Watlow Electric 980, 985 User Manual

Watlow

Controls, 1241 Bundy Blvd.,

Microprocessor-Based

Auto-tuning Control

(

User’s Manual)

P.O. 8ox

5580,

Winona, MN 55987-5580,

Phone:

507/454-5300,

Fax:

507/452-4507

W985-MA58-9307

February, 1993

Supersedes:

W985-MA70-9043

$10.00

Made in the U.S.A.

0

Printed on

0

Recycled

Paper

How to Use the Manual

First..

Starting Out

Install/Wire

Front Panel

Set Up

Tuning

Appendix

NOTE:

Details of a *‘Note**

appear here, in the

narrow box on the

outside of each page.

This manua/ will make

tion

is a good way to become familiar with the Series

Chapter 1, Page

Chapter

Chapter 3, Page 22.

Chapter 4, Page 24.

Chapter 5, Page 29.

Specifications, Page 34

Cali bration

Glossary

Warranty

2,

Page

4.

6.

your

job

easier.

Reading it and applying the informa-

980/985.

An overview:

Notes

The user’s manual contains informational notes to alert you to important details.

When you see a note icon, look for an explanation in the margin.

1 orJ3

Safety Information

This user‘s manual also has boldface safety information notes to protect both

LLL

CAUTION:

Details of a “Caution”

appear here, in the

narrow box on the

outside of each page.

you and your equipment. Please be attentive to them. Here are explanations:

The Caution symbol (exclamation point) in the wide text column alerts you to a

“CAUTION,” a safety or functional hazard which could affect

its performance. A full explanation is in the narrow column on the outside of

the page.

0

WARNING:

Details of a “Warning”

appear here, in the

narrow box on the

outside of each page.

2

WATLOW Series 9801985 User’s Manual

The Warning symbol (lightning bolt) in the wide text column alerts you to a

**WARNING,” a safety hazard which could affect you and

explanation is in the narrow column on the outside of the page.

Your Feedback

Your comments or suggestions on this manual are welcome, please send them

to: Technical Writer, Watlow Winona, Inc., 1241 Bundy Blvd., Winona, MN

55987, or phone

and integral software are copyrighted by Watlow Winona, Inc.,

rights reserved.

T

A

0

507-454-5300.

The Watlow Series 9801985 User’s Manual

your eguipment

the equipment.

©

1988, with all

How to Use the Manual

or

A full

blrO293

Chapters

Figures, Table, Charts

page

Item

Chapter 1

4 Starting Out With The Watlow Series

4

General Description

Putting Your Control To Work

5

Overview of the Series

5

980/985

Menus

980/985

Chapter 2

6

How To Install And Wire The Series

6

System Planning

6

Sensor Installation Guidelines

6

Installation Guidelines For Preventing Noise

7

Noise

Checking For Ground Loops

9

9

Noise Suppression Devices Available..

10

Line Filtering Configurations For Controls

11

How To Install The Series

13

How To Wire The Series

21

System Wiring Example

980/985

980/985

980/985

Chapter 3

22

How To Use The Keys

22

Series

980/985

Displays & Load LED’s

Series

980/985

23

Keys

and

Displays

-

Chapter 4

24

How To Set Up The Series

24

Entering

25

Set Up Parameters

26

Set Up Menu

27

Operation Parameters

28

Operation Menu

Chapter

29

How To Tune And Operate

29

Tuning - Manual

30

Tuning - Automatic

31

Manual and Automatic Operation

31

Using Alarms

How To Deal With Error Codes

32

34

Appendix

34

Specifications

36

Model Number Information

37

Calibration Menu

38

Calibration Procedures

38

Glossary

41

42

42

43

43

Set Up Menu

5

Index

Returns

Shipping Claims

Warranty

Watlow Controls

980/985 -

-

page

4

Series

5

Overview of the

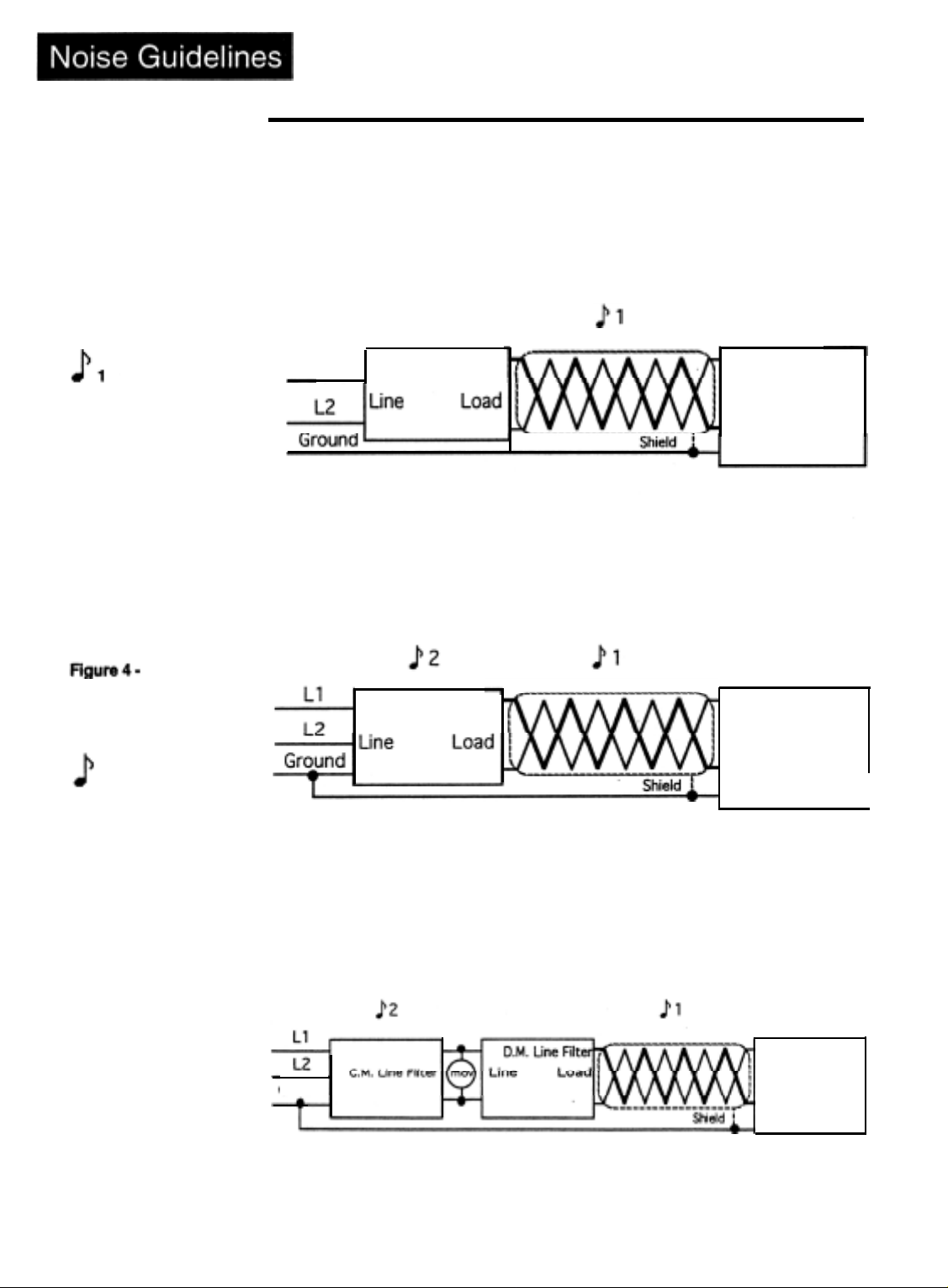

Differential Mode Filter Wiring

10

Common Mode

10

Combination

10

12

Series

Series

12

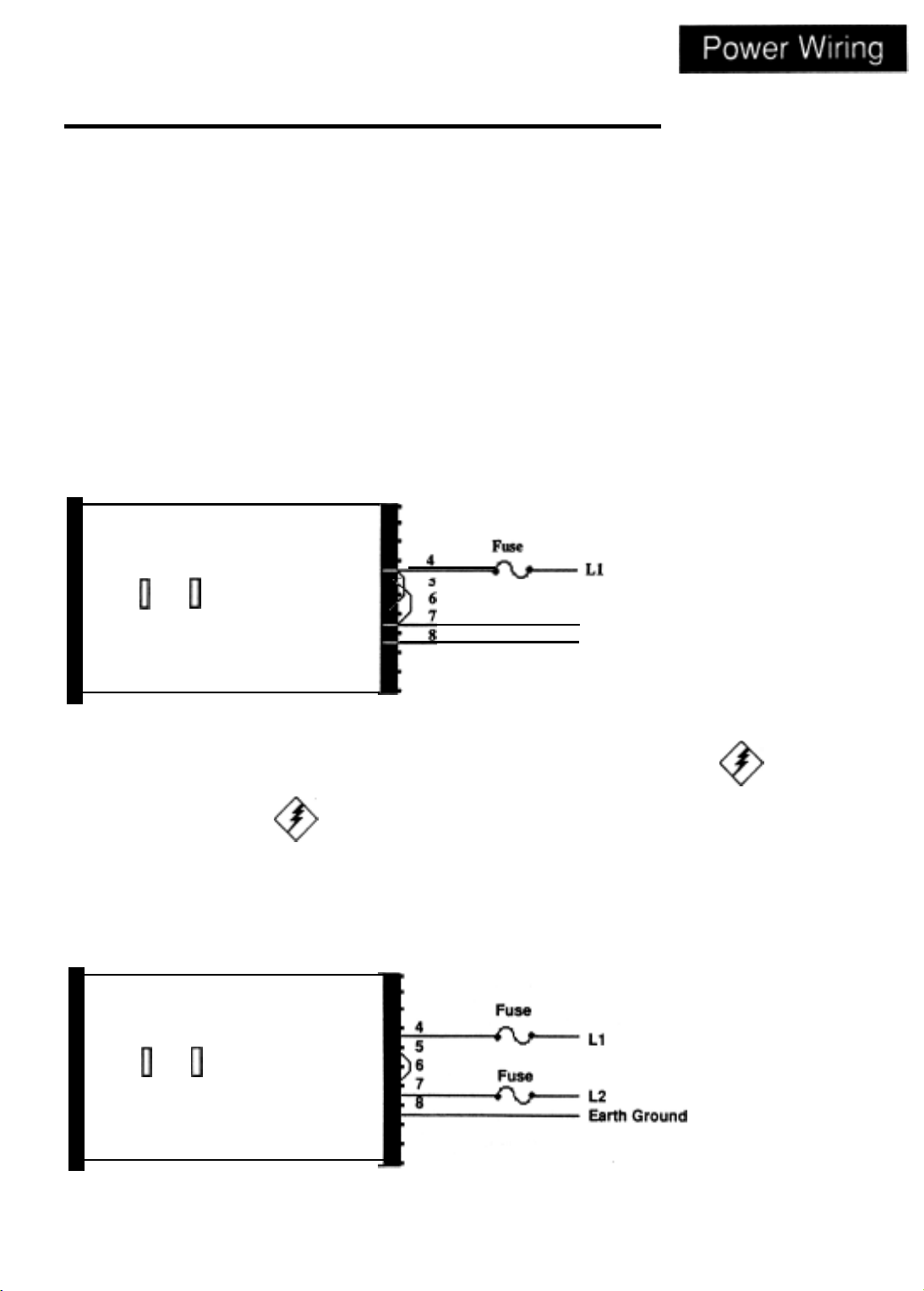

115 VAC Power

13

230 VAC Power

13

14

Thermocouple

14

Process Wiring Diagram

RTD

15

15

16

16

l?

17

18

18

19

19

20

20

21

22

23

24

24

27

31

32

37

38

9

39

26

26

28

(2 wire) Wiring Diagram

RTD

(3 wire) Wiring Diagram

Solid State Relay, Output 1 Wiring

DC Output 1 (Open Collector) Wiring

6 Amp Relay, Output 1 Wiring

O-lOVDC,

4-2OmA,

O-2OmA,

0-5VDC,

S.S. Relay, Output 2 Wiring

DC Output, Output 2 Wiring

6A Mechanical Relay, Output 2 Wiring

System

Series

Series

Entering the Set Up Menu

The Set Up Menu

The Operation Menu

Alarm Display Examples

Error

Code Display Examples

The Calibration Menu

Calibration Parameters

Noise Suppression Device Ratings

RTD Settings

Set Up Menu

Input Ranges

Operation Menu Prompts/Description

Item

980/985

Input & Output Overview

Series

980/985

Fifter Wiring

filter

Wiring

980/985

980/985

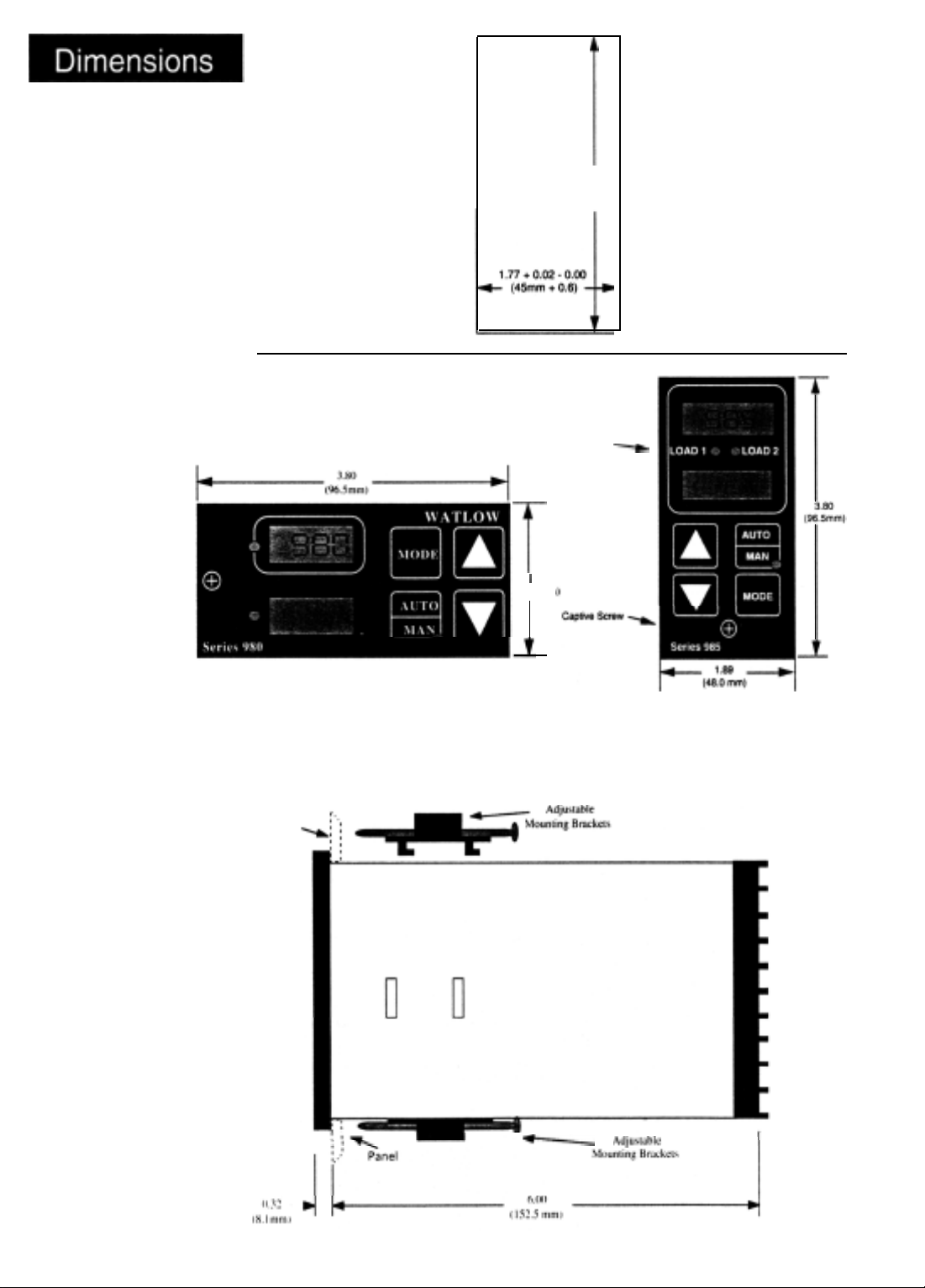

Panel Cutout Dimensions

Dimensions

Wiring

Wiring

Wimg Diagram

Output 1 Wiring

Output 1 Wiring

Output 1 Wiring

Output 1 Wiring

Wiring

Example

980/985

Displays

980/985

Keys

Prompts/Description

Figure

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

31

32

33

34

Tables

1

2

Charts

1

2

3

How to Use

the

Manual

Chapter 1

Starting Out With The

Watlow Series 9801985,

Flgure 1

Series 980/985

and

-

Output

Overview

Input

A Microprocessor-Based

Dual

Single Input

Type J, K, T, N or

Pt2

PID

User Selectable

Control

Outputs-

or ON/OFF

Heat, Cool or Alarm

Output 1 or 2

Percent Power

Output

Auto-tuning

1,

Heating

4

WATLOW Series

980/985

General Description

Welcome to the Watlow Series

cessor-based,

matic/Manual capability with

has closed loop control with sensory feedback, while the Manual mode has

open loop control with user defined output power level.

a Type J, K, T, N, or Platinel2 thermocouple,

primary output is Heating or Cooling, while the secondary output can be Heat,

Cool or Alarm.

With the Series

Output 2. You may input a complete set of

and select automatic tuning for Output 1 from the front panel. This includes

proportional band, reset, rate and cycle

tional band to zero, the Series 9801985 becomes a simple ON/OFF control with

a

3°F

or

Operator-friendly features include automatic LED indicators to aid in monitoring

and set-up, as well as a calibration offset at the front panel. The Watlow

Series

User’s Manual

980/985

1/8

DIN, auto-tuning temperature control, featuring the Auto-

980/985

1.7°C

switching differential,

automatically stores all information in a non-volatile memory.

you can select either

980/985,

bumpless

0.3°F

a dual output, single input, micropro-

transfer. In the Auto mode, the control

The

980/985

RTD,

or process input. The

PID

or ON/OFF for Output 1 or

PID

parameters for both outputs,

time.

By setting either output’s propor-

or

0.17°C

for 0.1 °

RTD.

Getting Started,

accepts

Chapter

1

Putting Your Control To Work

To put your Series

Read the User’s Manual.

Plan your installation and wiring.

Cut the panel mounting hole and install the control.

Wire your Series

Start the system and tune the Series

Make final adjustments to the control parameters and record the data.

That’s all there is to it.

Overview of the Series

Before getting into the details of installing and wiring the Series

look at Figure 2, and at the three different menus. “Setup”, “Operation”, and

“Calibration”. After you feel comfortable with the names and their functions,

move on to installation and wiring.

Setup

980/985

980/985

to work, we suggest the following steps:

to the system.

980/985.

980/985

Configure the

application. Establish levels of operator

access, input type, units of measure, low and

high range limits, and Output 2 configuration.

Menus

980/985’s

features to your

980/985,

take a

Figure 2

Overview

Series 980/985.

of the

Operation

Calibration

Enter the set point and the

and alarm set points here. Parameters for

proportional band, reset, rate and cycle time for

Outputs 1 and 2; alarm low and high;

band: calibration offset and auto-tune

are here also.

Supply various input signals to the

Series

calibration. Calibration procedures

should only be attempted with

proper equipment and by qualified

personnel.

980/985,

and it performs

PID

tuning values

dead-

auto-

Where To Go From Here

If your Series 980/985 is already installed and wired, go directly to “How to Use

the Keys and Displays”, Chapter 3. If not, turn the page to Chapter 2, “How to

Install and Wire the Series

980/985”,

and proceed from there.

Getting

Started,

Chapter 1

WATLOW

Series 980/985

User’s Manual

Chapter 2

How to Install and Wire the

Series 9801985

System Planning

This chapter tells you how to install the

wiring information is right here.

tested and "burned

to install when you receive it.

But before you begin working, read through this chapter to gain an understanding of the entire installation. Consider sensor installation carefully. You’ll need

to look at the noise reduction guidelines before making your panel cutout.

in"

before leaving the factory, the Series

Because

Series 980/985.

Watlow

controls are thoroughly

All mounting and

980/985

is ready

Sensor Installation Guidelines

We suggest that you mount the sensor at a location in your process or system

where it reads an average temperature.

the material or space that you want to control.

be moderate. The sensor should be thermally insulated from the sensor

mounting.

Put the sensor as near as possible to

Air flow past this sensor should

Installation Guidelines For Preventing Noise

For improved electrical noise immunity, install the Series

as possible from motors, relays, and other similar noise generators.

Do not run low power (sensor input) lines in the same bundle as AC power

lines. Grouping these lines in the same bundle can create electrical noise

interference which may result in error codes in the Series

980/985

980/985.

as far away

6

WATLOW

The Culprit

Most noise problems stem from wiring practices. They’re the major means of

coupling noise from its sources to the control circuit The following information

will tell you how to eliminate or decrease noise.

An Information Resource

An outstanding resource for information for wiring guidelines is the IEEE

Standard No.

New York, NY 10017.

Series 980/985 Users Manual

518-1982

and is available from IEEE, Inc. 345 East 47th Street,

Install

and

Wire,

Chapter 2

Noise Sources

Switches and relay contacts

operating

inductive loads such as

motor,

coils,

solenoids, and relays, etc.

Thyristors or other semiconductor devices which are not zero

crossover-fired

(randomly-fired or phase angle-fired devices).

All welding machinery.

Heavy

current

carrying conductors.

Fluorescent and neon lights.

How To Decrease Noise Sensitivity

Physical separatlon and

planning the layout of the system.

should be bundled together and physically kept separate from input signal

lines (sensor lines). A 12 inch minimum separatlon is usually effective. Keep

all switched output signal lines (high power level) separate from input signal

lines (sensor lines). Cross other wiring at

is unavoidable.

Another important practice is to look at the system layout and identify electrical noise sources such as solenoids, relay contacts, motors, etc., and where

they are physically located. Then route the wire bundles and cables as far

away as possible from

devices close to a microprocessor control. Don’t have phase angle-fired

devices in the same electrical enclosure or on the same power line with the

control.

wire

routing must be given careful consideration in

For example, A.C. power supply lines

90°

angles whenever crossing lines

these noise

sources.

Don’t mount relays or switching

Shielded cables should be used for all low power signal

lines

to protect from

magnetic and electrostatic coupling of noise. Some simple pointers are:

• Whenever possible, low level signal

lines

should be run unbroken from

signal source to the control circuit.

• Connect the shield to the control circuit common at the control end only.

Never leave the shield unconnected at both ends. Never connect both

shield ends to a common or ground.

• If the shield is broken at some termination point and then continued on, the

shield must be connected to maintain shield continuity.

• If the shield is used as a signal return, no electrostatic shieldlng should be

assumed. If this must be done, use a

triaxed

cable

(electrostatically

shielded coaxial cable).

Twisted pair wire should be used any time control circuit signals must travel

over two feet or when they are bundled in parallel with other wires.

The size or gauge of wire should be selected by calculating the maximum

circuit current and choosing the gauge meeting that requirement. Using

greatly larger wire sizes than required generally will increase the likelihood of

electrostatic (capacitance) coupling of noise.

Install

and Wire, Chapter 2

WATLOW Series

980/985 User's

Manual

7

• Ground loops must be eliminated in the entire control system. There are

obvious loops which can be spotted by studying the"as-built" wiring diagram.

There are also the not-so-obvious ground loops that result from the technique

of connecting internal circuit commons in the manufacturer's equipment. An

example of this would be if a control circuit is designed to work with a

grounded sensor input.

• Do not daisy chain A.C. power (or return) lines, or output signal (or return)

lines to multiple

control

circuits.

each input requiring A.C. power. Avoid paralleling L1 (power lead) and

(return lead) to load power solenoids,

Use a direct line from the power source to

L2

If L1

contactors,

and control circuit

ts.

(power lead) is used to switch a load, L2 (return lead) will have the same

switched signal and could couple unwanted noise into a control circuit.

• Grounding the chassis of each piece of equipment in the system is very

important. The simple practice of connecting each individuai chassis to the

overall equipment chassis immediately adjacent to that piece, and then tie all

the major chassis ground

wire) to ground at one single point will work best.

terminals

together with one lead (usually green

Don’t connect ground to

the control case if the control is mounted in grounded enclosure (prevent

ground loops).

• Do not confuse chassis grounds (safety ground) with control circuit commons

or with AC. supply lines L2 (return or neutral line).

Each return system

wiring must be kept separate. Be absolutely sure chassis ground (safety) is

never used as a conductor to return circuit current

How To Eliminate Noise

• Use “snubbers”

such as relays, relay contacts, solenoids, motors, etc. A snubber is a simple

filter device using a 0.1µ

100 ohm,

to

effectively

• The

For other

1/2

general

‘QUENCHARC”

PAKTRON

P.O. Box 5438

Lynchburg, VA 24502

Phone:

804-239-6941

• Metal Oxide Varistor

occur on the A.C. supply lines as a result of lightning strikes, switching large

motors, etc. The MOV is available in several varieties and for 115 or 230

volt lines. The

so repeatedly, deteriorates its ability to function.

• Watlow stocks several

("QUENCHARC™")

f,

600 volt, non-polarized capacitor in series with a

to filter out noise generated by devices

watt resistor. The device can be used on A.C. or D.C. circuits

dampen noise at its source.

purpose Watlow snubber, described above, is 0804-0147-0000.

sizes contact

(MOV)

can be used to limit voltage “spikes” that

device

dissipates the voltage “spikes” to ground and in doing

MOVs

have a limited life.

MOVs.

See Table 1.

8

WATLOW

Series

980/985

User's Manual

Install and

Wire,

Chapter 2

"Islatros"

for the control

Devices like the

electric

capabilities of the filter with power demands of the circuit.

and other similar power line filters are designed to

circuit

lslatrol

circuits to

and “buffer” the control circuit from

use media (electromagnetic filtering) other than

filter

out electrical noise. Take care in matching the power

A.C.

carry

the power

line noise.

Keep line

filters

as

close to the control as possible to minimize the area for interference pick up.

lslatrols

are available from:

Control Concepts Corporation

328 Water Street

P.O. Box 1360

Blnghamton, NY

Phone:

I

- 101 (1A,l20VAC) I I - 105

I - 115

(5A, 120VAC) I (15A, 120VAC)

The ultimate protection is an

“uninterruptable”

607/724-2464

202

207

the A.C. power line; when the line fluctuates, a battery powered

verted circuit takes over, supplying power within

139O2-1360

(2.5A, 208/240VAC)

(7.5A, 208/240VAC)

power supply.

one-half

This 'senses'

to one cycle of the

6OHz

in-

A.C. line; very expensive.

How To Check For Ground Loops

To check for ground loops, disconnect the ground wire at the ground

tion.

Measure the resistance from the wire to the point where it was

The ohmmeter should read a high ohm value.

If you have a low ohm value

across this gap, there is at least one ground loop present in your system.

Or check for continuity; your reading should be "open”.

If you do find

ity, you must now begin looking for the ground loops. Begin disconnecting

grounds in the system one at a time, checking for continuity after each disconnection. When continuity reads "open” you have eliminated the ground loop(s).

Also, as you reconnect grounds, keep making the continuity test.

to reconnect a ground loop.

termina-

connected.

continu-

It is possible

Noise Suppression Devices Available From Watlow

Watlow Controls stocks a few key noise suppression parts. You may order

these by calling your local Watlow distributor.

Item

Common Mode Line

Differential

Metal Oxide

MOV

MOV

MOV

Install and Wire, Chapter 2

Mode Line Filter

Varistor

Filter

Electrical Ratlngs Part Number

25OV,

3 Amp 0804-0196-0000

Refer to the

15OV,

13OV,38

275V,

275V,

lslatrol

listing above.

80 Joule

Joule 0802-0304-0000

75 Joule

140 Joule

0802-0273-0000

802-0304-0000

0802-0266-0000

0802-0405-0000

WATLOW

Series

Table 1

NoiseSuppressIon

Device

Ratings

98O/985

User’s Manual

9

Figure

3

-

Differential

Filter

Wiring

NOTE: Keep filters

12

inches or less

from the control.

Minimize

Mode

the line

distance where

nolse can be

introduced to

control.

re-

Line Filtering Configurations For Controls

These three diagrams show you filter configurations for removing input power

noise. Choose the one best suited for your system.

For very dirty or

applications - use a microcomputer-regulated power supply or

Power Supply (U.P.S.)

Don’t fasten common mode line filters or filters with

metal cases to metal that is at ground potential. This prevents ground loops

and maintains filter effectiveness.

D.M.

Ll

.

Line Filter

critical

Uninterruptable

Control

Common

Wiring

NOTE: To prevent

ground loops do not

fasten

mode line

filters

cases to metal that

is at ground

tlal.

reduce filter effectiveness.

Figure 5

Combination

Differential/

Common Mode Filter

Wiring

Mode

2

Filter

common

filters

or

with metal

poten-

Doing so will

-

C.M. Line Filter

Control

I

Control

Ground

10 WATLOW

Series 980/985 User's Manual

Install and Wire, Chapter 2

How to Install the Series

980/985

Figures 6,7

and 8 provide the Series

980/985’s

panel cutout and dimensions.

Do not, however, make your panel cutout until you are sure that you are

placing the control in the best location. Read the noise guidelines at the

beginning of this chapter before installing and wiring the Series

Figure

1.

Place

the panel cutout in the desired location.

6 shows you the

980/985.

panel cutout dimensions.

2.

To install,

carefully

insert the Series

980/985

into the panel cutout.

Push

the unit in until the bezel is seated securely against the panel.

3.

Included with your control are two adjustable mounting brackets; one for the

top and one for the bottom of the control case.

Installing the mounting

brackets requires access to the back side of the panel.

On the top and bottom of the case are a series of slots running the length of

the case.

The first two shorter slots are for attaching the mounting brack-

ets. Figure 8 shows a side view with both mounting brackets.

4.

Loosen the mounting bracket screws with a Phillips screwdriver far enough

to allow for the panel thickness.

5.

Make sure that each bracket is placed in the first two slots from the front of

the control, with the head of the screw facing the back of the control.

to

Figure

8 for screw and bracket placement.

Refer

NOTE:

1

Removing the

Series

980/985 chassis

from its case may

make mounting

easier.

6.

To attach, place the bracket into the slots (head of the screw facing the

back of the

case.

7.

Make sure the Series

control

and push backward, securing the brackets to the control

Do the same for the other side of the control.

980/985

case is seated properly. Tighten the

installa-

tion screws firmly against the panel to secure the unit in place.

8.

To remove the unit from its enclosure, loosen the captive screw at the

bottom of the

980/985’s

front panel with a Phillips screwdriver.

Pull the unit

from its case.

9.

To release the mounting brackets, push the brackets forward and pull out to

release them from the control case.

Install and Wire, Chapter

2

WATLOW

Series 980/985

User’s Manual

11

Panel Cutout

Max. Panel

Thickness

0.50

(12.7mm)

Figure 6

Series

-

980/985

Panel Cutout

Dimensions

3.82

+0.03 -

(92mm + 0.8)

T

I .89

(48.0 mm

~

0.00

Load Power

indicators

V

Figure 7

Series

-

980/985

Dimensions

Panel

_

Adjustuble

12

WATLOW Series 9801985 User’s Manual

‘Install and Wire, Chapter 2

How

to Wire the Series

980/985

The Series

unit sticker on the control and compare your model number to those shown

here and also the model number breakdown in the back of this manual.

Series

while connections and terminal designations appear “outside” the line drawing.

All outputs are referenced to a de-energized state. The final wiring figure is a

typical system example.

All wiring and fusing should conform to the National Electric Code and to any

locally applicable codes as well

When you apply power without sensor inputs on the terminal strip, the Series

980/985

Press the AUTO/MANUAL key twice, and an ER 7 is displayed for one second.

This error indicates an open sensor. Remove power to the control and connect

the sensor properly, see Page 14.

980/985

980/985

will display “-

II

wiring is illustrated by model number option. Check the

internal circuits appear “inside“ the line drawing of the

II

.

”-in the Upper display, and a

-

Jumper #4 to #6 and

Jumper #5 to #7 for

115

VAC operation

980/985,

"O"

in the Lower display.

L2

Earth

Ground

Figure 8

115 VAC Power

Wiring

-

II 0

Install and Wire Chapter 2

0

Jumper #5 to #6 for

230 VAC operation

WATLOW

To

National

Code (NEC) safety

practices when

wiring and connecting this unit to a

power source and to

electrical sensors or

peripheral devices.

Figure 9

230 VAC Power

Wiring

Series

980/985 User’s Manual

0

avoid potential

electric

CAUTION:

shock, use

Electric

-

13

lnput Options

“1

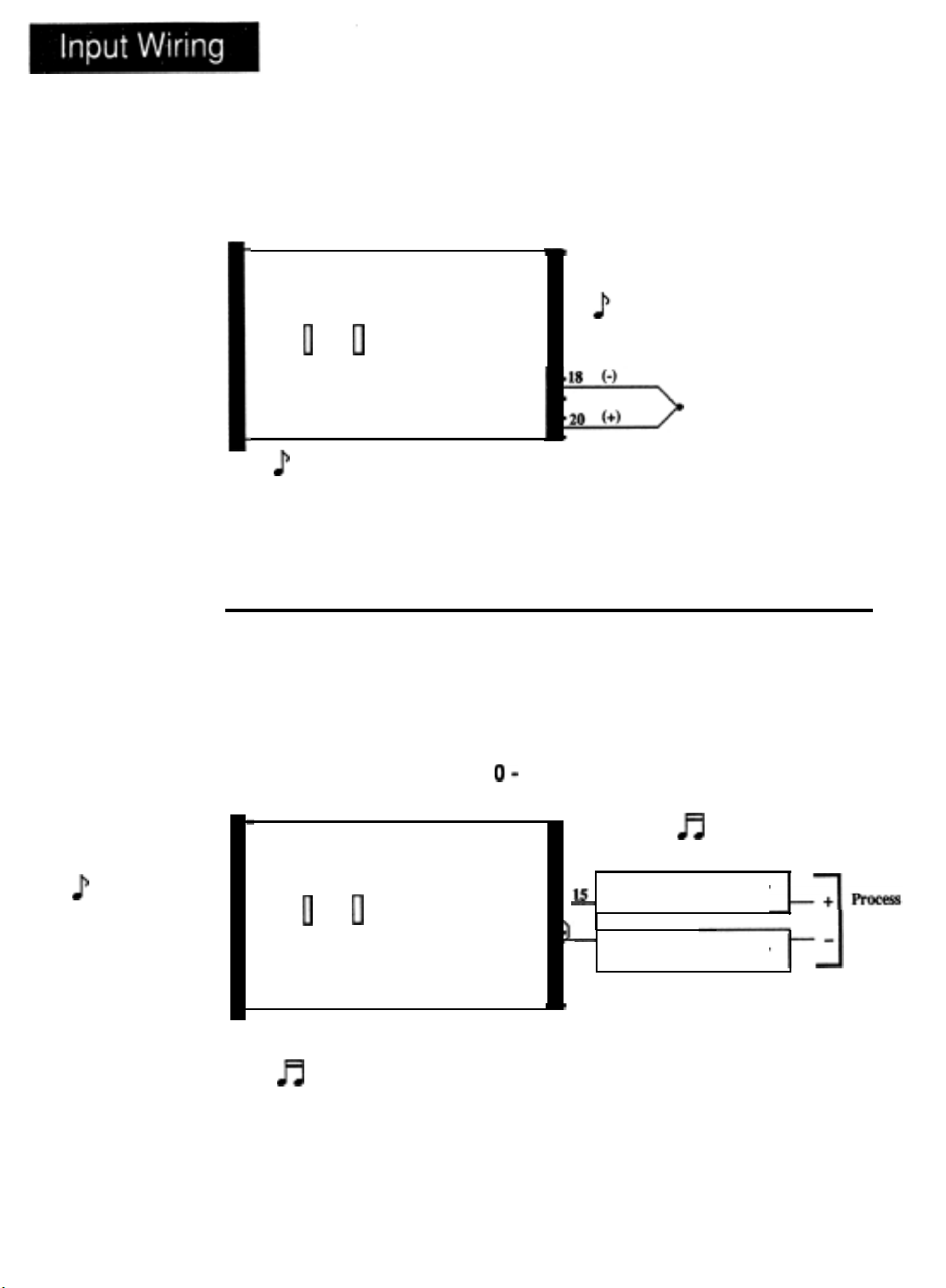

Terminals 18 & 20

“, “2” & “3”,

Thermocouple Input

Figure 10

Input Options

**2* & *3’, Thermocouple Wiring

Diagram.

-

“1”,

Model # 98

II

– A - 1 _ _ - 0-0000

98_A-2 – –

98_A-3-

– –

0-0000

0-0000

II

I

1

NOTE:

You must use an isolated or ungrounded thermocouple if an external

output device with a non-isolated circuit common is connected to the

output.

Extenslon wire for thermocouples must be of the same alloy as the thermocouple

itself to limit errors.

These input connections are used in conjunction with your units sensor

type. (Thermocouple and RTD only)

4-20mA

4-20mA

Flgure

Input Options

"3"

Wlring

11

-

"2" &

Process Input

Diagram.

1

NOTE:

When using a

2OmA

process

Input, the input

impedance is

2 4 9 o h m s

4-

Input Options

Terminals 15 -

Model

#98_A - 2 _ _ 0 - 0000

“2’ & “3”,

17

Process or Remote Set Point Input

98_A - 3 _ _ 0 - 0000

fl

0-5VDC 4-20mA INPUT

0 II

.

J3

When using a process input such

scale the display to match the measured range of the process signal. When using

a

0-5VDC

An example of this is: A pressure transducer operates over a range of 0

delivering a

the Series

Jumper Terminal 16

to Terminal 17 when

using a

input.

NOTE:

process input, the input impedance is 100K ohms.

4-20mA

980/985

4-20mA

output signal for this range. By setting rL= 0 and rH = 300,

is now displayed as a direct reading of pressure.

as

O-5VDC

16

17

0-5VDC, 4-20mA

or

4-2OmA,

INPUT

the rL and rH settings

-

300 PSI,

Input

Voltage

14

WATLOW

Series

980/985

User’s Manual

Install and Wire, Chapter 2

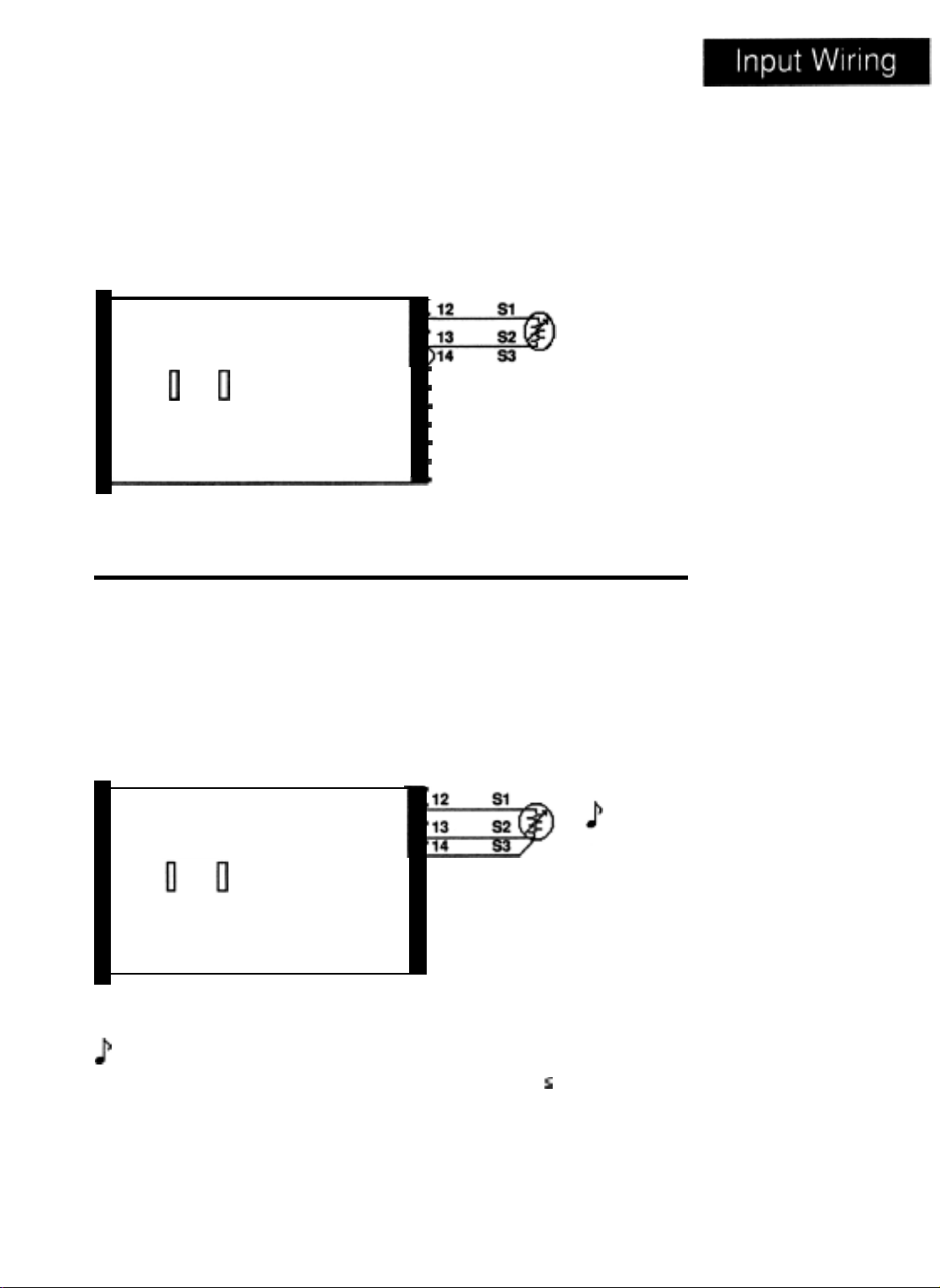

Input Options

“2” & "3"

Terminals 12 - 14

RTD - 2 Wire

ModeI#98

_A-2_

98_A-3_

II

II

Input Options

Terminals 12 -

_0-0000

_0-0000

Jumper#l3to#l4

“2” & "3"

RTD - 3 Wire

14

Figure 12

Input Options "2" &

“3”,

Sensor

.

.

.

.

.

.

-

RTD (2

Wiring.

wire)

Model#

98_

A-2_ _ 0-0000

98_A-3_

_0-0000

Figure 13

Input Options

‘*3”,

Sensor Wiring.

.

.

.

.

.

.

-

J

NOTE:

Long lead lengths create electrical resistance. There will be

input error for every

That resistance, when added to the

erroneous input to the instrument. To overcome this problem, use a three wire

RTD sensor, which compensates for lead length resistance. When extension wire

is used for a three wire RTD, all three extension wires must have the same

electrical resistance. (i.e. same gauge, copper stranded).

1ohm

of lead length resistance when using a two wire

resistance

of the

a

S

1° approximate

RTD

element, can result in

RTD.

“2’ &

RTD (3 wire)

Install and Wire, Chapter 2

WATLOW Series

980/985 User's Manual

15

Loading...

Loading...