Watlow WATROD Duct Specifications

391

WATLOW

®

Air Heaters

Duct Heaters

LDH SERIES and D SERIES

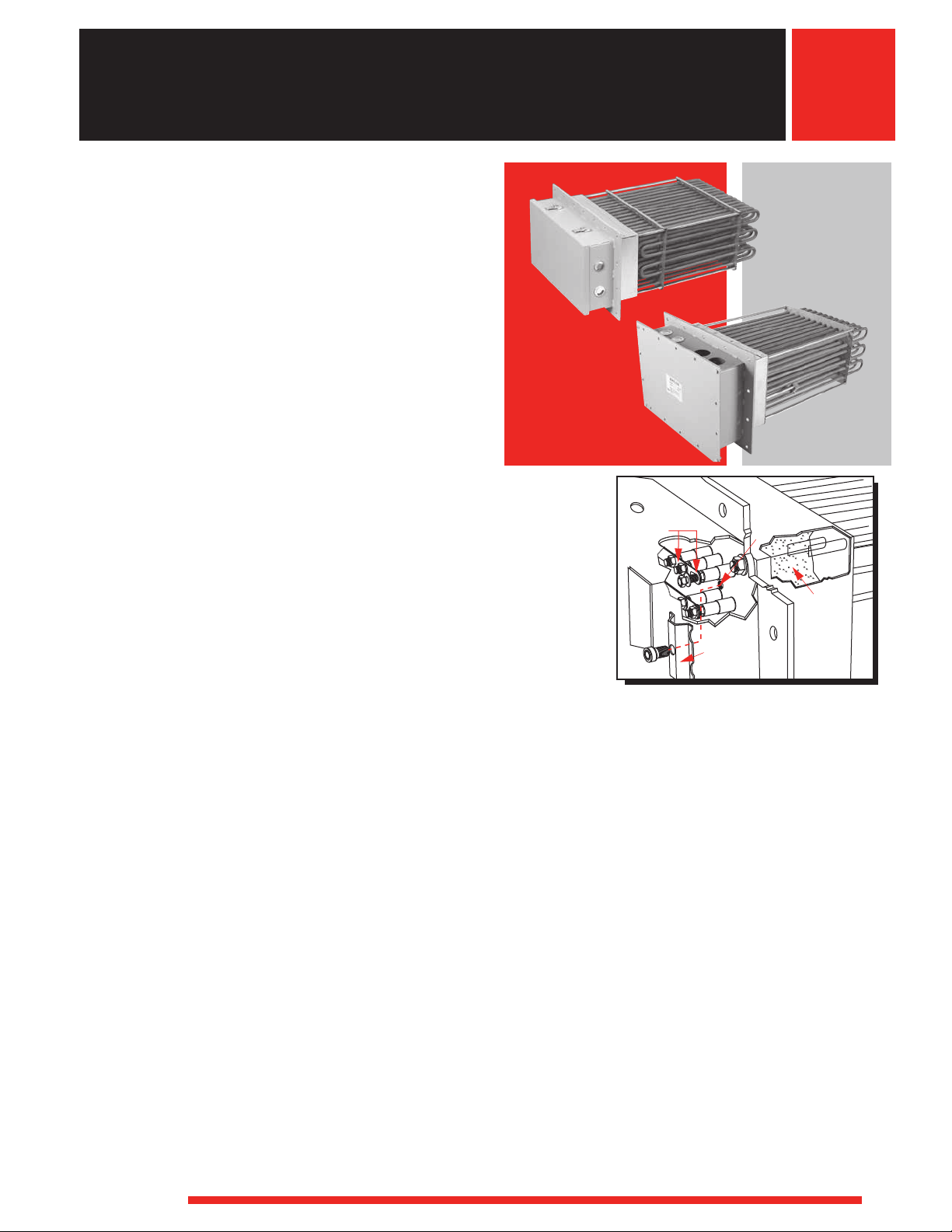

Constructed of sturdy 0.430 in. (11 mm) diameter

WATROD™ heating elements mounted to a 1/4 in.

(6 mm) thick steel flange, duct heaters are easily

adapted to many non-pressurized air-heating systems.

They are easily installed in applications requiring a wide

range of temperature versus air flow combinations.

The modular duct heater offers increased reliability. The

individual modules are removable through the housing of

the assembly, which eliminates the need to pull the

complete heater from the duct work. This reduces

downtime costs because the heating elements can be

replaced individually. Performance improvements include

quicker response time and reduced infiltration from the air

stream being heated into the electrical enclosure.

Watlow® duct heaters offer advantages over gas or oil

fired and open coil electric units with:

• Installation flexibility—no flues or fuel lines

• 100 percent energy efficient—no energy loss up

the flue

• Universal availability of electricity

• Resistance coil in sheath is protected from corrosive

environments

Performance Capabilities

• Watt densities up to 40 W/in2 (6.2 W/cm2)

• Recommended process temperatures from

-20 to 1200°F (-29 to 650°C)

• Catalog P/N wattages up to 225kW

• Voltages up to 600VAC

Features and Benefits

Long life alloy 840 sheath

• Resists corrosion/oxidation while protecting resistance

coils against contamination

MgO insulation filled elements compacted to rock

hard density

• Maximizes dielectric strength, heat transfer and life

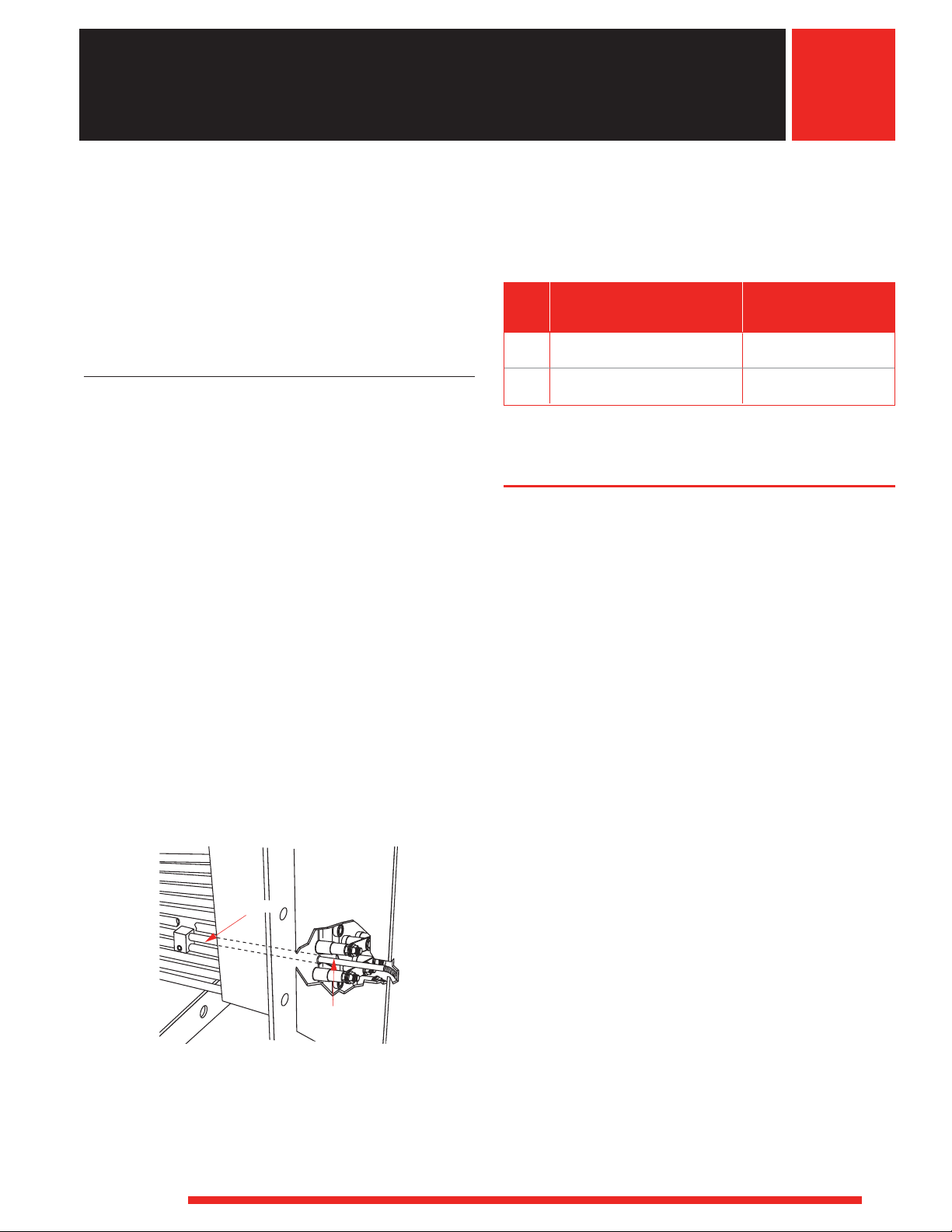

Field replaceable heating elements

• Permits easy service and reduces downtime. Element

change-out is made simple by a single screw clamp

(D SERIES only)

31/2 in. (90 mm) thick mineral insulation

• Keeps wiring cooler and reduces heat loss

Silicone resin seals rated to 221°F (105°C)

• Protects elements against moisture and other

contaminants

General purpose terminal enclosure

• Offers easy access to wiring

1

/4 in. (6 mm) inside diameter thermowell

• Accepts an optional Type J or K thermocouple for

accurate sheath temperature sensing (D SERIES only)

Rigid stainless steel supports

• Prevents element sagging or deformation in various

mounting positions

1

/4 in. (6 mm) thick steel flange with 3/8 in. (9.5 mm)

diameter mounting holes

• Easily bolts to the duct wall

WATROD hairpins are repressed (recompacted)

after bending to assure MgO density

• Eliminates hot spots and electrical insulation voids

Stock heaters feature from 3 to 60 elements

• Meets a wide variety of kilowatt demands

One or three phase voltages

• Meets local power supplies

Maximum 48 amperes per circuit

• Complies with National Electrical Code (NEC)

Duct heaters with general purpose enclosures

meet UL

®

and CSA component recognition to 480

and 600VAC maximum respectively—UL® and CSA

file numbers are E52951 and 31388

Single

Screw

Clamp

Bussing

Mineral

Insulation

Threaded

Hole

LDH SERIES

D SERIES

WATLOW

®

392

Choosing a Duct Heater

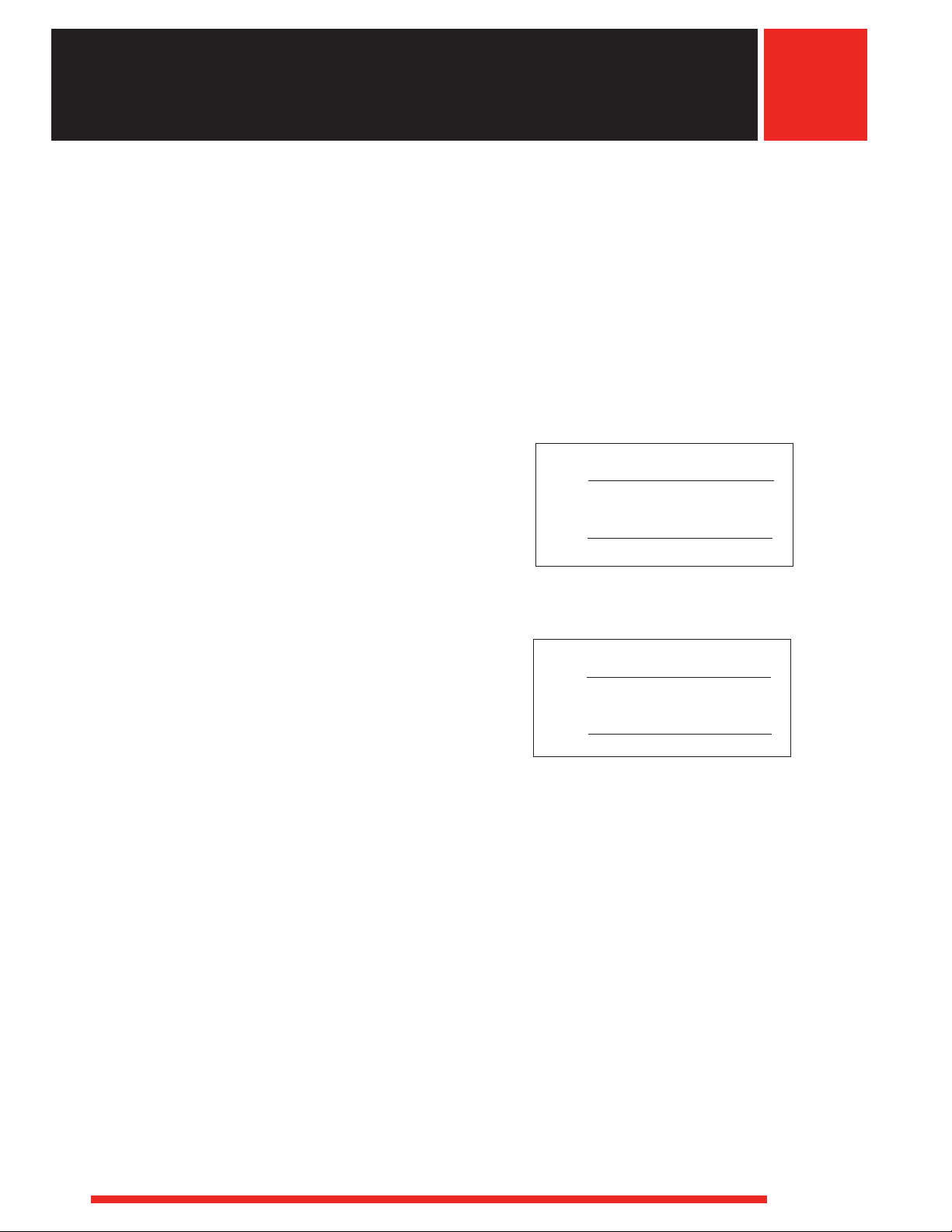

The English and metric graphs, shown on the following

pages will help you to select the correct duct heater.

These graphs include: Watt Density vs. Air Temperature/

Velocity, Watt Density vs. Sheath Temperature and

Pressure Drop vs. Air Velocity.

These graphs, with the quick formulas on this page,

along with information specific to your application,

will determine the correct duct heater specifications.

However, if engineering assistance is needed, contact

your Watlow representative.

Note: The duct heater, or combination of duct heaters,

used for the process should be equal to or exceed the

minimum wattage calculation.

English

CFM measured at standard conditions

Duct cross section area at heater in ft

2

Metric

CMM measured at normal conditions

Duct cross section area at heater in m

2

English

CFM x Delta T (°F) x 1.1 (safety factor)

3000

Metric

CMM x Delta T (°C) x 1.1 (safety factor)

48

• Air velocity in feet per minute (FPM); meters per minute

(MPM) which equals:

• Minimum duct heater wattage (kW). This can be

determined by:

kW =

kW =

FPM =

MPM =

Air Heaters

Duct Heaters

LDH SERIES and D SERIES

Typical Applications

• Drying ovens

• Autoclaves

• Furnaces

• Load banks

• Heat treating

• Reheating

• HVAC

• Paint drying

Required Application Information

• Desired outlet air temperature

• Inlet air temperature

• Delta T—the temperature difference between inlet and

desired outlet temperature

• Air volume (CFM/CMM) measured at both inlet

temperature and pressure

393

WATLOW

®

Air Heaters

Duct Heaters

LDH SERIES and D SERIES

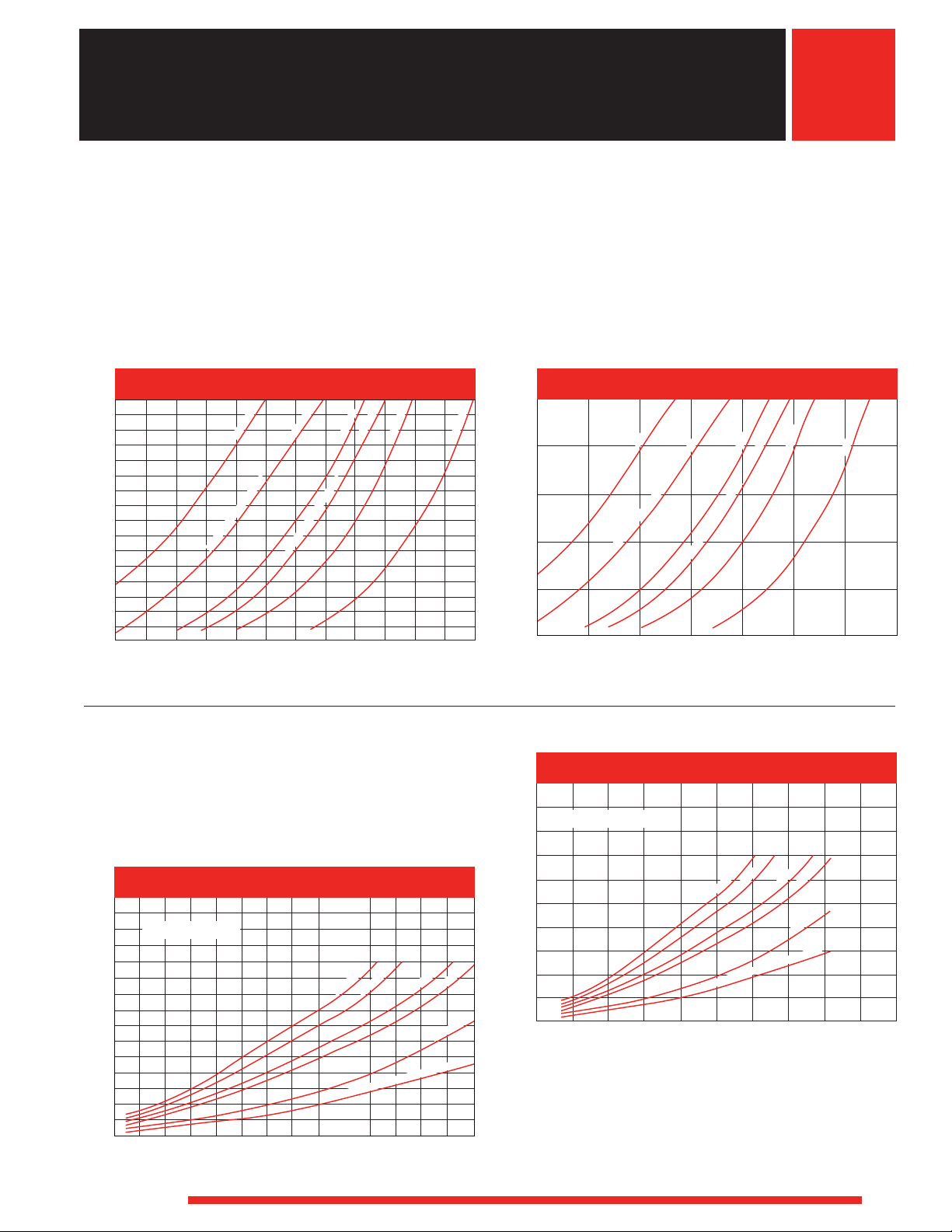

Sheath Temperature—°F

Watt Density—W/in

2

100

4

8

12

16

20

24

28

32

36

40

44

48

52

56

60

0

200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

Inlet Temperature at

75°F

1200 FPM

760 FPM

680 FPM

300 FPM

60 FPM or Natural Convection

1550 FPM

Sheath Temperature—°C

100

Watt Density—W/cm

2

5

4

3

2

1

6

7

8

9

10

200 300 400 500 600 700 800 900 1000

365 MPM

235 MPM

180 MPM

90 MPM

18 MPM or Natural Convection

475 MPM

Inlet Temperature at 25°C

To decide watt density requirements, first determine

the desired outlet air temperature and velocity in feet

per minute. Then, follow the lines on the graph for

velocity and process temperature to the watt density

The Watt Density vs. Sheath Temperature graph shows

the air velocity (FPM or MPM) required to operate a

WATROD duct heater at specific watt densities or sheath

temperatures. Also depicted is the appropriate watt

density vs. sheath temperature at a specified air flow.

Process Temperature—°F

Air Velocity—FPM

100

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

200 300 400 500 600 700 800 900 1000 1100 1

200

40 W/in230 W/in

2

23 W/in

2

20 W/in

2

16 W/in

2

8 W/in

2

Catalog Duct Heaters

Catalog Duct Heaters

Estimated Sheath Temperature = 1400°F

Process Temperature—°C

Air Velocity—MPM

100

500

Estimated Sheath Temperature = 760°C

400

300

200

100

200 300 400 500 600

700

4.65 W/cm

2

3.5 W/cm

2

3.1 W/cm

2

2.5 W/cm

2

1.25 W/cm

2

Catalog Duct Heaters

6.2 W/cm

2

Catalog Duct Heaters

WATROD Duct Heater

Watt Density Vs. Air Temperature Velocity

curve’s intersecting point. This shows the recommended

watt density based on a maximum sheath temperature

of 1400°F (760°C). For longer heater life, lower watt

densities should be chosen.

WATROD Duct Heater

Watt Density Vs. Air Temperature Velocity

Watt Density vs. Sheath Temperature

WATROD Duct Heater

Watt Density Vs. Sheath Temperature

WATROD Duct Heater

Watt Density Vs. Sheath Temperature

Watt Density vs. Air Temperature/Velocity

394

WATLOW

®

Air Heaters

Duct Heaters

LDH SERIES and D SERIES

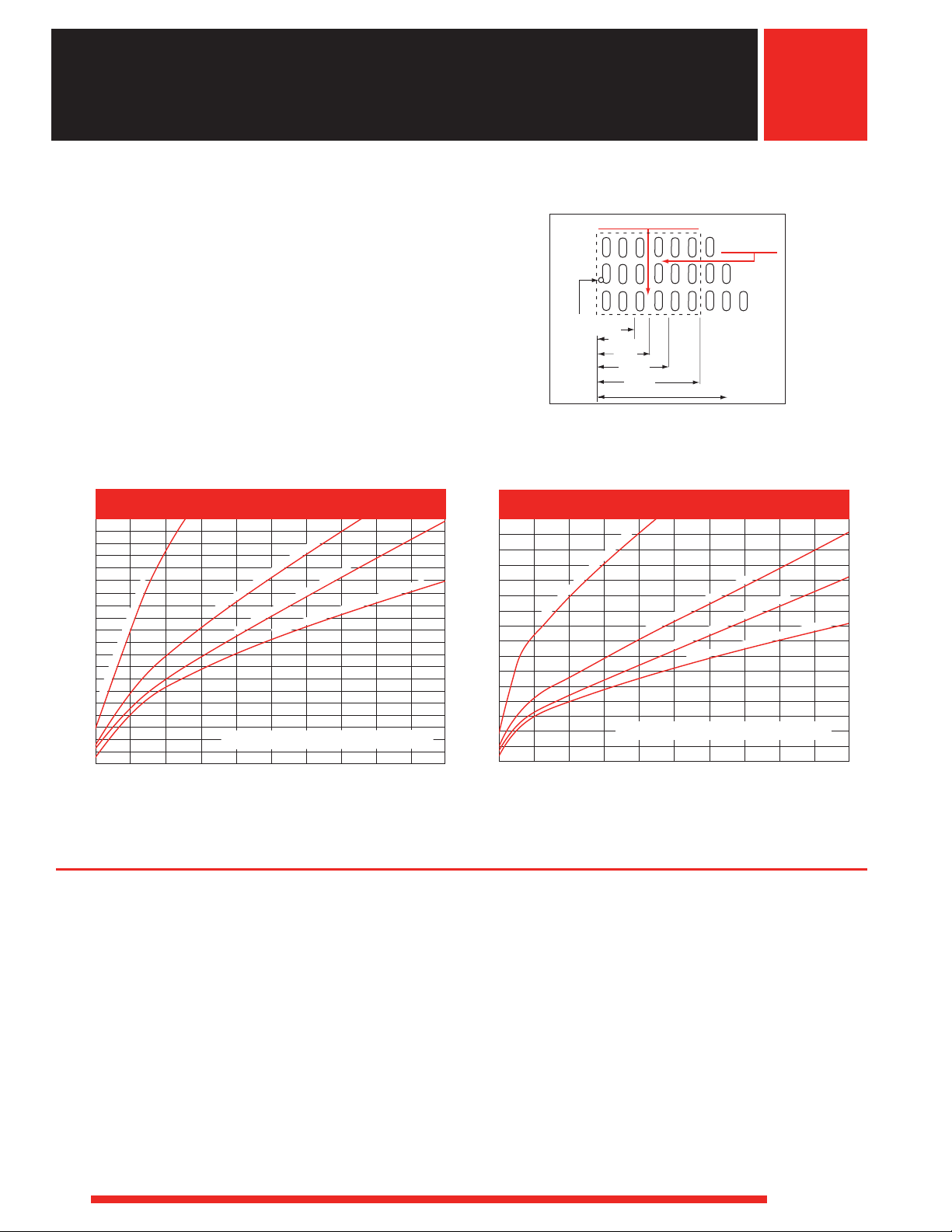

The rate at which pressure drops through the duct heater

is critical for properly sizing blowers and pumps. The

Pressure Drop vs. Air Velocity graph gives recommended

maximum velocities in feet per minute and meters per

minute according to the air velocity and duct heater size.

To determine the pressure drop through the duct heater,

follow the air velocity (FPM or MPM) over to the

appropriate curve, which identifies the duct heater

size. Then, take the intersecting point down to the

approximate pressure drop value.

Thermowell

Air Flow for ≥ 24kW

>18kW

6kW

9kW

12

kW

18kW

Air flow for

6 to 18kW

1 FIREBAR

®

flat tubular element duct heaters are available as extended capabilities to enhance your application output or performance. Although duct

heaters are not normally constructed with FIREBAR elements, the pressure drop reduction using FIREBAR as a distinct advantage is shown above.

Wattages/Voltages

To meet specific application needs, voltage and wattage

combinations outside stock product parameters

are available.

For more information about this option, contact your

Watlow representative.

Note: Viewing from the element ends—the

recommended air flow direction through

element bundle changes at >18kW.

Approximate Pressure Drop— Inches of Water

2000

Air Velocity—FPM

Round Tubular Duct Heater D24 - D125

0.02

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18 0.20

Round Tubular Duct Heater D18

Round Tubular Duct Heater D12

Round Tubular Duct Heater D6

FIREBAR Duct Heater of Equivalent kW is 30%

the Pressure Drop of a Round Tubular Duct Heater

®

1

Approximate Pressure Drop—Kilopascals

800

Air Velocity—MPM

0.005

750

700

650

600

550

500

450

400

350

300

250

200

150

100

50

0.010 0.015 0.020 0.025 0.030 0.035 0.040 0.045 0.050

Round Tubular Duct Heater D12

Round Tubular Duct Heater D24 - D125

Round Tubular Duct Heater D18

Round Tubular Duct Heater D6

FIREBAR Duct Heater of Equivalent kW is 30%

the Pressure Drop of a Round Tubular Duct Heater

®

1

Options

Round and FIREBAR Tubular Duct Heaters

Pressure Drop vs. Air Velocity

Round and FIREBAR Tubular Duct Heaters

Pressure Drop vs. Air Velocity

Pressure Drop vs. Air Velocity

395

WATLOW

®

Air Heaters

Duct Heaters

LDH SERIES and D SERIES

Options

(Continued)

Terminal Enclosures

In addition to the standard, general purpose terminal

enclosure, Watlow offers a moisture resistant optional

terminal enclosure to meet specific application

requirements.

Thermocouples

Type J or K thermocouples, inserted in the thermowell,

accurately sense element sheath temperature for

over-temperature conditions.

To sense process temperature, the sensing element

should be located downstream from the duct heater. This

will eliminate incorrect sensing caused by radiant heat.

Thermocouples are supplied with 120 in. (3050 mm)

leads, longer lead lengths are available (this applies to “D”

SERIES only). Unless otherwise specified, thermocouples

are supplied with temperature ranges detailed on the

Thermocouple Types chart.

Using a thermocouple requires an appropriate

temperature and power controller. These must be

purchased separately. Watlow offers a wide variety of

temperature and power controllers to meet virtually all

applications. Temperature controllers can be configured

to accept process variable inputs, too. Contact your

Watlow representative for details.

To order a thermocouple, add the appropriate suffix letter

to the duct heater’s base part number, as indicated on

the Ordering Information chart on page 404.

Application Hints

• Mount duct heaters horizontally to lower enclosure

temperatures and promote unit life.

• Orient heating elements as per the air flow illustration

on page 394.

• Promote heater life by keeping sheath temperature

below the 1400°F (760°C) maximum.

• Measure process temperature in the outlet stream,

away from the heater.

• Maintain wiring integrity by keeping enclosure

temperature below 400°F (205°C).

• Thermal cycling can cause terminations to loosen.

Periodically check and tighten all electrical

connections.

• Size power feeder wires in accordance with NEC and

other applicable codes.

• Protect employees against electrical shock by properly

grounding the unit per NEC specifications.

1Type J and Type K thermocouples are rated 32 to 1382°F and 32

to 2282°F (0-750°C and 0-1250°C), respectively. Watlow does not

recommend exceeding temperature ranges shown on this chart for

the tubular product line.

Thermocouple Types

Duct heater thermowell holds thermocouple for sensing

sheath temperature.

Thermocouple

Thermowell

Recommended

1

ASTM Conductor Characteristics Temperature Range

Type Positive Negative °F (°C)

J Iron Constantan 0 to 1000 (-20 to 540)

(Magnetic) (Non-magnetic)

K Chromel® Alumel® 0 to 2000 (-20 to 1100)

(Non-magnetic) (Magnetic)

396

WATLOW

®

Air Heaters

Extended Capabilities For Duct Heaters

LDH SERIES and D SERIES

E

XTENDE

D

C

APABILITY

Performance Capabilities

• Wattages to 2.2 megawatts

Features and Benefits

Ceramic fiber insulation available

• Keeps wiring cooler and reduces heat loss

Greater than 1/4 in. (6 mm) with 304 or 316

stainless steel flange material

• Easily bolts to the duct wall

60 plus element designs available

• Meets a wide variety of kilowatt demands

Sheath Material

Watlow duct heaters can be made with the following

sheath materials:

• 304, 316, 321 SS

• Alloy 800, 840

• Laminated alloy 600 (hi-temp)

• Hastelloy C276

Contact your Watlow representative for details and

availability.

Terminal Enclosures

In addition to the standard, general purpose terminal

enclosure, Watlow offers the following optional terminal

enclosures to meet specific application

requirements:

• Explosion resistant (contact your Watlow

representative)

• High-temperature stand-off enclosures

Options

Loading...

Loading...