Watlow WATROD Duct Data sheet

W A T L O W

Tubular and

Process Assemblies

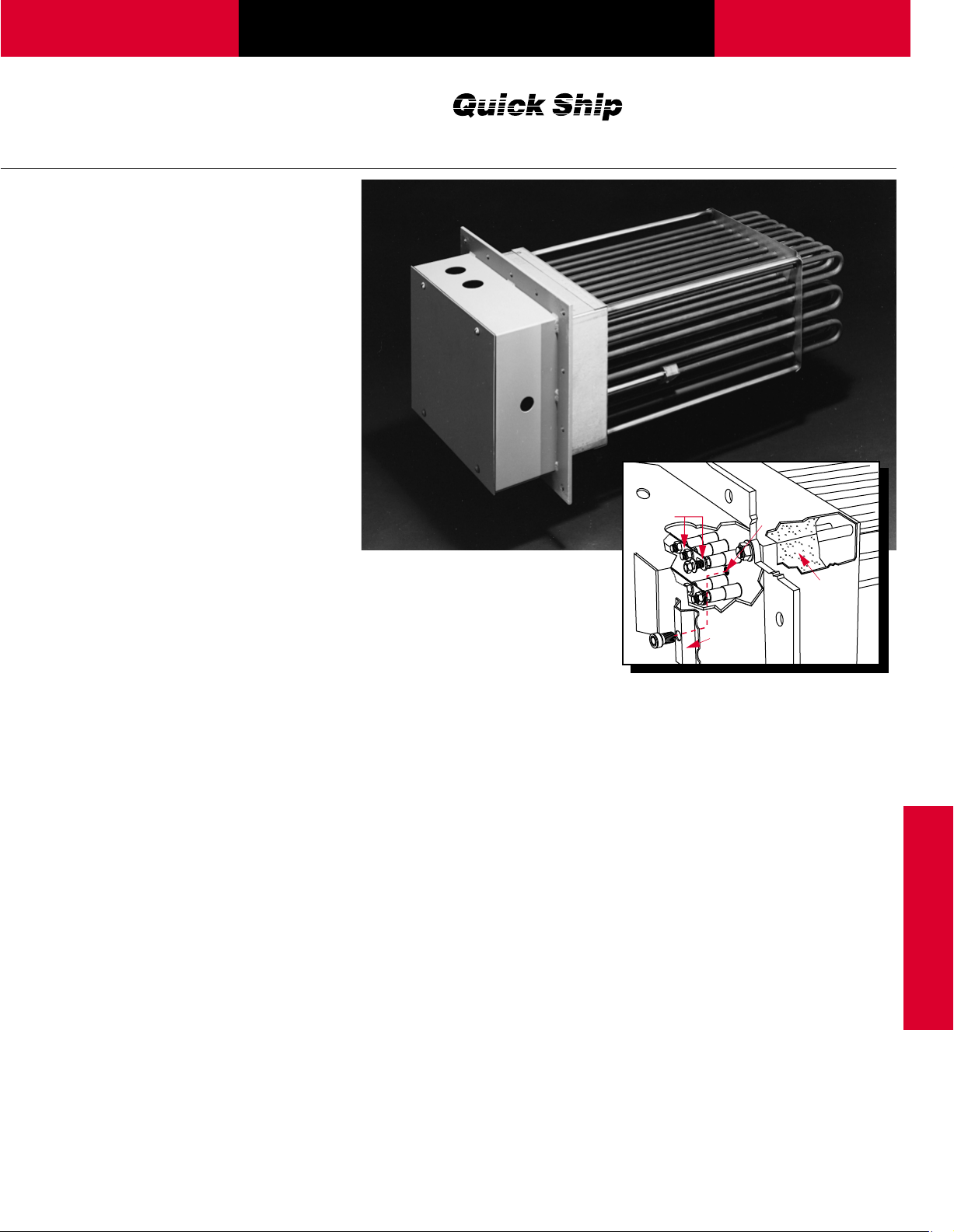

Duct Heaters

Constructed of sturdy 0.430 inch

(11 mm) diameter WATROD heating

elements mounted to a 1⁄4 inch

(6 mm) thick steel flange, duct

heaters are easily adapted to many

non-pressurized, air-heating

systems.

They are easily installed in

applications requiring a wide range

of temperature vs. air flow

combinations.

Watlow duct heaters offer

advantages over gas or oil fired and

open coil electric units with:

• Installation flexibility—

no flues or fuel lines.

• 100 percent energy efficient—

no energy loss up the flue.

• Universal availability of electricity.

• Resistance coil in Incoloy

sheath is protected from corrosive environments.

Performance Capabilities

• Watt densities to 40 W/in

(6.2 W/cm2)

• Recommended process

temperatures from -20 to 1200°F

(-7 to 650°C)

• Wattages to 2.2 megawatts

• Voltages to 600VÅ(ac)

Features and Benefits

• Long life Incoloy®sheath

resists corrosion/oxidation while

protecting resistance coils

against contamination.

• MgO insulation filled elements,

compacted to rock hard density

maximize dielectric strength, heat

transfer and life.

• Field replaceable heating

elements permit easy service

and reduce downtime. Element

change-out is made simple by a

single screw clamp.

Incoloy®is a registered trademark of

Special Metals Corporation.

®

2

1

⁄2 inches (90 mm) thick

• 3

mineral insulation keeps wiring

cooler and reduces heat loss.

• Vented general purpose

(NEMA 1) terminal enclosure

ensures cooler terminations.

• A 1⁄4

inch (6 mm) inside

diameter thermowell accepts

an optional Type J or K

thermocouple for accurate

sheath temperature sensing.

• Rigid stainless steel suppor ts

prevent element sagging or

deformation in various mounting

positions.

1

• A

⁄4 inch (6 mm) thick steel

flange, with 3⁄8 inch (10 mm)

diameter mounting holes, easily

bolts to the duct wall.

®

is a registered trademark of

UL

Underwriter's Laboratories, Inc.

On stock chart units:

• Three to five working days on most heaters

• 10 working days on special voltages and/or

wattages

• 15 working days on special element lengths

Bussing

Single

Screw

Clamp

Threaded

Hole

Mineral

Insulation

• WATROD hairpins are

repressed (recompacted) after

bending to assure MgO density

that eliminates hot spots and

electrical insulation voids.

• Stock heaters feature 6, 12, 18,

24, 30, 36, 42, 48, 54, and 60

elements to meet a wide variety

of kW demands.

• One or three phase voltages to

meet local power supplies.

• Maximum 48 amps per circuit

complies with National Electrical

Code (NEC).

• Duct heaters with general

purpose enclosures meet UL

and CSA component recognition to 480 and 600VÅ(ac)

maximum respectively—UL

and CSA file numbers are

E52951 and 31388.

Duct Heaters

®

®

411

Tubular and

Process Assemblies

Duct Heaters

Applications

• Dr ying ovens

• Autoclaves

• Furnaces

• Load banks

• Heat treating

• Reheating

•HVAC

• Paint dr ying

Choosing a Duct Heater

The following English and metric

graphs, shown on pages 413 to

414, will help you to select the

correct duct heater. These graphs

include: Watt Density vs. Air

Temperature/Velocity, Watt Density

vs. Sheath Temperature and

Pressure Drop vs. Air Velocity.

These graphs, with the quick

formulas on this page, along with

information specific to your

application, will determine the

correct duct heater specifications.

However, if engineering assistance

is needed, contact your Watlow

representative.

Required Application Information

• Desired outlet air temperature

• Inlet air temperature

• Delta T—the temperature

difference between inlet and

desired outlet temperature

• Air volume (CFM/CMM)

measured at both inlet

temperature and pressure

• Air velocity in feet per minute

(FPM); meters per minute (MPM)

which equals:

• Minimum duct heater wattage

(kW). This can be determined by:

English

CFM measured at standard conditions

FPM =

Duct cross section area at heater in ft

Metric

MPM =

kW =

kW =

CMM measured at normal conditions

Duct cross section area at heater in m

English

CFM x Delta T (°F) x 1.1(safety factor)

3000

Metric

CMM x Delta T (°C) x 1.1(safety factor)

48

2

2

412

Note: The duct heater, or

combination of duct heaters, used

for the process should be equal to

or exceed the minimum wattage

calculation.

W A T L O W

WATROD Duct Heater

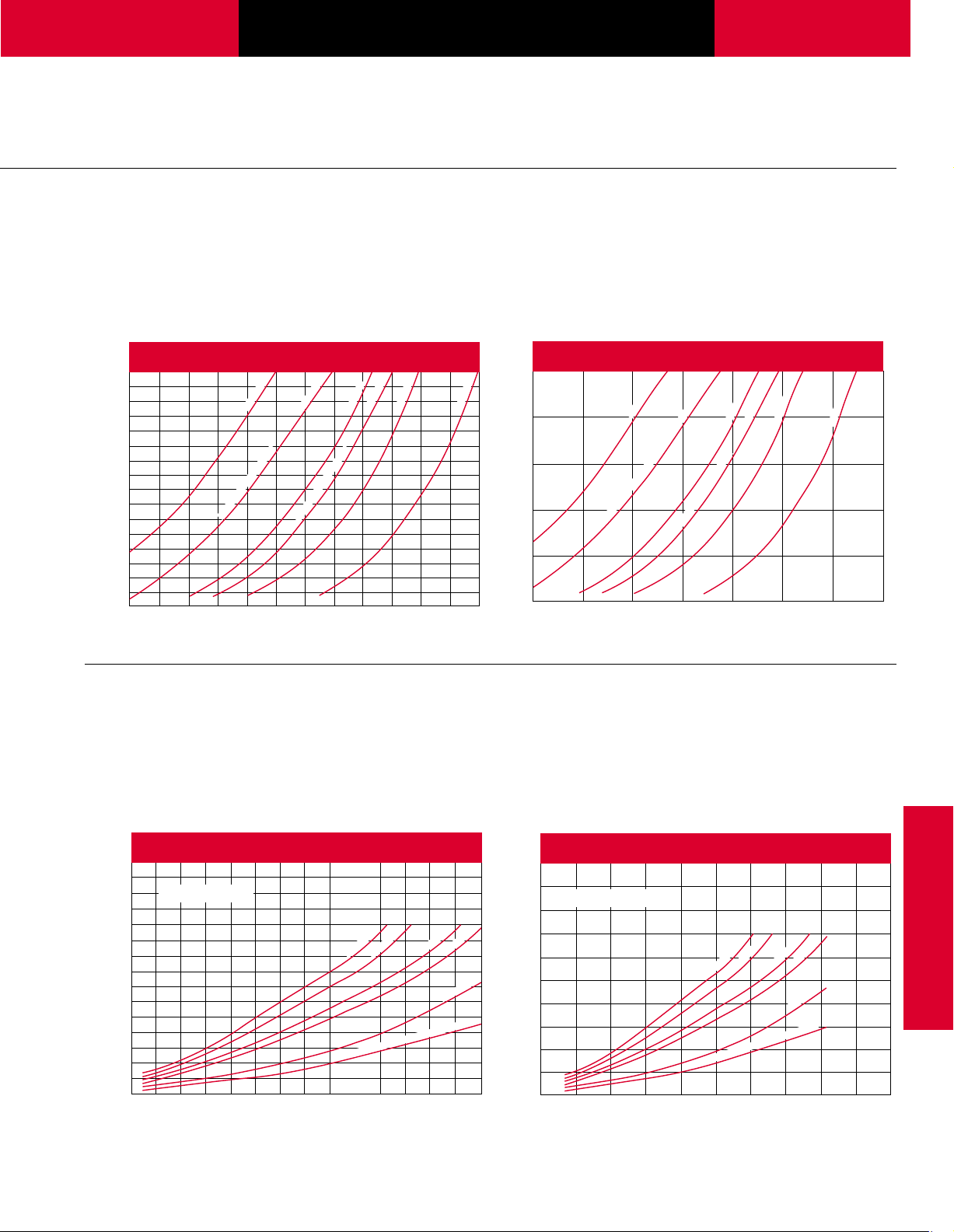

Watt Density vs. Air Temperature/Velocity

Process Temperature—°F

Air Velocity—FPM

100

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

200 300 400 500 600 700 800 900 1000 1100 1200

40 W/in230 W/in

2

23 W/in

2

20

W/in

2

16 W/in

2

8 W

/in

2

Catalog Duct Heaters

Catalog Duct Heaters

Estimated Sheath Temperature = 1400°F

Process Temperature—°C

Air Velocity—MPM

100

500

Estimated Sheath Temperature = 760°C

WATROD Duct Heater

Watt Density vs. Air Temperature/Velocity

400

300

200

100

200 300 400 500 600 700

4.65 W

/cm

2

3.5 W/cm

2

3.1 W/cm

2

2.5 W/cm

2

1.25 W

/cm

2

Catalog Duct Heaters

6.2 W

/cm

2

Catalog Duct Heaters

Sheath Temperature—°F

Watt Density—W/in

2

100

4

WATROD Duct Heater

Watt Density vs. Sheath Temperature

8

12

16

20

24

28

32

36

40

44

48

52

56

60

0

200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

Inlet Temperature at

75 Degrees Fahrenheit

1200 FPM

760 FPM

680 FPM

300 FPM

60 FPM or Natural Convection

1550 FPM

Sheath Temperature—°C

100

WATROD Duct Heater

Watt Density vs. Sheath Temperature

Watt Density—W/cm

2

5

4

3

2

1

6

7

8

9

10

200 300 400 500 600 700 800 900 1000

365 MPM

235 MPM

180 MPM

90 MPM

18 MPM or Natural Convection

475 MPM

Inlet Temperature at

25 Degrees Celsius

Tubular and

Process Assemblies

Duct Heaters

Watt Density vs. Air

Temperature/Velocity

To decide watt density

requirements, first determine the

desired outlet air temperature and

velocity in feet per minute. Then

follow the lines on the graph for

velocity and process temperature to

the watt density curve’s intersecting

point. This shows the recommended

watt density based on a maximum

sheath temperature of 1400°F

(760°C). For longer heater life,

lower watt densities should be

chosen.

Watt Density vs. Sheath

Temperature

The Watt Density vs. Sheath

Temperature graph shows the air

velocity (FPM or MPM) required to

operate a WATROD duct heater at

specific watt densities or sheath

temperatures. Also depicted is the

appropriate watt density vs. sheath

temperature at a specified air flow.

Duct Heaters

413

Loading...

Loading...