Watlow Electric 142 User Manual

Series 142

User’s Manual

Safety High Limit or

On-Off Heat Controller

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507,

Internet: http://www.watlow.com

The Watlow Series 142 Safety Limit is a compact,

environmentally protected safety limit or temperature

controller. The limit has a single thermocouple input and

is available in several common ranges.

The Series 142 Safety Limit has a single mechanical

relay output, and operates as a high limit, latching control

with manual and/or auto-power reset. Fixed set points are

available.

The Series 142 Safety Limit controller is ideally

suited for limit applications requiring tamper-proof operation, agency approvals and immunity to hostile environments.

• The factory-fixed set point cannot be altered by operator

action or neglect.

• Agency approvals ensure compliance with recognized

standards.

• Epoxy potting makes the Series 142 resistant to envi-

ronments with vibration or humid/corrosive conditions.

Compact size and sub-panel mounting make the

Series 142 readily adaptable to many applications. Its

single, factory-fixed set point thermocouple input and

Form C, 3 amp electromechanical relay output provides

simplicity and reliability for many applications. Sensor

break protection ensures fail-safe process shut down upon

input failure.

We use note, caution and warning symbols throughout this manual to draw your attention to important operational and safety information.

A “NOTE” marks a short message to alert you to an

important detail.

A “CAUTION” safety alert appears with information

that is important for protecting your equipment and performance. Be especially careful to read and follow all

cautions that apply to your application.

A “WARNING” safety alert appears with information

that is important for protecting you, others and equipment

from damage. Pay very close attention to all warnings that

apply to your application.

The safety alert symbol, ç, (an exclamation point in

a triangle) precedes a general CAUTION or WARNING

statement.

The electrical hazard symbol, Ó, (a lightning bolt in a

triangle) precedes an electric shock hazard CAUTION or

WARNING safety statement.

Safety Information

General Description

0600-0023-0000 Rev E

March 2002

Supersedes

0600-0023-0000 Rev D

$5.00

Made in the U.S.A.

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

2 ■ User’s Manual Watlow Series 142

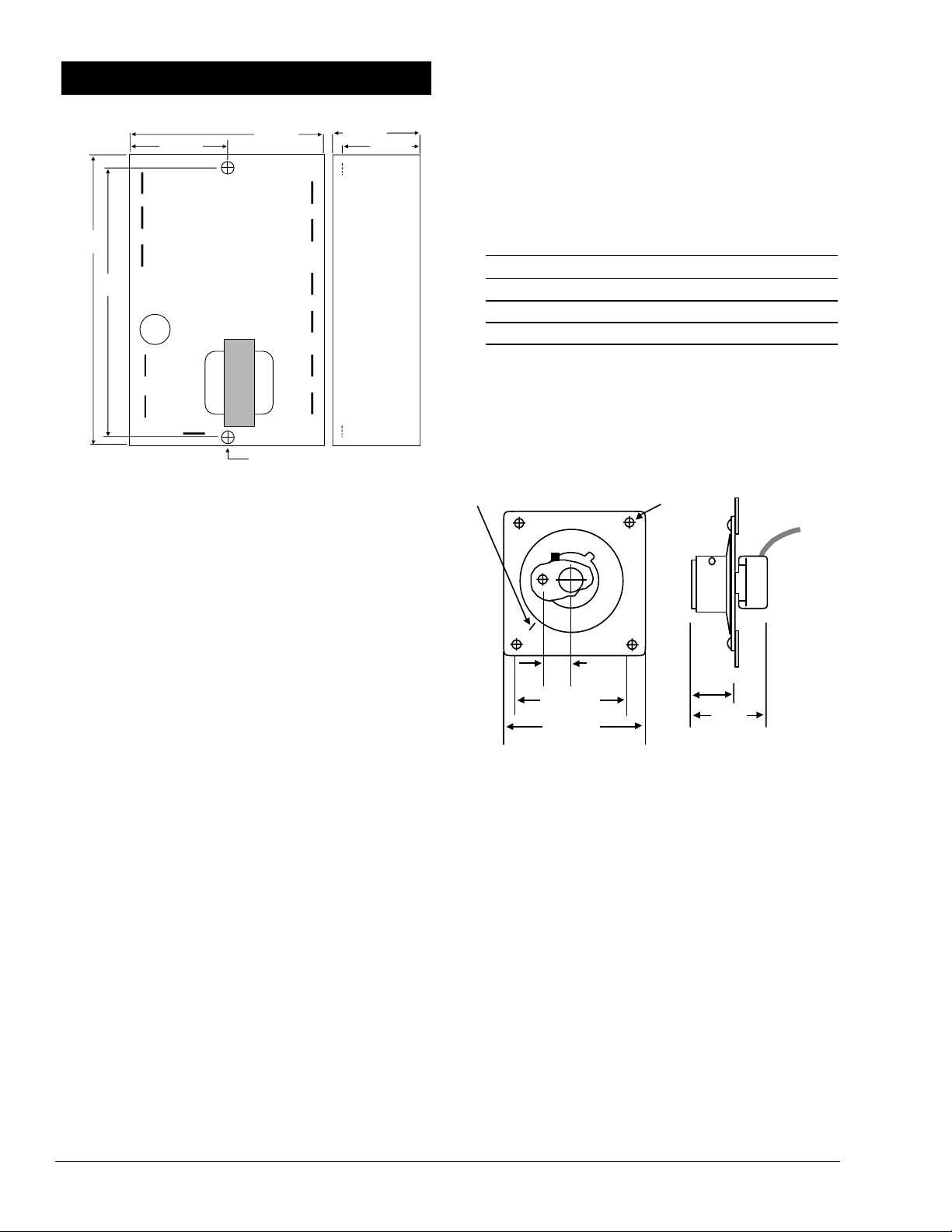

Figure 2a — Series 142 dimensions.

Installation Procedure

1. Drill two 5mm (0.187 in.) diameter holes in the desired

panel location.

2. Mount the unit with two 6-32 screws, 6mm (0.25 in.) hex

nut and #6 internal tooth lock washer.

3. Use the correct thermocouple type per the model number on the unit sticker. See the side of the case.

• Use correct thermocouple polarity. Red is negative.

• Insulate the thermocouple mounting from the mount-

ing surface to prevent heat migration input errors.

• Thermocouple leads should be twisted pair wire and

routed separately from any other lines.

• In electrically-noisy environments (heavy switching

contactors, motors, solenoids, etc.), use shielded thermocouple lead wire with the shield connected at the

sensor end only.

• Use a separate thermocouple to maintain the limit

function of this controller; do not parallel thermocouple input from the primary

controller.

4. All wiring and fusing must conform to the National

Electric Code (NEC) NFPA70 and any other locally

applicable codes.

5. Fuse the independent load voltage on the L1 (hot) side

and connect it to the common (C) side of the relay.

NOTE: For applications where the CE mark is required, all quick

connect and spade terminals must be pre-insulated to meet IEC

730 specifications.

Units With Remote Setpot Assembly

1. Drill two 51mm (2.0 in.) diameter holes in the desired

remote setpot assembly location. See Figure 2b.

2. Using the dial scale as a location template, center and

mark all four mounting holes on the dial scale with a

center punch.

3. For bolted dial scale assembly, drill four 3mm (0.125 in.)

diameter clearance holes. If you are using a screw

assembly, use a tap drill. Tap drill sizes used are:

Tap Drill Size Screw/Thread Size

#44 - 2mm dia. (0.086 in.) #4.36

#43 - 2mm dia. (0.089 in.) #4.40

#42 - 2mm dia. (0.093 in.) #4.48

4. Drill four 5mm (0.189 in.) diameter holes in desired

panel location. See Figure 2b.

5. Mount the Series 142 with four screws.

6. Connect sensor, load and remote setpot assembly per

Wiring Diagram. See the wiring pages.

Figure 2b — Setpot dimensions and mechanical zero

location.

Dial Scale Alignment to Mechanical Zero

1. Turn the dial scale knob completely counterclockwise (to

mechanical zero).

2. If the “Indicator” line on the setpot knob skirt, and

“Mechanical Zero” (represented by a small line beyond

the low end of the scale) are not aligned, loosen both set

screws on the setpot knob, and rotate the knob until

both lines meet.

3. Tighten both set screws.

(1.38 in.)

Installation

103mm

(

4.05 in.

)

89mm

3.50 in.

)

(

Use a 6mm (0.25 in.) hex nut

for proper clearance.

35mm

Two 5mm (0.187 in.) dia.

70mm

(2.76 in.)

mounting holes

35mm

(

1.38 in.

)

29mm.

(1.13 in)

13mm

4 mounting holes

23mm

(0.9 in.)

43mm.

(1.72 in)

Mechanical Zero

(2.69 in. sq.)

(3.00 in. sq.)

(0.53 in.)

68mm

76mm

Watlow Series 142 User’s Manual ■ 3

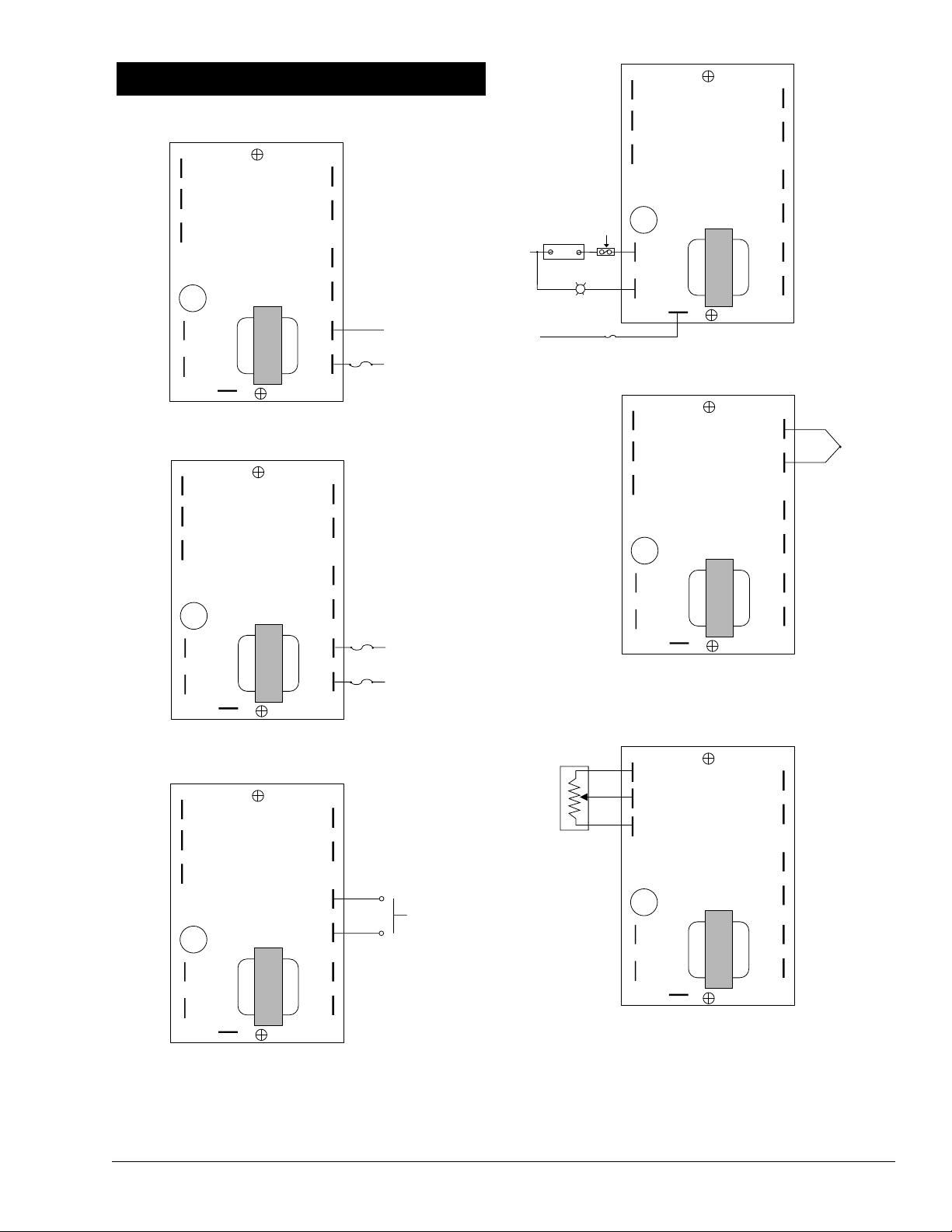

NOTE: All terminals are 4mm (1/4 in.) quick connects.

Figure 3a — 120V~ power wiring (142A - _ _ _ _ - 1 _ 00).

Figure 3b — 208/240V~ power wiring

(142A - _ _ _ _ - 2 _ 00).

Figure 3c — Reset switch.

NOTE: Jumpering the reset terminals does not convert from limit

to an on-off control mode.

Figure 3d — 3A mechanical relay wiring.

Figure 3e — Thermocouple wiring.

NOTE: Extension wire for thermocouples must be of the same alloy

as the thermocouple itself to limit errors.

Figure 3f — Remote setpot (142A - 2 _ _ _ - _ _ 00).

Remote Setpot

Green

Black

Red

P3

P2

P1

N.O.

N.C.

Reset

L2

L1

COM

Thermocouple +

Thermocouple -

P3

P2

P1

N.O.

N.C.

Reset

L2

L1

Red

COM

Thermocouple +

Thermocouple -

P3

P2

P1

N.O.

N.C.

Reset

L2

L1

Temperature

Control Output

Fuse

L1

External

Load

L2

COM

Thermocouple +

Thermocouple -

P3

P2

P1

N.O.

N.C.

Reset

L2

L1

Customer Supplied

N.O. Momentary Switch

COM

Thermocouple +

Thermocouple -

P3

P2

P1

N.O.

N.C.

Reset

L2

L1

Fuses

208/240V~

COM

Thermocouple +

Thermocouple -

P3

P2

P1

N.O.

N.C.

Thermocouple +

Thermocouple -

Reset

L2

L1

120V~

Fuse

COM

Neutral

Hot

Wiring

Loading...

Loading...