none, switched dc

Digital Output (or Input) 6 (optional)

none, switched dc

Output

Functions

off, heat, cool,

duplex, alarm,

retransmit,

event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

off, heat, cool,

alarm, event

Serial Communication Capabilities

• Supports network connectivity to a PC or PLC

• Available in a wide range of protocol choices, including Modbus RTU, EtherNet/IP™, Modbus TCP

Watlow EZ-ZONE® PM Integrated Controller • 7 • Chapter 1 Overview

2

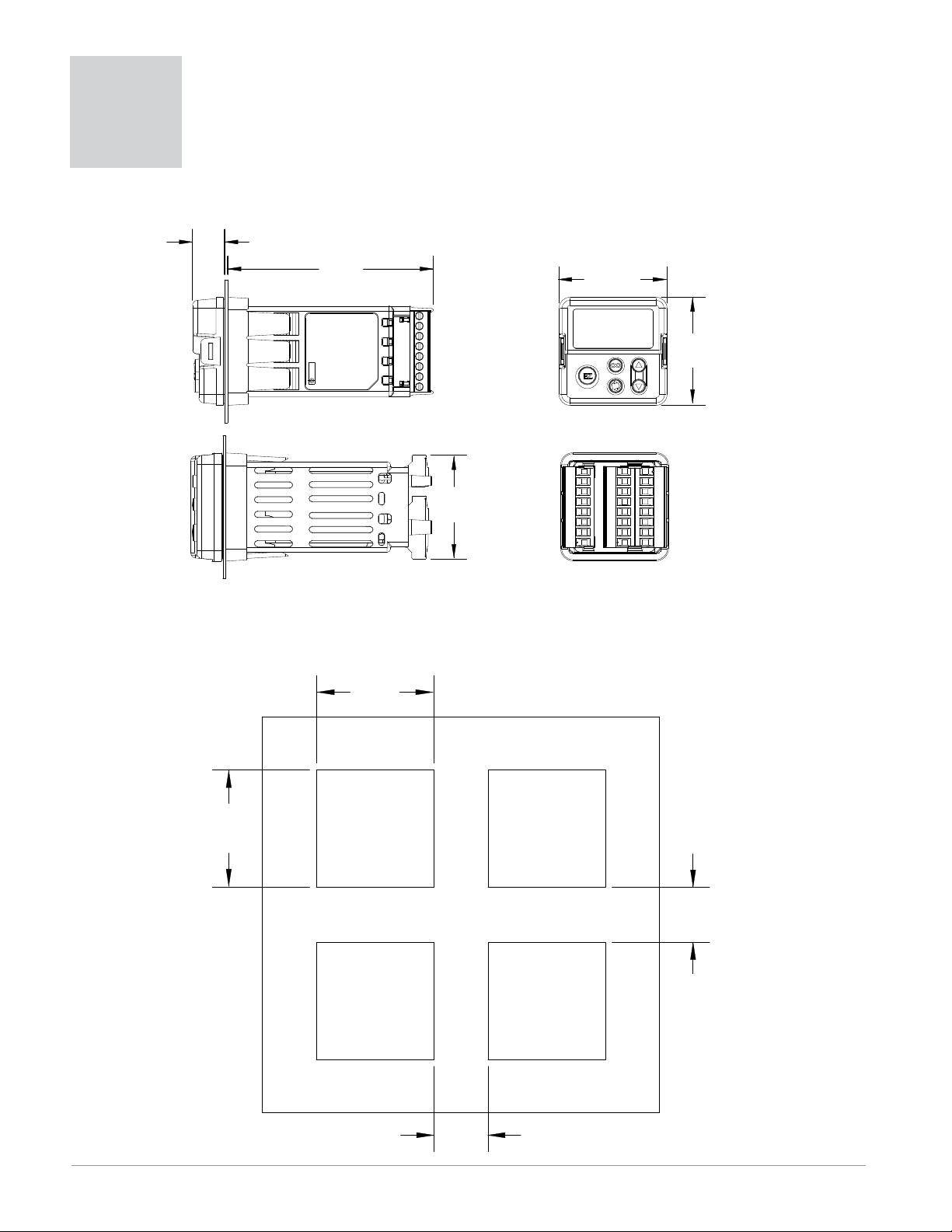

Dimensions

Chapter 2:

Install and Wire

15.8 mm

(0.62 in)

101.6 mm

(4.00 in)

53.3 mm

(2.10 in)

53.3 mm

(2.10 in)

45.2 mm

(1.78 in)

Side

51.2 mm

(2.02 in)

Top Back

Front

L1

K1

J1

L2

K2

T1

S1

R1

45.2 mm

(1.78 in)

Recommended panel spacing

L3

K3

J3

L4

K4

T2

S2

R2

98

99

CF

CD

CE

B5

D6

D5

panel thickness 1.53 to 9.52 mm

(0.060 to 0.375)

21.6 mm

(0.85 in)

21.6 mm

(0.85 in)

Watlow EZ-ZONE® PM Integrated Controller • 8 • Chapter 2 Install and Wire

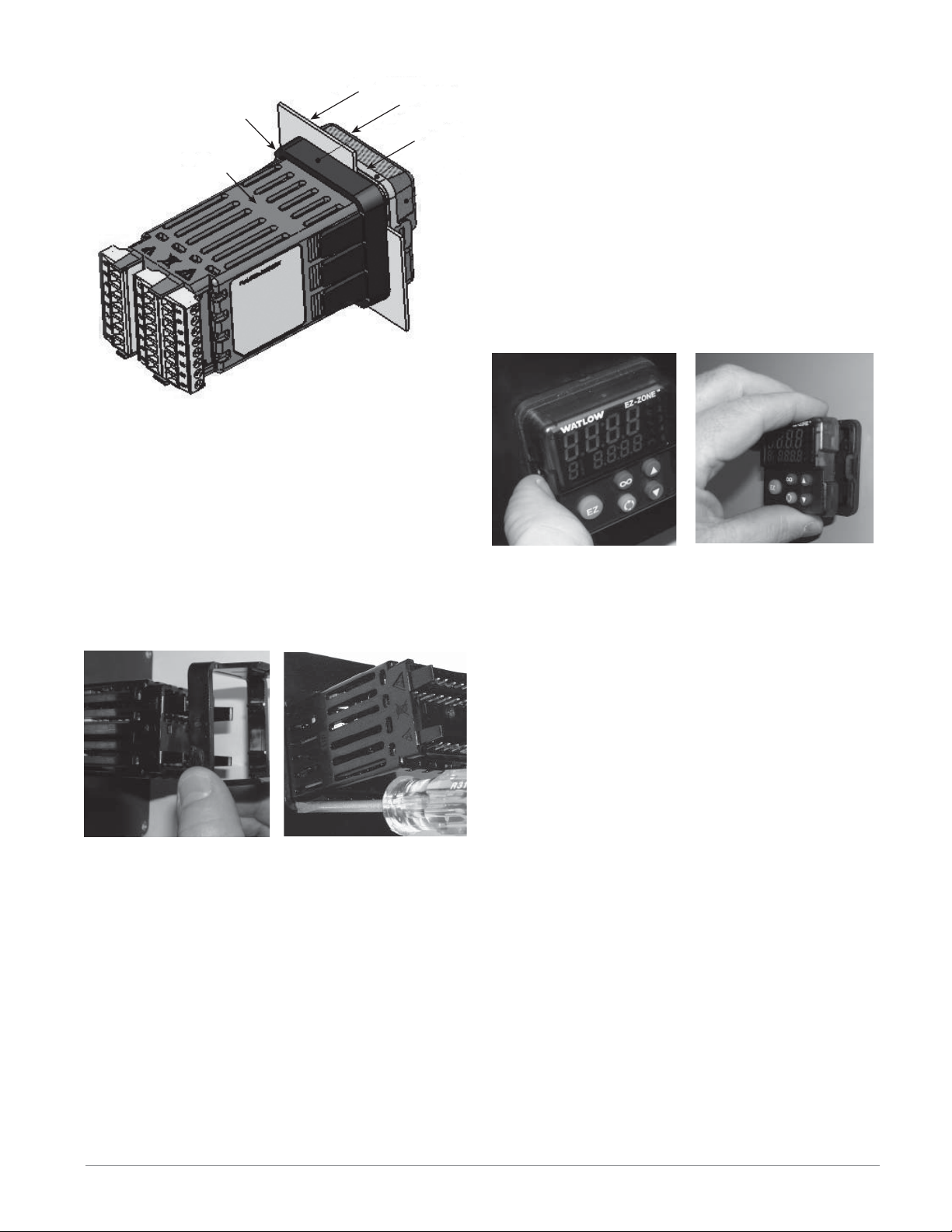

Installation

retention collar

panel

bezel

gasket

The tabs on each side of the mounting collar have

teeth that latch into the ridges on the sides of the

controller. Each tooth is staggered at a different

depth from the front so that only one of the tabs,

on each side, is locked onto the ridges at a time.

case

1. Make the panel cutout using the mounting template dimensions in this chapter.

Insert the case assembly into the panel cutout.

2. While pressing the case assembly firmly against

the panel, slide the mounting collar over the back

of the controller.

If the installation does not require a NEMA 4X

seal, slide the mounting collar up to the back of

the panel tight enough to eliminate the spacing

between the gasket and the panel.

Note: There is a graduated measurement difference between

the upper and lower half of the display to the panel. In order to

meet the seal requirements mentioned above, ensure that the

distance from the front of the top half of the display to the panel

is 16 mm (0.630 in.) or less, and the distance from the front of

the bottom half and the panel is 13.3 mm (0.525 in.) or less.

Removing the Mounted Controller from Its Case

1. From the controller's face, pull out the tab on

each side until you hear it click.

Pull out the tab on each side

until you hear it click.

2. Once the sides are released, grab the unit above

and below the face with two hands and pull the

unit out.

If it is difficult to pull the unit out, remove the

connectors from the back of the controller. This

should make it easier to remove.

Grab the unit above and below

the face and pull forward.

Ó

Warning:

• This equipment is suitable for use in class 1, div. 2, Groups

A, B, C and D or Non-Hazardous locations only. Temperature

Code T4A.

• WARNING – EXPLOSION HAZARD. Substitution of component

may impair suitability for class 1, div. 2.

• WARNING – EXPLOSION HAZARD. Do not disconnect equip-

ment unless power has been switched off or the area is known

to be nonhazardous.

Slide the mounting collar over

the back of the controller.

Place the blade of a screwdriver in the notch of the

mounting collar assembly.

3. For a NEMA 4X (UL50, IP66) seal, place the

blade of a screwdriver in the notch of the mounting collar assembly and push toward the panel

while applying pressure to the face of the controller. Don't be afraid to apply enough pressure to

properly install the controller. The seal system is

compressed more by mating the mounting collar

tighter to the front panel (see pictures above). If

you can move the case assembly back and forth

in the cutout, you do not have a proper seal.

Watlow EZ-ZONE® PM Integrated Controller • 9 • Chapter 2 Install and Wire

Returning the Controller to its Case

1. Ensure that the orientation of the controller is

correct and slide it back into the housing.

Note: The controller is keyed so if it feels that it will not

slide back in do not force it. Check the orientation again

and reinsert after correcting.

2. Using your thumbs push on either side of the controller until both latches click.

Chemical Compatibility

This product is compatible with acids, weak alkalis,

alcohols, gamma radiation and ultraviolet radiation.

This product is not compatible with strong alkalis,

organic solvents, fuels, aromatic hydrocarbons, chlorinated hydrocarbons, esters and keytones.

Ó

Warning:

All electrical power to the controller and controlled circuits

must be disconnected before removing the controller from the

front panel or disconnecting other wiring.

Failure to follow these instructions may cause an electrical

shock and/or sparks that could cause an explosion in class 1,

div. 2 hazardous locations.

Watlow EZ-ZONE® PM Integrated Controller • 10 • Chapter 2 Install and Wire

Slot A Slot B

Output Terminal Function Configuration

1234

X1

W1

Y1

F1

G1

H1

L1

K1

J1

W2

Y2

L2

K2

L2

K2

X3

W3

Y3

W4Y4dc-

F3

G3

H3

L3

K3

J3

L4K4normally open

common (Any switched dc output can use this common.)

dc- (open collector)

dc+

dc+

voltage or current voltage +

current +

normally open

common

normally closed

normally open

common

common

L1K1L2K2L3K3L4K4normally open

common

Communications

CB

CA

CC

CB

CA

C5

C3

C2

V+

CH

SH

CL

E8

E7

E6

E5

E4

E3

E2

E1

Modbus RTU EIA-485 T+/R+

Modbus RTU EIA-485 T-/RModbus RTU EIA-485 common

Modbus RTU EIA-485 T+/R+

Modbus RTU EIA-485 T-/RModbus RTU EIA-232 common

Modbus RTU EIA-232 to DB9 pin 2

Modbus RTU EIA-232 to DB9 pin 3

DeviceNet™ power

Positive side of DeviceNet™ bus

Shield interconnect

Negative side of DeviceNet™ bus

V-

DeviceNet™ power return

EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP receive EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP receive +

EtherNet/IP™ and Modbus TCP transmit EtherNet/IP™ and Modbus TCP transmit +

Inputs

12

T1

S1

R1

Terminal Definitions for Slots A and B.

Slot A

Output 1 Output 2 Input 1

Slot B Slot C

Output 3 Output 4 Input 2

T2

S2

R2

T2

S2

Power485 CommsDig I/O 5 & 6

S2 (RTD) or current +, potentiometer wiper

S3 (RTD), thermocouple -, current - or volts S1 (RTD), thermocouple + or volts +

mA ac

mA ac

Slot B

Communications

Switched dc/open collector

output 1: PM6 _ _ C _-_ _ _ _ A _ _

output 3: PM6 _ _ _ _-_ _ C _ A _ _

Switched dc

output 2: PM6 _ _ _ C-_ _ _ _ A _ _

output 4: PM6 _ _ _ _-_ _ _ C A _ _

Universal Process

output 1: PM6 _ _ F _-_ _ _ _ A _ _

output 3: PM6 _ _ _ _-_ _ F _ A _ _

Mechanical Relay 5 A, Form C

output 1: PM6 _ _ E _-_ _ _ _ A _ _

output 3: PM6 _ _ _ _-_ _ E _ A _ _

No-arc 15 A, Form A

output 2: PM6 _ _ _ H-_ _ _ _ A _ _

Mechanical Relay 5 A, Form A

output 2: PM6 _ _ _ J-_ _ _ _ A _ _

output 4: PM6 _ _ _ _-_ _ _ J A _ _

Solid-state Relay 0.5 A, Form A

output 1: PM6 _ _ K _-_ _ _ _ A _ _

output 2: PM6 _ _ _ K-_ _ _ _ A _ _

output 3: PM6 _ _ _ _-_ _ K

_ A _ _

output 4: PM6 _ _ _ _-_ _ _ K A _ _

Modbus RTU 232/485 Communications

PM6 _ _ _ _-2 A A A A _ _

DeviceNet™ Communications

PM6 _ _ _ _-5 A A A A _ _

Ethernet 10/100 supporting EtherNet/IP™

and Modbus TCP

PM6 _ _ _ _-3 A A A A _ _

Universal Sensor

input 1: all configurations

input 2: PM6 _ _ _ _-_ (R or L) _ _ A _ _

Current Transformer

PM6 _ _ _ _-_ T _ _ A _ _

or

Watlow EZ-ZONE® PM Integrated Controller • 11 • Chapter 2 Install and Wire

Slot C Terminal Function Configuration

9899power input: ac or dc+

power input: ac or dc-

CC

Standard Bus or Modbus RTU EIA-485 common

CA

Standard Bus or Modbus RTU EIA-485 T-/R-

CB

Standard Bus or Modbus RTU EIA-485 T+/R+

CF

Standard Bus EIA-485 common

CD

Standard Bus EIA-485 T-/R-

CE

Standard Bus EIA-485 T+/R+

B5

digital input-output common

D6

digital input or output 6

D5

digital input or output 5

all

Standard Bus or Modbus

PM6 _ _ _ _-1 _ _ _ A _ _

PM6 _ _ _ _-(A, 2 or 3) _ _ _ A _ _

PM6 _ 2 _ _-_ _ _ _ A _ _

PM6 _ 4 _ _-_ _ _ _ A _ _

Terminal Definitions for Slot C.

Slot A

Output 1 Output 2 Input 1

Slot B Slot C

Output 3 Output 4 Input 2

Power485 CommsDig I/O 5 & 6

or

Slot B

Communications

Controller

Power Supply

12 to 40VÎ (dc)

24 to 28VÅ (ac)

85 to 264VÅ (ac)

Safety Isolation

Low voltage power bus

and

internal bus

No Isolation

No Isolation

No Isolation

Low-voltage

Isolation

Safety Isolation

Low-voltage

Isolation

Low-voltage

Isolation

Low-voltage

Isolation

Digital Inputs and

Outputs 5 & 6

Switched DC, Open

Collector, Process Outputs

Analog Input 1

Analog Input 2

Mechanical Relay,

Solid-state Relay &

No-arc Relay Outputs

EIA-485

Communications Port

RS-232/EIA-485

Communications Port

Ethernet

Communications Port

PM Integrated isolation blocks.

Low-voltage Isolation: 42V peak

Safety Isolation: 1,528VÅ (ac)

Watlow EZ-ZONE® PM Integrated Controller • 12 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

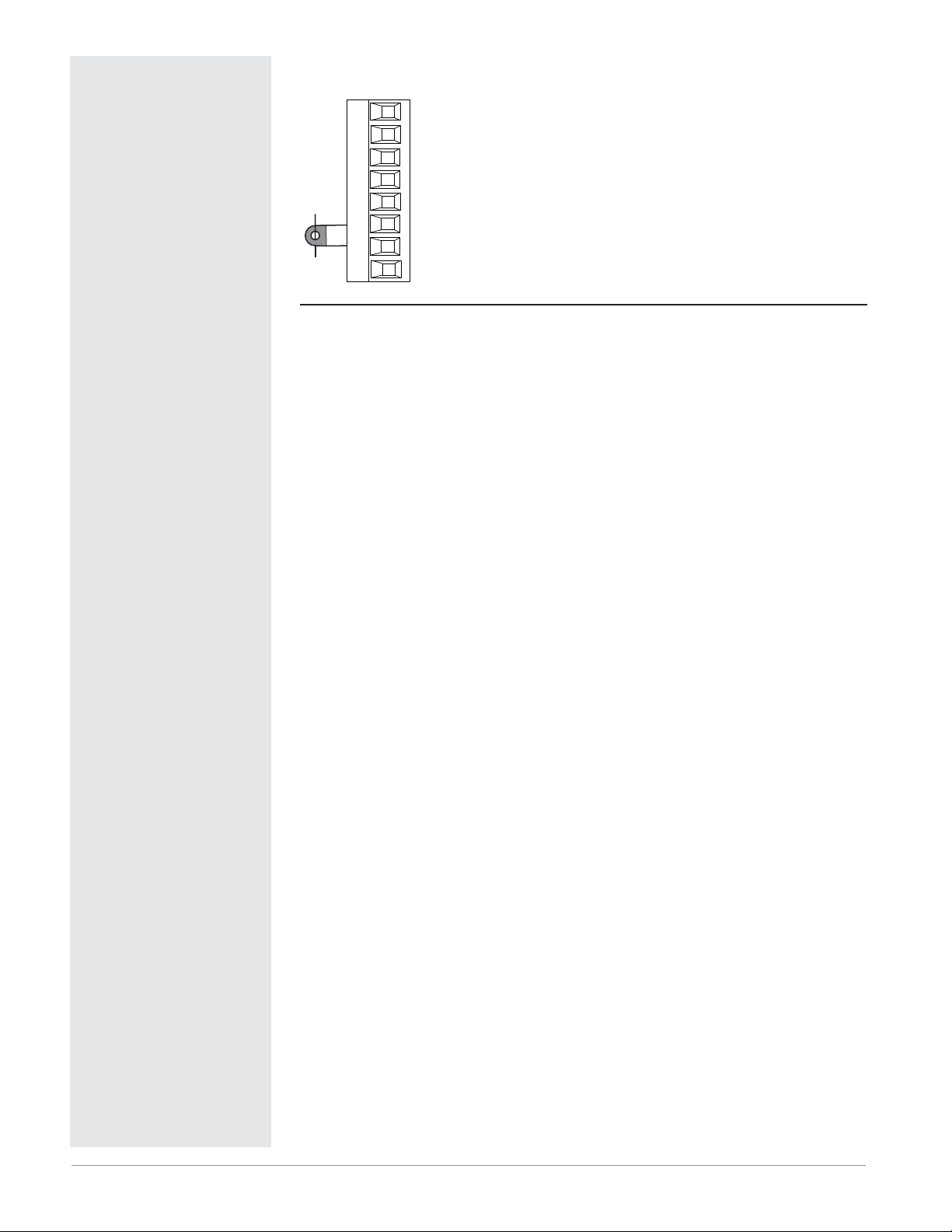

Low Power

Slot C

98

99

CF

CD

CE

B5

D6

D5

power

power

High Power

Slot C

98

99

CF

CD

CE

B5

D6

D5

power

power

fuse

• 12 to 40VÎ (dc)

• 20 to 28VÅ (ac)

• 20 to 28VÅ (ac) Semi Sig F47

• 47 to 63 Hz

• 10VA maximum power consumption

PM6 _ (3 or 4) _ _-_ _ _ _ A _ _

fuse

• 85 to 264VÅ (ac)

• 100 to 240VÅ (ac) Semi Sig F47

• 47 to 63 Hz

• 10VA maximum power consumption

PM6 _ (1 or 2) _ _-_ _ _ _ A _ _

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

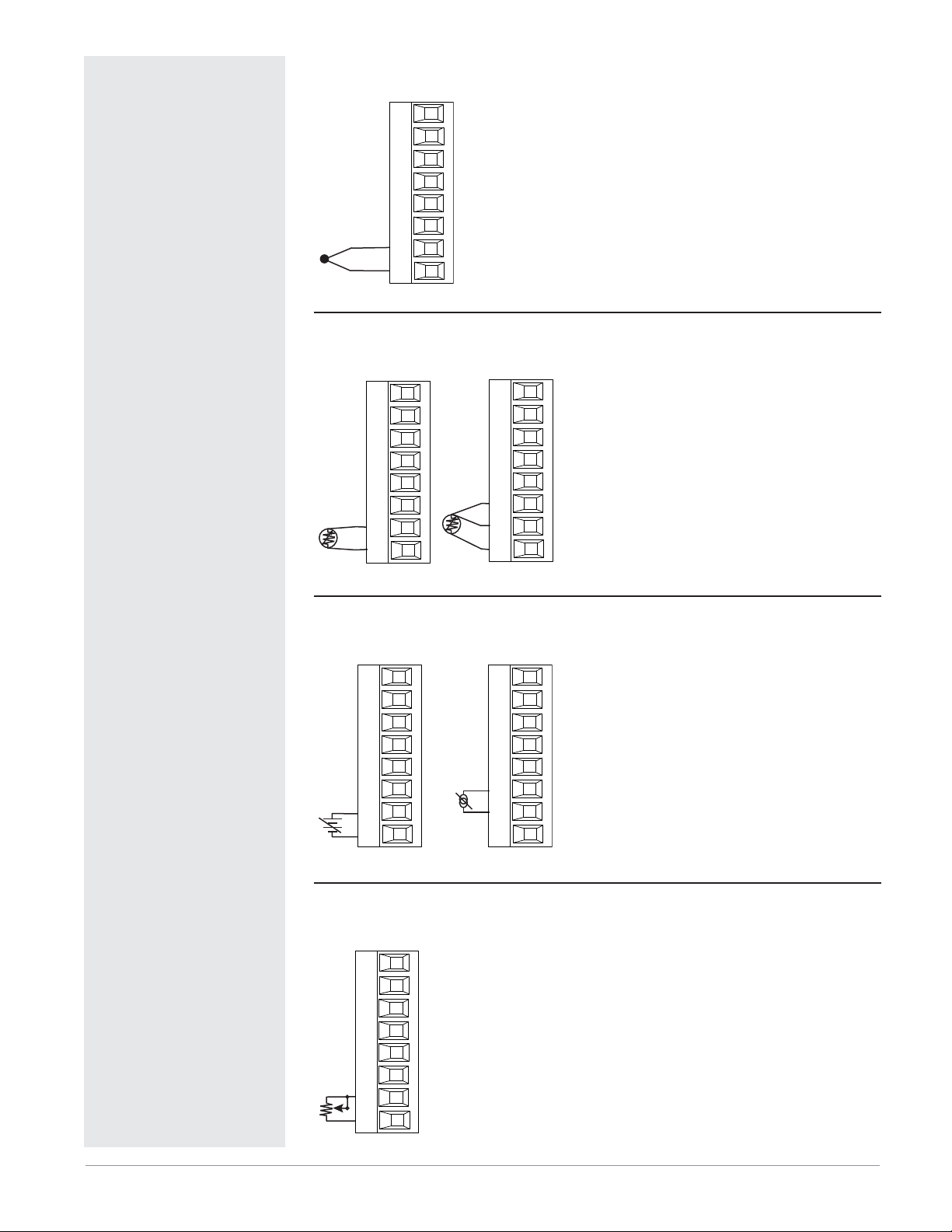

Digital Input or Output 5

Slot C

98

99

CF

CD

CE

common -

B5

D6

input or output +

D5

Digital Input

• update rate 10 Hz

• dry contact or dc voltage

DC voltage

• maximum input 36V at 3 mA

• minimum high state 3V @ 0.25 mA

• maximum low state 2V

Dry contact

• minimum open resistance 500 Ω

• maximum closed resistance 100 Ω

• maximum short circuit 13 mA

Digital Input or Output 6

Slot C

98

99

CF

CD

CE

common -

B5

input or output +

D6

D5

Digital Input

• update rate 10 Hz

• dry contact or dc voltage

DC voltage

• maximum input 36V at 3 mA

• minimum high state 3V @ 0.25 mA

• maximum low state 2V

Dry contact

• minimum open resistance 500 Ω

• maximum closed resistance 100 Ω

• maximum short circuit 13 mA

Digital Output

• update rate 10 Hz

• output voltage 24V

• current limit, Output 5, 24 mA

maximum

• capable of driving a 3-pole

DIN-A-MITE

• open-circuit voltage 22 to

32VÎ (dc)

PM6 _ (2 or 4) _ _-_ _ _ _ A _ _

Digital Output

• update rate 10 Hz

• output voltage 24V

• current limit, Output 6, 10 mA

maximum

• capable of driving a single-pole

DIN-A-MITE

• open-circuit voltage 22 to

32VÎ (dc)

PM6 _ (2 or 4) _ _-_ _ _ _ A _ _

Watlow EZ-ZONE® PM Integrated Controller • 13 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

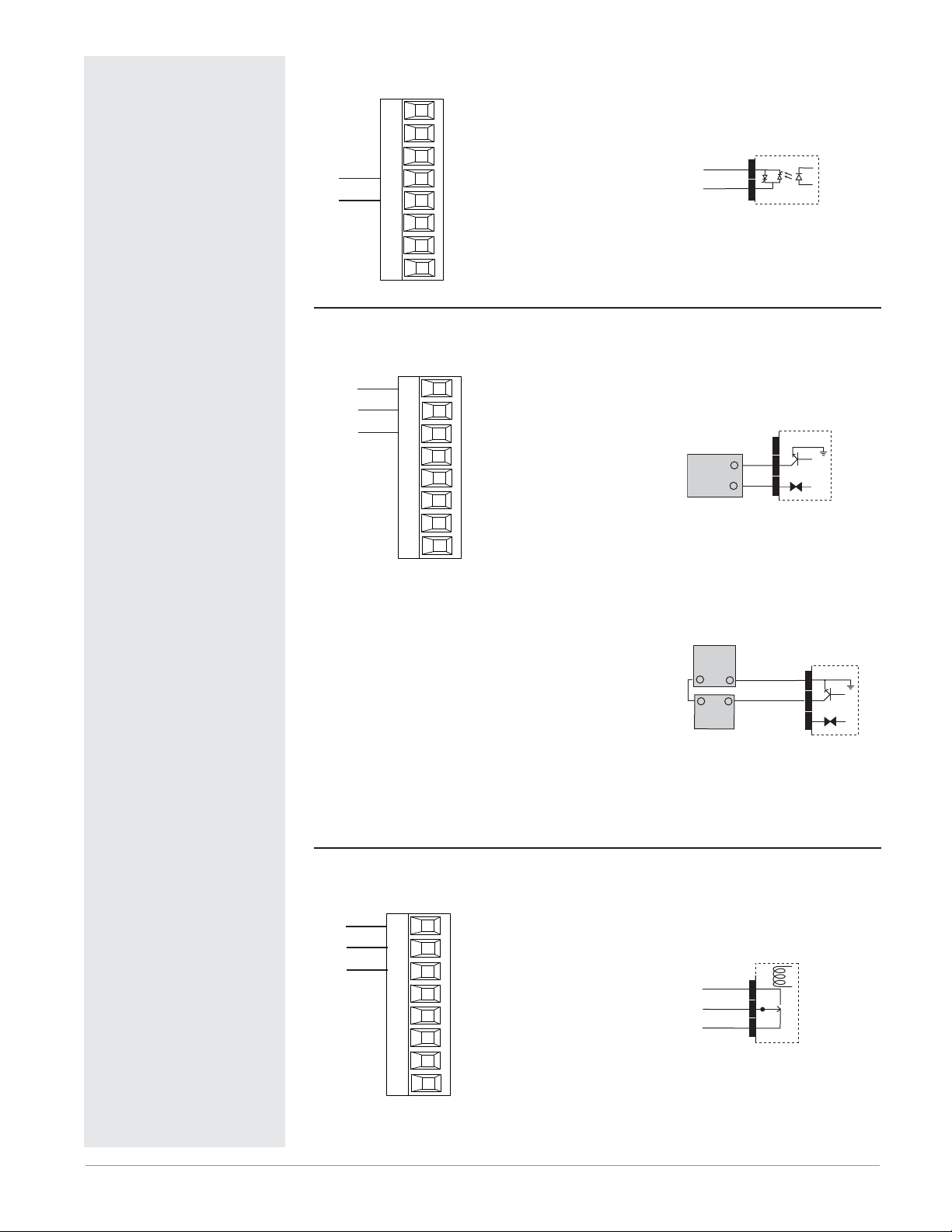

Input 1 Thermocouple

Slot A

L1

K1

J1

L2

K2

T1

-

S1

+

R1

Input 1 RTD

Slot A

L1

K1

J1

L2

K2

T1

S3

S1

S1

R1

2-wire

S2

S3

S1

• 20 Ω maximum source resistance

• >20 MΩ input impedance

• 3 microampere open-sensor detection

• Thermocouples are polarity sensitive. The negative lead (usually

red) must be connected to S1.

• To reduce errors, the extension wire for thermocouples must be

of the same alloy as the thermocouple.

PM6 _ _ _ _-_ _ _ _ A _ _ (all)

Slot A

L1

K1

J1

L2

K2

T1

S1

R1

3-wire

• platinum, 100 and 1,000 Ω @ 0°C

• calibration to DIN curve (0.00385 Ω/Ω/°C)

• 20 Ω total lead resistance

• RTD excitation current of 0.09 mA typical. Each

ohm of lead resistance may affect the reading by

0.03°C.

• For 3-wire RTDs, the S1 lead (usually white) must

be connected to R1.

• For best accuracy use a 3-wire RTD to compensate

for lead-length resistance. All three lead wires must

have the same resistance.

PM6 _ _ _ _-_ _ _ _ A _ _ (all)

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Input 1 Process

Slot A

L1

K1

J1

L2

K2

T1

-

S1

+

R1

volts

Input 1 Potentiometer

Slot A

L1

K1

J1

• Use a 1 kΩ potentiometer.

PM6 _ _ _ _-_ _ _ _ A _ _ (all)

CW

CCW

L2

K2

T1

S1

R1

+

-

Slot A

L1

K1

J1

L2

K2

T1

S1

R1

amperes

• 0 to 20 mA @ 100 Ω input impedance

• 0 to 10VÎ (dc) @ 20 kΩ input impedance

• 0 to 50 mVÎ (dc) @ 20 kΩ input impedance

• scalable

PM6 _ _ _ _-_ _ _ _ A _ _ (all)

Watlow EZ-ZONE® PM Integrated Controller • 14 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

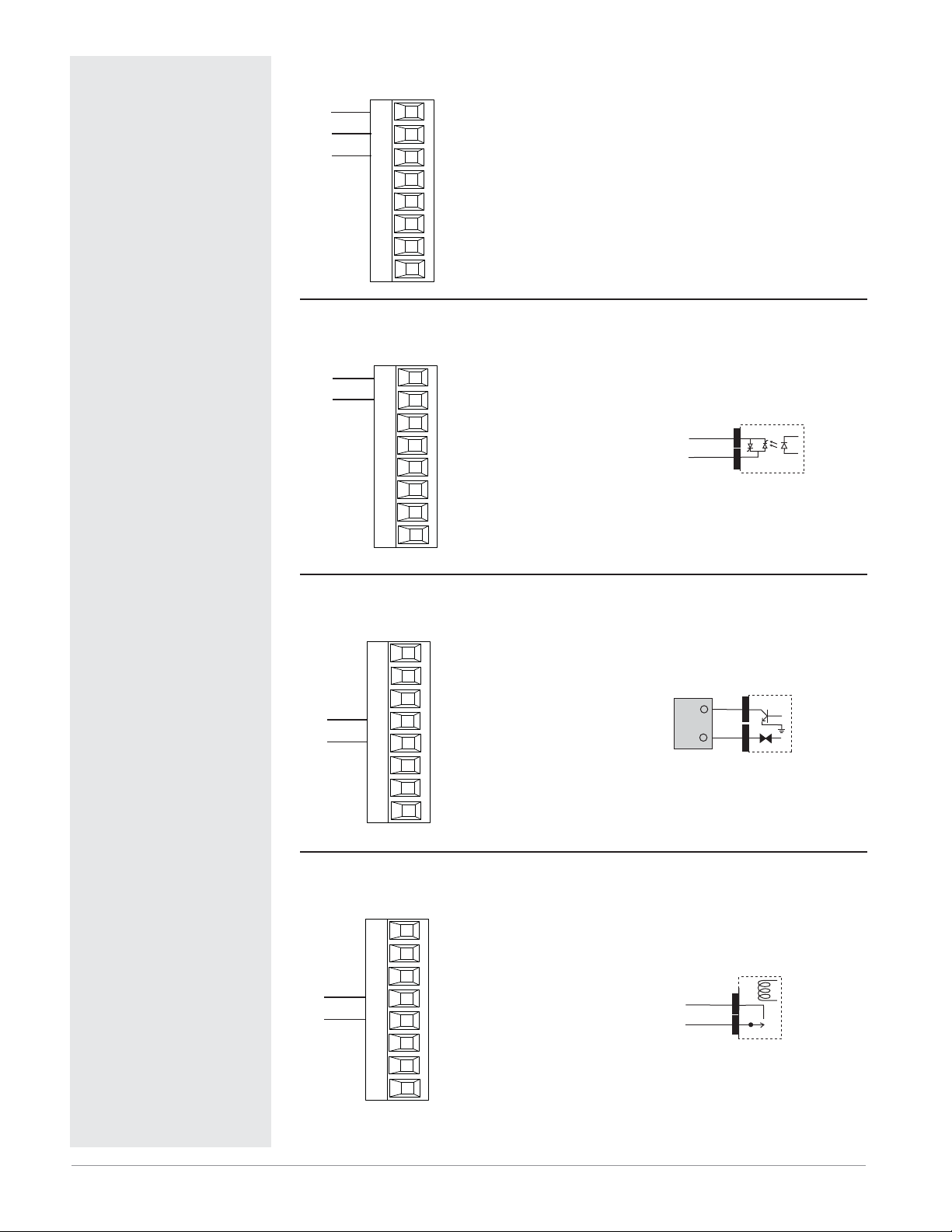

Input 2 Thermocouple

Slot B

L3

K3

J3

L4

K4

T2

-

S2

+

R2

Input 2 RTD

Slot B

L3

K3

J3

L4

K4

T2

S3

S2

S1

R2

2-wire

S2

S3

S1

• 20 Ω maximum source resistance

• >20 MΩ input impedance

• 3 microampere open-sensor detection

• Thermocouples are polarity sensitive. The negative lead (usually

red) must be connected to S2.

• To reduce errors, the extension wire for thermocouples must be

of the same alloy as the thermocouple.

PM6 _ _ _ _-_ (R or L) _ _ A _ _

Slot B

L3

K3

J3

L4

K4

T2

S2

R2

3-wire

• platinum, 100 and 1,000 Ω @ 0°C

• calibration to DIN curve (0.00385 Ω/Ω/°C)

• 20 Ω total lead resistance

• RTD excitation current of 0.09 mA typical. Each

ohm of lead resistance may affect the reading by

0.03°C.

• For 3-wire RTDs, the S1 lead (usually white) must

be connected to R2.

• For best accuracy use a 3-wire RTD to compensate

for lead-length resistance. All three lead wires must

have the same resistance.

PM6 _ _ _ _-_ (R or L) _ _ A _ _

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Input 2 Process

Slot B

L3

K3

J3

L4

K4

T2

-

S2

+

R2

volts

Input 2 Potentiometer

Slot B

L3

K3

J3

• Use a 1 kΩ potentiometer.

PM6 _ _ _ _-_ (R or L) _ _ A _ _

CW

CCW

L4

K4

T2

S2

R2

+

-

Slot B

L3

K3

J3

L4

K4

T2

S2

R2

amperes

• 0 to 20 mA @ 100 Ω input impedance

• 0 to 10VÎ (dc) @ 20 kΩ input impedance

• 0 to 50 mVÎ (dc) @ 20 kΩ input impedance

• scalable

PM6 _ _ _ _-_ (R, T or L) _ _ A _ _

Watlow EZ-ZONE® PM Integrated Controller • 15 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Input 2 Current Transformer

Slot B

L3

K3

J3

L4

K4

T2

S2

R2

• Input range is 0 to 50 mA.

• current transformer part number: 16-0246

• 100 Ω input impedance

• response time: 1 second maximum

• accuracy +/-1 mA typical

PM6 _ _ _ _-_ T _ _ A _ _

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Watlow EZ-ZONE® PM Integrated Controller • 16 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

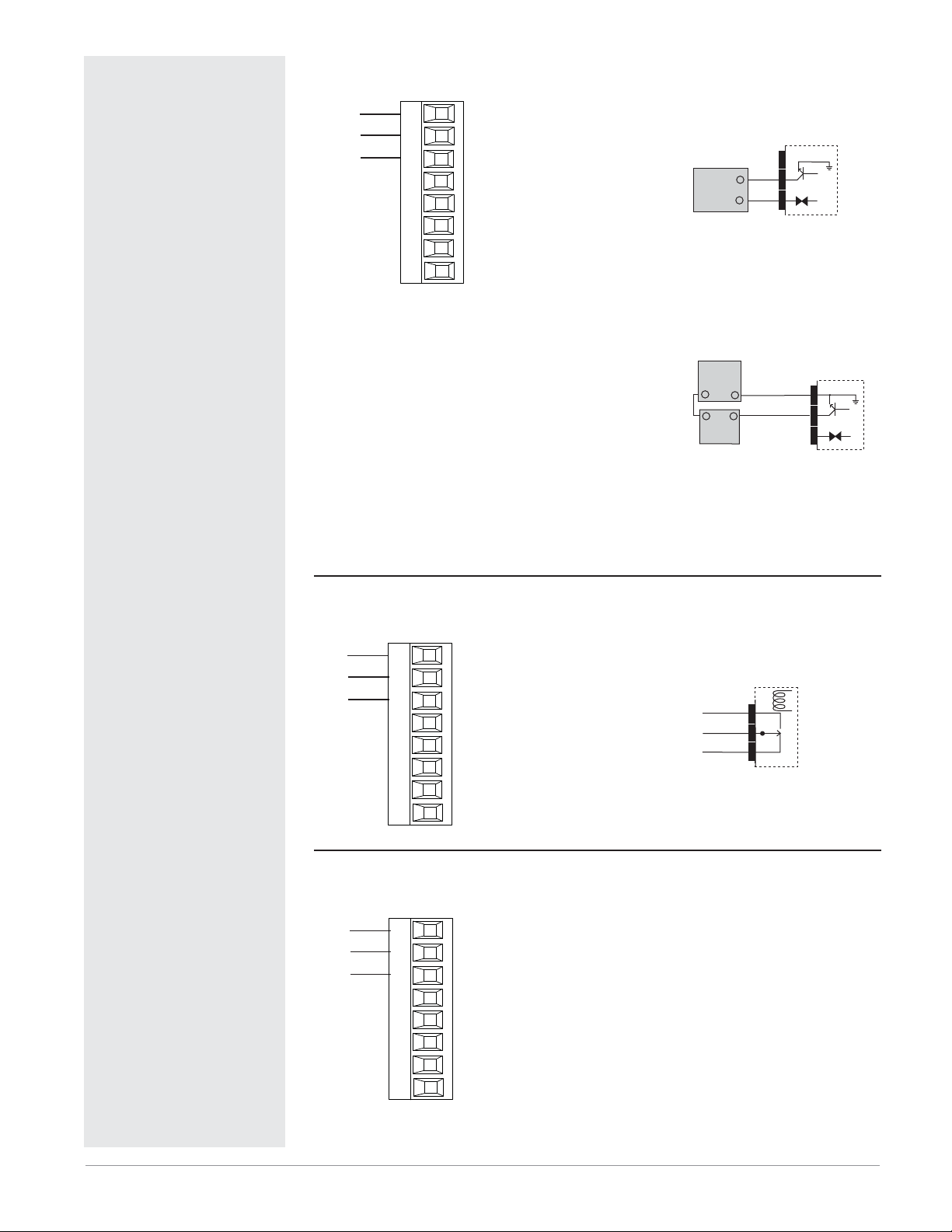

Output 1 Switched DC/Open Collector

Switched DC

Slot A

common

dc - (open collector)

dc +

X1

W1

Y1

L2

K2

T1

S1

R1

• 30 mA dc maximum supply

current

• short circuit limited to <50 mA

• 22 to 32VÎ (dc) open circuit

voltage

• Use dc- and dc+ to drive external solid-state relay.

• DIN-A-MITE compatible

• single-pole: up to 4 in parallel

or 4 in series

• 2-pole: up to 2 in parallel or 2

in series

• 3-pole: up to 2 in series

Open Collector

• 100 mA maximum output current sink

• 30VÎ (dc) maximum supply

voltage

• Any switched dc output can

use the common terminal.

• Use an external power supply

to control a dc load, with the

load positive to the positive

of the power supply, the load

negative to the open collector

and common to the power supply negative.

See Quencharc note.

PM6 _ _ C _-_ _ _ _ A _ _

Output 1 Mechanical Relay, Form C

normally open

common

normally closed

L1

K1

J1

L2

K2

T1

S1

R1

Slot A

• 5 A at 240VÅ (ac) or 30VÎ (dc)

maximum resistive load

• 20 mA at 24V minimum load

• 125 VA pilot duty at 120/240VÅ

(ac), 25 VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

• for use with ac or dc

See Quencharc note.

PM6 _ _ E _-_ _ _ _ A _ _

Load

Powe r

Supply

+

normally

L1

common

K1

J1

normally

+

Load

open

closed

-

+

-

-

Switched DC

dc-

W1

dc+

Y1

X1

common

W1

Mechanical

Relay

Internal

Circuitry

Internal

Circuitry

dc-

dc+

Open

Collector

Internal

Circuitry

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Quencharc Note:

Switching pilot duty inductive

loads (relay coils, solenoids,

etc.) with the mechanical

relay, solid state relay or

open collector output options

Output 1 Universal Process

volts or current -

volts +

current +

F1

G1

H1

L2

K2

T1

S1

R1

Slot A

• 0 to 20 mA into 800 Ω maximum load

• 0 to 10VÎ (dc) into voltage 1

kΩ minimum load

• scalable

• output supplies power

• cannot use voltage and current

outputs at same time

• Output may be used as retransmit or control.

PM6 _ _ F _-_ _ _ _ A _ _

requires use of an R.C. suppressor.

Note: If output 1 is a universal process output, output 2 cannot function as a variable-time-base output.

Watlow EZ-ZONE® PM Integrated Controller • 17 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

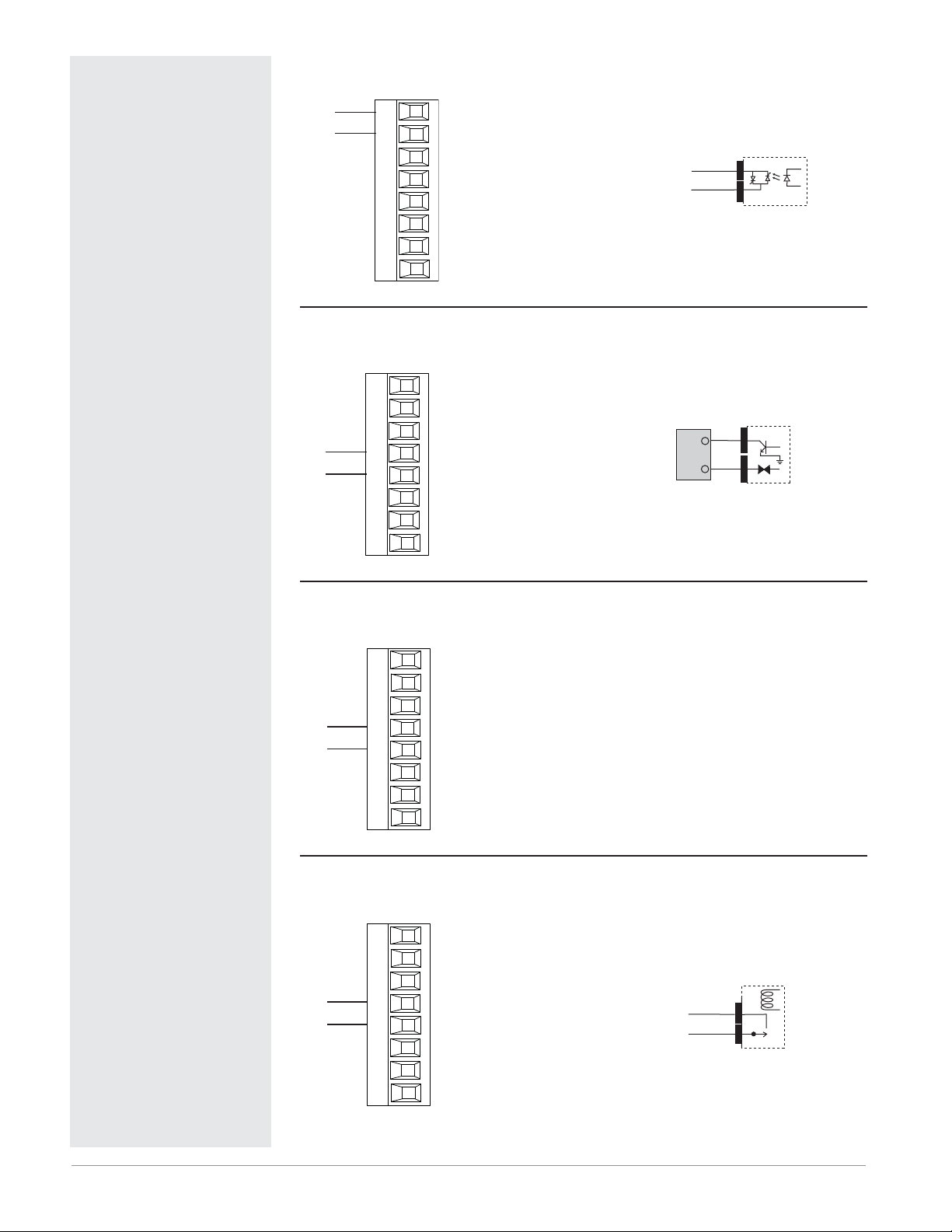

Output 1 Solid-state Relay, Form A

normally open

common

L1

K1

L2

K2

T1

S1

R1

Slot A

• 0.5 A at 20 to 264VÅ (ac) maxi-

mum resistive load

• 20 VA 120/240VÅ (ac) pilot duty

• opto-isolated, without contact

suppression

• maximum off state leakage of

105 microamperes

• output does not supply power

• Do not use on dc loads.

• See Quencharc note.

PM6 _ _ K _-_ _ _ _ A _ _

Output 2 Switched DC

dc+

dc-

Slot A

L1

K1

J1

W2

Y2

T1

S1

R1

• 10 mA DC maximum supply

current

• short circuit limited to <50 mA

• 22 to 32VÎ (dc) open circuit

voltage

• use dc- and dc+ to drive external solid-state relay

• DIN-A-MITE compatible

• single-pole: up to 2 in series,

none in parallel

PM6 _ _ _ C-_ _ _ _ A _ _

L1

K1

Load

common

+

normally

open

dc-

W2

dc+

Solid-state Relay

Internal Circuitry

Switched DC

Y2

Internal

Circuitry

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Quencharc Note:

Switching pilot duty inductive

loads (relay coils, solenoids,

etc.) with the mechanical

relay, solid state relay or

open collector output options

requires use of an R.C. suppressor.

Output 2 No-arc Relay, Form A

Slot A

normally open

common

L1

K1

J1

L2

K2

T1

S1

• 15 A at 85 to 264VÅ (ac) resis-

tive load only

• 2,000,000 cycle rating for no-arc

circuit (preliminary)

• 100 mA minimum load

• 2 mA maximum off state leakage

• Do not use on dc loads.

• Output does not supply power.

PM6 _ _ _ H-_ _ _ _ A _ _

R1

Output 2 Mechanical Relay, Form A

Slot A

normally open

common

L1

K1

J1

L2

K2

T1

S1

R1

• 5 A at 240VÅ (ac) or 30VÎ (dc)

maximum resistive load

• 20 mV at 24V minimum load

• 125 VA pilot duty @ 120/240VÅ

(ac), 25 VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

• for use with ac or dc

See Quencharc note.

PM6 _ _ _ J-_ _ _ _ A _ _

L2

K2

normally

open

common

Mechanical

Relay

Internal

Circuitry

Watlow EZ-ZONE® PM Integrated Controller • 18 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Output 2 Solid-state Relay, Form A

normally open

common

Slot A

L1

K1

J1

L2

K2

T1

S1

R1

• 0.5 A at 20 to 264VÅ (ac) maxi-

mum resistive load

• 20 VA 120/240VÅ (ac) pilot duty

• opto-isolated, without contact

suppression

• maximum off state leakage of

105 microamperes

• Output does not supply power.

• Do not use on dc loads.

See Quencharc note.

PM6 _ _ _ K-_ _ _ _ A _ _

Output 3 Switched DC/Open Collector

Switched DC

Slot B

common

dc - (open collector)

dc +

X3

W3

Y3

L4

K4

T2

S2

R2

• 30 mA dc maximum supply

current

• short circuit limited to <50 mA

• 22 to 32VÎ (dc) open circuit

voltage

• Use dc- and dc+ to drive external solid-state relay.

• DIN-A-MITE compatible

• single-pole: up to 4 in parallel

or 4 in series

• 2-pole: up to 2 in parallel or 2

in series

• 3-pole: up to 2 in series

Open Collector

• 100 mA maximum output current sink

• 30VÎ (dc) maximum supply

voltage

• Any switched dc output can

use the common terminal.

• Use an external power supply

to control a dc load, with the

load positive to the positive

of the power supply, the load

negative to the open collector

and common to the power supply negative.

See Quencharc note.

PM6 _ _ _ _-_ _ C _ A _ _

L2

K2

+

Load

Powe r

Supply

+

Load

common

normally

open

-

+

-

-

Solid-state Relay

Internal Circuitry

Switched DC

dc-

W3

dc+

Y3

Internal

Circuitry

X3

common

dc-

W3

dc+

Open

Collector

Internal

Circuitry

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Quencharc Note:

Switching pilot duty inductive

loads (relay coils, solenoids,

etc.) with the mechanical

relay, solid state relay or

open collector output options

Output 3 Mechanical Relay, Form C

normally open

common

normally closed

L3

K3

J3

L4

K4

T2

S2

R2

Slot B

• 5 A at 240VÅ (ac) or 30VÎ (dc)

maximum resistive load

• 20 mA at 24V minimum load

• 125 VA pilot duty at 120/240VÅ

(ac), 25 VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

• for use with ac or dc

See Quencharc note.

PM6 _ _ _ _-_ _ E _ A _ _

L3

K3

J3

normally

open

common

normally

closed

Mechanical

Relay

Internal

Circuitry

requires use of an R.C. suppressor.

Watlow EZ-ZONE® PM Integrated Controller • 19 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Output 3 Universal Process

volts or current -

volts +

current +

F3

G3

H3

L4

K4

T2

S2

R2

Slot B

• 0 to 20 mA into 800 Ω maximum load

• 0 to 10VÎ (dc) into voltage 1

kΩ minimum load

• scalable

• Output supplies power.

• cannot use voltage and current

outputs at same time

• Output may be used as retransmit or control.

PM6 _ _ _ _-_ _ F _ A _ _

Output 3 Solid-state Relay, Form A

Note: If output 3 is a universal process

output, output 4 cannot function as a

variable-time-base output.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

normally open

common

Slot B

L3

K3

• 0.5 A at 20 to 264VÅ (ac) maxi-

• 20 VA 120/240VÅ (ac) pilot

• opto-isolated, without contact

L4

K4

T2

S2

R2

• maximum off state leakage of

• Output does not supply power.

• Do not use on dc loads.

See Quencharc note.

PM6 _ _ _ _ -_ _ K _ A _ _

Output 4 Switched DC

Slot B

• 10 mA DC maximum supply

• short circuit limited to <50 mA

• 22 to 32VÎ (dc) open circuit

• Use dc- and dc+ to drive exter-

• DIN-A-MITE compatible

• single-pole: up to 2 in series,

PM6 _ _ _ _-_ _ _ C A _ _

dc-

dc+

L3

K3

J3

W4

Y4

T2

S2

R2

mum resistive load

duty

suppression

105 microamperes

current

voltage

nal solid-state relay.

none in parallel

L3

K3

Load

normally

open

common

+

-

Solid-state Relay

Internal Circuitry

Switched DC

dc-

W4

dc+

Y4

Internal

Circuitry

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Quencharc Note:

Switching pilot duty inductive

loads (relay coils, solenoids,

etc.) with the mechanical

relay, solid state relay or

open collector output options

Output 4 Mechanical Relay, Form A

Slot B

normally open

common

L3

K3

J3

L4

K4

T2

S2

R2

• 5 A at 240VÅ (ac) or 30VÎ (dc)

maximum resistive load

• 20 mV at 24V minimum load

• 125 VA pilot duty at 120/240VÅ

(ac), 25 VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

• for use with ac or dc

See Quencharc note.

PM6 _ _ _ _-_ _ _ J A _ _

L4

K4

normally

open

common

Mechanical

Relay

Internal

Circuitry

requires use of an R.C. suppressor.

Watlow EZ-ZONE® PM Integrated Controller • 20 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Output 4 Solid-state Relay, Form A

normally open

common

Slot B

L3

K3

J3

L4

K4

T2

S2

R2

• 0.5 A at 20 to 264VÅ (ac) maxi-

mum resistive load

• 20 VA 120/240VÅ (ac) pilot duty

• opto-isolated, without contact

suppression

• maximum off state leakage of

105 microamperes

• Output does not supply power.

• Do not use on dc loads.

See Quencharc note.

PM6 _ _ _ _-_ _ _ K A _ _

L4

K4

normally

open

common

Solid-state Relay

Internal Circuitry

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Quencharc Note:

Switching pilot duty inductive

loads (relay coils, solenoids,

etc.) with the mechanical

relay, solid state relay or

open collector output options

requires use of an R.C. suppressor.

Watlow EZ-ZONE® PM Integrated Controller • 21 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Maximum wire size termination and torque rating:

• 0.0507 to 3.30 mm2 (30 to

12 AWG) single-wire termination or two 1.31 mm2 (16

AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be

labeled differently, depending on the model number.

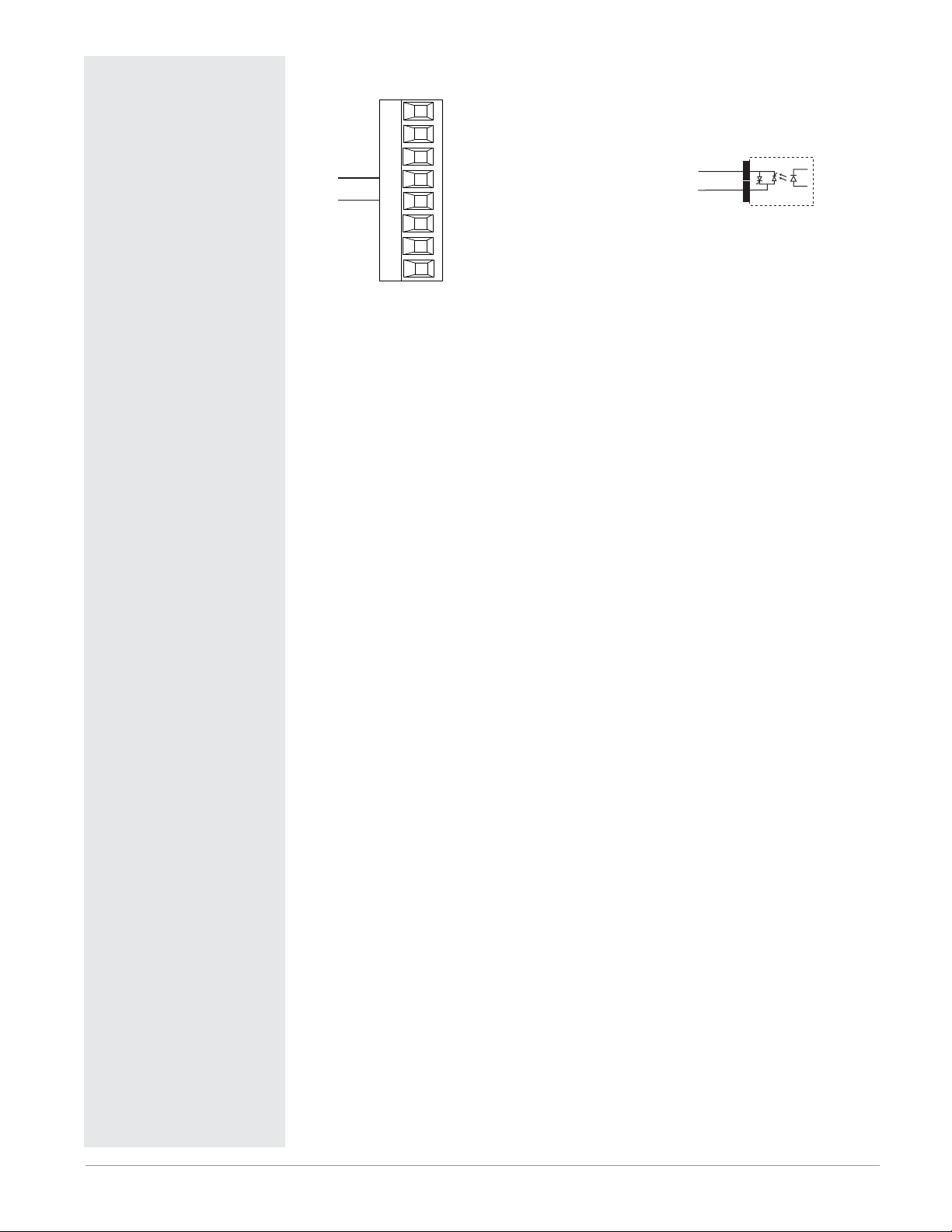

Standard Bus EIA-485 Communications

Slot C

98

99

CF

CD

CE

B5

D6

D5

common

T-/R-

T+/R+

• Wire T-/R- to the A terminal of

the EIA-485 port.

• Wire T+/R+ to the B terminal of

the EIA-485 port.

• Wire common to the common

terminal of the EIA-485 port.

• Do not route network wires

with power wires. Connect network wires in daisy-chain fashion when connecting multiple

devices in a network.

• Do not connect more than 16

EZ-ZONE

network.

• maximum network length:

1,200 meters (4,000 feet)

• 1/8th unit load on EIA-485 bus

PM6 _ _ _ _-(A, 2 or 3) _ _ _ A _ _

Modbus RTU or Standard Bus EIA-485 Communications

Slot C

98

99

CC

CA

CB

B5

D6

D5

common

T-/R-

T+/R+

• Wire T-/R- to the A terminal of

the EIA-485 port.

• Wire T+/R+ to the B terminal of

the EIA-485 port.

• Wire common to the common

terminal of the EIA-485 port.

• Do not route network wires

with power wires. Connect network wires in daisy-chain fashion when connecting multiple

devices in a network.

• A termination resistor may be

required. Place a 120 Ω resistor

across T+/R+ and T-/R- of last

controller on network.

• Only one protocol per port is

available at a time: either Modbus RTU or Standard Bus.

• Do not connect more than 16

EZ-ZONE

Standard Bus network.

• Maximum number of EZZONE

network is 247.

• maximum network length:

1,200 meters (4,000 feet)

• 1/8th unit load on EIA-485 bus.

PM6 _ _ _ _-1 _ _ _ A _ _

®

PM controllers on a

®

controllers on a

®

controllers on a Modbus

Note:

To prevent damage to the

controller, do not connect

wires to unused terminals.

Note:

Maintain electrical isolation

between analog input 1, digital input-outputs, switched

dc/open collector outputs and

process outputs to prevent

ground loops.

Note:

The control output common

terminal and the digital common terminal are referenced

to different voltages and

must remain isolated.

Note:

Avoid continuous writes

within loops. Excessive

writes to EEPROM will cause

premature EEPROM failure.

The EEPROM is rated for

1,000,000 writes.

EIA-232/485 Modbus RTU Communications

Slot B

485 T+/R+

485 common

485 T+/R+

232 common

232 (TX) to DB9 pin 2 (RD)

232 (RD) to DB9 pin 3 (TX)

Modbus-IDA

Terminal

DO A CA or CD T-/R-

D1 B CB or CE T+/R+

common common CC or CF common

485 T-/R-

485 T-/R-

EIA/TIA-485

CB

CA

CC

CB

CA

C5

C3

C2

Name

• Wire T-/R- to the A terminal

of the EIA-485 port.

• Wire T+/R+ to the B terminal of the EIA-485 port.

• Wire common to the common terminal of the EIA485 port.

• Do not route network wires

with power wires. Connect

network wires in daisychain fashion when connecting multiple devices in a

network.

• A termination resistor may

be required. Place a 120 Ω

resistor across T+/R+ and

T-/R- of last controller on

network.

• Do not wire to both the EIA485 and the EIA-232 pins at

the same time.

• Two EIA-485 terminals of

T/R are provided to assist in

daisy-chain wiring.

Watlow Termi-

nal Label

Function

• Do not connect more than

one EZ-ZONE

ler on an EIA-232 network.

• Do not connect more than

16 EZ-ZONE

on a Standard Bus EIA-485

network.

• Maximum number of EZZONE

Modbus network is 247.

• maximum EIA-232 network

length: 15 meters (50 feet)

• maximum EIA-485 network

length: 1,200 meters (4,000

feet)

• 1/8th unit load on EIA-485

bus.

PM6 _ _ _ _-2 AAA A _ _

®

PM control-

®

controllers

®

controllers on a

Watlow EZ-ZONE® PM Integrated Controller • 22 • Chapter 2 Install and Wire

Loading...

Loading...