Page 1

Tubular and

Process Assemblies

WATROD Heating

Elements

Multicoil Single- or DoubleEnded Elements

Watlow’s new tubular element with

multiple coils and/or thermocouples

inside one sheath answers the

need for a versatile, innovative

tubular heater. Our new, patentpending method of packaging a

thermocouple inside of a heater

with one or more resistance coils,

gives the ability to sense a heaters’

internal temperature accurately,

every time.

Moreover, this is the first tubular

heater in the industry with threephase capability. The three coil,

three-phase heater will offer a lower

amperage solution while delivering

the full power required in a

compact heater package.

Previously three separate heaters

would have been required to do the

same job; therefore Watlow’s new

multicoil heater capabilities save

money.

Watlow has the capability to put up

to two coils in a 0.375 or 0.430

diameter heater and up to three

coils in a 0.475 or 0.490 diameter

heater. Any one or more of these

coils can be a resistance wire or a

thermocouple. The bending

formations are virtually limitless;

while mounting options are similar to

other Watlow tubular heaters. The

three-phase multicoil heaters can be

single ended with three leads for

three-phase wye hook up. Watlow

recommends using an epoxy

moisture seal or silicone-based seal.

Watlow’s multicoil heaters are

available in all standard materials

such as Incoloy

stainless steel, and can be formed

into almost any configuration. Our

five thermocouple and/or coil

options for multicoil tubular

configurations will meet most

requirements; however, we are

always interested in discussing the

use of different materials or

changing the number of coils and

thermocouples.

®

, 304 and 316

Features and Benefits

• Three-phase capability results

in one element versus three,

lower amperage, reduced installation time and lower overall cost.

• Internal thermocouple allows

responsive and accurate, internal, high-limit sensing and

reduced assembly costs.

• Single ended allows for mount-

ing in a

fitting with three-phase capability.

• Multiple coil options reduce

inventory by allowing dual

voltage capability.

• Versatile forming capabilities

can be formed into virtually any

configuration.

• Internal construction allows

space savings because drilling

and tapping of flange is

unnecessary; plus, the interior

thermocouple eliminates

contamination buildup around the

external sensing tip, reducing the

possibility of false readings.

Applications

• Foodservice

• Process

• Medical

• Milled groove

• Plastics

• Plating

• Oven heating

• Semiconductor

1

inch NPT or

⁄2

3

inch NPT

⁄4

276

Page 2

W A T L O W

Tubular and

Process Assemblies

WATROD Heating

Elements

Multicoil Single- or DoubleEnded Elements

Continued

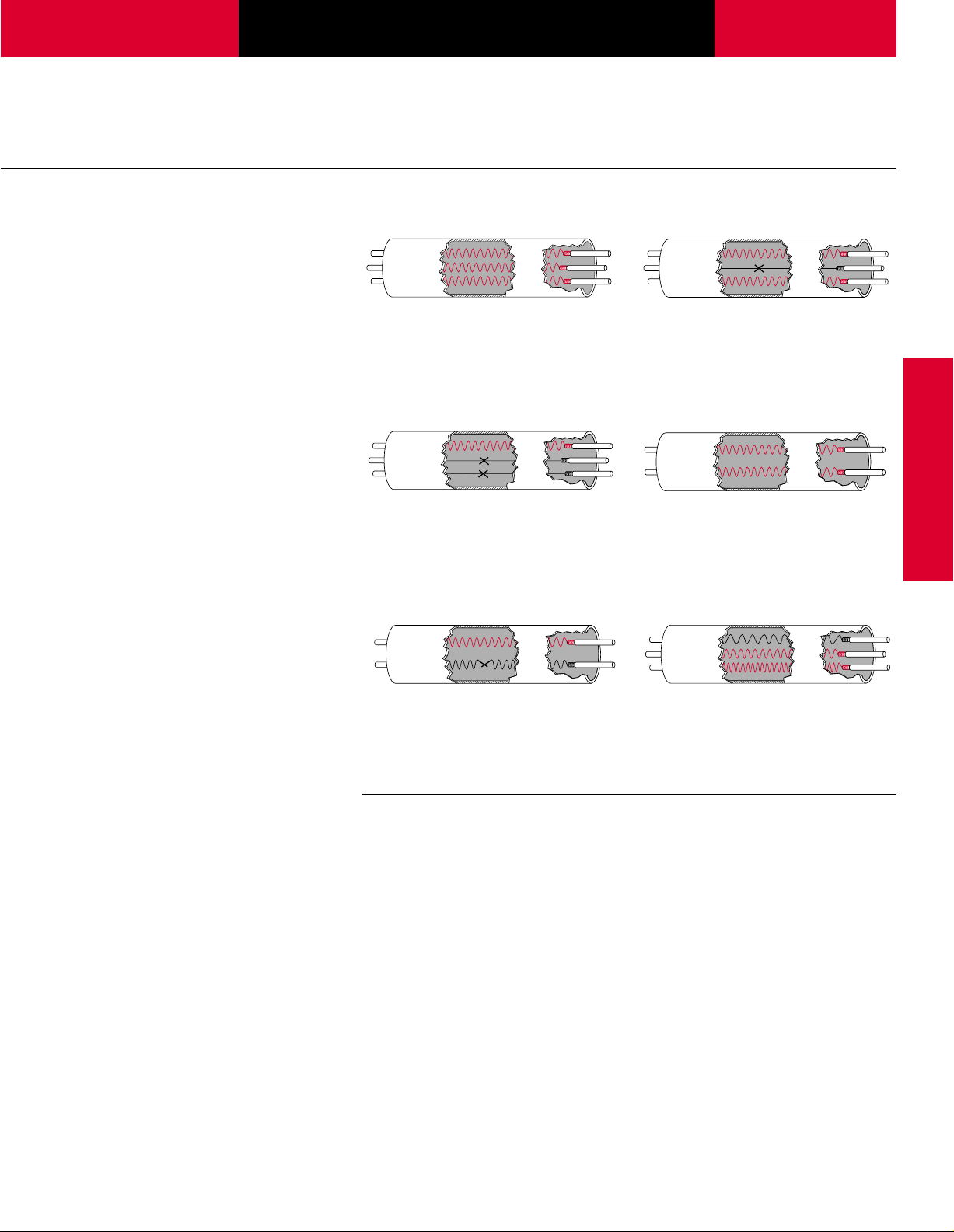

Options

Option A

3-phase tubular, 0.475 and 0.490

inch diameter.

Option C

1-phase tubular with one resistance

wire and two thermocouples, 0.475

and 0.490 inch diameter.

Option E

Option B

1-phase tubular with two resistance

wires and one thermocouple, 0.475

and 0.490 inch diameter.

Option D

1-phase tubular with three different

one phase circuits, 0.475 and 0.490

inch diameter

Option F

.

WATROD

Sil-A-Blend™is a trademark of Radix Wire

Company.

1-phase tubular with two resistance

coils, 0.375, 0.430, 0.475 and 0.490

inch diameter.

Specifications

Termination style is currently

limited to lead wires 392°F (200˚C)

Sil-A-Blend

Moisture seals are required,

options include:

• Standard epoxy with temperature

rating to 266˚F (130°C). Typical

applications include water/oil

immersion.

• Lavacone with temperature rating

to 300˚F (148.9°C). Typical

application includes air heating.

• High-temp ceramic rated to

2800˚F (1537.8°C).

• Consult factory for other moisture

seal options.

• ULTRAGARD with temperature

rating to 700˚F (375˚C).

™

or 482°F (250˚C) GGS.

1-phase tubular with one resistance

coil and one thermocouple, 0.375,

0.430, 0.475 and 0.490 inch

diameter.

Mounting options include:

• Mounting brackets

• Locator washers

• Mounting collars

• Water-tight bulkheads

Maximum trim length is 237 inches

(6020 mm). Heater designs with trim

length greater than 120 inches

(3048 mm) must be reviewed with

factory.

®

Sheath materials: Incoloy

and 316 stainless steel, consult

factory for other sheath material

options.

Internal thermocouple options:

Type K is used, consult factor y for

Type J ther mocouple options.

U.S. Patent Pending

, 304

277

Page 3

Tubular and

Process Assemblies

WATROD Heating

Elements

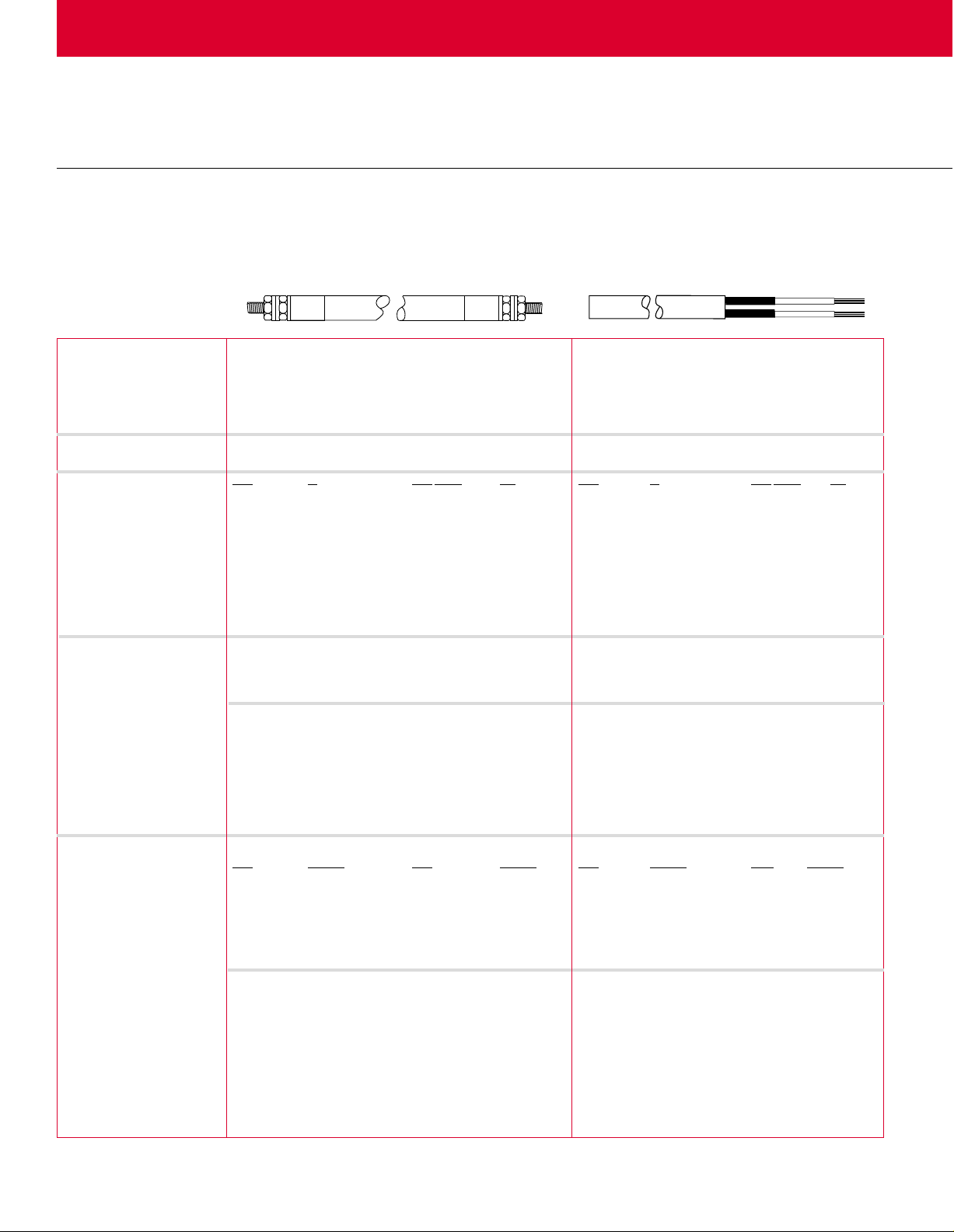

Specifications

Double-Ended Single-Ended

Applications Direct immersion Vacuums Platens

Hot runner mold (manifold) Semiconductor Forced air

Forced air Deicing antennas

Ovens Plastic wrap cutting

Radiant Seal bars

Clamp-on

Watt Density Stock: up to 60 (9.3) Stock: up to 20 (3.1)

2

W/in

(W/cm2) Made-to-Order (M-t-O): up to 120 (18.6) M-t-O: up to 45 (6.9)

Element Diameters Dia.

inch (mm) 0.210 0.660 (5.3) (4.26) 0.375 1.178 (9.5) (7.600)

and Surface Area per Linear 0.260 0.817 (6.6) (5.27) 0.430 1.351 (10.9) (8.717)

inch (cm) 0.315 0.990 (8.0) (6.38) 0.475 1.492 (12.0) (9.626)

Diameter Tolerance 0.332 1.043 (8.4) (6.73) 0.490 1.539 (12.4) (9.930)

± 0.005 inch (0.13 mm) 0.375 1.178 (9.5) (7.60) 0.625 1.963 (15.9) (12.665)

0.430 1.351 (10.9) (8.72)

0.475 1.492 (12.0) (9.63)

0.490 1.539 (12.4) (9.93)

0.625 1.963 (15.9) (12.66)

Sheath Materials Stock: Incoloy

Maximum Operating 316 stainless steel 1200°F (650°C)

Temperature Steel 750°F (400°C)

M-t-O: Inconel

Sheath Length By Diameter

inch (mm) Dia.

Stock: Stock:

0.260 20 to 80 (6.6) (510 to 2030) 0.375 15 to 40 (9.5) (380 to 1015)

0.315 12 to 100 (8.0) (305 to 2540)

0.375 11 to 180 (9.5) (275 to 4555)

0.430 15 to 120 (10.9) (380 to 3050)

0.475 20 to 157 (12.0) (510 to 3990)

M-t-O: M-t-O:

0.210 9 to 130 (5.3) (230 to 3300) 0.375 11 to 125 (9.5) (280 to 3175)

0.260 9 to 275 (6.6) (230 to 6980) 0.430 11 to 106 (10.9) (280 to 2690)

0.315 9 to 270 (8.0) (230 to 6850) 0.475 11 to 125 (12.0) (280 to 3175)

0.332 9 to 125 (8.5) (230 to 3170) 0.490 11 to 125 (12.4) (280 to 3175)

0.375 11 to 325 (9.5) (280 to 8255) 0.625 11 to 125 (15.9) (280 to 3175)

0.430 11 to 268 (10.9) (280 to 6810)

0.475 11 to 275 (12.0) (280 to 6985)

0.490 11 to 275 (12.4) (280 to 6985)

0.625 11 to 275 (15.9) (280 to 6985)

2

in

®

Copper 350°F (175°C)

®

600 1800°F (980°C) M-t-O: Incoloy

®

Incoloy

316 stainless steel 1200°F (650°C) 304 stainless steel 1200°F (650°C)

304 stainless steel 1200°F (650°C) Steel 750°F (400°C)

Steel 750°F (400°C)

Copper 350°F (175°C)

®

Monel

Titanium Consult Factory

Sheath Sheath Sheath Sheath

Length Dia. Length Dia. Length Dia. Length

Dia. (mm) cm

1600°F (870°C) Stock: Incoloy

1600°F (870°C) 316 stainless steel 1200°F (650°C)

Consult Factory

2

Dia. in

2

®

®

Dia. (mm) cm

1200°F (650°C)

1600°F (870°C)

2

278

Page 4

W A T L O W

Tubular and

Process Assemblies

WATROD Heating

Elements

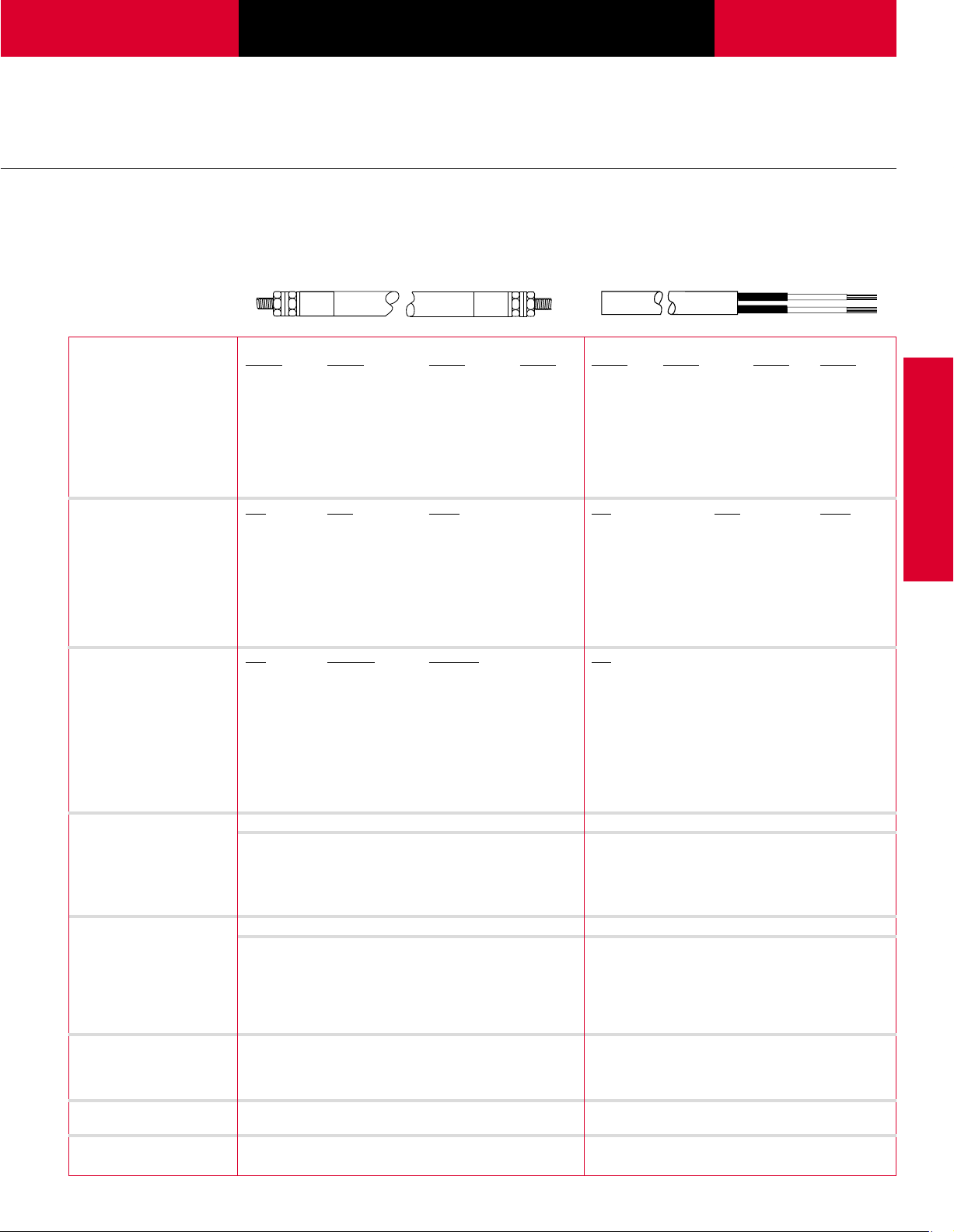

Specifications

Double-Ended Single-Ended

Minimum No-Heat Length Sheath No-Heat Sheath No-Heat Sheath No-Heat Sheath No-Heat

inch (mm) Length Length Length Length Length

11 to 20 1 (280 to 510) (25) 11 to 20 11⁄2 (280 to 5100) (38)

21 to 50 1

51 to 80 1

81 to 110 1

111 to 140 1

141 to 170 2 (3580 to 4320) (51)

171 to 200 2

201 & up 2

Maximum V oltage/Amperage

By Dia. 0.260 (6.6) 250VÅ(ac) 15 0.375 (9.5) 480VÅ(ac) 30

inch (mm) 0.315 (8.0) 480VÅ(ac) 30 0.430 (10.9) 480VÅ(ac) 30

Ohms Per Heated Inch Dia.

By Dia. 0.210 0.100Ω 16Ω

inch 0.260 0.080Ω 25Ω 0.375 0.200Ω 34Ω

Terminations Stock: Threaded stud Stock: Flexible lead wires

Seals Stock: Silicone resin 390°F (200°C) Stock: Silicone resin 390°F (200°C)

Mounting Options Threaded bulkheads Threaded bulkhead

Surface Finish Options Belt polishing Bright Anneal Belt polishing Bright Anneal

Agency Recognition UL

Dia. Volts Amps Dia. Volts Amps

0.332 (8.5) 480VÅ(ac) 30 0.475 (12.0) 480VÅ(ac) 30

0.375 (9.5) 480VÅ(ac) 30 0.490 (12.4) 480VÅ(ac) 30

0.430 (10.9) 600VÅ(ac) 40 0.625 (15.9) 480VÅ(ac) 30

0.475 (12.0) 600VÅ(ac) 40

0.490 (12.4) 600VÅ(ac) 40

0.625 (15.9) 600VÅ(ac) 40

0.315 0.050Ω 25Ω 0.430 0.200Ω 34Ω

0.332 0.050Ω 23Ω 0.475 0.200Ω 34Ω

0.375 0.020Ω 18Ω 0.490 0.200Ω 34Ω

0.430 0.025Ω 30Ω 0.625 0.200Ω 34Ω

0.475 0.030Ω 30Ω

0.490 0.030Ω 30Ω

0.625 0.030Ω 25Ω

M-t-O: Threaded stud M-t-O: Flexible lead wires

M-t-O: Ceramic base 2800°F (1535°C) M-t-O: Silicone rubber

Mounting brackets Locator washers

Locator washers Mounting collars

Mounting collars

Passivation Passivation

®

Component to 480VÅ(ac) (file # E52951/E56488) UL®Component to 240VÅ(ac) (file # E52951)

CSA Component to 600VÅ(ac) (file # 31388) CSA Component to 240VÅ(ac) (file # 31388)

1

⁄4

1

⁄2 (1295 to 2030) (38) 51 to 80 21⁄8 (1295 to 2030) (54)

5

⁄8

3

⁄4 (2820 to 3555) (44) 111 to 125 25⁄8 (2820 to 3175) (67)

1

⁄4 (4345 to 5080) (57)

1

2 (5105 & up) (64)

⁄

Minimum Maximum Dia. Minimum Maximum

Screw lug (plate) Rubber overmolds

Quick connect (spade)

Flexible lead wires

Rubber overmolds

ULTRAGARD 700°F (375°C) ULTRAGARD 700°F (375°C)

Ceramic-to-metal 500°F (260°C) Silicone resin 392°F (200°C)

Silicone rubber

Silicone resin 392°F (200°C)

Epoxy resin 266/350°F (130/177°C)

(535 to 1270) (32) 21 to 50 1

(2055 to 2795) (42) 81 to 110 2

1

2 inch (13 mm) No-heat length on all blunt ends

⁄

(RTV)

500°F (260°C) Epoxy resin 266/350°F (130/177°C)

Length Length Length

3

⁄4

3

⁄8

(533 to 1270) (44)

(2055 to 2795) (60)

(RTV)

500˚F (260°C)

➀

WATROD

➀ Not applicable to 0.375 inch diameter single-ended WATROD

279

Page 5

Tubular and

1

/

8

"(3 mm)

Approx.

Sheath Diameter

A

B

C

Process Assemblies

WATROD Heating

Elements

Options

Moisture Resistant Seals

WATROD’s MgO insulating material

is hygroscopic. To prevent moisture

contamination from entering the

heater, an appropriate moisture seal

must be used. Choosing the correct

seal is important to the life and

the maximum continuous use

temperature is not exceeded at the

seal location. Most end seals are

applied with a small cavity in the

end of the heater. The seal will also

help prevent arcing at the terminal

ends.

performance of the heater. Be sure

End Seal Options

Code Seal UL

End Seal Number Color Depth Recognition Temperature Typical or General Usage/Application

Standard Epoxy EC Cream

Intermediate Epoxy EB Blue

High-Temp. Epoxy HTE Amber

Silicone Resin SR Clear

Silicone Fluid SF Clear N/A No 392°F (200°C) Moisture resistance of the MgO, or High-Temp.

Lavacone LC Dark Brown3⁄16" Yes 392°F (200°C) Porous seal for the FIREBAR

Silicone Rubber RTV RTV Red-Orange

ULTRAGARD UG Clear

High-Temp. Ceramic HTC White

3

⁄16" Yes 266°F (130°C) General purpose for moisture resistance

3

⁄16" Yes 350°F (177°C) Intermediate temp. rating for moisture resistance

3

⁄16" No 450°F (232°C) Higher temp. rating for moisture resistance

1

⁄16" Yes 392°F (200°C) General usage on tubular products

3

⁄16" Yes 500°F (260°C) General usage on FIREBAR applications

3

⁄16" Yes 700°F (350°C) High temp. around seal area and for

3

⁄16" No 2800°F (1538°C) Very high temperature applications

®

Max. Cont. Use

ceramic seal (storage only)

vacuum applications

Ceramic-to-Metal End Seal

External Finishes

Belt Polishing

Belt polishing sands the oxidized

sheath to a bright finish. This finish

is available only on alloy sheath

materials.

To order, specify belt polishing.

280

Sheath

Diameter A B C Thread

inch (mm) inch (mm) inch (mm) inch (mm) Size

0.260 (6.6) 1

0.315 (8) 1

0.430 (10.9) 21⁄8 (54)1⁄2 (13)21⁄32 (10) #1⁄4-28

To order specify, ceramic-to-metal end seal.

Ceramic-to-metal end seals with

threaded stud terminations provide

an air-tight seal for continuous

terminal temperatures up to 500°F

Bright Annealing

A process that produces a smooth,

metallic finish. It is a special

annealed finish created in a nonoxidizing atmosphere. This finish is

popular in the pharmaceutical and

food and beverage markets.

To order, specify bright annealing.

11

⁄16

7

⁄8 (43)1⁄2 (13)13⁄32 (10) #10-32

(40)

1

⁄2

(13)

13

⁄32

(10) #8-32

(260°C). Watlow does not

recommend this seal if terminations

are exposed to temperatures

exceeding 500°F (260°C).

Passivation

During the manufacturing process,

particles of iron or tool steel may

become embedded in the stainless

steel or alloy sheath. If not removed,

these particles may corrode,

produce rust spots and/or

contaminate the process. For critical

sheath applications, passivation will

remove free iron from the sheath.

To order, specify passivation.

Page 6

W A T L O W

1

"

(25 mm)

19

/32

"

(15 mm)

5

/16

"

(8 mm)

3

/4

"

(19 mm)

5

/16

"

(8 mm)

18

/32

"

(15 mm)

1

/2

"

(13mm)

1

/2

"

(13 mm)

1

/2

"

(13 mm)

1

/2

"

(13 mm)

1

/2

"

(13 mm)

1

/2

"

(13 mm)

1

/4

"

(6 mm)

3

/4

"

(19 mm)

1

1

/2

"

(38 mm)

19

/32

"

(15 mm)

1

/4

"

(6 mm)

1

/2

"

(13 mm)

A

B

Sheath Diameter

3

/4

" min.

straight req'd

Tubular and

Process Assemblies

WATROD Heating

Elements

W A TROD T erminations

Double-ended WATROD elements

are available with a variety of

terminations. Single-ended

WATROD elements are available

with only flexible lead wires.

The following table and illustrations

detail the terminations available with

double- or single-ended

WATRODs—for each available

sheath diameter.

Standard flexible lead wires are

12 inches (305 mm), Sil-A-Blend™

390°F (200°C) unless otherwise

specified. Insulation options include

TGGT (480°F/250°C) plus other

temperature ratings. Consult factory

for availability.

Overmolds are available for flexible

lead wires only. Available in silicone

rubber (390°F/200°C), neoprene

(212°F/90°C) and other materials.

Consult factory for details.

Sheath Threaded Screw Lug Quick Connect Flexible Lead Wire

WATROD Diameter Stud

aa

(Plate) (Spade) Lead Wires Overmolds

Element inch (mm) ABCDEFG H J

Double- 0.260 (6.6) #6-32 Yes Yes Yes Yes Yes Yes Yes Yes

Ended 0.315 (8.0) #10-32 Yes Yes Yes Yes Yes Yes Yes Yes

0.335 (8.5) #10-32 Yes Yes Yes Yes Yes Yes Yes No

0.375 (9.5) #10-32 Yes Yes Yes Yes Yes Yes Yes No

0.430 (10.9) #10-32 Yes Yes Yes Yes Yes Yes Yes Yes

0.475 (12.0) #10-32 Yes Yes Yes Yes Yes Yes Yes Yes

0.490 (12.4) #10-32 Yes Yes Yes Yes Yes Yes Yes No

0.625 (15.9) #10-32 Yes Yes Yes Yes Yes Yes Yes No

Single- 0.375 (9.5) No No No No No No No Yes No

Ended 0.430 (10.9) No No No No No No No Yes Yes

0.475 (12.0) No No No No No No No Yes Yes

0.490 (12.4) No No No No No No No Yes No

0.625 (15.9) No No No No No No No Yes Yes

Threaded Stud Screw Lug (Plate) Quick Connect (Spade) Flexible Lead Wires

BA

E

H

WATROD

a Optional #8-32, 1⁄4 inch and 4 or

5 mm studs available. Consult

factory for details.

C

D

F

G

J

Rubber Overmolds

Overmold Availability

Sheath

Diameter A B

inch (mm) inch (mm) inch (mm)

0.260 (6.6) 21⁄2 (63.5)1⁄2 (13.0)

0.315 (8.0) 2

1

⁄2 (63.5)1⁄2 (13.0)

0.375 (9.5) 21⁄2 (63.5)5⁄8 (15.9)

1

0.430 (10.9) 2

0.475 (12.0) 2

⁄2 (63.5)5⁄8 (15.9)

1

⁄2 (63.5)5⁄8 (15.9)

0.625 (15.9) 21⁄2 (63.5)7⁄8 (22.2)

281

Page 7

Tubular and

F

R

A

H

Dia.

R

1

A

H

Dia.

R

1

<°

(Angle)

F

R

2

A

K

Dia.

R

1

R

2

H

Process Assemblies

WATROD Heating

Elements

Double-Ended W A TR OD Bend

Formations

Double-ended WATROD heating

elements can be formed into

Minimum radius for various sheath

diameters and lengths are shown in

the Bend Formations chart below.

Illustrated on pages 282 to 286 are

the 36 common bend configurations

available on both stock and madeto-order WATROD heating elements.

spirals, compounds, multi-axis and

multi-planes from 36 common bend

configurations. Custom bending

with tighter tolerances can be made

to meet specific application needs.

Formation is limited by the minimum

bend radius (R) and the straight

length (F) required beyond the

bend. In order to locate the end of a

heated length within a bend, the

radius must be three inches (76 mm)

or larger. Additionally, overall length

tolerance (T) must be included in

one or more of the straight lengths.

WATROD Length Tolerance (T)

Sheath Length Length Tolerance

inch (mm) inch (mm)

11-50 (280-1270) ±1⁄8 (±3)

51-110 (1295-2795) ±3⁄16 (±5)

111-170 (2820-4320) ±

171-200 (4345-5080) ±3⁄8 (±10)

201 & up (5105 & up) ±1⁄2 (±13)

Single-Ended WATROD Bend

Formations

Watlow does not recommend field

bending single-ended WATROD

elements. Formation is limited by

the minimum radius of a bend (R)

1

⁄4 (±6)

Bend Formations

and the straight length (F) beyond

the bend. The radius must be

three inches (75 mm) or more for

the heated length’s end to be inside

a bend.

Additionally, the overall length

tolerance (T) must be provided for

in one or more of the specified

lengths.

The four common bend configurations available for standard and

made-to-order single-ended

WATROD elements are Figures 1, 6,

22 and 28.

To order a common bend formation,

specify the bend figure number,

dimensions and critical tolerances.

WATROD Minimum Radius

Sheath Diameter Field Bend R

inch (mm) inch (mm) inch (mm) inch (mm)

0.260 (6.6)

0.315 (8.0)

0.335 (8.5) 1 (25)

0.375 (9.5) 1 (25)

0.430 (10.9) 1 (25)

0.475 (12.0) 1 (25)

0.490 (12.5) 1 (25)

0.625 (15.9) 11⁄2 (38)

a R is the inside radius of a bend.

b F is the distance from the sheath’s end to the start of the first

bend.

3

⁄4 (19)

3

⁄4 (19)

aa

Factory RaaFbbDimension

3

⁄8 (10)

1

⁄2 (13)

1

⁄2 (13) 1 (25)

1

⁄2 (13)

1

⁄2 (13)

5

(16) 1 (25)

⁄8

5

⁄8 (16) 1 (25)

3

⁄4 (19) 1 1⁄2 (38)

1

⁄2 (13)

1

⁄2 (13)

1

⁄2 (13)

3

⁄4 (19)

Figure 1 Figure 2 Figure 3

282

SL = 2A + 1.14R1- 0.43 Dia.

(For pricing, use 1 bend)

SL = 2A + 2F + 1.14R1+ 0.0175 (<°)

(2R2+ Dia.) - 0.43 Dia.

(For pricing, use 3 bends)

SL = 2K - 0.86R2- 2.86 Dia. + 2A + 1.14R

(For pricing, use 3 bends)

1

Page 8

W A T L O W

Dia.

R

1

R

2

H

B

R

3

R

3

B

K

A

C

View B

View A

<°

(Angle)

Dia.

R

1

R

2

H

H

A

C

L

Dia.

R

1

R

2

H

Dia.

R

2

R

1

L

A

H

Dia.

R

1

C

A

L

X Hairpins

A

H

Dia.

R

1

R

2

R

1

L

A

K

Dia.

R

1

R

2

R

1

R

3

H

L

Dia.

B

L

K

R

1

R

1

R

4

R

2

R

3

A

H

Dia.

R

1

H

R

2

R

1

View B

R

3

K

L

R

3

View A

B

K

A

Tubular and

Process Assemblies

WATROD Heating

Elements

Figure 4 Figure 6Figure 5

WATROD

View A: SL = 2K- 1.72R3- 7.72 Dia. + 2C

- 0.86R2+ 2A + 1.14R

1

View B: SL = 2K- 2.28R3- 3.72 Dia. + 2C

- 0.86R2+ 2A + 1.14R

1

SL = 0.0175(<˚) (2R2+ Dia.)

+1.14R1+ 0.43 Dia.

(For pricing, use 3 bends)

SL = L + 1.14R2- 0.86 Dia. + C + 1.14R1+ A

(For pricing, use 2 bends)

(For pricing, use 5 bends)

Figure 7 Figure 8 Figure 9

SL = 2A + 2.28R

(For pricing, use 3 bends)

- 1.29 Dia. + 2L + 1.14R

2

1

X = number of outside hairpins

SL = 2A + 3.42R

- 1.29 Dia. + 2L

1

(For pricing, use 5 bends)

SL = 2A + 2.28R1- 1.29 Dia. + 2L + 1.14R

(For pricing, use 3 bends)

Figure 10 Figure 11 Figure 12

2

SL = 2K - 0.86R3- 3.72 Dia. + 2A + 2L

(For pricing, use 5 bends)

+ 2.28R1+ 1.14R

SL = 2K - 086R

2

- 0.86R4- 6.15 Dia. + 2B + 2A

3

+ 2L + 2.28R1+ 1.14R

(For pricing, use 7 bends)

View A: SL = 2K + 2B + 2A + 2L + 2.28R

2

+ 1.14R2- 1.72R3- 6.15 Dia.

View B: SL = 2K + 2A + 2L + 2.28R1+ 1.14R

1

2

- 2.28R3- 2.15 Dia.

(For pricing, use 5 bends)

283

Page 9

Tubular and

R

3

R

3

R

2

H

C

A

L

K

B

R

1

R

1

Dia.

Dia.

A

L

K

B

R

1

R

1

R

3

R

2

H

R

4

A

Dia.

B

X Hairpins

K

H

R

4

L

R

1

R

1

R

1

R

2

R

2

R

3

X Hairpins

R

1

R

1

R

1

R

2

R

2

H

A

Dia.

L

R

1

R

2

X Hairpins

Dia.

R

1

R

1

R

2

A

L

H

K

R

3

A

R

4

R

3

X Hairpins

Dia.

R

1

R

1

R

1

R

2

R

2

C

L

H

B

K

Process Assemblies

WATROD Heating

Elements

Figure 13

SL = 2B + 2A + 2L - 6.717 Dia. - 1.717R

- H - 0.858R2- 0.858R

(For pricing, use 5 bends)

3

1

SL+2K+2A+2L+2.28R1+1.14R2+2B

-6.15 Dia. -0.86R3+0.86R

4

(For pricing use 7 bends)

Figure 15Figure 14

X = number of outside hairpins

SL = 2K + 2A + 2K(X - 1) + 2B - 0.86R

+ 1.14R1(X) + 1.14R2(X - 1) - 4.86 Dia. - (2X - 1)

(For pricing, use 9 bends if X = 3 hairpins)

Figure 16 Figure 17 Figure 18

0.43 Dia.

- 0.86R

3

4

X = number of outside hairpins

SL = 2A + 0.43 Dia. (1 - 2X) + 2L (X - 1) + 1.14R

+ 1.14R2(X - 1)

(For pricing, use 5 bends if X = 3 hairpins)

284

X = number of outside hairpins

SL = 1.14R

1

+ 1.14R1X -0.86R3+ 2L X - 2L + 2A + 2K

X - 0.88 Dia. X - 1.14R2 - 2 Dia.

2

(For pricing, use 7 bends if X = 3 hairpins)

X = number of outside hairpins

SL = 2L + 2K + 2B + 2C (X - 1) - 0.86R

- 0.86R4- 4.86 Dia. + 1.14R1(X)

+ 1.14R2(X - 1) - (2X - 1) 0.43 Dia.

(For pricing, use 9 bends if X = 3 hairpins)

3

Page 10

W A T L O W

A

C

R

1

R

3

X

Hairpins

R

1

R

5

R

2

R

2

L

H

K

R

4

B

R

1

R

4

K

B

R

5

VIEW A

OPTIONAL VIEW B

C

R

1

(6 places)

Dia.

C

M

B

H

E

L

A

K

Ref.

Ref.

R

2

R

3

L

K

R

1

R

1

Dia.

R

2

H

A

A

H

R

1

Dia.

A

H

R

1

R

2

Dia.

K

A

H

R

1

R

1

R

2

Dia.

L

R

3

K

L

R

1

(4 places)

R

2

(2 places)

Dia.

K

B

A

H

L

A

Dia.

R

2

(2 places)

B

H

K

R

1

(4 places)

C

R1 (4 places)

Dia.

R

3

L

B

K

A

R

2

(2 places)

H

Tubular and

Process Assemblies

WATROD Heating

Elements

Figure 19 Figure 20 Figure 21

WATROD

X = number of outside hairpins

View A and B: SL = 2K + 2A + 2B + 2C + 2L (X - 1)

+ 1.14R1(X) + 1.14R2(X - 1) - 0.86R3- 0.86R

4

SL = 2K + 2C + B + 2A + 2L - 2.58R1- 0.86R2-

0.86R3- 12.15 Dia.

(For pricing, use 10 bends)

SL = 2A + 2K - H - 2.28R

- 3.29 Dia.

(For pricing, use 4 bends)

- 0.86R

1

2

- 0.86R5- 7.29 Dia. - (2X - 1) 0.43 Dia.

(For pricing, use 11 bends if X = 3 hairpins)

Figure 24Figure 23Figure 22

SL = 2A - 0.86R1- 1.43 Dia. + H

(For pricing, use 2 bends)

SL = 2K - 0.86R2- 3.86 Dia. + 2A - 0.86R1+ H

(For pricing, use 4 bends)

SL = 2K + 2L + H - 0.86R

- 7.29 Dia.

(For pricing, use 6 bends)

- 0.86R2- 0.86R

1

3

Figure 27Figure 26Figure 25

SL = 2K + 2A + 2L - H - 1.72R

(For pricing, use 6 bends)

- 6.92 Dia.

- 0.86R

1

2

SL = 2K + 2A + 2L - H - 1.72R

- 0.86R

1

2

- 6.29 Dia.

(For pricing, use 6 bends)

SL = 2K + 2A + 2L + 2B - H - 1.72R

- 1.72R2- 8.72 Dia.

(For pricing, use 8 bends)

1

285

Page 11

Tubular and

G

R

1

Dia.

F

A

H

A

F

L

Dia.

G

K

R

2

Dia.

G

R

1

B

A

H

A

L

G

H

F

R

1

Dia.

G

H

VIEW BVIEW A

R

1

A

L

F1

F2

G

Dia.

A

L

G

Dia.

F

<°

(Angle)

R

1

Dia.

H

R

3

F

R

1

Dia.

R

2

<°1

(Angle)

<°2

(Angle)

R

1

K

H

G

Dia.

Process Assemblies

WATROD Heating

Elements

Figure 30Figure 29Figure 28

SL = 0.0175 <° (R1+ 0.5 Dia.)

(For pricing, use 1 bend)

SL = (G + Dia.) 3.14 + 1.14R

+ 3.71 Dia. - H

(For pricing, use 4 bends)

1

+ 2F

SL = 0.0175 <°1 (2R2+ Dia.) + 2F + 1.14R

+ 0.0175 <°2 (2R3+ Dia.) - 0.43 Dia.

(For pricing, use 5 bends)

SL = (G + Dia.) 3.14 + 1.14R

+ 2B + 1.14R2+

1

2K + 3.28 Dia. - H

(For pricing, use 6 bends)

1

SL = (G + Dia.) 3.14 + 1.14R1+ 2K

+ 3.28 Dia. - H

(For pricing, use 4 bends)

Figure 33Figure 32Figure 31

SL = [(G + Dia.) (3.14) (Number of 360°’s)]

+ F1 + F2

(For pricing, consult factory)

Figure 36Figure 35Figure 34

SL = [(G + Dia.) (3.14) (Number of 360°’s)]

286

(For pricing, consult factory)

+ 2F

(For pricing, consult factory)

+ 2F

SL = [(G + Dia.) (3.14) (Number of 360°’s)]

SL = [(G + Dia.) (3.14) (Number of 360°’s)]

+ (G ÷ 2) + A + F

(For pricing, consult factory)

Page 12

W A T L O W

3

1

/4

"

(83 mm)

1

1

/2

"

(38 mm)

1

1

/2

"

(38 mm)

1

3

/8

"

(35 mm)

(3) 0.25"

(6 mm)

Dia. Holes

1

/2

" (13 mm)

1

"

(25 mm)

B

Wall

Washer

Nut

Gasket

C

A

D

b

1" (25 mm)

1

1

/2

"

(38 mm)

+

+

3

/4

"

(19 mm)

1

/2

"

(13 mm)

0.250" Hole

Tubular and

Process Assemblies

WATROD Heating

Elements

Mounting Methods

Brackets

A 0.065 inch (1.7 mm) thick

stainless steel bracket provides

element mounting in non-pressurized applications. Attached to the

heater sheath, these brackets are

not suited for liquid-tight mountings.

The bracket is located 1⁄2

(13 mm) from the sheath’s end,

unless otherwise specified.

To order, specify mounting bracket.

inch

Single Leg Bracket

1

⁄2 inch (38 mm) x 1 inch (25 mm)

A 1

wide x 16 gauge stainless steel

bracket with one element hole and

one mounting hole 1⁄2 inch from end.

To order, specify single leg bracket.

Locator Washers

Stainless steel locator washers

retain the heated area of the sheath

in the work zone, while allowing for

expansion and contraction during

cycling.

To order, specify locator washer,

along with dimension from the

heater’s end.

Mounting Collars

WATROD

Plated steel mounting collars

secure the heater sheath with set

screws to serve as adjustable stops

for through-the-wall mounting.

Collars are shipped in bulk.

To order, specify mounting collars.

Threaded Bulkheads

A threaded bushing with flange on

the heater sheath provides rigid,

leak-proof mounting through the

walls of tanks. A gasket, plated

steel washer and hex nut are

included. The threaded end of the

bushing is flush with the sheath’s

end unless otherwise specified.

Threaded bulkheads are available

in brass, steel or stainless steel as

indicated in the table.

To order, specify threaded

bulkheads and the specifications

from the table.

Threaded Bulkhead Specifications

A➀ BC

Element Flange Threaded Overall

Diameter Thread Size/Style Length Length

inch (mm) Material Size inch (mm) inch (mm) inch (mm)

0.260 (6.6) Brass

0.260 (6.6) Steel

0.260 (6.6) S. Steel1⁄2 - 20 UNF3⁄4 Round (19)

0.315 (8.0) Brass

0.315 (8.0) Steel

0.315 (8.0) S. Steel1⁄2 - 20 UNF3⁄4 Round (19)

0.375 (9.5) Brass

0.375 (9.5) Steel

0.375 (9.5) S. Steel

0.430 (10.9) Brass

0.430 (10.9) Steel

0.430 (10.9) S. Steel

0.475 (12.1) Brass

0.475 (12.1) Steel

0.475 (12.1) S. Steel5⁄8 - 18 UNF 1 Round (25)

0.490 (12.4) Brass

0.490 (12.4) Steel

0.490 (12.4) S. Steel3⁄

0.625 (15.9) S. Steel

a Designates the dimension across flats for hex flange style and outside diameter for round

flange style.

b Equal to “B” Dimension unless otherwise specified.

1

⁄2 - 20 UNF3⁄4 Round (19)

1

⁄2 - 20 UNF3⁄4 Hex (19)

1

⁄2 - 20 UNF3⁄4 Round (19)

1

⁄2 - 20 UNF3⁄4 Hex (19)

1

⁄2 - 20 UNF3⁄4 Round (19)

1

- 20 UNF

2

⁄

1

⁄2 - 20 UNF3⁄4 Round (19)

5

⁄8 - 18 UNF7⁄8 Hex (22)

5

- 18 UNF

8

⁄

5

⁄8 - 18 UNF 1 Round (25)

5

- 18 UNF

8

⁄

5

⁄8 - 18 UNF 1 Round (25) 1 (25.0) 11⁄8 (29)

3

4 - 16 UNF 1 Round (25)

⁄

3

⁄4 - 16 UNF 1 Hex (25)

- 16 UNF 1 Round (25)

4

7

⁄8 - 14 UNF 1 Round (25)

3

Hex (19)

4

⁄

7

Round (22)

8

⁄

7

Round (22)

8

⁄

5

⁄8 (15.9)

5

⁄8 (15.9)

5

⁄8 (15.9)

5

⁄8 (15.9)

3

⁄4 (19.0)

3

⁄4 (19.0)

5

⁄8 (15.9)

3

(19.0)

4

⁄

3

⁄4 (19.0)

3

⁄4 (19.0)

3

(19.0)

4

⁄

3

⁄4 (19.0)

3

(19.0)

4

⁄

3

⁄4 (19.0)

3

4 (19.0) 1 (25)

⁄

3

⁄4 (19.0) 1 (25)

3

(19.0) 1 (25)

4

⁄

3

⁄4 (19.0) 1 (25)

3

⁄4 (19)

3

⁄4 (19)

3

⁄4 (19)

3

⁄4 (19)

15

⁄16 (24)

27

⁄32 (21)

3

⁄4 (19)

15

16

⁄

27

⁄32 (21)

15

⁄16 (24)

15

16

⁄

15

⁄16 (24)

15

16

⁄

15

⁄16 (24)

(24)

(24)

(24)

287

Loading...

Loading...