Page 1

W A T L O W

63

Thermocouples

Mineral Insulated

Watlow’s mineral insulated thermocouples are fast-responding,

durable, and capable of handling

high temperatures.

These thermocouples are manufactured with best-in-class

XACTPAK®, Watlow’s trademark for

metal sheathed, mineral insulated

(MI) thermocouple material.

XACTPAK responds fast because the

protective metal outer sheath allows

the use of smaller diameter

thermocouple conductors. The rock

hard compacted MgO insulation

further enhances the sensor’s ability

to “read” temperature by transferring

heat quickly to the measuring

junction.

The XACTPAK protecting sheath and

compacted insulation outperforms

bare wire thermocouples in most

applications.

Performance Capabilities

• Easily handles temperatures up

to 1200°C (2200°F)

• Meets or exceeds initial calibration

tolerances per ASTM E 230

Features and Benefits

Special mineral insulation

• Protects thermocouple from

moisture and thermal shock

• Permits operation in high

temperature, high pressure

environments

Diameters as small as 0.010 in.

(0.25 mm)

• Ideal when physical space or

extremely fast response are

critical

Flexibility of the XACTPAK

material

• Allows you to form and bend the

thermocouple, without risk of

cracking, to meet your design

requirements

Outer sheath

• Protects the wires from oxidation

and hostile environments

Wide range of sheath materials,

diameters, and calibrations

• Meet specific requirements

In-house manufacturing of

XACTPAK material

• Rigid quality control procedures

• Assures high standards are met

• Single source reliability

Custom capabilities

• Include options such as special

lead lengths, lead wires and

terminations

Applications

• Heat treating

• Furnaces/kilns

• Turbines

• Bearing temperature

• Power stations

• Steam generators

• Diesel engines

• Nuclear reactors

• Atomic research

• Jet engines and test cells

• Rocket engines

• Semiconductor manufacturing

• Refineries/oil processing

• Catalytic reformers

• Food processing

Thermocouples

Page 2

72

3. Sheath O.D. (inch)

J = 0.250

4. Connection Head

C = Polypropylene (

1

⁄2 inch NPT thermocouple

opening only)

D = Small cast iron

E = Small aluminum

H = Explosion proof (1⁄2 inch NPT and 3⁄4 inch NPT

thermocouple opening only)

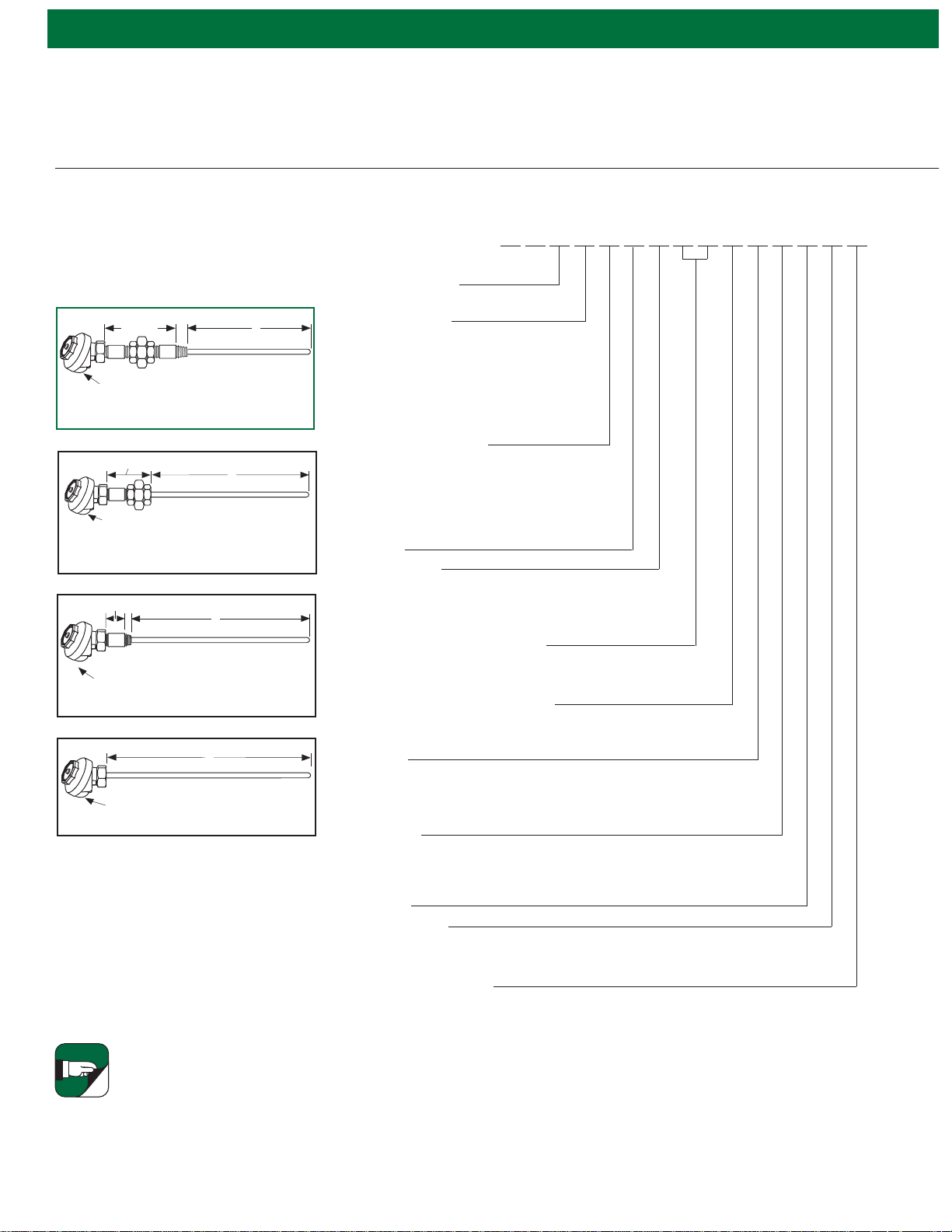

5. Cold End Configuration

1 = Type 1, six inch nipple-union-nipple

2 = Type 2, four inch nipple-union

3 = Type 3, three inch nipple

4 = Type 4, no extensions

Note: Steel nipple and unions are standard.

6. Enter “0”

7. Sheath Material

A = 304 SS

F = 316 SS

Q = Alloy 600 (Type K)

8-9. Sheath Length “L” (whole inch)

Available lengths: 01 to 99, over 99 consult factory

10. Sheath Length “L” (fractional inch)

0 = Not required, complete assembly

1=

1

⁄8 3=3⁄8 5=5⁄8 7=7⁄8

2=1⁄4 4=1⁄2 6=3⁄4

11. Junction

Grounded Ungrounded

Single GU

Dual, isolated — W

12. Calibration

EJKNT

Standard limits E JKNT

Special limits 2 3 4 — 8

13. Enter “0”

14. Spring-Loading

Y = Yes

N=No

15. Special Requirements

0 = None

X = Special requirements, consult factory

AT 00

123456789101112131415

Thermocouples

Mineral Insulated

For Use With Thermowells

Style AT

Note: For a complete sensor, add thermowell

part number to the 15-digit AT part number.

For sheath length use “AR” (as required) and

factory will determine correct length.

See thermowell section, pages 144 to 146.

See the hardware section,

pages 156 to 157, for a

complete description of

Watlow connection heads.

Custom Ordering Information—Items in Bolded Green Type are preferred

with shorter lead times.

J

6 inch N-U-N Typical (2 each 1⁄2 x 3 inch steel

pipe nipples and 1 each malleable union)

4 inch N-U typical (1 each

1

⁄2 x 3 inch steel pipe

nipple and 1 each malleable union)

3

/4

in. (19 mm) NPT

Nom. 4 in. (152.4 mm)

L

1

⁄2 X 3 inch long steel pipe nipple typical

3

/4

in. (19 mm)

NPT

Nom. 2 in. (50.8 mm)

L

3

/4

in. (19 mm)

NPT

L

3

/4

in. (19 mm) NPT

Nom. 6 in.

(152.4 mm)

L

Type 1

Type 2

Type 3

Type 4

Page 3

W A T L O W

73

Thermocouples

Thermocouples

Mineral Insulated

Style AT With Thermowells

1.75 in.

(44 mm)

ìU

”

6 in.

(152 mm)

Overall Length

7.75 in. + “U”

3

/4 in. NPT

“U” Overall Length

Calibration in. (mm) in. (mm) Part Number

J

2.5 (64) 10.25 261 ATJE1SF024UJ0Y0

4.5 (114) 12.25 312 ATJE1SF044UJ0Y0

7.5 (191) 15.25 388 ATJE1SF074UJ0Y0

10.5 (267) 18.25 465 ATJE1SF104UJ0Y0

K

2.5 (64) 10.25 261 ATJE1SF024UK0Y0

4.5 (114) 12.25 312 ATJE1SF044UK0Y0

7.5 (191) 15.25 388 ATJE1SF074UK0Y0

10.5 (267) 18.25 465 ATJE1SF104UK0Y0

1.75 in.

(44 mm)

“U”

6 in.

(152 mm)

3

/4 in. NPT

Overall Length

7.75 in. + “U”

J

2.5 (64) 10.25 261 ATJE1TF024UJ0Y0

4.5 (114) 12.25 312 ATJE1TF044UJ0Y0

7.5 (191) 15.25 388 ATJE1TF074UJ0Y0

10. 5 (267) 18.25 465 ATJE1TF104UJ0Y0

K

2.5 (64) 10.25 261 ATJE1TF024UK0Y0

4.5 (114) 12.25 312 ATJE1TF044UK0Y0

7.5 (191) 15.25 388 ATJE1TF074UK0Y0

10.5 (267) 18.25 465 ATJE1TF104UK0Y0

Straight Well

Tapered Well

Rapid Ship sensors come with 316 SS straight well, nipple-union-nipple, 0.250 inch diameter

spring loaded element, small aluminum connection head and ungrounded junction.

Rapid Ship sensors come with 316 SS tapered well, nipple-union-nipple, 0.250 inch diameter

spring loaded element, small aluminum connection head and ungrounded junction.

Rapid Ship Sensors

Rapid Ship Sensors

“U” Overall Length

Calibration in. (mm) in. (mm) Part Number

Loading...

Loading...