Watlow Electric 146 User Manual

1 ■ Watlow Series 146 User’s Manual

Series 146

User’s Manual

Temperature Regulator

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507, Internet: http://www.watlow.com

$5.00 Made in the U.S.A.

0600-0004-0010 Rev D

December 2001

Supersedes: 0600-0004-0010 Rev C

(2089)

Control Mode

• High or low limit, factory selectable

• Manual or automatic reset on power loss, factory selectable

• Latching alarm with manual reset on over or under temperature

• Internal and/or customer supplied external reset switch

Operator Interface

• LED indication of output status

• Dial scale calibrated to compensate for sensor

non-linearities

• Integral or remote set point

• Dual temperature scale (°C and °F)

• Fixed set point

• Manufactured to specified value

Input

• Thermocouple or platinum RTD available

• Thermocouple with automatic cold junction compensation

• Thermocouple may be isolated or grounded

• Thermocouple and RTD break protection de-energizes output

• 2- or 3-wire RTD input, 100Ω @ 0°C calibrated for 0.003850Ω/Ω

°C curve

Output

• Electromechanical relay, 8A, Form C, SPDT: 8A @ 240VÅ resistive, 8A @ 28VÎ (dc) resistive, 275VA pilot duty rated

Accuracy

Adjustable Set Point, integral or remote

• Calibration accuracy: ±1% of span, at 25°C ± 3°C (77°F ±5°F)

ambient and rated line voltage ± 1%

• Set point accuracy: ±3% of dial scale

• Accuracy span: 540°C (1000°F) minimum

Fixed Set Point

• Calibration accuracy: ±6°C/±10°F of setting, at 25°C ±3°C (77°F

±5°F) ambient and rated line voltage ±1%

Temperature Stability

• Thermocouple: Typically 9µV/°C ambient (5µV/°F ambient) input

referenced

• RTD: Typically 0.2°C/°C ambient (0.2°F/°F ambient)

Voltage Stability

• ±0.01% of span (min. span of 540°C or 1000°F) per % of rated

line voltage

Agency Approvals

• CE: EN61010 - Safety

EN61326 - Industrial Immunity, Class B Emissions

Installation Category 2, Pollution Degree 2

• 873, File #E43684

• to C22.2 No. 24, File #E43684

• Approved for use in commercial cooking applications

• FM Class 3545, File J.I. 3007307

Terminals

• Captive screw, cage clamp connection, 4 mm (0.155 in.) max.

width screwdriver blade, 30 to 14-gauge wire

Mounting

• DIN rail, DIN EN50022, 35 mm x 7.5 mm

• Sub-panel flush mounting

Power

• 24V~, +10%/-15%, 50/60 Hz

• 120V~, +10%/-15%, 50/60 Hz

• 230V~ to 240~, +10%/-15%, 50/60 Hz

• 10VA maximum power

Operating Environment

• 0 to 55°C (32 to 131°F)

• 0 to 90% RH, non-condensing

• Storage temperature: -20 to 85°C (-4 to 185°F)

Dimensions

• Width: 60 mm (2.28 in)

• Height: 115 mm (4.45 in)

• Depth: 100 mm (3.89 in)

Weight

• 0.3kg (0.7 lb.)

UL®is a registered trademark of Underwriter’s Laboratories, Inc.

Note: Specifications subject to change without notice.

Specifications

The Watlow Series 146 is a DIN rail mount, temperature regulating controller with a thermocouple or RTD

sensor input. The DIN rail mounting offers quick and easy

installation with the use of simple hand tools. The controller may also be flush mounted.

The Series 146 is designed to meet the needs of a

wide range of safety applications. Factory selectable

options include high or low control mode with either

manual or automatic reset on power loss.

The Series 146 has an LED for output status

indication and can be ordered with an integral or remote

adjustable set point, or a fixed set point.

General Description

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

Registered Company

Winona, Minnesota USA

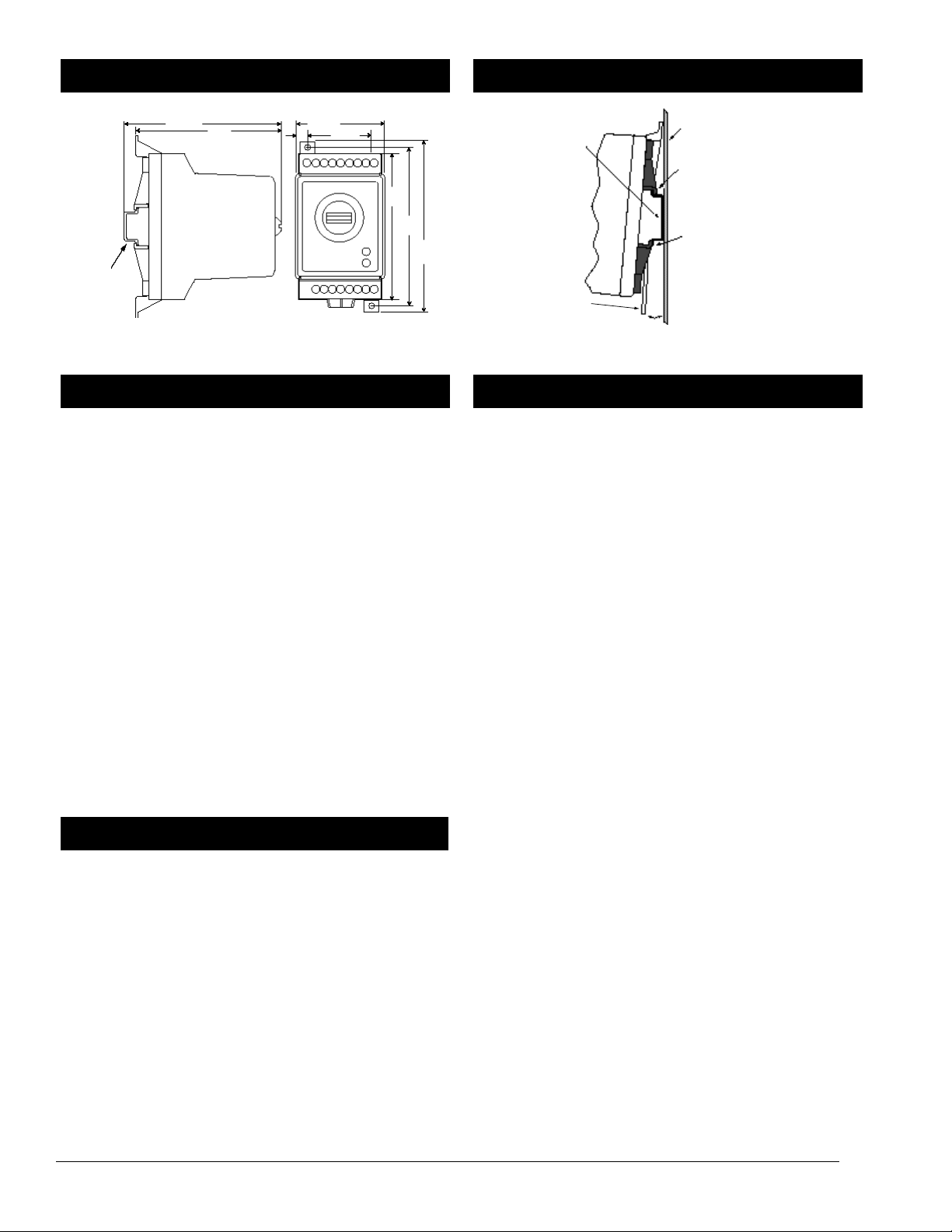

Figure 2a — Series 146 dimensions.

Sub-Panel Mounting the Series 146

NOTE: FM approval requires limit switches to be suitably enclosed

to minimize casual readjustment of set temperature.

1. Using the controller as a location template, mark both

mounting holes.

2. Drill two 5 mm (0.19 in.) diameter holes in the desired

panel location. See Figure 2a for hole locations.

3. Mount the Series 146 using two #8-32 screws.

DIN Rail Mounting the Series 146

1. Place the Series 146 upper mounting clip on the top edge

of the DIN rail. See Figure 2b on this page.

2. Press down firmly on the top front edge of the Series

146. The controller “snaps” securely onto the rail. If the

controller does not snap on, check to see if the DIN rail

is bent. Minimum clipping distance is 34.8 mm (1.37 in.),

the maximum is 35.3 mm (1.39 in.).

Removing the Series 146 from the DIN Rail

1. Place your fingers on the release lever located at the

base of the Series 146.

2. While gently pressing on the top of the case, above

Terminals 1-9, pull forward on the release lever.

Note, caution and warning symbols appear throughout this

book to draw your attention to important operational and

safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is

important for protecting your equipment and performance.

A “WARNING” safety alert appears with information that is

important for protecting you, others and equipment from

damage. Pay very close attention to all warnings that apply

to your application.

The ç symbol (an exclamation point in a triangle) precedes

a general CAUTION or WARNING statement.

The Ó symbol (a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety

statement.

Figure 2b — Series 146 side view mounting.

• Use the correct sensor type per the model number on the

unit sticker.

• Use the proper thermocouple or RTD polarity.

• Insulate the thermocouple mounting from the mounting

surface to prevent heat migration input errors.

• Thermocouple leads should be twisted pair wire and

routed separately from any other lines.

• In electrically noisy environments (heavy switching of

contactor, motors, solenoids, etc.) use shielded thermocouple lead wire with the shield connected at the sensor end

only.

• All wiring and fusing must conform to the National

Electric Code (NEC) NFPA70 and any other locally applicable codes.

• Fuse the independent load voltage on the L1 (hot) side

and connect it to the common (COM) side of the relay.

ç

CAUTION: A power disconnect located near the controller is

recommended to shut down power in case of controller failure.

• Long lead lengths create electrical resistance. When using

a two wire RTD, there will be an additional error for

every 1Ω of lead length resistance. That resistance when

added to the resistance of the RTD element, can result in

erroneous input to the temperature limit. To overcome

this problem, use a three wire RTD sensor, which compensates for lead length resistance. When extension wire is

used for a three wire RTD, all three extension wires must

have the same electrical resistance. (i.e. same gauge,

copper stranded.

Wiring Guidelines

Mounting

Safety Information

Installation

Dimensions

2 ■ Watlow Series 146 User’s Manual

58 mm

(2.28 in.)

41 mm

(1.62 in.)

96 mm

(3.75 in.)

104 mm

(4.10 in.)

113 mm

(4.45 in.)

35 mm x 7.5 mm

Rail is not

included in

the assembly

99 mm

(3.89 in.)

95 mm

(3.72 in.)

Panel

DIN Rail

Upper Mounting Clip

Lower Mounting Clip

Release Lever

Snap Action

Loading...

Loading...