Watlow Electric Electric Tubular Heaters User Manual

WAT RO D T U B U L A R H E AT E R S

WATROD Tubular

Heaters Provide

Optimum Manifold

Heating

Available in single- or double-ended termination styles, the

versatile and economical WATROD tubular heating element

lends itself to efficient heating of hot runner manifolds. The

single-ended WATROD tubular design has both terminals at

one end. The opposite end is sealed to resist contamination.

Standard 305 mm (12 in.) flexible lead wires are crimp

connected to the terminal pin and have silicone impregnated

fiberglass oversleeves. With its round cross-section

geometry, the double-ended WATROD is highly adaptable for

bending – especially when bending is performed in the field.

Both single- and double-ended WATRODs share many

construction features that deliver long life—the resistance

wire is centered in the heater sheath and electrically insulated

with compact, high-grade magnesium oxide for superior

manifold heating. Watlow’s double-sided multicoil tubular

elements offer various combinations of resistor coils and

thermocouples inside one sheath. They have the ability to

sense the heater’s internal temperature accurately every time,

or offer three-phase capability in one element.

Performance Capabilities

Single-Ended WATROD

• Watt densities to 6.9 W/cm

®

• UL

and CSA component recognition to 240V~(ac)

• Incoloy

Double-Ended WATROD

®

and stainless steel sheath temperatures to

650°C (1200°F)

• Watt densities to 18.6 W/cm

®

•UL

and CSA component recognition to 480 and

600V~(ac) respectively

• Inconel

®

sheath temperatures to 982°C (1800°F)

2

(45 W/in2)

2

(120 W/in2)

Features and Benefits

Precision wound nickel-chromium resistance wire

• Distributes heat evenly to the sheath for optimum heater

performance

Silicone resin seals

• Protect against moisture contamination and manifold

leakage and are rated to 200°C (390°F)

MgO insulation filled sheath

• Maximizes dielectric strength, heat transfer and life

Standard sheath materials include

• Copper, steel 316 stainless steel and Inconel

• Optional materials, available on made-to-order, include

304 stainless steel, Inconel

36 standard bend formations

• Allows for exacting fit to the manifold

• Spirals, compound bends, multi-axis and multi-plane

configurations

Resistance wire fusion welded to the terminal pin

• For a stronger, positive electrical connection

Stainless steel studs

• Fusion welded to terminal pins for mechanical strength

with ceramic insulator

®

, Monel®and titanium

®

Incoloy®, Inconel®and Monel®are registered trademarks of

Special Metals Corporation (formerly Inco).

®

is a registered trademark of Underwriter’s Laboratories, Inc.

UL

© Watlow Electric Manufacturing Company, 2001

Watlow Hannibal

#6 Industrial Loop Drive

P.O. Box 975

Hannibal, MO 63401

Phone: +1 (573) 221-2816

Fax: +1 (573) 221-3723

Internet: www.watlow.com

e-mail: info@watlow.com

Watlow GmbH

Lauchwasenstr. 1, Postfach 1165

Kronau 76709 Germany

Phone: +49 (0) 7253-9400-0

FAX: +49 (0) 7253-9400 44

e-mail: info@watlow.de

HAN-WRD-1001

WAT R O D T U B U L A R H E AT E R S

Moisture Resistance Seals

WATRODs MgO insulating material is hygroscopic. To

prevent moisture contamination from entering the heater, an

appropriate moisture seal must be used. Choosing the correct

seal is important to the life and performance of the heater. Be

sure the maximum continuous use temperatures is not

exceeded at the seal location. Most end seals are applied

with a small cavity in the end of the heater. The seal will also

help prevent arching at the terminal ends.

Applications

• Hot runner molds

Bend Formations

Single-Ended WATROD

Watlow does not recommend field bending single-ended

WATROD elements. The minimum radius of the bend and the

straight length beyond the bend limits formation. The radius

must be 76 mm (3 in.) or more for the heated length’s end to

be inside a bend.

Double-Ended WATROD

Double-ended WATROD heating elements can be formed

into spirals, compounds, multi-axis and multi-planes from 36

common bend configurations. Custom bending with tighter

tolerances can be made to meet specific application needs.

The minimum bend radius and the straight length required

beyond the bend limits formation. In order to locate the end of

a heated length within a bend, the radius must be 76 mm

(3 in.) or larger. Additionally, overall length tolerances must

be included in one or more of the straight lengths.

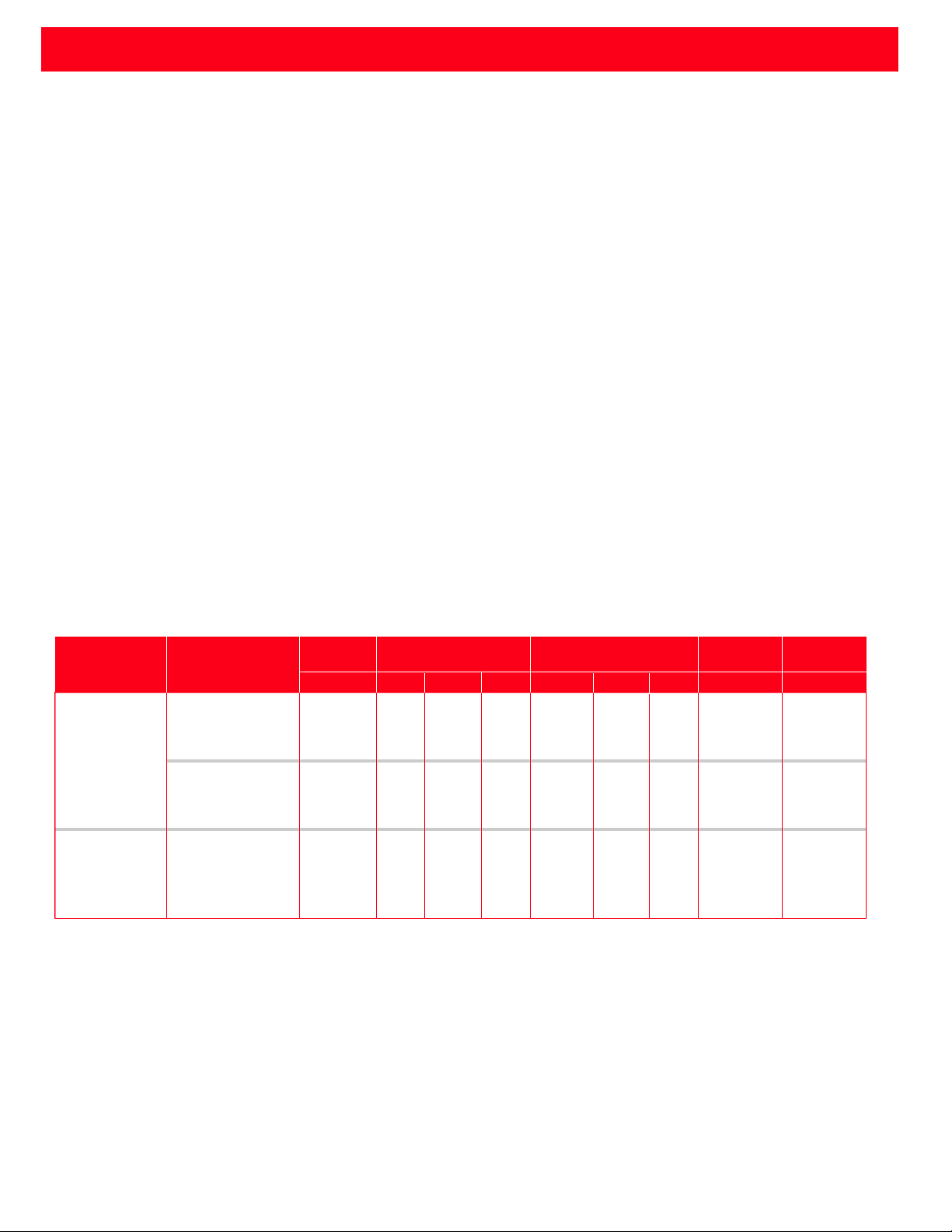

WATROD Termination Options

Double-ended WATROD elements are available with a variety of terminations. Single-ended WATROD elements are available with

only flexible lead wires. The following table and illustrations detail the terminations available with double- or single-ended

WATRODs – for each available sheath diameter.

Standard flexible lead wires are 305 mm (12 in.) unless otherwise specified. Insulation options include TGGT (250°C/480°F) plus other

temperature ratings. Consult factory for availability. Overmolds are available for flexible lead wires only and are available in silicone

rubber (200°C/390°F), neoprene (90°C/212°F) and other materials. Consult your Watlow representative for details.

Sheath Threaded Screw Lug Quick Connect Flexible Lead Wire

WATROD Diameter Stud

Element mm inch A B C D E F G H J

Double-Ended 6.6 0.260 #6-32 Yes Yes Yes Yes Yes Yes Yes Yes

8.0 0.315 #10-32 Yes Yes Yes Yes Yes Yes Yes Yes

8.5 0.335 #10-32 Yes Yes Yes Yes Yes Yes Yes No

9.5 0.375 #10-32 Yes Yes Yes Yes Yes Yes Yes No

10.9 0.430 #10-32 Yes Yes Yes Yes Yes Yes Yes Yes

12.0 0.475 #10-32 Yes Yes Yes Yes Yes Yes Yes Yes

12.4 0.490 #10-32 Yes Yes Yes Yes Yes Yes Yes No

15.9 0.625 #10-32 Yes Yes Yes Yes Yes Yes Yes No

Single-Ended 9.5 0.375 No No No No No No No Yes No

10.9 0.430 No No No No No No No Yes Yes

12.0 0.475 No No No No No No No Yes Yes

12.4 0.490 No No No No No No No Yes No

15.9 0.625 No No No No No No No Yes Yes

a

(Plate) (Spade) Lead Wires Overmolds

Loading...

Loading...