Watlow Electric 1500 User Manual

Series 1500

ACTUAL

ADJUST

Ramping and Profiling

Microprocessor-Based

Control

User's Manual

Watlow Controls, Inc: 1241 Bundy Blvd., Winona, MN 55987 507/454-5300, Fax: 507/452-4507

W150-MA30-9043

October, 1990

Supersedes:

W150-MA20-8843

$10.00

Made in the U.S.A.

Use The Manual

How to Use the Manual

First...

Starting Out

Sample Program

Install/Wire

Programming

Appendix

Quick Reference

NOTE:

Details of a "Note"

appear here, in the

narrow box on the

outside of each page.

This manual will make your job easier.

way to become familiar with the Series 1500. Here's an overview.

Introduction, Chapter 1, Page 4.

A Sample Program in Action, Chapter 2, Page 16.

Installation and Wiring, Chapter 3, page 26.

Technical Reference, Chapter 4, Page 40.

Calibration

Specification

Ordering Information

Technical Service

Glossary

Index

Quick Reference on Back Cover

Reading it and applying the information is a good

Notes

This user's manual contains informational notes to alert you to important details. When you

see a note or note icon, look for an explanation in the margin.

Safety Information

NOTE:

Details of a "Warning"

appear here, in the

narrow box on the

outside of each page.

!

NOTE:

Details of a "Caution"

appear here, in the

narrow box on the

outside of each page.

This user's manual also has boldface safety information notes to protect both you and your

equipment. Please be attentive to them. Here are explanations.

∫

(The Stop Sign or Lightning Bolt Sign in the wide text column alerts you to a "WARNING," a safety

hazard which could affect you and the equipment. A full explanation is in the narrow column on

the outside of the page).

!

(The Deer Crossing Sign or Exclamation Point Sign in the wide text column alerts you to a "CAUTION,"

a safety or functional hazard which could affect your equipment or its performance. A full explanation is in

the narrow column on the outside of the page).

Technical Assistance

If you encounter a problem with your Watlow control, review all of your configuration information to verify that your selections are consistent with your application...Inputs, Outputs, Alarms,

Limits, etc. If the problem persists after checking the above, you can get technical assistance

by dialing: 1-507-454-5300

An Application Engineer will discuss your problem with you. Please have the following

information available when calling:

• Complete model number • Serial Number

• All configuration information • User's Manual

The model and serial numbers can be found on the outside of the case.

Your Feedback

Your comments or suggestions on this manual are welcome, please send them to: Technical

Writer, Watlow Controls, 1241 Bundy Blvd., Winona, MN 55987, phone 507/454-5300, fax 507/

452-4507. The Watlow Series 1500 User's Manual and integral software are copyrighted by

Watlow Winona, Inc., © 1985, 1986, 1987, 1988 with all rights reserved.

2 blf1090

WATLOW Series 1500 User's Manual

Page Item

4 Starting Out with the Series 1500 -Chapter 1

4 General Description

5 Opening the 1500

6 Setting the DIP Switches

7 Quick Wire

9 Overview of the 1500 Modes

10 Reading the Displays and Keys

12 Overview of the Software

16 Learning the Series 1500: A Sample Program

in Action - Chapter 2

16 ApplePie Sample Program

16 Sample Program Chart

17 Setting Event Outputs

17 Modes of Operation

18 Clear Memory, Set DIP Switches

19 Programming

22 Start Your Program

22 Halt Conditions

23 Ramping Conditions

23 Wait Step

24 Jump Loop Step

24 Recycle

25 Interactive Changing Set Points & Events

26 Install and Wire the Series 1500 - Chapter 3

26 Sensor Installation Guidelines

27 Event Input and Remote Hold Input

27 Noise

29 Input Power Wiring

32 Eliminating Noise

32 Opening the 1500

34 Installation Procedure

34 Electrical Connections and Wiring

40 Technical Reference - Chapter 4

40 How to Program

40 Select the Proper DIP Switch Settings

41 Programming CHG DATA

42 Halt Conditions

43 Set Point Step Programming

44 Jump Loop Step Programming

45 Wait Step Programming

45 Next Step Programming

46 Altering a Program

46 Programming CHG PARA

47 Guarded Access Programming

49 Alarms

49 Alarm Options

49 Event Alarm Output Option

49 Latching Option

49 Alarms

50 Upper/Lower Set Point Limits

51 Event Outputs

51 Event Input

51 Remote Hold Input

52 Analog Retransmit Outputs

53-56 RTD and T/C Guarded Access/Parameter Charts

57 Programming Chart

58 Tuning

58 Initial Settings

58 Simple ON/OFF Control

59 Run and Halt a Program

59 How to Run a Program

59 How to Halt a Program

Contents

Contents

59 Restarting a Program

59 Remote Hold Input

60 Data Communications

60 Communication Parameters

60 Protocol

60 Command Rules & Words

61 Syntax

73 Data Communication Error Codes

74 Troubleshooting

75 Field Calibration Procedure

80 Specifications

82 Model # Information

83 Technical Service

83 Warranty Information

83 Returning Merchandise

84 Shipping Claims

85 Glossary

89 Index

90 Quick Reference

Figures

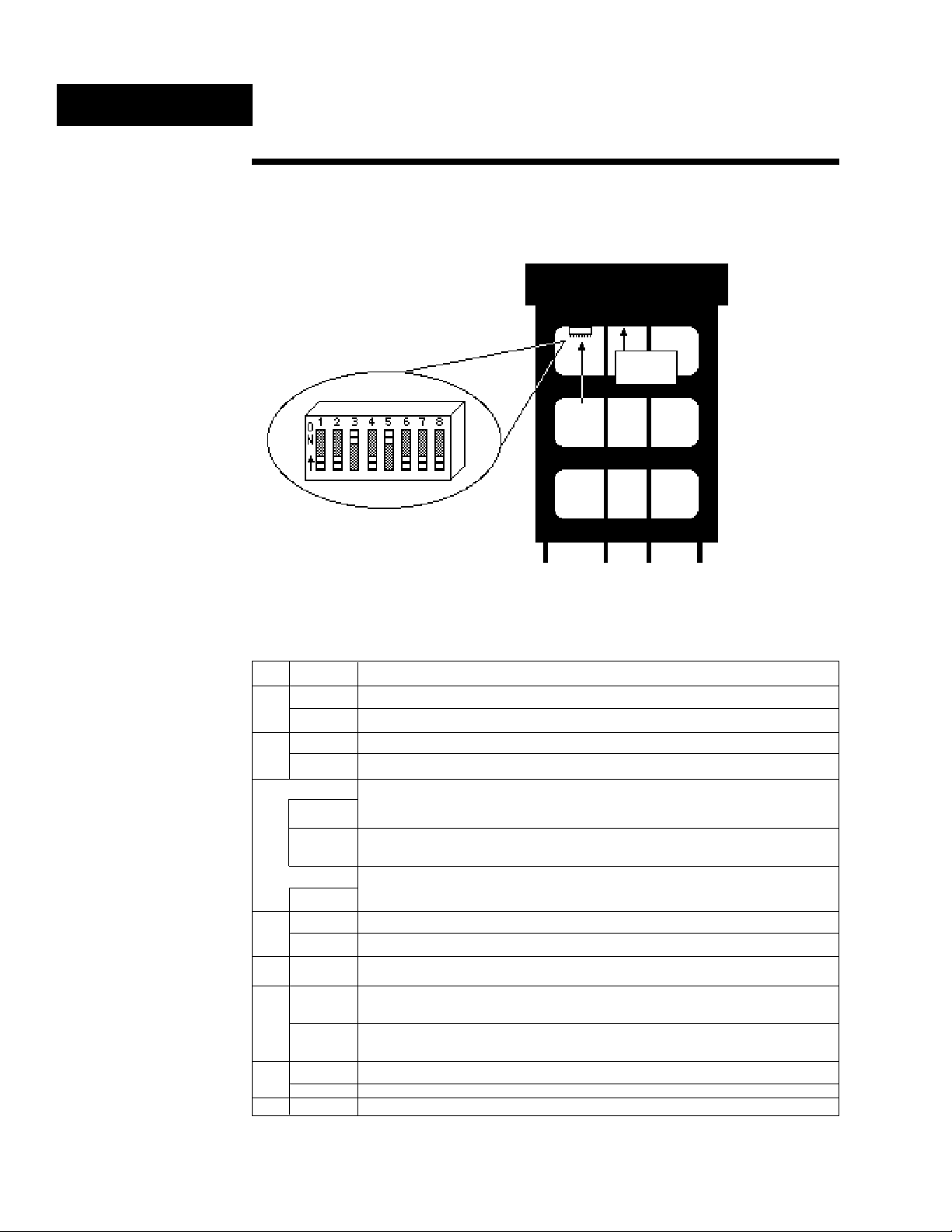

4 Series 1500 Input and Output Overview 1

6 DIP Switch Location and Setting 2

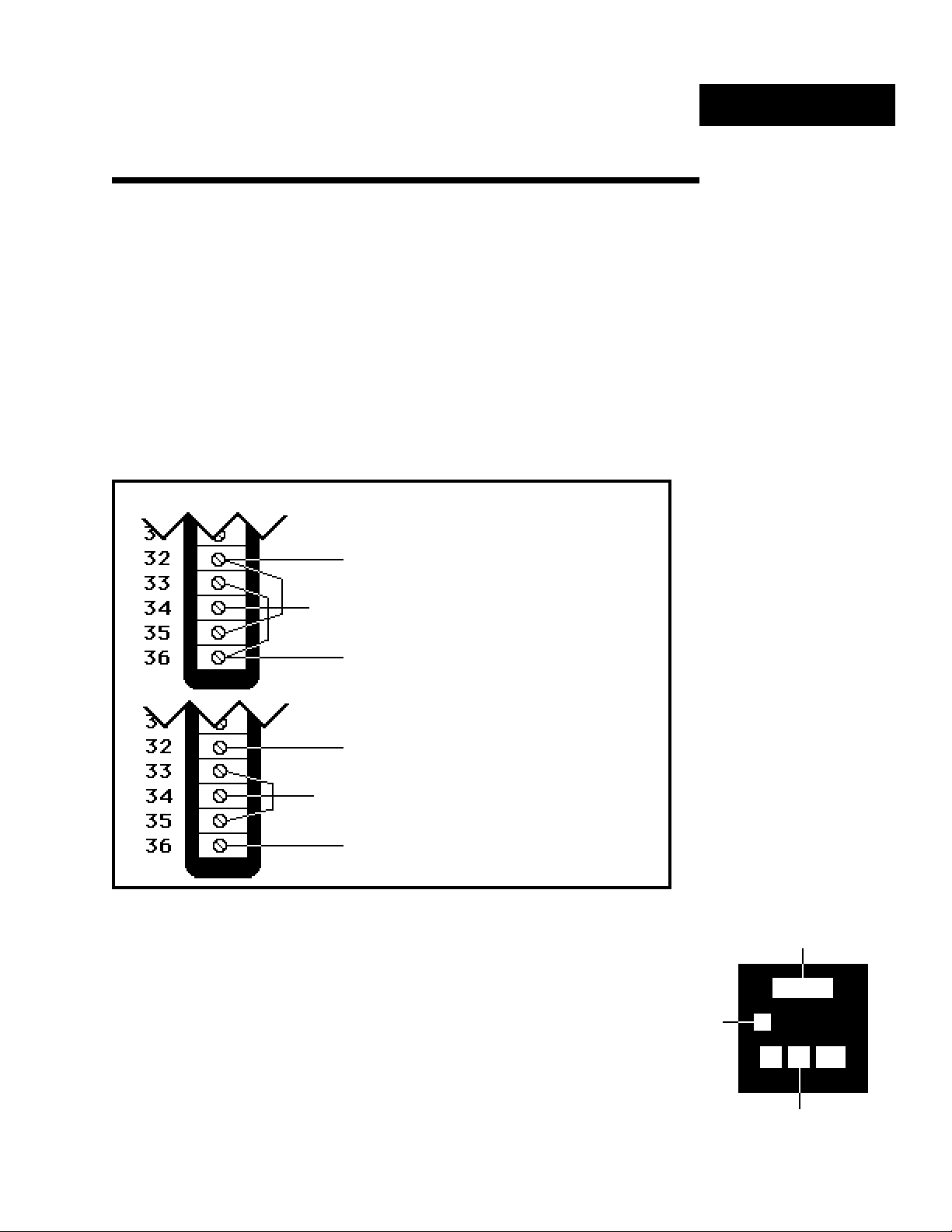

7 Quick Wire AC Power Connection 3

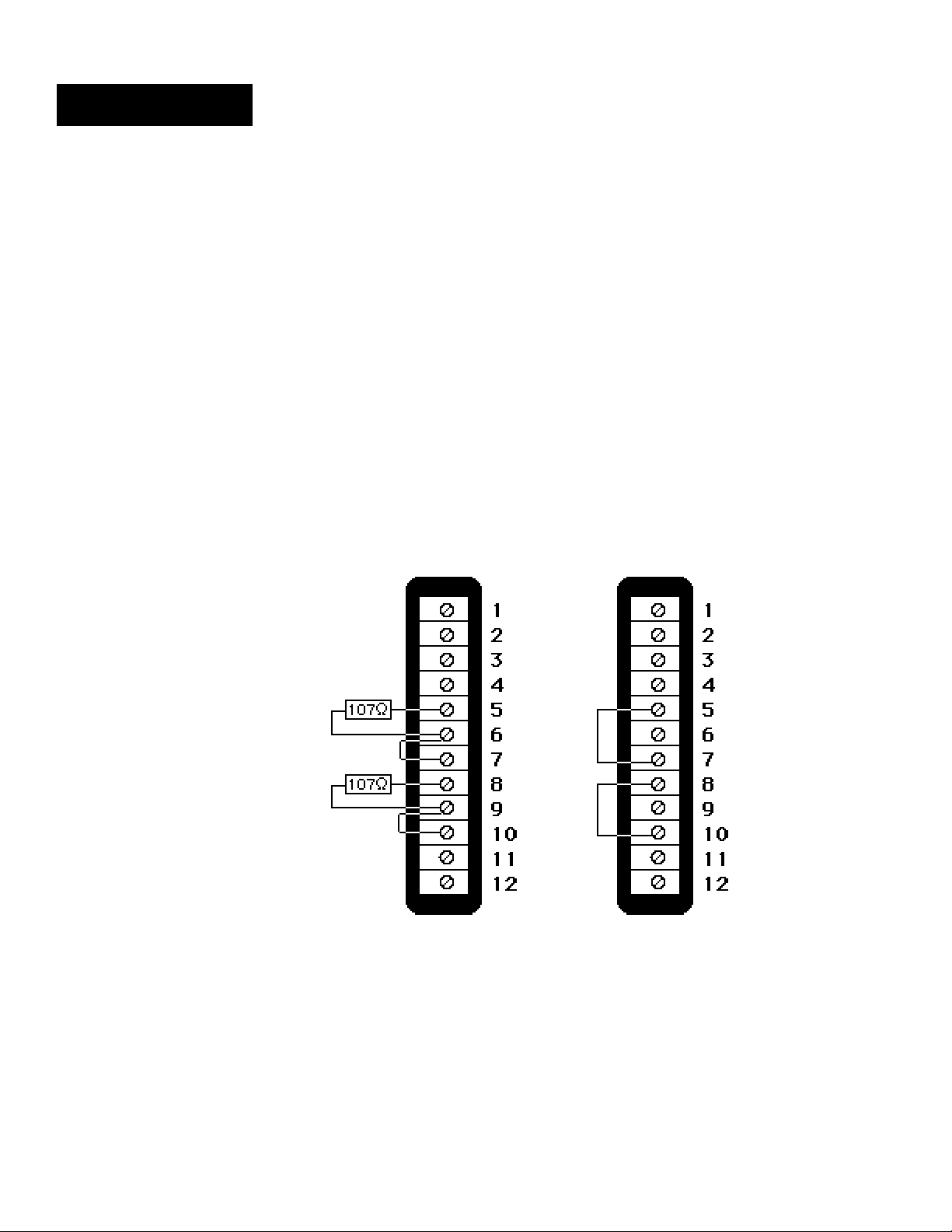

8 Quick Wire Simulated Sensor Wiring 4

9 Overview of the Series 1500 Operating Modes 5

10 Series 1500 Front Panel Components 6

13 Monitor Data (MNTR DATA) Mode Overview 7

14 Change Data (CHG DATA) Mode Overview 8

15 Change Parameter (CHG PARA) Mode 9

31 Differential Mode Filter Diagram 10

31 Common Mode Filter Diagram 11

31 Differential Common Mode Filter Diag. 12

33 Unit and Panel Cutout Dimensions 13

35 Signal Conditioner Connections and Jumpers 14

36 Event Output, Remote Hold Input, Event Input

Conn. for Dual Solid State Relay Version 15

37 Event Output, Remote Hold Input, Event Input

Conn. for Dual Solid State Switch Version A 15

36 Power Supply Input, Temp & RH Output Conn.

for Dual Solid State Relay Version 16

37 Power Supply Input, temp & RH Output Conn.

for Dual Solid State Switch Version A 16

38 Power Supply Input, CH-1 & CH-2 Output Conn. 17

38 Wiring to Disable Channel 2 18

39 RS-422/423 Pin Designations and Jumpers 19

42 Change Data Mode Flow Diagram 20

46 Change Parameter Mode Flow Diagram 21

Tables

6 DIP Switch Position and Function Table 1

17 Sample Program Event Outputs Table 2

21 Sample Program Steps Table 3

31 Noise Suppression Device Ratings Table 4

Charts

17 Series 1500 Sample Program Chart Chart 1

53 RTD Guarded Access Chart Chart 2

54 T/C Guarded Access Chart Chart 3

55 RTD General Parameter Chart Chart 4

56 T/C General Parameter Chart Chart 5

57 Programming Chart Chart 6

WATLOW Series 1500 User's Manual 3

Starting Out

Chapter 1

Starting Out with the Watlow Series 1500

"Read Me First."

Congratulations, you're about to become a fully-qualified user of the Watlow Series

1500! It is a versatile microprocessor-based control; powerful, yet simple to learn. In

this chapter of the user's manual, you'll get an overview of the 1500 and its software.

You'll "light" the displays and get a feel for moving through the control functions.

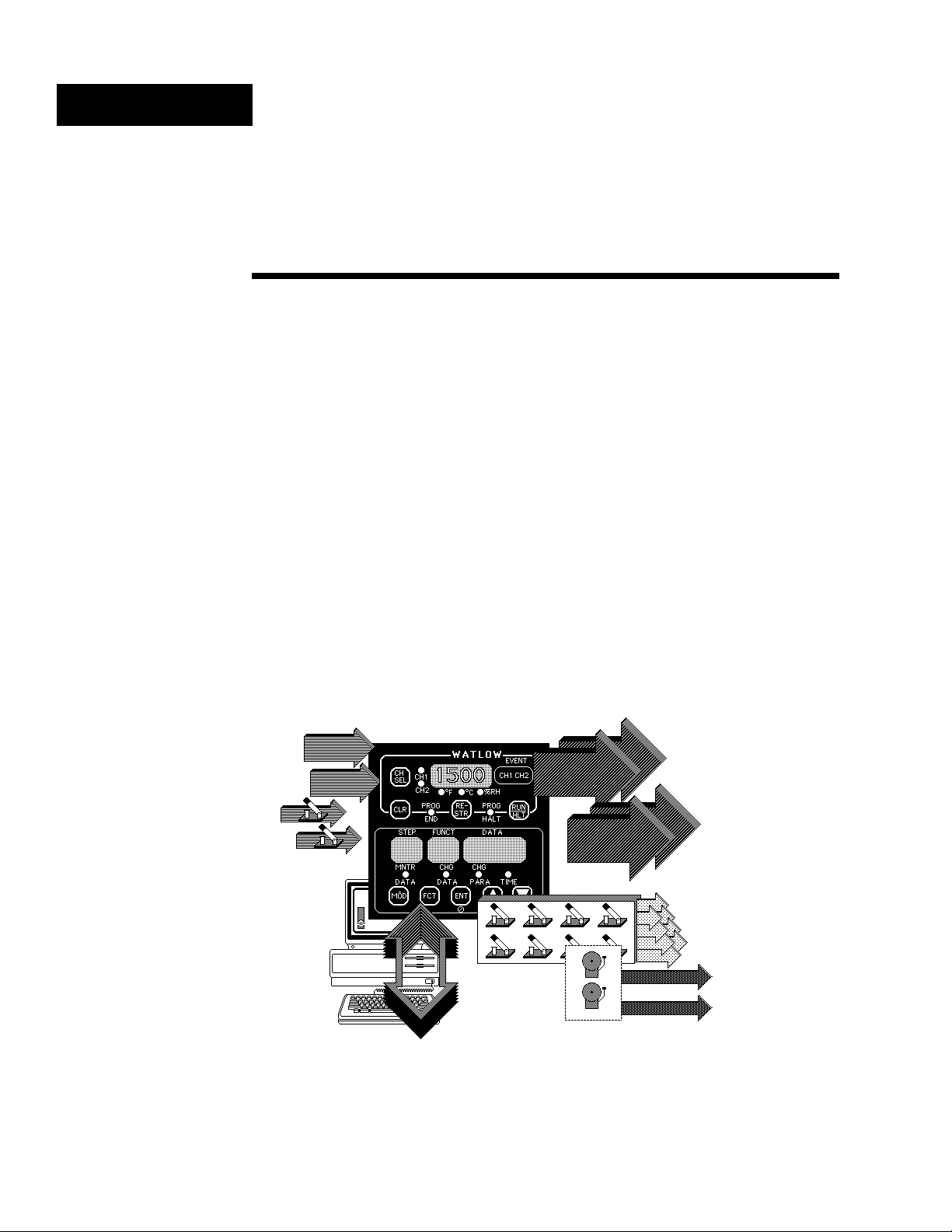

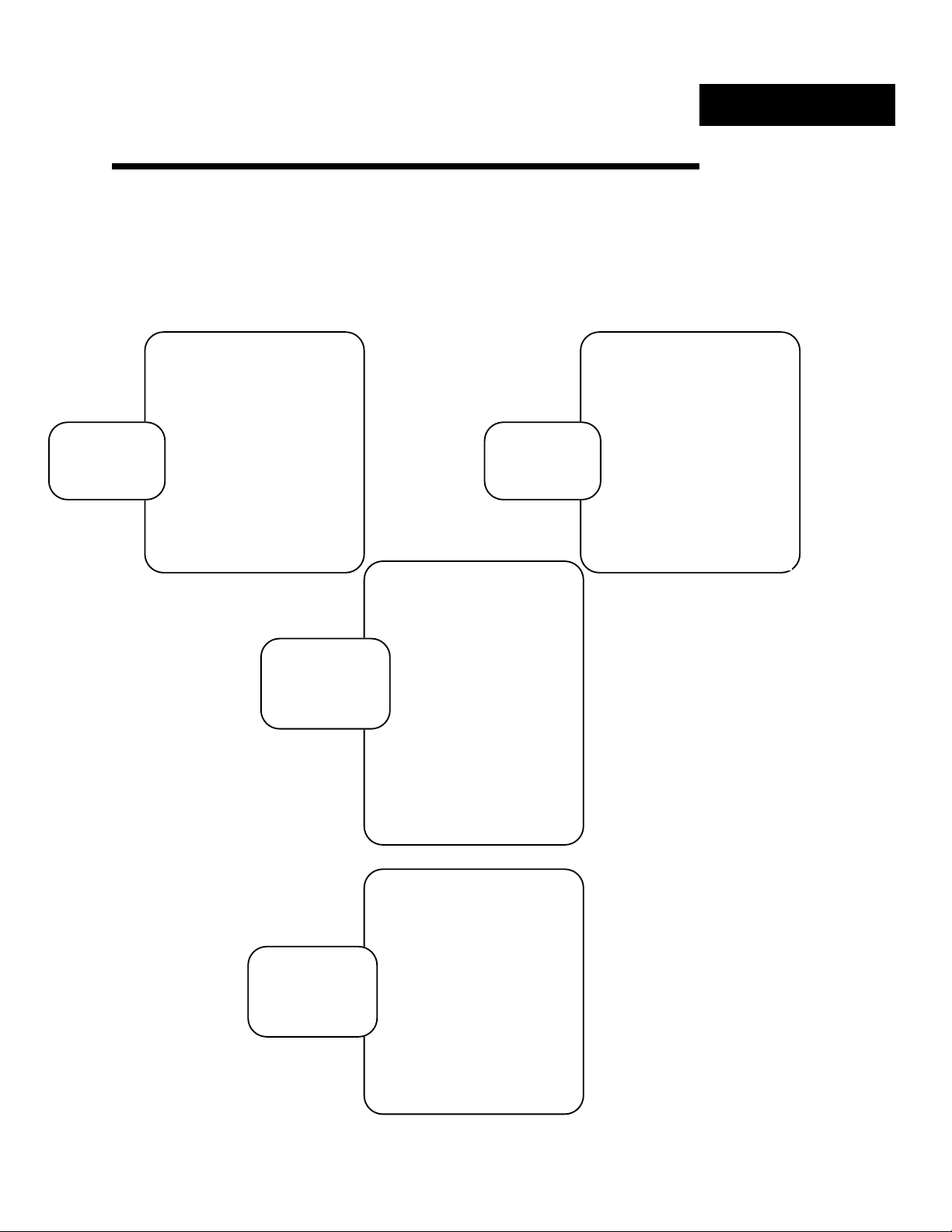

Figure 1 is a simplified view of the 1500's capabilities. The control has dual inputs,

one per channel, and dual control outputs for each channel. There is a choice of

auxiliary (event) or alarm outputs, an event input and remote hold input. An "Event

Output" in the Series 1500 is an ON/OFF solid state relay or solid state switch output

for activating periphered equipment or processes. Models with optional communications may be connected to a computer via a serial communications interface.

Figure 1 Series 1500

Input and Output

Overview

TEMP and %RH or

TEMP

See Pages 6, 8 & 35

Event Input

See Pages 36 & 51

The Series 1500 will handle 51 separate control steps. Each step duration is variable

from one second to 24 hours, 59 minutes, 59 seconds. The 1500 is a "profiling"

control because it will control up to 51 consecutive steps with a single program; the

resulting graph of all the steps makes a program "profile." The 1500 is a "ramping"

Dual Inputs

See Pages 6, 35 & 82

Remote Hold Input

See Pages 36 & 51

Dual Control

Outputs/Channel

See Pages 6 & 82

Heat/Cool

See Page 36

Humidify/

De-Humidify or

Heat/Cool

See Page 36

8 Auxiliary (Event)

Outputs, 4/Channel

See Pages 36 & 51

or

RS-422A/RS-423A (RS-232C)

Serial Communications Interface

See Page 62

4 WATLOW Series 1500 User's Manual

3 Auxiliary (Event)

Outputs/Channel and 1

Alarm Output/Channel

See Pages 36, 49 & 51

Starting Out, Chapter 1

control because it will move from one process variable to another in a uniform

manner.

Operator-friendly features include automatic "prompts," or entry codes, to assist you

in programming and monitoring. The Series 1500 has other display codes to indicate

a variety of alarm conditions about your process. The 1500 also has a "Jump Loop"

option for repeating program steps or segments. A "Wait For" option makes this

control responsive to particular process conditions, an external switch conditions or

real times of day.

In addition, you can change the three-mode, PID control to a simple ON/OFF control

by setting the proportional band parameter in each channel to zero.

When there's a power outage, the 1500 has memory protection provided by an

internal Lithium battery and optional battery-backed clock.

The standard RTD version Series 1500 is factory-configured to operate in degrees

Centigrade (°C) on Channel One and per cent relative humidity (%RH) on Channel

Two. A software selection, the "Temp-Temp" option, is also available for the RTD

unit. The Series 1500 Thermocouple version is strictly a "Temp-Temp" control. The

1500 has at least two switches you must set prior to entering your program. Information on how to set these switches follows in this chapter.

When you first apply power, the unit will "come up" with default values for set points,

alarm points, control parameters, recycle, events and time. These default values

provide minimum operating instructions until you enter your data. The default values

are listed in Chapter 4, "Technical Reference."

Starting Out

Remove the Series 1500 carefully from its shipping container. Be sure to set this

literature aside where it will not be discarded.

Packing List

Included with your Watlow Series 1500 RTD version are two 107Ω resistors, four

jumper wires, two mounting brackets with integral screws, and this manual. The

resistors and two jumpers will serve as pseudo-sensors at approximate room conditions while you learn the control. The other jumpers are for power connections.

How to Open the 1500

Before going further, open the Series 1500 and pull the control chassis from its case.

Here's how:

The control chassis fastens to the case with a single screw located at the lower front

panel. Turn the screw counterclockwise to loosen it. Three strip connector plugs, in

the rear of the control chassis, feed power and signals through the back of the case

to the triple terminal strip. These plugs will let go as you pull.

!

Pull firmly but gently to remove the Series 1500 from its case. The 1500 chassis will

not fit into the case upside down. However, always check to see that it is oriented

correctly before returning the chassis to the case. Press the unit in firmly, then turn

the front panel screw clockwise to secure it. Do not overtighten the screw.

!

CAUTION:

Before attempting to

open a Series 1500

with data communications (RS-422/423

interface), remove

the two screws and

DB-15 male connector from the rear of

the case.

WATLOW Series 1500 User's Manual 5

Starting Out

!

CAUTION:

Power must be

interrupted before a

change in DIP

Switch will take

effect.

Figure 2 DIP Switch Location and Setting

How to Set the DIP Switches

The Watlow Series 1500 has a set of Dual In-Line Package (DIP) switches on circuit

board, A007-1318. The location of the board and switches appear in Figure 2. The

switches are clearly numbered; the "ON" direction is indicated by an arrow. Look at

the DIP switches from the bottom of the control. You'll see them as they appear

below.

!

A007-1318

Board

DIP Switches

Table 1DIP Switch Position and Function

Control Chassis - Bottom View

Set the DIP switches according to Table 1 below. Make your initial choices now; you

may always return to change them later. Set DIP Switch #6 ON for a "Cold Start."

Sw Position Function

#1 ON Auxiliary (Event) Output #4 for both Ch-1 and Ch-2 are alarm outputs.

OFF Auxiliary (Event) Output #4 for both Ch-1 and Ch-2 are event outputs.

#2 ON Alarms are latching (displayed until cleared manually).

OFF Alarms are non-latching (displayed only as long as alarm condition exists).

RTD Unit Only

#3 ON The Ch-2 sensor is an RTD sensor. Jumpers W151 and W153 on the Signal

Conditioner board (A007-1316) must be installed.

OFF The Ch-2 inputs is a 0-5V signal representing 0-100% RH. Jumpers W150

and W154 on the Signal Conditioner board (A007-1316) must be installed.

T/C Unit Only

#3 ON Not Used. Set in the ON position.

#4 ON Dual PID per channel - #4 OFF Single PID per channel.

#5 ON Factory use only. Must be in the ON position.

#6 ON Cold Start on power-up. (Memory cleared, parameters set to default values.)*

OFF Warm Start on power up. (Programmed values are retained for all parameters.)*

#7 ON °C function after a Cold Start.

OFF °F function after a Cold Start.

#8 OFF Not Used. Set in the Off position.

*

For further Warm and Cold Start information, see the Technical Reference, Chapter

4.

6 WATLOW Series 1500 User's Manual

Starting Out, Chapter 1

Quick Wire

Starting Out

You may "power up " the Series 1500 with the following operational check-out. This

procedure also prepares you for the Sample Program in Chapter 2. Or, you may skip

this section and the sample program, and go directly to Chapter 3, Installation and

Wiring.

∫

1. Put the 1500 chassis back in its case. Then place the unit on a bench and

connect AC power lines and the jumper wires to the Power Supply terminal

strip. Use Figure 3 below.

115VAC

L2

CHASSIS

GROUND

L1

For 115VAC control operation,

install a jumper wire from Terminal

32 to Terminal 35, and a separate

jumper wire from Terminal 33 to

Terminal 36. Bring line power in to

Terminals 32 and 36. Connect the

line ground wire to Terminal 34.

∫

WARNING:

To avoid potential

electric shock use

National Electric

Code safety practices when wiring

and when connecting this unit to a

power source and to

electrical sensors or

peripheral devices.

Figure 3 Quick Wire AC

Power Connections

230VAC

L2

CHASSIS

GROUND

L1

2. As soon as you apply power, the FUNCTION display will alternately flash "A1C1, A1-C1." Press the CLEAR key to clear the flashing A1. The display will

then flash another A-code.

When you apply power without sensor inputs on the Signal Conditioner

terminal strip, the Series 1500 will show a flashing "A-digit" in the FUNCTION

display. The digit is an alarm code The ACTUAL display will show four

steady dashes, "----," meaning "open sensor." These are normal displays for a

unit without sensors.

Starting Out, Chapter 1

For 230VAC control operation,

install a jumper wire from Terminal

33 to Terminal 35. Bring line power

in to Terminals 32 and 36. Connect

the ground wire to Terminal 34.

WATLOW Series 1500 User's Manual 7

ACTUAL

Display

CLEAR

Key

FUNCTION

Display

Starting Out

3. If you did not set DIP Switch #6 in the "ON" position before, do that now:

Disconnect power from the unit. Open the 1500, set DIP Switch #6 to ON for a

Cold Start. Replace the control chassis in the enclosure. Reapply power to

the unit. (This clears all previously entered information from the 1500; it is a

"clean" or "cold" start).

4. Now remove power again, open the unit, and set Switch #6 to OFF. (This will

make the next start a "warm" one, retaining all subsequently entered information in the processor's memory). Close the 1500.

5. Locate the Signal Conditioner terminal strip on the back of the Series 1500, it's

on the far left as you look at the back of the unit. The resistors, or jumper wires

for the T/C version, will simulate input sensors at room temperature for this

procedure. Make the correct connections using Figure 4.

• For an RTD unit, connect a 107Ω resistor (provided) across Terminals 5 and

6, and another 107Ω resistor across Terminals 8 and 9. Also connect a jumper

wire (provided) across Terminals 6 and 7, and another jumper wire across

Terminals 9 and 10. See Figure 4.

• For a T/C unit, connect a jumper wire (provided) across Terminals 5 and 7,

and another jumper wire across Terminals 8 and 10.

Figure 4 Quick Wire Simulated Sensor

Wiring

RTD T/C

6. Apply power to the unit. With the CLEAR key, clear the "A1" alarm code and

any other "A" code that appears after it. The ACTUAL display will be reading

Channel 1 at simulated room temperature. Or the ACTUAL display will show

Channel 2 at a simulated %RH or temperature reading. Use the CH.SELECT

key to switch from one channel to the other.

If your Series 1500 responds this way, continue learning about the control. If your

unit does not respond like this, call Watlow at 507/454-5300 and ask for an applications engineer.

8 WATLOW Series 1500 User's Manual

Starting Out, Chapter 1

Overview of the Three Operating Modes

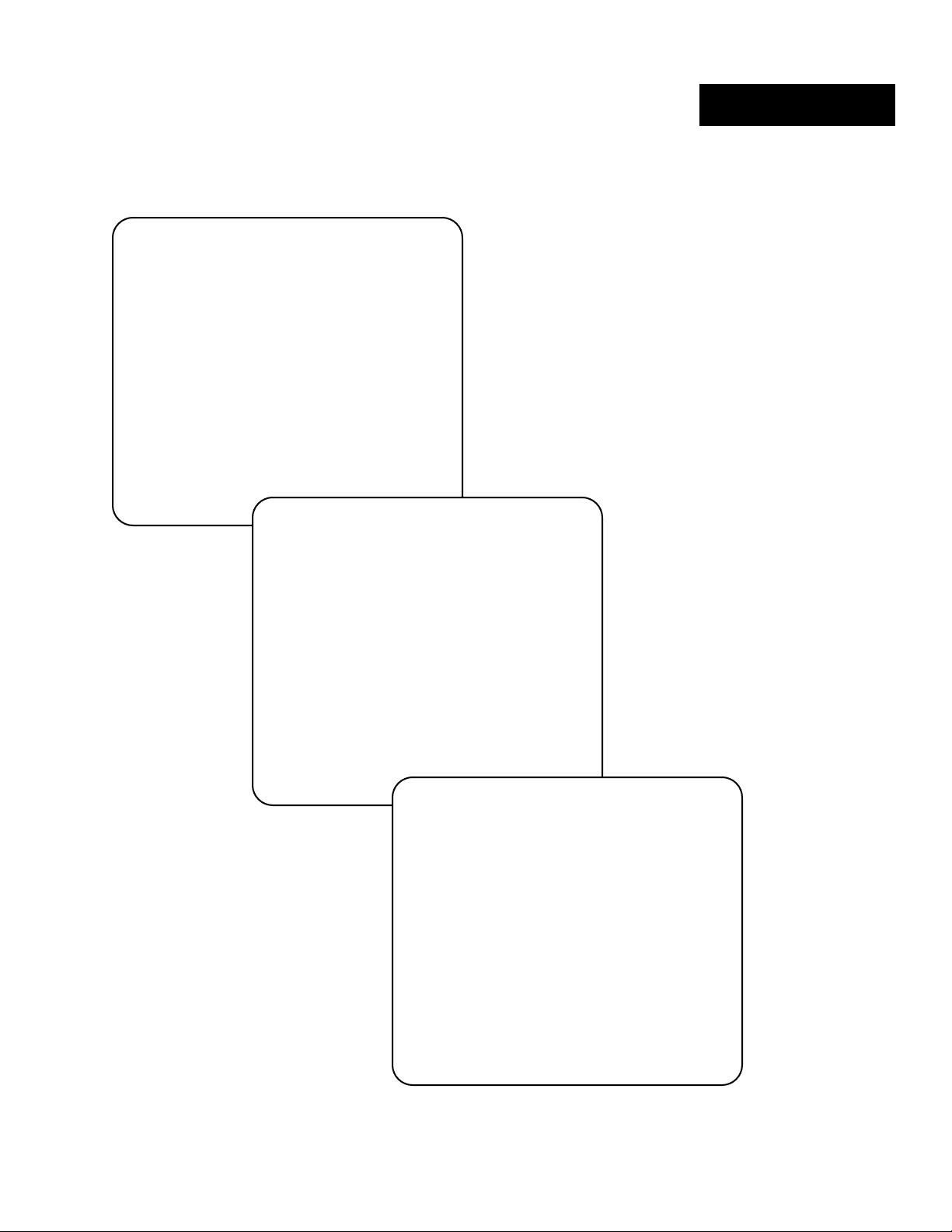

Before getting into the details of the Series 1500's keys and displays, take a look at

Figure 5, showing the three different modes. After you feel comfortable with the

names of the modes and their functions, go ahead to learn the keys and displays.

Series 1500: Four Mode Types

Series 1500: Three Mode Types

Starting Out

See Your

Program

Monitor Data Mode

(MNTR DATA)

Examine current

step information

in a running program.

Set Up

Program

Steps

OR

Change Data Mode

(CHG DATA)

Set up or change

step type, program

loops, wait for…

conditions,

set points,

auxiliary (event)

outputs ON/OFF,

and step duration.

Set a NonRamping

Set Point

Monitor Data Mode

(MNTR DATA)

Generate a

Set a non-ramping

non-ramping (fixed)

(fixed) set point and

set point and

manipulate event

manipulate event

outputs. At MNTR

outputs. At MNTR

DATA, halt the pro-

DATA, halt the pro-

gram and press

gram and press

RESTART. Select C1,

RESTART. Select C1,

C2, E1 or E2.

C2, E1 or E2.

Figure 5 Overview of the

Series 1500

Operating Modes

Starting Out, Chapter 1

Set Up

Your

System

Change Parameter

Mode (CHG PARA)

Set up or change

system-wide parameters such as real

time, high/low range,

alarm types, alarm

points, PID settings,

RS-422 address.

WATLOW Series 1500 User's Manual 9

Starting Out

Figure 6 Series 1500 Front Panel

Components

CH SEL key: CHANNEL

SELECT--Selects either

Channel 1 or Channel 2

for the ACTUAL display.

How to Read the Displays and Use the Keys

Here's an understanding of the Series 1500 displays, keys and LEDs. Use Figure 6

to locate the keys, LEDs and displays described here. Try everything! You'll learn

quickly how the 1500 works. The detailed overviews in the next section will further

your knowledge.

CH-2 EVENT LEDs:

Indicates the status of

each Channel 2 Event

ACTUAL display: Shows the actual

value of the variable in Channel 1 or

Channel 2, in four digits.

Output with one of four

LEDs visible only when the

output is energized (ON).

An Event Output in the

Series 1500 is an ON/OFF

solid state relay or

switched DC output for

activating periphered

equipment or processes.

CH-1, CH-2 LEDs:

Indicates the channel

in the ACTUAL display.

°F LED: When lit indicates the value

in the ACTUAL display is temperature in degrees Fahrenheit.

10 WATLOW Series 1500 User's Manual

% RH LED: When lit

indicates per cent relative

humidity in the ACTUAL

display.

°C LED: When lit, indicates tempera-

ture in degrees Celsius in the

ACTUAL display.

CH-1 EVENT LEDs:

Indicates the status of

each Channel 1 Event

Output with one of four

LEDs visible only when the

output is energized (ON).

Starting Out, Chapter 1

Figure 6 (Con't) Series 1500 Front Panel

Components

PROG END LED: PROGRAM END--

Indicates that the processor has

reached the end of the program.

Starting Out

PROG HALT LED: PROGRAM HALT--When lit, indicates

that the processor is in the HALT condition. A RUN/HALT

key press, or a "Blank Step" in the program causes a

HALT. When flashing, indicates that the processor is in

"Remote-Hold" condition. See RUN/HALT key.

CLEAR (erase) key:

a. Clears alarm codes

from FUNCTION display in

MONITOR DATA mode.

b. Clears the step in the STEP

display in CHANGE DATA mode

when the unit is in the HALT

condition.

c. Clears all 51 programmed steps

when the unit in the HALT

condition, and in GUARDED

ACCESS area of the CHANGE

PARAMETER mode. (This

prevents an operator from

accidentally clearing an entire

program. The GUARDED

ACCESS data is not cleared).

STEP display: Indicates the current

step number being programmed in

the CHANGE DATA mode, or the

current step being monitored in the

MONITOR DATA mode.

RE-START key: Returns

the controller to the initial

program step only when

the 1500 is in the PROGRAM HALT condition.

See RUN/HALT key.

FUNCTION display: Shows the

prompts used in the three modes. It

also displays hours when TIME is

selected in MONITOR DATA,

CHANGE PARAMETER or CHANGE

DATA modes. The FUNCTION

display shows a flashing alarm code

if one is activated.

RUN/HALT key: Starts or

stops the program. The

processor will resume a

program where it was

interrupted, unless the RESTART key was pressed,

or the step number or set

point data at the current

step was changed during

the HALT condition.

DATA display: Indicates

the entered data or

monitored value in four

digits.

CHG DATA LED:

When lit indicates

the processor is in

the CHANGE DATA

mode.

MNTR DATA LED:

When lit, indicates

the processor is in

the MONITOR

DATA mode.

MODE key: Selects

either the MONITOR

DATA, CHANGE

DATA or CHANGE

PARAMETER

mode.

Starting Out, Chapter 1

FCTN key: The

FUNCTION key

steps through the

prompts in each of

the three modes.

ENTER key: Enters

selected data or

NEXT STEP

operations in the

CHANGE DATA and

CHANGE PARAMETER modes.

CHG PARA LED: When

lit indicates the processor

is in the CHANGE

PARAMETER mode.

TIME LED: When lit,

indicates that the FUNCTION and DATA displays

are showing time.

UP key: Increases

the value in the

DATA display. A

light touch increases

the value by one.

Holding the key

down causes the

DATA display to

increase rapidly.

WATLOW Series 1500 User's Manual 11

DOWN key: Acts opposite

the UP key. Ramps the

value in the DATA display

downward. A light touch

decreases the value by

one. Holding the key

down causes the DATA

display to decrease

rapidly.

Starting Out

Now that you have a good idea how the 1500's front panel works, look again at the

operating modes. This time take a more detailed look.

Overview of the Mode Software

Again, the Series 1500 has three Operating Modes: Monitor Data, Change Data and

Change Parameter. These modes change with the MODE key. They make up the

basic software routines that run the Series 1500. Each mode has sub-routines and

different prompts that appear in the FUNCTION display whenever you press the

FCTN key.

Examine the three figures on the next pages, one for each of the modes. Understanding how these modes control the Series 1500 is the key to learning the control.

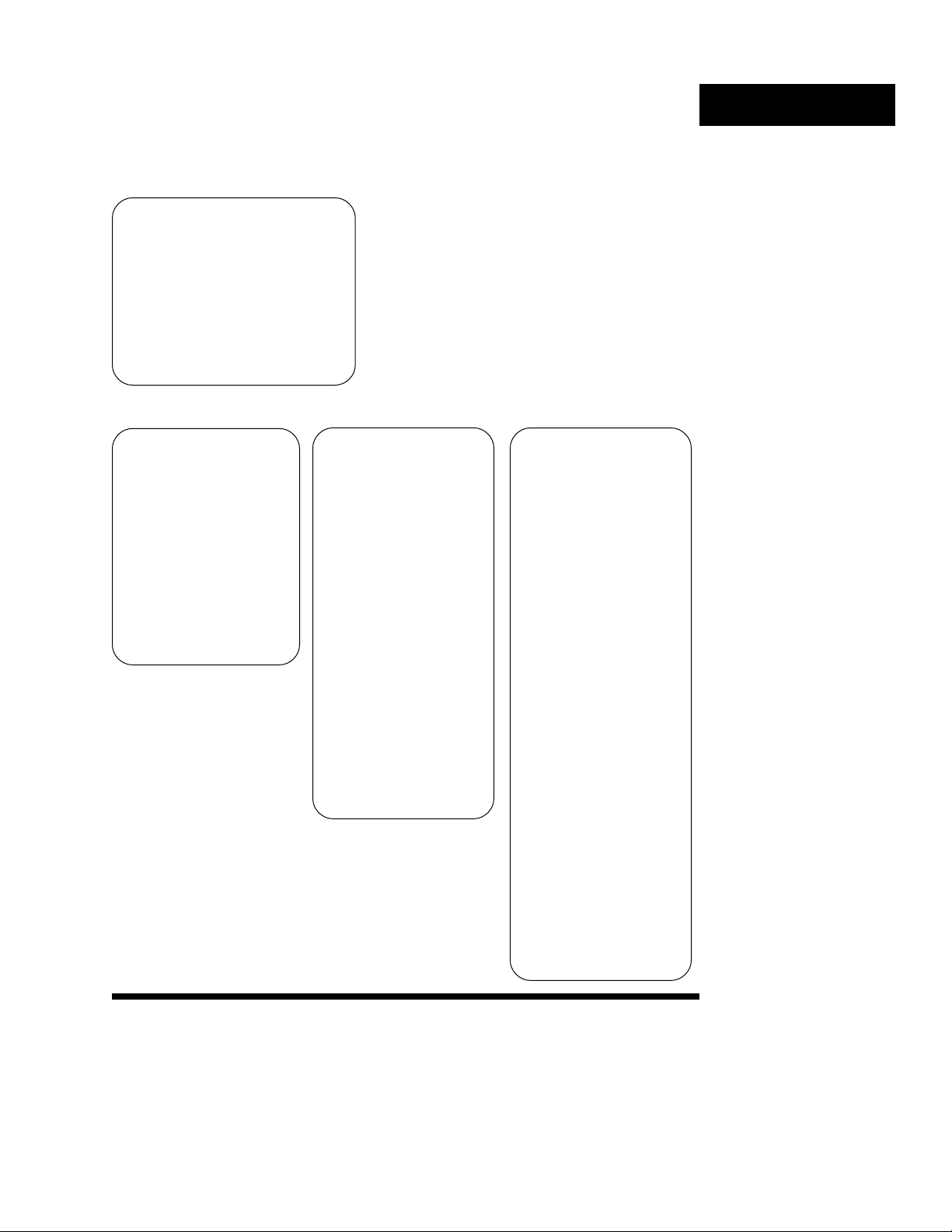

Figure 7 - Monitor Data (MNTR DATA) Mode Overview

Figure 8 - Change Data (CHG DATA) Mode Overview

Figure 9 - Change Parameter (CHG PARA) Mode Overview

12 WATLOW Series 1500 User's Manual

Starting Out, Chapter 1

Monitor Data Mode (MNTR DATA):

Starting Out

Monitoring a Halted Program

You may look at any step, but must

be in the CHG DATA mode to

change the step number.

You'll see:

• Step type.

• Ch-1 and Ch-2 set points.

• Auxiliary outputs programming.

• Step duration.

Monitoring a Running Program

You may look at the current step.

You'll see:

Figure 7 Monitor Data

(MNTR DATA)

Mode Overview

• Ch-1 and Ch-2 current set points.

• Auxiliaries programmed ON or OFF.

• Time remaining.

Set a Non-Ramping Set Point

Set a non-rampong (fixed)

set point and manipulate

event outputs.

Starting Out, Chapter 1

WATLOW Series 1500 User's Manual 13

Starting Out

Figure 8 Change Data (CHG

DATA) Mode

Overview

Change Data Mode (CHG DATA):

Three Step Types for Entering Program Data

Set Point (SP):

a simple,

regular profile

step.

Set Point Step,

Program:

This Step#

is an SP

step.

Set Point

for Ch-1.

Set Point

for Ch-2.

Auxiliary

(Event)

Outputs,

ON/OFF.

Step

Duration.

Go to any

next step.

Jump Loop (JL): Wait for…(WT):

a means for

jumping to

a step out of

numerical

sequence.

Jump Loop Step,

Program:

This Step#

is a JL

step.

Jump to

Step# __.

a means to

wait for a

particular

condition or

time.

Wait for Step,

Program:

This Step#

is a WT

step.

Wait for

this Ch-1

value to

Repeat that

occur, __.

step, __

times (Jump

Counts).

Wait for

this Ch-2

value to

Go to any

occur, __.

next step.

Wait for

Input Event

to achieve a

specified

conditon.

Wait for

this real

time, ___.

14 WATLOW Series 1500 User's Manual

Go to any

next step.

Starting Out, Chapter 1

Change Parameter Mode (CHG PARA)

Starting Out

For Entering System-Wide Parameters

Program Real Time

Then proceed to one of

three "Guarded Access"

areas – code-protected

system setup parameters.

Program These

Parameters:

Set Ch-1 & Ch-2

alarm type and

high/low points.

Leave "Guarded

Access."

Program These

Parameters:

Set Recycle Option

(program repeat).

Set up Ch-1 PID

parameters and

calibration offset.

Set up Ch-2 PID

parameters and

calibration offset.

Leave "Guarded

Access."

Figure 9 Change Parameter

(CHG PARA) Mode

Overview

Program These

Parameters:

Set up Ch-1 and

Ch-2 high and low

ranges.

Select Series 1500

Ch-1/Ch-2

Operation,

TEMP-TEMP or

TEMP-RH.

Set Recycle Option

(program repeat).

Select RS-422

Address #.

Select keyboard

lock status.

Leave "Guarded

Access."

Where To Go From Here

You are now ready to go to the Sample Program, Chapter 2, or to Installation and

Wiring, Chapter 3.

If you skip the sample program, do not forget to check the position of DIP Switch 6

before you begin programming your control after installation. With DIP Switch 6 OFF,

the 1500 saves your program whenever power is removed (Warm Start). With DIP

Switch 6 ON, the 1500 will clear its memory of all programmed information whenever

power is removed,substituting default values (Cold Start).

Starting Out, Chapter 1

WATLOW Series 1500 User's Manual 15

Sample Program

Chapter 2

Learning the Series 1500 — A Sample Program

in Action

This chapter will guide you through an easy sample program for the Series 1500.

You can quickly grasp the necessary terms and concepts by entering and observing

this exercise.

If you feel that your knowledge of programmable controllers does not require a

sample program to learn the Series 1500, feel free to skip this chapter. In the

Technical Reference section (Chapter 4), you will find details on all material here.

IMPORTANT

NOTE:

If you have a

Series 1500 T/C

version, or are

using the RTD

version for 2

channels of temperature control

(TEMP-TEMP), then

simply consider

all sample program

references to

relative humidity

as a second

channel of temperature. Use the

sample values as

temperatures

rather than relative

humidities.

The Series 1500 Wonderful-Apple-Pie

Sample Program

Let's assume that Great-Grandma handed down to you her secret recipe for wonderful apple pie. It's not that her ingredients are so different; but she took great care to

control baking temperature and humidity, and to add topping ingredients at just the

right times in the baking cycle. These really are fantastic apple pies, so you've

bought an oven with a Series 1500 control, and you're starting an apple pie business.

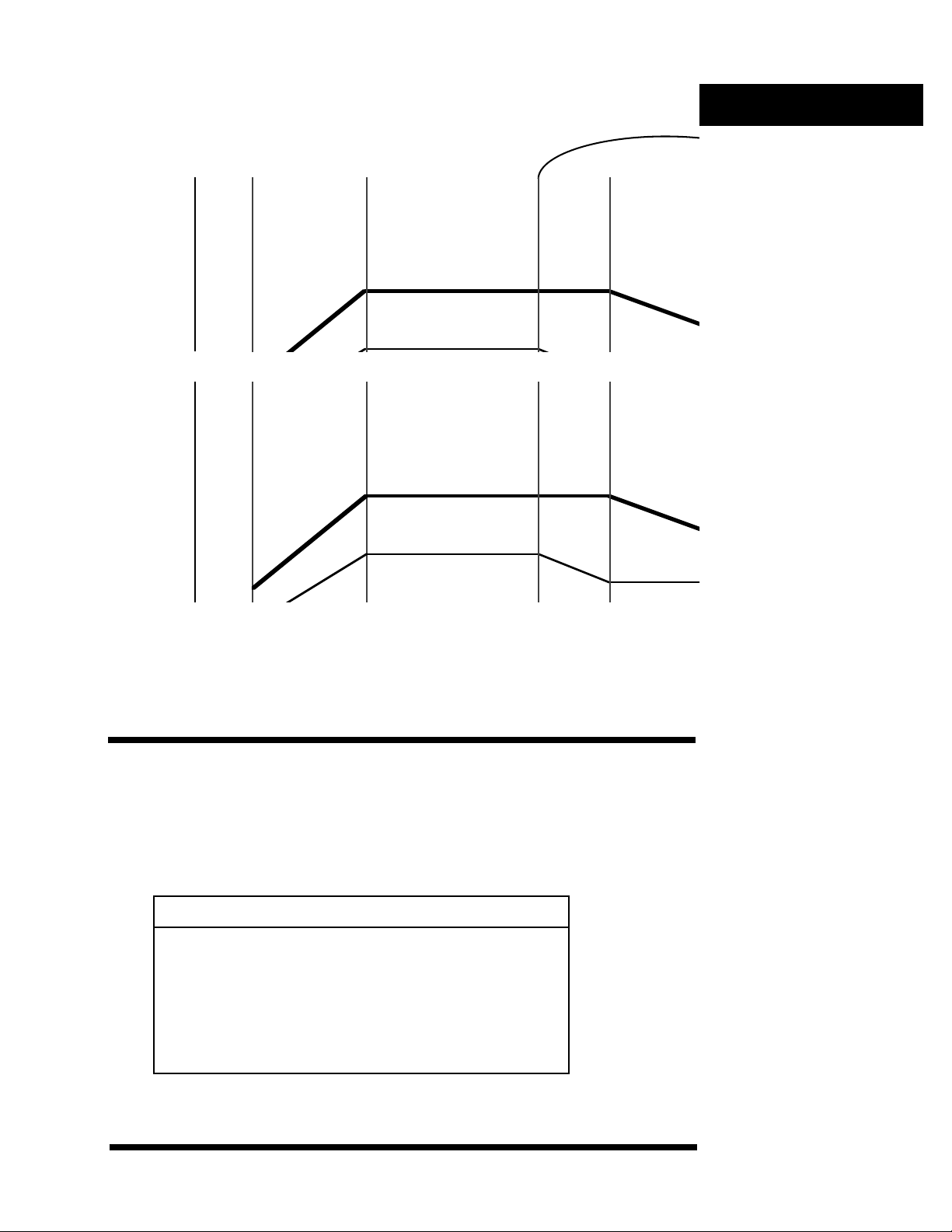

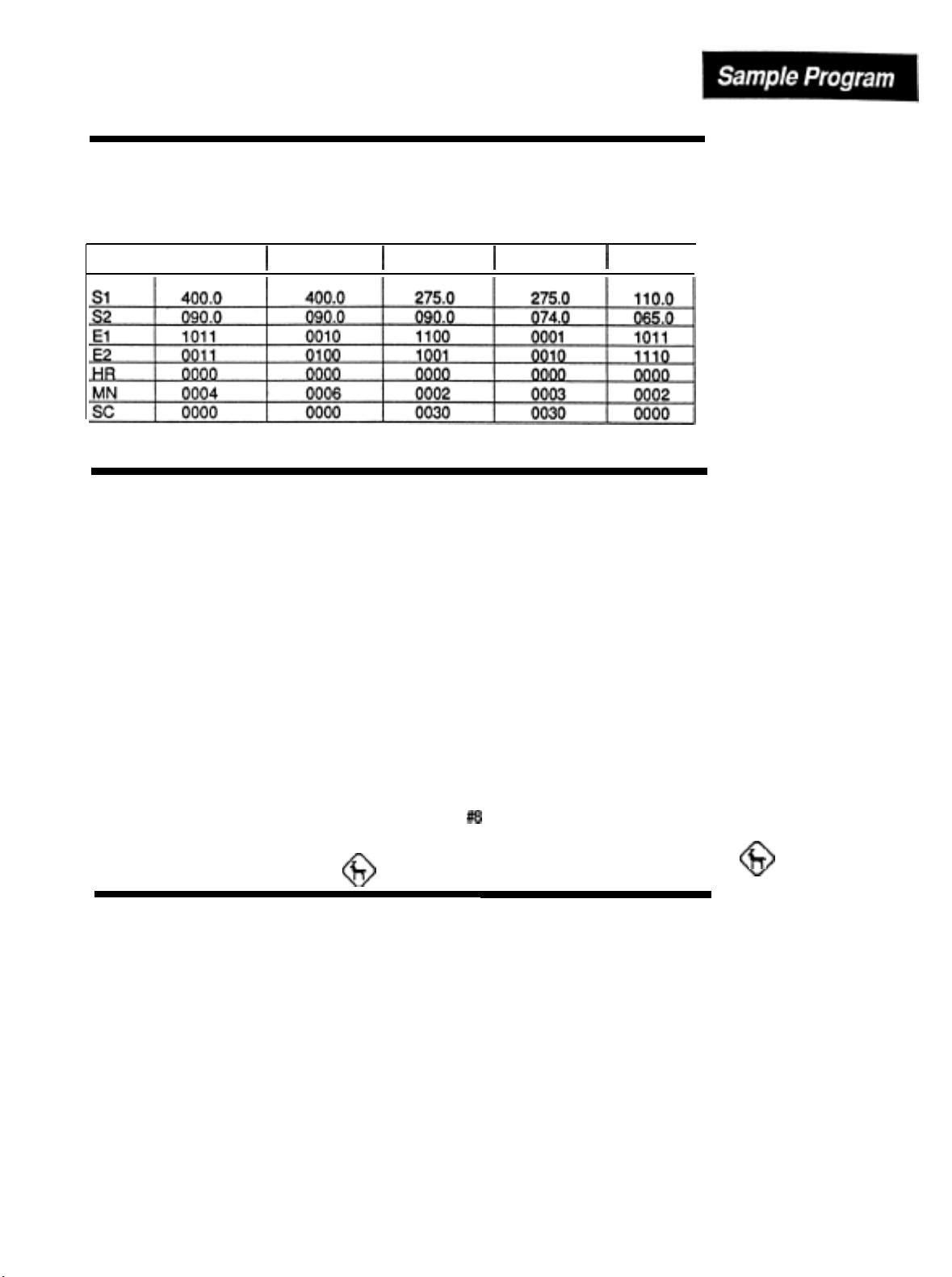

Sample Program Chart

The chart here shows the baking process. Grandma's original recipe had Grandpa

turn the oven on early in the morning. Grandpa would raise and lower the oven

temperature at certain times, too. That is one of Grandma's secrets. With the Series

1500 you'll be able to make your oven "loop" between 275° and 110° three times

before a pie is done.

If Great-Grandma was right, this process should turn out a really fine apple pie.

Since your bakery will begin baking pies at the same time every morning, you'll want

your Series 1500 to automatically start the process each day.

The chart below details the "wonderful-apple-pie" sample program for the Series

1500.

16 WATLOW Series 1500 User's Manual Sample Program, Chapter 2

Temp/

h

%RH

Step 1 Step 2

Step 3

Perform Steps 4-6 T

Step 4 Step 5

Sample Program

Chart 1 Series 1500

Sample Program

Chart

(Wait)

Temp/

Step 1 Step 2

%RH

(Wait)

*

50%RH

Setting Event Outputs

90% RH

Step 3

90% RH

400°F

74% RH

Step 4 Step 5

74% RH

275°F

To make the pie process even more automated, you have your toppings — sugar,

cinnamon and nutmeg—connected to solenoid dispensers controlled by the 1500's

"Event Outputs." As you enter the sample program, you'll set the Event Outputs to

trigger just when you want them to. You even have an Event Output to put your pies

in and take them out of the oven at just the right times. You'll need to turn the

Events ON as follows:

STEP CH #1 EVENTS CH #2 EVENTS

1 Wait 0 0

2 1, 2, 4 1, 2

32 3

4 3, 4 1, 4

51 2

6 1, 2, 4 2, 3, 4

8 3, 4 1, 3

Understanding the Modes of Operation

Sample Program, Chapter 2

WATLOW Series 1500 User's Manual 17

Table 2 Sample Program

Event Outputs

Sample Program

Before you begin entering the program, notice three small lights (LEDs) on the

bottom half of the 1500's front panel. They are labeled "MNTR DATA" (Monitor

Data), "CHG DATA" (Change Data), and "CHG PARA" (Change Parameters). Press

the MODE key to move through these three modes as you read about each one.

Another LED, labeled "TIME" indicates when time is being displayed.

"MNTR DATA": While a program is running, you'll want to observe what's happening. Some items can be observed in the "ACTUAL" display and in the nearby top half

of the front panel: Actual Temperature or Relative Humidity, Events ON/OFF, etc.

But you'll also want to know which step is being performed, and the amount of time

remaining in the step.

You can monitor information in a running program by pressing the MODE key until

the MNTR DATA LED is ON. Then press the FCTN key until you are observing the

data you want. Right now you don't have a program entered, so no meaningful data

is available. As soon as you enter the sample program, use this mode to watch

things happen.

"CHG DATA": This is the mode where you'll enter program operating DATA (set

points, time interval for each step and Event Outputs). In this mode, you can also

change data or correct errors in the program. If you want to wait until a specific time

before doing something or to set up program loops, you also enter that information in

CHG DATA. With the CHG DATA LED on, pressing the FCTN key will move you

through the functions you can program.

!

CAUTION:

This sample program will activate

some of the "Control

Outputs" and "Event

Outputs" on the

Series 1500 terminal

strips. To avoid any

damage to your

equipment while

running the sample

program, be sure all

Event and Control

Outputs are disconnected from the

Series 1500 terminals. Or remove

power from any

external loads

attached to the

Series 1500.

"CHG PARA": Some Series 1500 information is more applicable to the overall

system than to just one specific program. This includes the "real time of day," system

maximum/minimum alarm limits and "PID Parameters" which tune the overall system.

This system-wide information is entered or changed in this mode.

Again – pressing the FCTN key selects functions while the CHG PARA LED is on.

Many of these functions are protected from accidental change by a "Guarded Access" (GA) code before they can be viewed or altered. You'll learn the GA codes

soon.

Before Y ou Begin…

Before you begin to enter your Sample Program, take this precaution:

!

Clear Memory, Set DIP Switches

To clear your Series 1500's memory, do a "Cold Start." Turn the power OFF, open

the 1500 and ensure that DIP Switches 2, 3, 5 and 6 are ON and that DIP Switches

1,4,7 and 8 are OFF. If you haven't done so already, attach the provided 107Ω

resistor and a jumper (or jumpers for a T/C version) to each sensor input as described in Chapter 1 under "Quick Wire." If you want to use your sensors, refer to

Chapter 3, Figure 11 for wiring. Then turn the power ON and press the "CLEAR" key

to clear the flashing alarm indication(s).

18 WATLOW Series 1500 User's Manual Sample Program, Chapter 2

4.

Press the

ENTER key:

the display will flash, then it will change to “MN.”

Use the UP/DOWN keys

5.

to place the correct value for minutes into the Data

Display; then press ENTER.

The display will show “SC” (seconds): again use the UP/DOWN keys to place

6.

seconds into the display and then press ENTER.

Press the FCTN key several times

7.

PARA

LED). You

should now see the correct real time on the display, with

until the TlME

LED is lit

(along with

the CHG

the seconds counting up.

Set the Recycle Option

Now, while still in the CHG

that you want your program to automatically repeat each day until you decide to halt it.

This “Recycle” condition is set within the “Guarded Access” (GA) section of the CHG

PARA

mode. Do that now:

1.

With

the CHG

Function Display. If you

around again.

2.

Place

“0006,”

one of the Guarded Access codes, into the Data Display using

the UP/DOWN keys.

3.

Press ENTER

Display.

PARA mode,

PARA

LED ON, press

pass

until

the "RC,"

“RC,”

there is one more thing to enter. Remember

the

FCTN key until “GA” appears in the

GA, keep pressing

FCTN

until GA comes

(Recycle) prompt appears in the Function

4.

Place a “0001” into the Data Display. Press ENTER.

Begin Entering Data

Now

that

you

have entered the real time and the Recycle option, go to the CHG

DATA mode to enter actual program data:

1.

Press the MODE key until the CHG DATA LED is lit. The display will read

“01

SP.”

Programming Step

Refer back to the sample program chart at the beginning of this section.

that while you’d like to load your program and press the start button now, the first

program step must hypothetically wait until early morning before it starts running. To

program Step #1 as a Wait Step,” do this:

Press the FCTN key until "WT" appears in the Function Display.

1.

Press the ENTER key,

2.

Since you are waiting for a

3.

FCTN

until

“WH”

1

W1”

(Wait for

specific

(Wait for Hours) appears.

Ch-1)

appears.

time, and not for input conditions, press

Remember,

Sample Program, Chapter 2

WATLOW Series

1500 Users

Manual

19

Sample Program

4. We suggest that you enter a time one hour from right now. Changing this

time later is a simple matter. You go to the CHG DATA mode with "WH"

displayed and then enter the new time. Select hours (0 to 23) and press

ENTER.

5. Also enter the "WM" (minutes) and "WS" (seconds). Select minutes, press

ENTER. Wait a moment for the display to change, then select seconds and

press ENTER.

6. You have completed entering Step #1 as a "Wait Step." The display should

now read "01 NX 0002." This indicates that the 1500 is ready to move on to

program Step #2 unless you tell it otherwise.

Programming Step 2

1. Since you do indeed want to program Step #2 now, just press ENTER. The

display should read "02 SP", and you are ready to begin programming Step

#2.

Refer again to the program chart. Note that the values you want to achieve are 400°,

90%RH. You want the 1500 to accomplish this in four minutes. You also want to

have Ch-1 Events 1, 2 and 4 ON, and Ch-2 Events 1 and 2 ON during Step #2. We

will now program all this data for Step #2:

1. Since the display reads "02 SP," and you do want to enter Set Point Data,

first press ENTER. The display changes to "S1" (Set Point for Ch-1).

2. Use the UP/DOWN keys to put "400.0" into the display. Some practice may

be necessary to stop at the right value. Then press ENTER. The display

changes to "S2" (Set Point for Ch-2).

3. Place "090.0" into the display and press ENTER. The display changes to

"E1" (Events for Ch-1). The Data Display is blank right now.

4. In the Data Display,

the left.

display and press ENTER. The display will change to "E2" (Events for

Ch-2).

5. Likewise, for Ch-2 Events #1 and 2 ON, ENTER the value "0011." The

6. Since Step #2 is only four minutes long, just press ENTER to enter "0000"

7. For Step #2 Minutes, ENTER "0004." The display changes to "SC."

8. For Step #2 Seconds, ENTER "0000." The display changes to "02 00

0400."

So, for Ch-1 Events #1, 2 and 4 ON, place "1011" into the

display changes to "HR" (The "hour" portion of the duration of Step #2).

hours. The display changes to "MN."

Event #1 is represented on the right and Event #4 is on

9. You have successfully programmed Step #2 as a "Set Point Step." The

display is indicating that Step #2 is programmed for a duration of 00 hours,

04 minutes, 00 seconds. Press either ENTER or FCTN; the display

changes to "02 NX 0003."

10. Again since you do want to program Step #3 now, press ENTER. The

20 WATLOW Series 1500 User's Manual

display changes to "03 SP."

Sample Program, Chapter 2

Programming Steps 3 through 6

Now that you see how it’s done, enter the data for Set Point

be sure to stop and then return to these instructions when the display reaches

SP.”

This is because you will be looping through Steps #4 through #6 three times.

Refer to the table below for

FCTN

STEP

I

#2

Steps

I

#3,4,5

STEP#3

and

I

6.

STEP

#4

I

Steps

STEP#5

#3,4,5,

&

I Step#6

6. But,

“07

Programming Step 7, a Jump Loop Step

You now

performed when Step #6 is completed.

“Set Point Step.” We want Step #7 to cause the 1500 to JUMP

times

a"JUMP LOOP

have Steps #1-6 programmed. When you run the program, Step

But, you do not want Step #7 to be a normal

back to

(for a

total

of 3 times through Steps

Step.”

1.

With

the STEP and FUNCTION displays now reading “07 SP,” press the

FCTN key until “07 JL” comes up.

That’s why you’ll program Step #7 as

#4-6).

#7

will be

Step #4 two

Table

3

-

Sample Program

Steps

2.

Press the ENTER key. The display changes to “JS” (Jump to Step

3.

Enter the number of the step the program will jump to (“0004”).

ENTER. The display changes to “JC” (Jump Count).

4.

Since you want to jump back to Step #4 two times (total of 3 times through

the loop), enter “0002.” Press ENTER. The display changes to “07 NX 0008.”

5.

Press ENTER (you do want to program Step #8 now). The diiplay

changes to “08 SP.”

Programming Step 8

You’re ready to enter Step

below (Stop with the display reading “08 NX 0009”):

S1

S2

El

E2

HR

MN

SC 0000

Recall that you set the Recycle (RC) option to ON, so the program will repeat

indefinitely. You have now entered the entire program.

110.0

065.0

1100

0101

0000

0006

#8.

@

It’s a normal Set Point Step, enter the information

You’re almost ready to run it.

#).

Press

f7

0

CAUTION:

Notice

on the

Sample Program

Chart (at the

beginning of this

section) that the

Series

1500

hoIds

the Step #8 set

points

and Step

#8

Event Outputs

ON as lt

and waits through

Step #1 before

beginning

program over.

recycles

the

Sample Program, Chapter 2

WATLOW Series

1500 Users Manual

21

Almost Ready to Run

Remember that Step #1 was a “Wait Step.”

you won’t see

You may want

ways to get back to Step #1 in

0009”; it is waiting for you to continue programming or monitoring.

key to put “0001” in the Data display and press ENTER. The display will show “01 WI”

(Step#l is a Wait Step). Now use the FCTN key to move through

“SC;” enter a time real time1 0 minutes from now.

any action until the time you programmed into Step

to go

back and

adjust that time to a different value.

CHG

DATA mode. Your display is now reading “08 NX

Even though you press the “RUN” key,

#1.

There

are various

Use the DOWN

“HR," “MN,”

and

Start Your Program!

The Wonderful Apple Pie

“RE-START’

“RUN/HALT’ key to start the program.

key

(upper

Sample Program

front panel) to set the program to Step

is all entered and ready. So press the

#1.

Then press the

Monitoring the Action

With the MNTR DATA LED lit, you can now use the FCTN key to check things out.

The control doesn’t seem to show much happening right now since Step #1 is a “Wait

Step.” Press the FCTN key.

programmed into Step

programmed time.

In one display you’ll see the “WT” (Wait for) time you

#1. The

1500

is

watching for its real time to match that

f?

CAUTION:

You

now

have a

basic

understandlng of how

the

Series 1500

handles a control

program. Please

read and then

continue

to the following

fine

“Helpful Hints”

sectlon will

your

the Series 1500

to the highest

level.

22

to refer

points.

The

raise

skills with

WATLOW

Now use the MODE

You can watch as real time approaches your programmed time. When the times

match, the step

lights come ON to coincide with the Events you programmed for Step

As

the

program runs its course, you can use the

key to view the process. As you observe the varying data, the individual functions will

become

following information to gain an even more detailed understanding.

quite

number changes

clear.

f?

Helpful Hints

Here are some Series 1500 fine points:

1.

Halt Conditions

A.

A Blank Step halts the Series 1500. A “Blank Step” is any step which is not

programmed. An “SP” will appear in the Function Display when you select

a Blank Step with the MODE key.

The Series 1500 can enter the HALT

B.

Blank Step in a program, or you press the RUN/HALT key while a program

is running.

Series 1500 User’s Manual

key to

move to the

to

After you have

CHG PARA

02.

You will also see the Ch-1 and Ch-2 Event

observed

mode with the

MNTR DATA mode and the FCTN

the program for awhile, read the

condition

in two ways:

TlME

LED also ON.

#2.

It encounters a

Sample Program, Chapter

2

While in the HALT condition, the Series

C.

Event Output conditions from the step it was in when it was halted, or from last

step before a

“Blank

Step” halted the control.

made no change to the step data, the 1500 will complete the step from the time it

stopped. If you

D.

Thus, if your sample

after performing Step

65%RH,

E.

If you press the RUN/HALT key at

and with Ch-1 Events 3 and 4 ON and Ch-2 Events 1 and 3 ON.

with the oven at

change data, the step begins from beginning.

program

#8,

275°, 83.2%RH,

Event 2 ON.

F.

However, you may not want the Step #8 conditions to be retained until

tomorrow.

Set Points of

You could add a step at the end of the program to establish

75°, 50%RH,

2. Ramping Conditions

A.

When running any Set Point step, the Series 1500 notes what the

existing starting conditions are and what the desired ending conditions are.

Then it follows a linear path between the two.

Although the desired ending conditions are specifically programmed into

B.

each step, the beginning conditions depend on the step performed just

previously. Know where you are going and where

1500

maintains the Set Points and

If you

restart

the control, having

did not have “Recycle” activated, it would halt

but would continue to hold the oven at 110°,

1-1/2

minutes into Step

and have

Ch-1

and with all Event

Event 1 ON and Ch-2

Cutputs

you've

OFF.

been.

#5,

it would Halt

Step #4 of your Sample Program is an example:

C.

l

As the chart on page 17 shows, you expect to start Step #4 at

ramp uniformly down to

time through Step

l

But when you “loop back-from Step

will be ramping upward from 11 O° to

l

If

this is not acceptable to you, you might want to jump loop back to Step

#2

to reach a full

3. Wait Step

A.

A Wait Step maintains the same Set Points that existed at the end of the

previous step. With Step #1 as a Wait Step, this means that the 1500 will

use the default values for Step #1

first run.

values (11 O°, 65%RH, Ch. #1 Events 3 & 4 ON and

ON).

If you were to halt the program during Step #3 and then “RESTART’ and run

it, Step #1 would retain the Step #3 values. Since this is not always desirable,

you could place a short (1 second) step immediately before the Wait Step to

establish different Set Point values.

275°.

This certainly is what happens on the first

#4.

400°

through Step #3 before you start Step

(75°, 50%RH,

However, when it recycles

from Step #6, it will retain the Step #8

#6,

your starting point is 11

275°.

ail events OFF) during its

Ch. #2 Events

400°,

#4.

1 &

O°.

3

and

You

When waiting for

B.

“53”

for Minutes, but enter nothing for Hours or Seconds, the programmed

time will be 53 minutes after midnight.

Sample Program, Chapter 2

"Time,”

program all three units (HR-MN-SC).

If you program

WATLOW

Series 1500 User's

Manual

23

In your sample program’s Wait Step, you used “Wait for time” because you

C.

aren’t connected to a variable oven yet.

could be as follows:

l

In Step

90%RH.

#2,

you have

Depending upon your system, this may either be impossible

to do, or you may reach the desired conditions much earlier than that.

This could

l

lf you reprogrammed Step #2 as a Wait Step, you could measure how

result

in bad apple pies.

long it takes to achieve the desired conditions, and then react

immediately. Much better apple pies.

l

But, there is a choice to make here: The Wait Step does not follow the

linear ramping path to reach the new conditions as a Set Point Step

does. A Wait Step uses the previous step’s Set Point. To optimize

control (reduce the overshoot and undershoot) a Wait Step uses the

“PID

Parameters” to satisfy the wait condition.

the step type which best matches your needs. (The

are discussed in the Technical Reference Section that follows).

4. Jump Loop Step (JL)

A.

In the sample program, you used this capability to jump from Step #6 back to

Step #4 two times. Your “Jump Count” (JC) was set to

1

to 255 can be used in loops of this type.

A more common use of the Wait Step

allowed

exactly four minutes to reach

400°,

In other words, select

PID

parameters

“2.”

Any value from

B.

If you program

“0”

into

“JC,”

the JUMP will occur infinitely. This

set up a never-ending loop if the jump is backwards. Or you can set up a

one-time “unconditional jump” if the jump is

forward.

If you use a forward

jump, the 0 choice makes no difference. The jump will be performed once.

l

But why would you ever want to simply jump forward and skip over some

steps, you ask?

Suppose your overall program has various functional sections, not all of

which you want to do every time.

By ending each section with a Jump

Step, you can easily alter the program to perform various sections in

diierent sequences.

During programming work, you may want to develop and test a program in

sections. You can develop the separate sections with unprogrammed

Blank Steps between them, then unite the separate sections laterwith

Jump Steps.

As you learned earlier, jumping or looping into Steps from “different

C.

directions” can sometimes cause unexpected results due to different

starting conditions as you enter a new step. Watch for such possibilities.

5. Recycle

With

the Recycle option active, you might expect to see continuous activity as the

process

immediately start Step #1 after it completes Step

repeats the program sequence. This sample program will, in fact,

#8.

action

could

24

WATLOW

Series 1500

User's

Manual

Sample

Program, Chapter

2

However, remember that Step #1 is programmed as a "Wait Step," so it will wait until

the same time tomorrow. Since you now know what a Wait Step does, you may want

to reprogram Step #1 as a simple "Set Point" step so that you can view the Recycle

action. If you do decide to reprogram Step #1, then read the following items.

• You cannot alter data or parameters while the program is running. The

1500 must be in the HALT condition.

• If you want to move to a different Step #, to see what is programmed there

and then modify that step, enter the CHG DATA mode. Then to reprogram it from the CHG DATA mode, go to the appropriate step as described above. Then press the CLEAR key. All programmed data (for this

step only) will clear, and you can now reprogram it.

6. Interactive Changing of Set Points and Events

When in the halted condition, the Series 1500 actively maintains the current set

points and Event Output status. At times, you may wish to change these conditions

without actually entering and running a profile step. To do this, you must be in the

"MONITOR DATA" mode, halted (PROG HALT LED ON) and "RESTART" key just

pressed. Then use the function key to move to the desired prompt ("C1", "C2", "E1"

or "E2"), use the INCREMENT/DECREMENT keys to move to the desired data, and

press the ENTER key. The Series 1500 will quickly change to controlling at the new

condition.

Sample Program

Where To Go From Here

As soon as you feel comfortable with the Series 1500 sample program, move on to

Installation and Wiring, Chapter 3. Or if you have already installed and wired your

system, go to the Programming Chart in Chapter 4 and begin entering and docu-

menting your Series 1500 program.

Sample Program, Chapter 2

WATLOW Series 1500 User's Manual 25

Installation-Wiring

Chapter 3

How to Install and Wire the 1500

This chapter tells you how to install and wire the Series 1500. There are also some

suggestions for sensor installation.

guidelines before making your panel cutout.

Sensor Installation Guidelines

Temp-RH

In this 1500 configuration, a dry bulb RTD measures temperature on Channel 1. A

wet bulb RTD, in combination with the dry bulb RTD, senses relative humidity on

Channel 2. The 1500 calculates the temperature difference between the two bulbs to

determine percent relative humidity.

Temp-Temp

For Temp-Temp RTD operation, each dry bulb RTD senses temperature for its

channel.

Also, be sure to look at the noise reduction

RTDs

The RTDs for the Series 1500 are customer-supplied items. They may be Gordon

Part #S001-0133-0000, which is a wire-wound RTD inside a sealed, 18% NickelSilver sheath, made for fast temperature response. The detector element is platinum

wire 100Ω at 0°C with a temperature coefficient of 0.003916Ω/Ω/°C. The sheath is

0.1875 in. (5 mm) diameter, 2.75 in. (70 mm) long. The three wire leads are 48 in.

(1219 mm) long and teflon insulated.

Contact Gordon at:

5710 Kenosha St., Box 500

Richmond, IL 60071

Phone: 815/678-2211

Excessive lead length in a two-wire RTD sensor can create indication errors. To

combat this, use a three wire sensor in long lead applications.

RTD - The Dry Bulb Installation

We suggest you mount the dry bulb RTD at a location in your process or system

where it reads an average temperature. Air flow past this sensor should be moderate. The sensor should be thermally insulated from the sensor mounting.

RTD - The Wet Bulb Installation

One way to prepare the RTD wet bulb sensor for reading relative humidity on Channel 2 is to slip a cotton wick over the sensor sheath, Watlow Part # 0830-0111-0000

or an equivalent. Put one end of the wick in water. Some systems use a small

trough of water with a float valve to replenish the evaporating liquid.

26 WATLOW Series 1500 User's Manual

Installation - Wiring, Chapter 3

Installation-Wiring

Use distilled water to avoid mineral deposits on the wick that can change the %RH

reading. The wicking distance should be as short as practical. The cotton wick must

be free of any sizing and starch. The "float valve-trough" systems should also remove the water when the ambient temperature goes below freezing or above boiling.

To obtain valid %RH readings, air flow past the %RH sensor must be sufficient to

evaporate the maximum amount of water from the wick without drying it out. Evaporation cools the sensor; the amount of cooling relates directly to the relative humidity

present.

Thermally insulate the wet bulb sensor from the sensor mounting. This prevents

mounting surface heat from flowing into the sensor sheath and changing the wet bulb

temperature. (The result of such heat flow will be a humidity reading higher than

actual.)

Thermocouple Installation Guidelines

Locate the thermocouples in your process or system where they read average temperatures. Air flow past these sensors should be moderate. The sensors must be

thermally insulated from the sensor mounting. Both thermocouples must be un-

grounded to obtain correct readings.

Wiring Practices for Preventing Noise

Most noise problems stem from wiring practices, the major means of coupling noise

from its sources to the control circuit.

An outstanding information resource for wiring guidelines is the IEEE Standard No.

518-1982 and is available from IEEE, Inc. 345 East 47th Street, New York, NY

10017.

Noise Sources

• Switches and relay contacts operating inductive loads such as motors, coils,

solenoids, and relays, etc.

• Thyristors or other semiconductor devices which are not zero crossover-fired

(randomly-fired or phase angle-fired devices).

• All welding machinery.

• Heavy current carrying conductors.

• Fluorescent and neon lights.

How to Decrease Noise Sensitivity

1. Our extensive noise testing has shown that the Series 1500 has a good level

of noise immunity. In extremely noisy environments, however, the testing has

shown that the most effective RFI techniques are:

a. An RFI filter (such as the Corcom 1ER1) in the power line mounted exter-

nal to the Series 1500 case. The RFI filter should be an RFI sealed type.

b. Shielded power cord with the shield terminated to the Series 1500 case

Installation - Wiring, Chapter 3

WATLOW Series 1500 User's Manual 27

Loading...

Loading...