Page 1

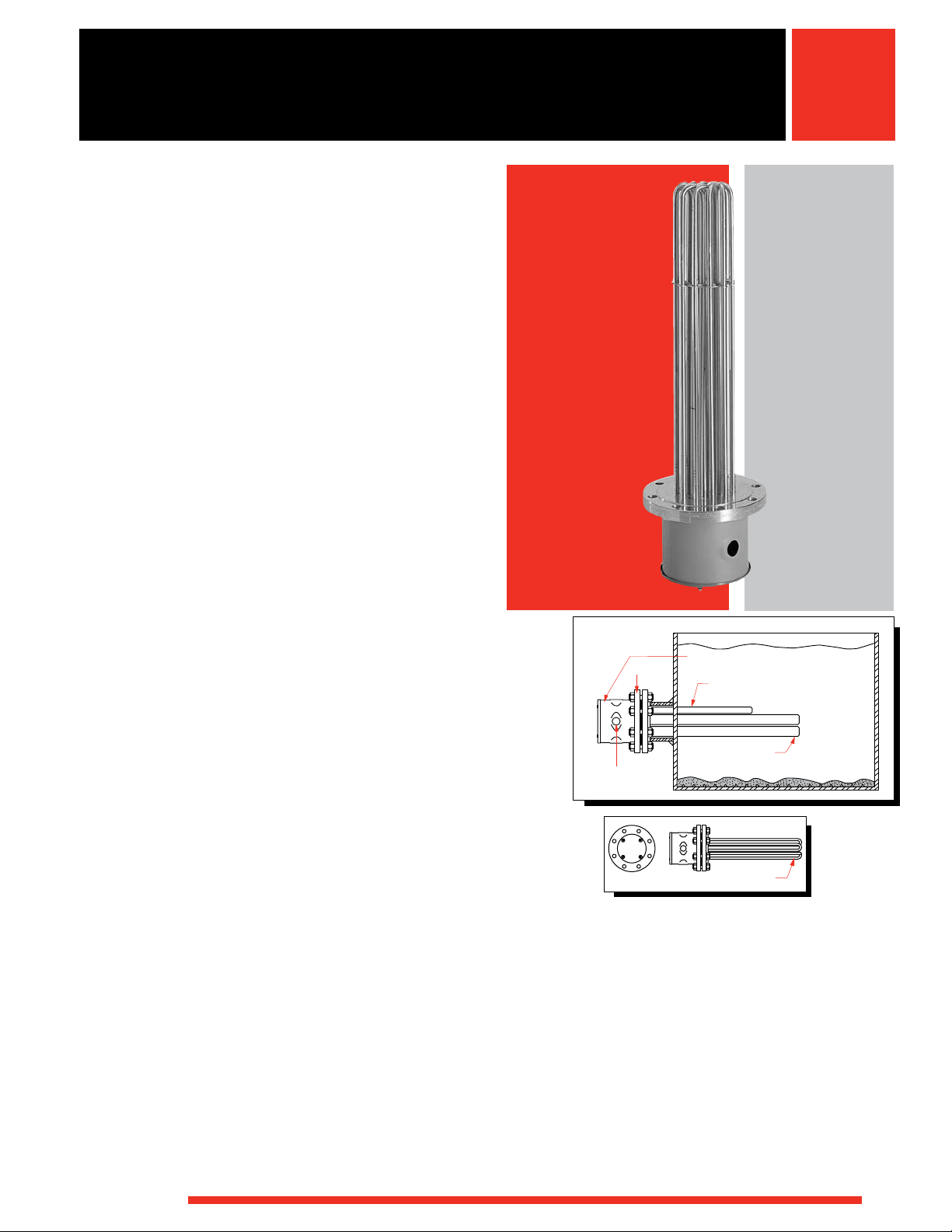

Immersion Heaters

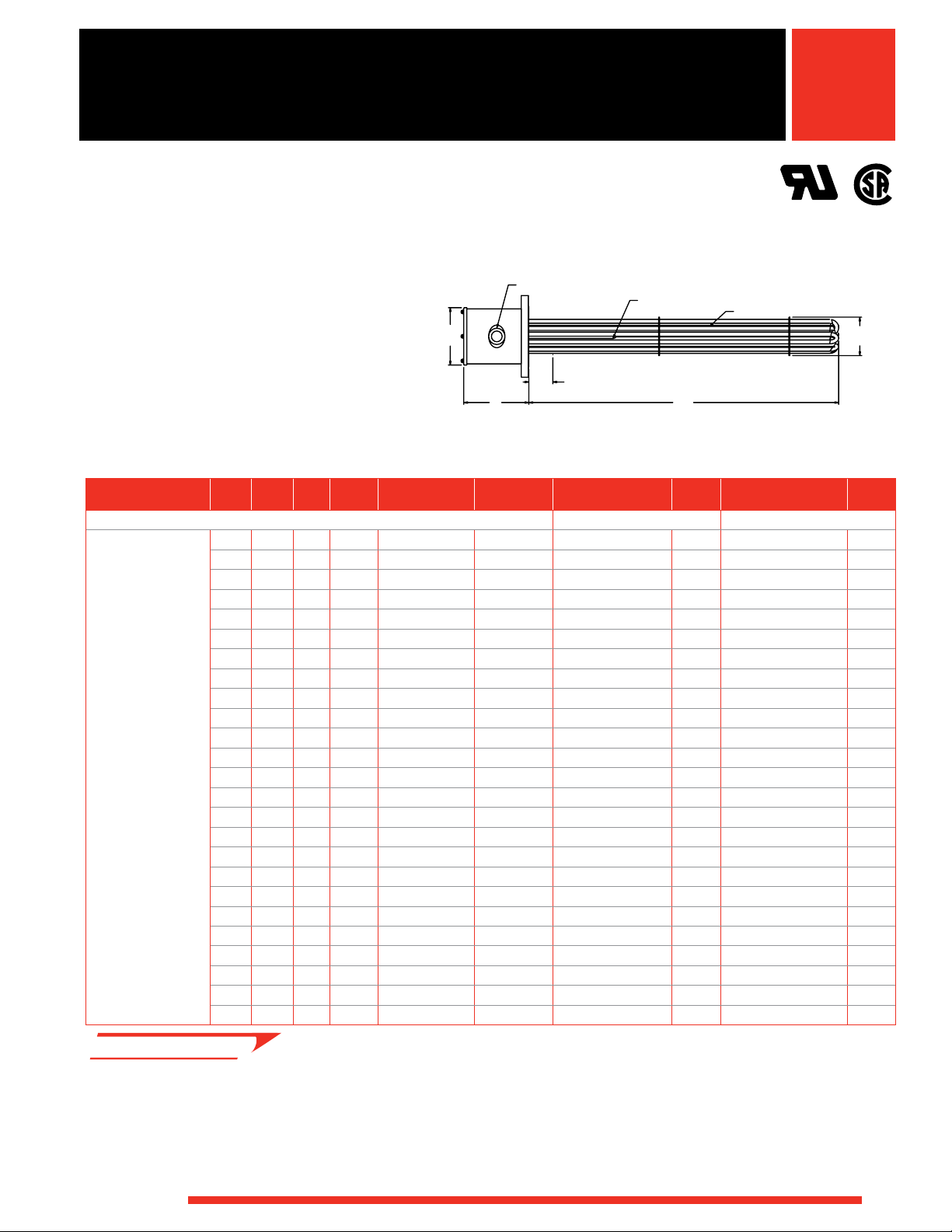

WATROD and FIREBAR ANSI Flange

Immersion Heaters

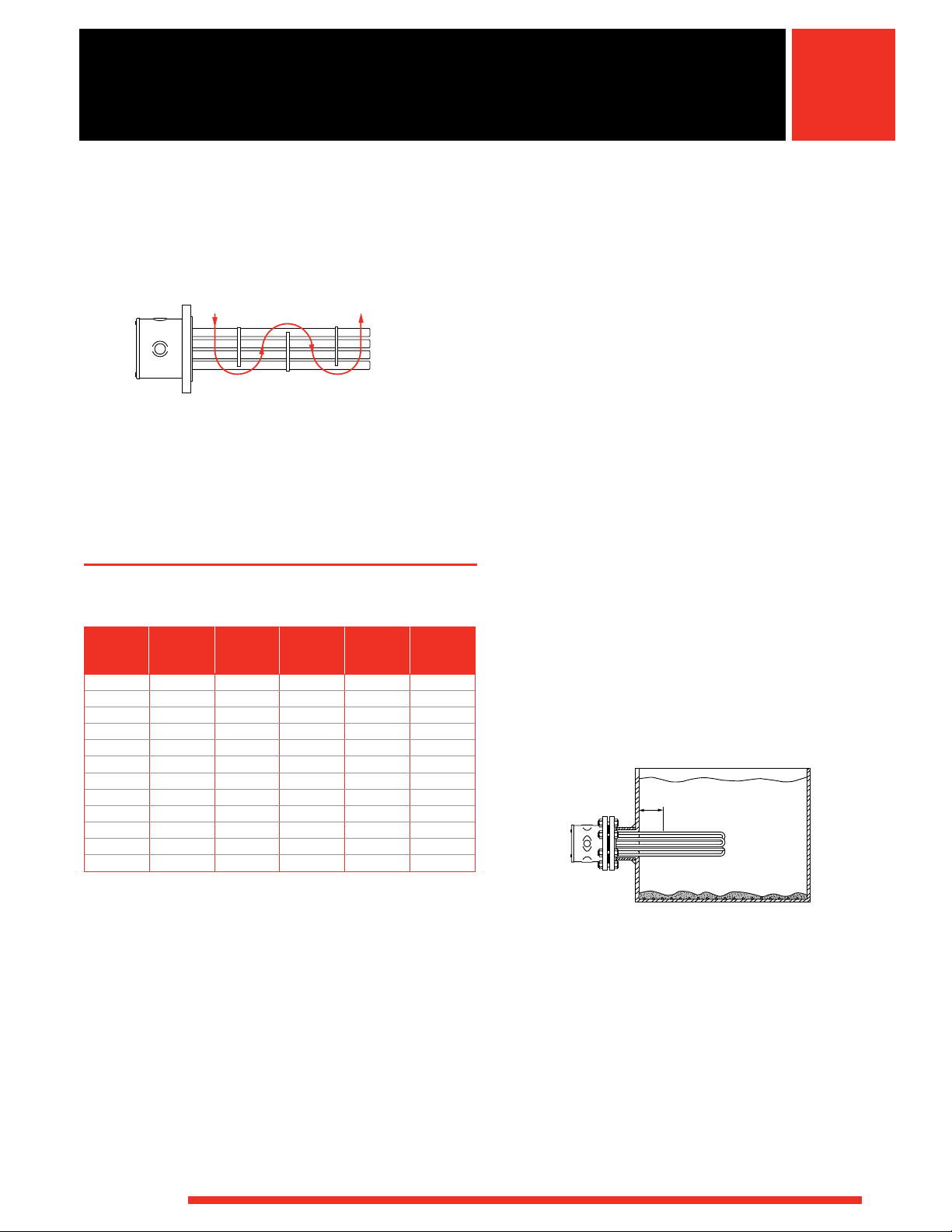

Watlow flange heaters are easy to install and maintain.

Designed for heating liquids and gases in tanks and

pressure vessels, flange immersion heaters are ideal for

applications requiring higher kilowatts.

Watlow flange heaters are made with WATROD or

FIREBAR tubular elements brazed or welded to a flange.

Stock flange heaters are equipped with a general purpose

terminal enclosure.

Flange heaters, with FIREBAR elements, also answer

the need for liquid immersion applications requiring high

kilowatts in small tanks. The FIREBAR element’s unique

flat surface geometry packs more power in a smaller

bundle, with lower watt density, making it especially

well-suited for petroleum-based liquid heating applications.

Performance Capabilities

• Watt densities up to 100 W/in2 (15.5 W/cm2)

• Wattages up to three megawatts

• UL® and CSA component recognition up to 600VAC

• Alloy 800/840 sheath temperatures up to 1600°F

(870°C)

• Passivated 316 stainless steel sheath temperatures up

to 1200°F (650°C)

• 304 stainless steel sheath temperatures up to

1200°F (650°C)

• Steel sheath temperatures up to 750°F (400°C)

• FIREBAR flange heaters deliver more kilowatts in

smaller bundles

• A conventional round tubular 10-inch ANSI flange can

be replaced by a 6-inch ANSI FIREBAR flange with

same immersed length

Flange

Conduit Opening

Terminal Enclosure

Thermowell

FIREBAR

Heating Element

Features and Benefits

ANSI and ANSI compatible 2, 21/2, 3 thru 48 inch

flanges

• Provides appropriate heater size-to-application and fit

Element sheath and flange materials

• Meets your application needs

Integral thermowells

• Provides convenient temperature sensor insertion and

replacement without draining the fluid being heated

Standard, general purpose terminal enclosure

• Offers easy access to wiring

WATLOW

®

WATROD Heating Element

Element support(s)

• Provides proper element spacing to maximize heater

performance and life

All units are inspected and/or tested

• Ensures element-to-flange pressure seals do not leak

Drilled and tapped eyebolt holes or lift lugs for eye

bolts on 10 inch and larger flange heaters

• Facilitates lifting during installation

WATROD hairpins are repressed (recompacted)

• Provides improved heater life, insulation resistance and

heat transfer

237

Page 2

Immersion Heaters

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Features and Benefits (Continued)

FIREBAR flange heaters pack more kilowatts into a

smaller bundle

• Includes a conventional round tubular 10 in. (254 mm)

ANSI flange which can be replaced by a 6 in.

(152 mm) ANSI FIREBAR flange with the same

immersed length

Branch circuits are designed for 48 amperes per

circuit maximum

• Reduces risk of failure due to excessive temperatures

generated by high amperage

UL® and CSA component recognition under file

numbers E52951 and 31388 respectively

• Simplifies obtaining third-party recognition for

assembly

Typical Applications

• Water:

Deionized

Demineralized

Clean

Potable

Process

• Industrial water rinse tanks

• Vapor degreasers

• Hydraulic oil, crude, asphalt

• Lubricating oils at API specified watt densities

• Air and gas flow

• Caustic solutions

• Chemical baths

• Process air equipment

• Boiler equipment

• Freeze protection of any fluid

• Anti-freeze (glycol) solutions

• Paraffin

Options

Terminal Enclosures

General purpose terminal enclosures, without

thermostats, are standard on all flange immersion

heaters. Optional terminal enclosures include:

• General purpose with a single or double pole

thermostat.

• Moisture resistant. Available with or without a single

or double pole thermostat.

• Corrosion resistant. Available with or without a single

or double pole thermostat.

• Explosion resistant Class 1, Div. 1 and 2, Groups B, C,

D, T1 - T6. Available with or without a single or double

pole thermostat.

• Explosion/moisture resistant combinations. Available

with or without a single or double pole

thermostat.

Prior to ordering, refer to the terminal enclosure

dimensions on page 243. Order by adding the

appropriate suffix letter(s) to the base flange heater

part number, as shown on the Ordering information chart.

Heater part numbers and suffix letters are depicted on

the charts, pages 244 to 305. Specify class and group,

if applicable.

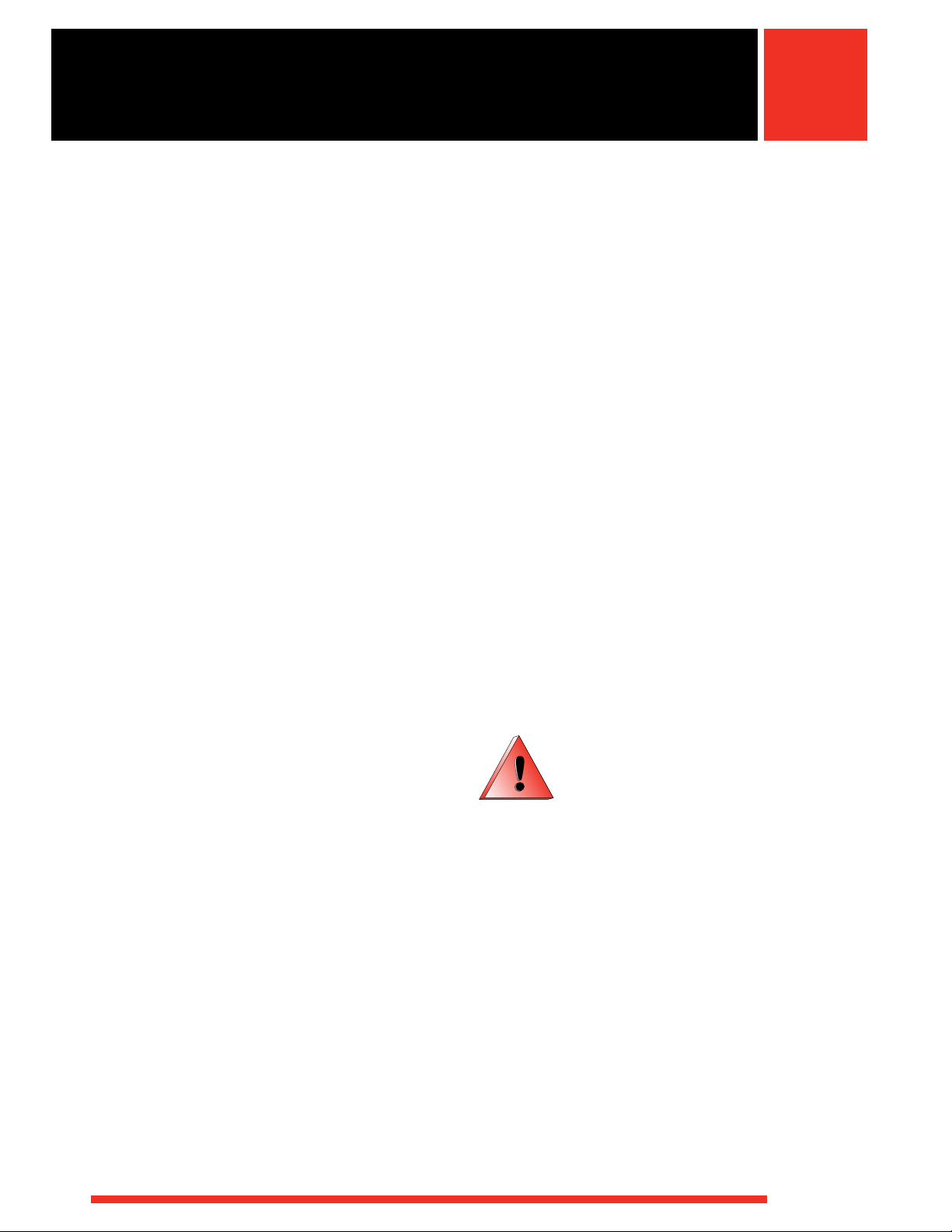

Caution

Explosion-resistant terminal enclosures are intended

to provide explosion containment in the electrical

termination/wiring enclosure only. No portion of the

assembly outside of this enclosure is covered under

this rating. Rating effectiveness may be compromised

by abuse or misapplication.

238

WATLOW

®

Page 3

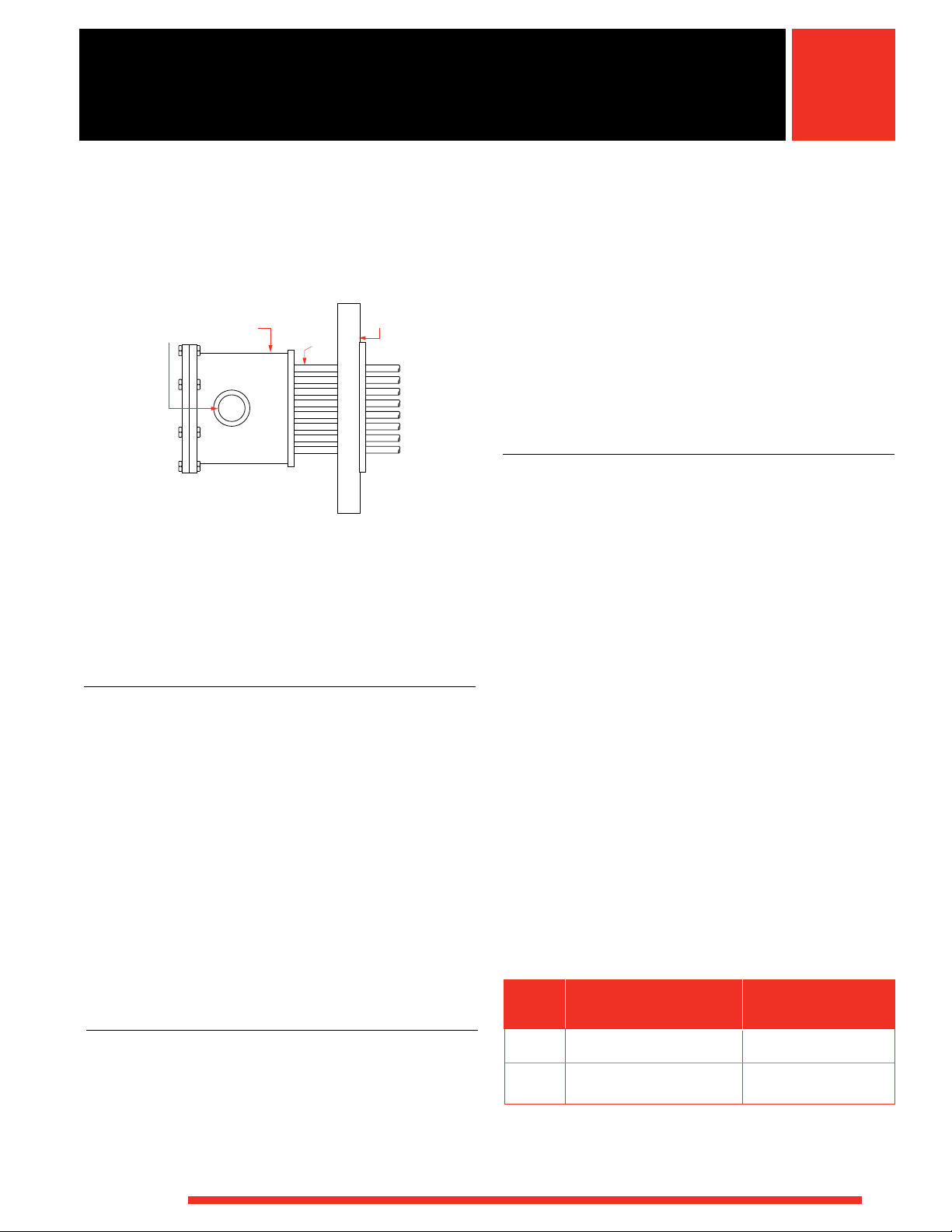

Immersion Heaters

Stand-off

Terminal

Enclosure

Conduit

Openings

Ref. 6 in.

(152 mm)

Stand-off

Height

ANSI

Flange

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Options (Continued)

Stand-off Terminal Enclosures

Ref. 6 in.

Conduit

Openings

Stand-off

Terminal

Enclosure

(150 mm)

Stand-off

Height

Stand-off terminal enclosures provide an air-insulating

barrier between the flange and terminal enclosure by

mounting the terminations and wiring away from the

flange. Stand-off terminal enclosures are recommended

whenever a process operating temperature exceeds

210°F (100°C). This helps minimize terminal enclosure

temperatures.

To order, specify stand-off terminal enclosure.

ANSI

Flange

Certified Enclosures

CSA, ATEX or IECEx certified enclosures protect wiring in

hazardous gas environments. These terminal enclosures,

covered under CSA file number 61707, ATEX certificate

# SIRA 10ATEX1155X or IECEx certificate # IECEx CSA

09.0010X are available on WATROD flange heaters. For

additional information, see page 567 and 568 or contact

your Watlow representative.

For products that will be installed in hazardous locations,

please provide the following information:

• Operating conditions

• Minimum and maximum ambient temperatures for the

installation location

• Mounting orientation

Watlow must understand this information so that an

appropriate design can be provided.

ASME Pressure Vessel Code Welding

Flange assemblies can be provided with an ASME

Section VIII, Div. I pressure vessel stamp upon request.

WATLOW

®

Thermostats

To provide process temperature control, Watlow offers

optional single pole, single throw (SPST) and double pole,

single throw (DPST) thermostats.

Unless otherwise specified, thermostats are mounted

inside the terminal enclosure. For details and ordering

information, refer to Thermostats on pages 534 to 537.

Please verify that the thermostat’s sensing bulb O.D. is

compatible with the flange heater’s thermowell I.D.

Thermocouples

ASTM Type J or K thermocouples offer more accurate

sensing of process and/or sheath temperatures. A

thermocouple may be inserted into the thermowell or

attached to the heater’s sheath.

Thermocouples are supplied with 120 in. (3050 mm)

leads (longer lead lengths available). Unless otherwise

specified, thermocouples are supplied with temperature

ranges detailed on the Thermocouple Types chart.

Using a thermocouple requires an appropriate

temperature and power controller. These must be

purchased separately. Watlow offers a wide variety of

temperature and power controllers to meet virtually all

applications. Temperature controllers can be configured

to accept process variable inputs, too. Contact your

Watlow representative for details.

To order, specify Type J or K thermocouple and lead

length. Indicate if the thermocouple is for process

temperature sensing or heater sheath high-limit

protection. Please specify if the flange heater will be

mounted vertical or horizontal in the tank. If vertical,

specify if the housing is on top or bottom.

If the flange heater is part of an in-line circulation heating

application, indicate flow direction relative to the heater’s

enclosure.

Thermocouple Types

Recommended

ASTM Conductor Characteristics Temperature Range

Type Positive Negative °F (°C)

J Iron Constantan 0 to 1000 (-20 to 540)

(Magnetic) (Non-magnetic)

K Chromel

(Non-magnetic) (Magnetic)

① Type J and Type K thermocouples are rated 32 to 1382°F and

32 to 2282°F (0-750°C and 0-1250°C), respectively. Watlow does

not recommend exceeding temperature ranges shown on this chart

for the tubular product line.

®

Alumel® 0 to 2000 (-20 to 1100)

①

239

Page 4

Immersion Heaters

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Options (Continued)

Wattages and Voltages

Watlow routinely supplies flange immersion heaters with

240 to 480VAC as well as wattages from 150 watts to

one megawatt.

Sheath Materials

The following sheath materials are available on WATROD

and FIREBAR flange heaters:

Standard Sheath Materials

WATROD Alloy 800, 840

316 SS

Steel

FIREBAR Alloy 800

Exotic Sheath Materials

Contact your Watlow representative for details and

availability.

External Finishing

Passivation

During the manufacturing process, particles of iron or

tool steel may become embedded in the stainless steel

or alloy sheath. If not removed, these particles may

corrode, produce rust spots and/or contaminate the

process. For critical sheath applications, passivation

will remove free iron from the sheath. To order,

specify passivation.

Other Finishes

Bright annealing available to meet cosmetic demands.

Flanges

Flange Sizes and Styles

Standard: 2①, 21/2①, 3 to 48 inch ANSI raised face/blind

flanges.

Made-to-Order: 16, 18, 20 and 24 inch in any

recognized configuration, as well as customer specified.

Over 48 inch ANSI flange, contact your Watlow

representative.

Flange Materials

Standard Carbon steel

316 SS

304 SS

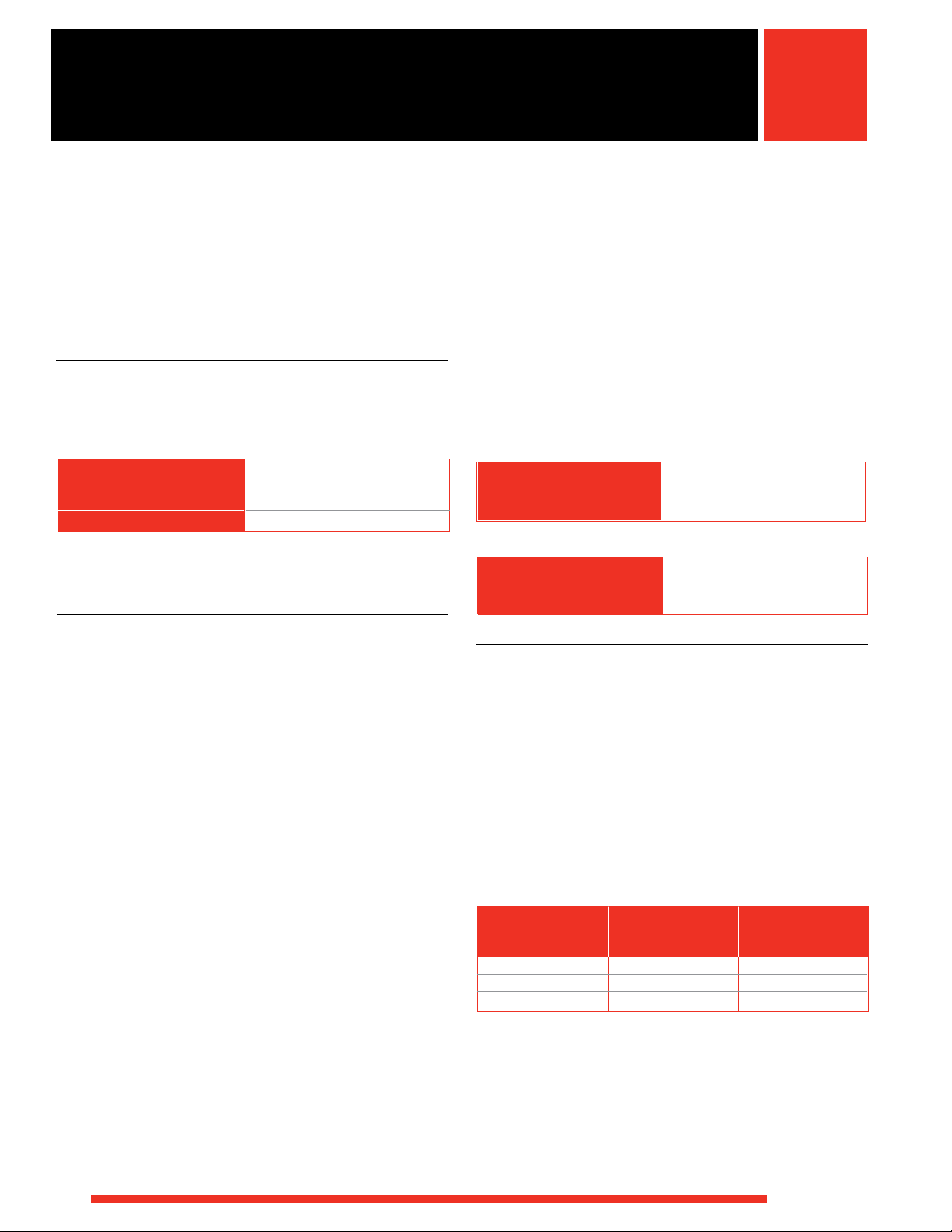

Pressure Classes

Standard 150 lb

300 lb

600 lb

① ANSI bolt pattern only

Gaskets

Rubber, asbestos-free and spiral wound gaskets are

available for all flange sizes. Order by specifying gasket

type, flange size/rating, process operating temperature

and pressure.

To make the correct selection, see the Gasket Selection

chart. It provides a recommended gasket type and

effective temperature rating.

To use this chart, multiply operating temperature by the

operating pressure to arrive at “Maximum PSIG x °F.”

This is listed in the chart’s first column.

Gasket Selection

Maximum Temperature

PSIG x °F °F Gasket Type

Up to 15,000 300 Rubber

Over 250,000 700 Asbestos-Free

Over 250,000 ③ Spiral Wound

Gasket

240

③ Depends on metal gasket material.

WATLOW

®

Page 5

Immersion Heaters

Direction of Flow

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Options (Continued)

Baffles

Direction of Flow

For forced circulation applications, 316 stainless steel

baffles can be arranged on the heating element bundle

to enhance and/or modify fluid or gas flow for better

heat transfer.

For open tank or convection heating applications,

standard element supports will be supplied.

To order, specify baffles.

ANSI Raised Face Blind Flange,

150# Class Dimensions

Pipe Size

3 7.50 0.94 6.00 0.75 4

4 9.00 0.94 7.50 0.75 8

5 10.00 0.94 8.50 0.88 8

6 11.00 1.00 9.50 0.88 8

8 13.50 1.12 11.75 0.88 8

10 16.00 1.19 14.25 1.00 12

12 19.00 1.25 17.00 1.00 12

14 21.00 1.38 18.75 1.12 12

16 23.50 1.44 21.25 1.12 16

18 25.00 1.56 22.75 1.25 16

20 27.50 1.69 25.00 1.25 20

24 32.00 1.88 29.50 1.38 20

Outside

Diameter

Flange

Thickness

Diameter

of Bolt

Circle

Diameter

of Bolt

Holes

Number of

Bolt Holes

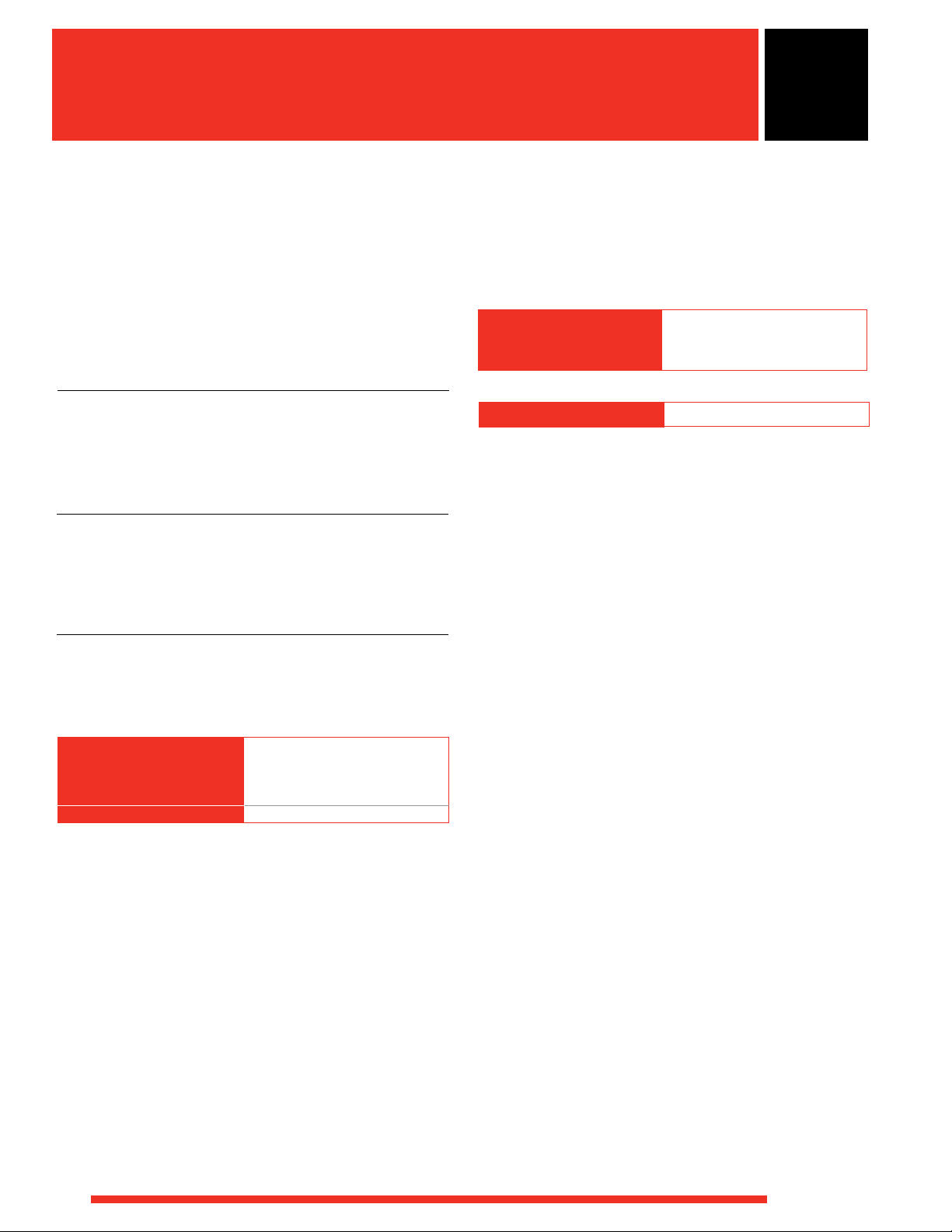

Application Hints

• Select the recommended heating element sheath

material and watt density for the substance being

heated. Use the Supplemental Applications Chart on

pages 555 to 560. If unable to determine the correct

heating element sheath material and type, contact your

Watlow representative.

• Extend the element no-heat section completely into

the fluid being heated to help prevent premature heater

failure. See accompanying illustration for proper

no-heat section placement.

• Locate flange heater low in the tank, but above the

sludge level.

• Choose a FIREBAR element when your application

requires a smaller system package or lower watt

density.

• Ensure wiring integrity by keeping terminal enclosure

temperature below 400°F (205°C).

• Size power feeder wires in accordance with National

Electrical Code guidelines and other applicable codes.

• Keep electrical connections clean, dry and tight.

• Minimize problems associated with low liquid level

conditions by using low liquid level sensor or sheath

temperature high-limit control.

No-Heat

Section

WATLOW

• Periodically remove the flange assembly to inspect

and clean the heating element(s). This preventive

maintenance will reduce premature failure and optimize

heater performance.

• Refer to the Installation and Maintenance Instructions

for correct orientation of FIREBAR elements. This is

important in air applications with customer-supplied

circulation tanks. Correct element orientation to flow

minimizes pressure drop and increases buoyancy force

and heater performance.

®

241

Page 6

Immersion Heaters

Extended Capabilities For

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Options

Enclosure Enhancements

• Enclosure heater to solve condensation and freeze

problems.

• Power distribution blocks to facilitate power feed line

wiring.

RTDs

If the process requires greater temperature sensing

accuracy than is possible with thermocouples, Watlow

can also supply RTDs in DIN or JIS calibrations. Contact

your Watlow representative for details.

Wattages and Voltages

If required, Watlow will make heaters with voltage up

to 600VAC and wattage beyond one megawatt. For

more information on special voltage and wattage

configurations, contact your Watlow representative.

xtEndEd

E

apability

C

Flanges

Flange Materials

Extended Exotic materials to

meet specific

application needs ①

Pressure Classes

Extended Over 600 lb ①

① Contact your Watlow representative

Sheath Materials

The following sheath materials are available on WATROD

and FIREBAR flange heaters:

Extended Sheath Materials

WATROD Titanium

304 and 321 SS

Hastelloy C276

Alloy 400 and 600

FIREBAR 304 SS

242

WATLOW

®

Page 7

Immersion Heaters

'K'

4" = 7 7/8

5" = 8 7/8

6" = 9 7/8

8" = 12 1/8

10" = 14 5/8

12" = 17 1/4

14" = 19 3/8

75⁄8 in.

(193.7 mm)

5

¾ in.

(146 mm)

7

½ in. Ref.

(191 mm)

“F”

3 in. - 150# ANSI Flange

“D”

3" AND 4" FLANGE

'K'

5" = 8 7/8

6" = 9 7/8

8" = 12 1/8

10" = 14 5/8

12" = 17 1/4

14" = 19 3/8

7½ in. Ref.

(191 mm)

“F”

5

¾ in. Ref.

(146 mm)

7

5⁄8

in.

(193.7 mm)

“D”

95⁄16 in.

(237 mm)

“F”

“D”

“K”

4 in. - 150# ANSI Flange

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Optional Moisture/Explosion Resistant

Enclosure Without Thermostat

Optional Moisture/Explosion Resistant

Enclosure With Thermostat

75⁄8 in.

(193.7 mm)

3 in. - 150# ANSI Flange

“D”

5⁄8

7

in.

(193.7 mm)

¾ in.

5

(146 mm)

7

½ in. Ref.

(191 mm)

“F”

4 to 14 in. - 150# ANSI Flange

“D”

“K”

77⁄8 in.

(200 mm)

“F”

“K”

Terminal Enclosure Dimensions

General Purpose & Moisture Resistant Enclosures

ANSI Flange

Size

in.

3

4

“F”

Thickness

in. (mm)

15

/16 (23.8) 53/4

15

/16 (23.8) 53/4

“K”

With

Thermostat

(146)

(146)

“K”

Without

Thermostat

See heater dwg.

See heater dwg.

“D”

in. (mm)

71/2

(191)

9 (229)

Note: 5 thru 12 in. (127 thru 305 mm) flange dimensions are on catalog

heater drawings.

Moisture/Explosion Resistant Enclosures

ANSI Flange

Size

in.

3

4

5

6

8

10

12

14

Optional General

Purpose/Moisture

Resistant Enclosure

“F”

Thickness

in. (mm)

15

/16 (23.8) N/A N/A 71/2 (191)

15

/16 (23.8) N/A

15

/16 (23.8)

1 (25.0)

11/8 (28.6)

13/16 (30.2)

11/4 (32.0)

13/8 (34.9)

“K”

With

Thermostat

“K”

Without

Thermostat

77/8 (200.0)

87/8 (225.4)

97/8 (250.8)

87/8 (225.4)

97/8 (250.8)

121/8 (308.0) 121/8 (308.0)

145/8 (371.5) 145/8

(371.5)

171/4 (438.0) 171/4 (438.0)

193/8 (492.1) 193/8 (492.1)

in. (mm)

9 (229)

10 (254)

11 (280)

131/2

16 (407)

19 (483)

21 (534)

Optional Moisture

Resistant Enclosure

With Thermostat

“D”

(343)

With Thermostat

“K”

“K”

¾

in. Ref.

5

(146 mm)

7½ in. Ref.

(191 mm)

7⁄8 in.

7

(200 mm)

“F”

“D”

3 and 4 in. - 150# ANSI Flange

“D”

5 to 14 in. - 150# ANSI Flange

To order: Reference the Ordering Information on page 306

WATLOW

®

9

5⁄16 in.

“F”

(237 mm)

3 in. - 150# ANSI Flange

Note: Dimensions for all 5 to 14 in. flange heaters with General Purpose

or Moisture Resistant Enclosure with thermostats are identical to units

supplied without thermostats.

“D”

“F”

4 in. - 150# ANSI Flange

“D”

95⁄16 in.

(237 mm)

“F”

243

Page 8

Immersion Heaters

2¾ in. O.D.

(70 mm)

¾ in. NPT Knockout

Thermowell

0.475 in. (12.1 mm)

Dia. Element

4 in. (102 mm) Cold (Ref.)

45⁄8 in.

(117.5 mm)

35⁄8 in. Dia.

(92.1 mm)

“B”

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

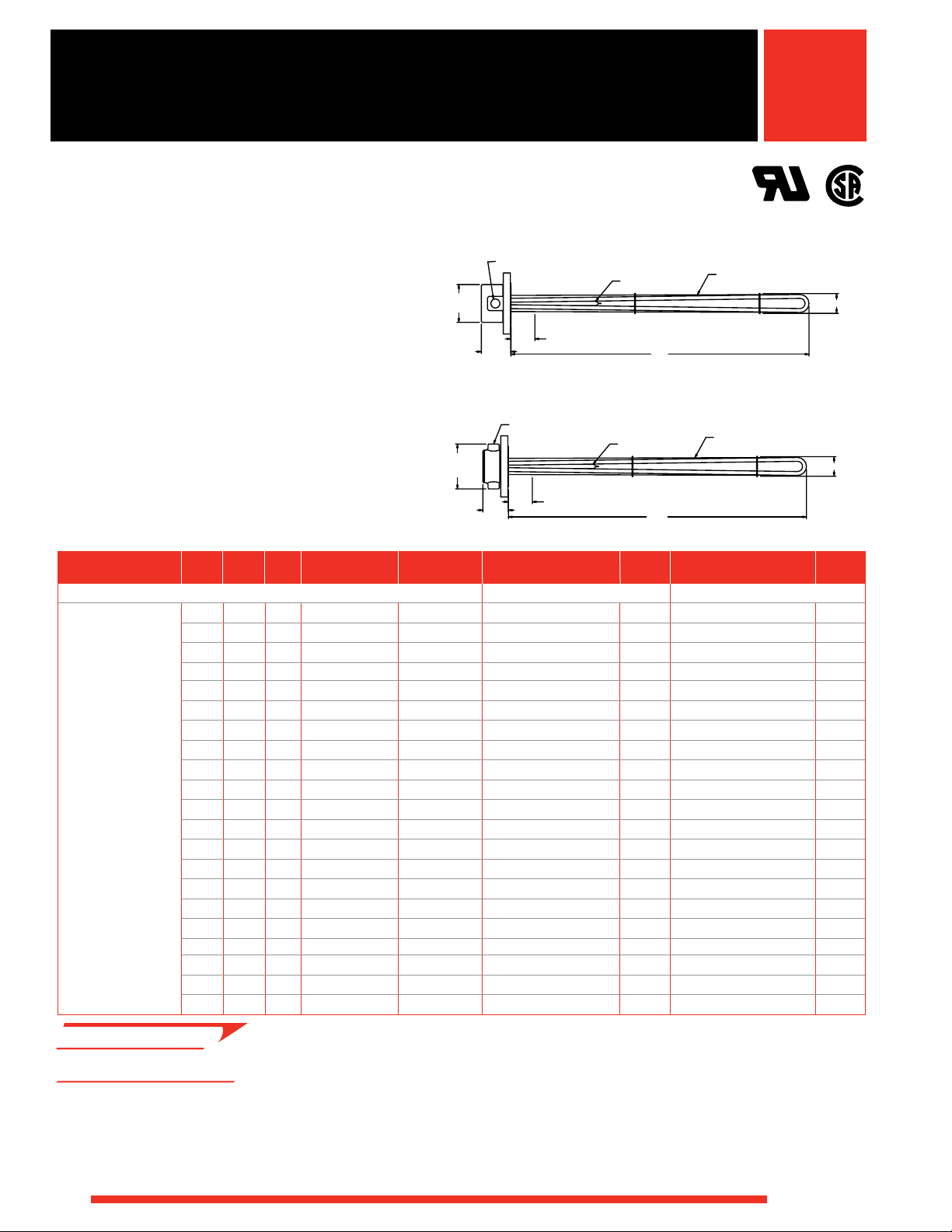

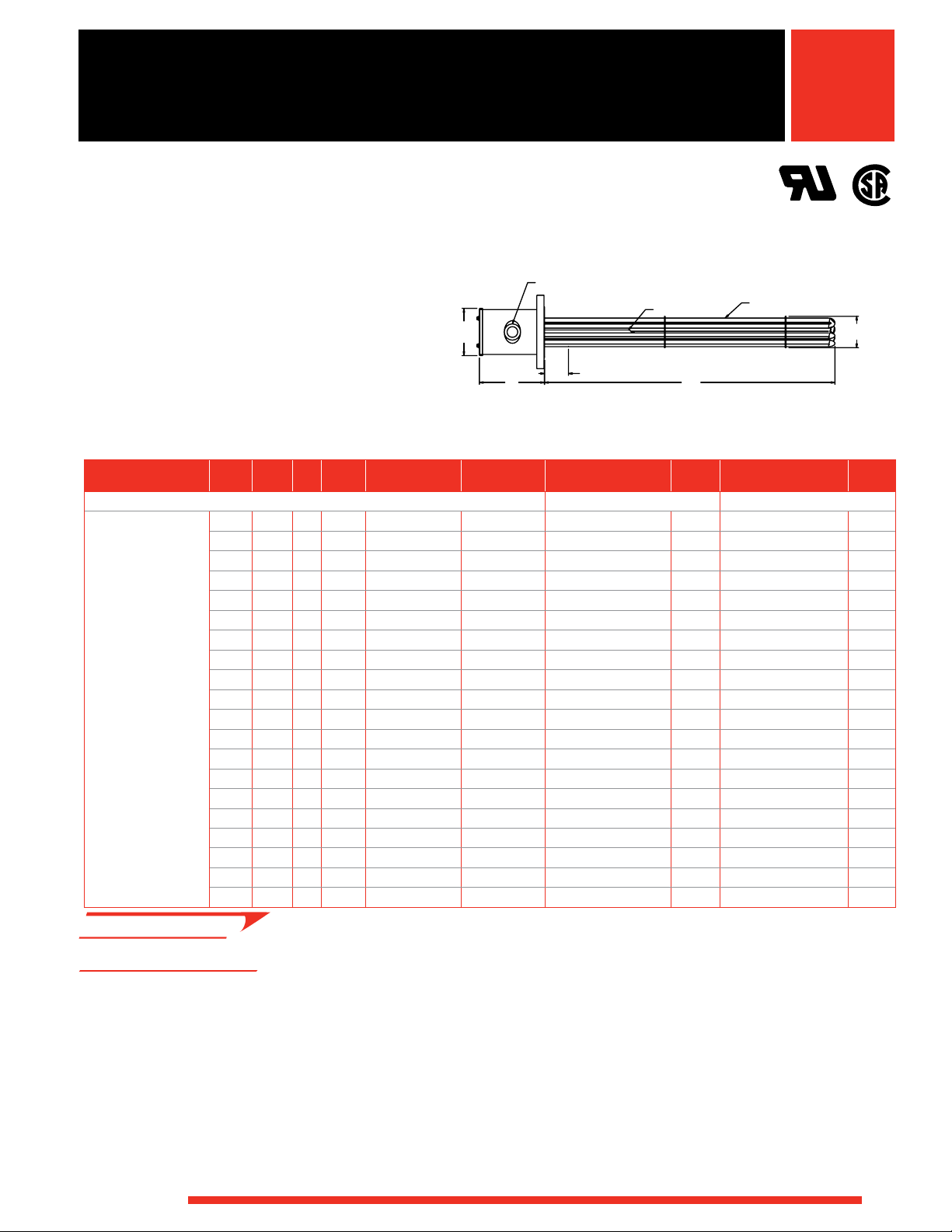

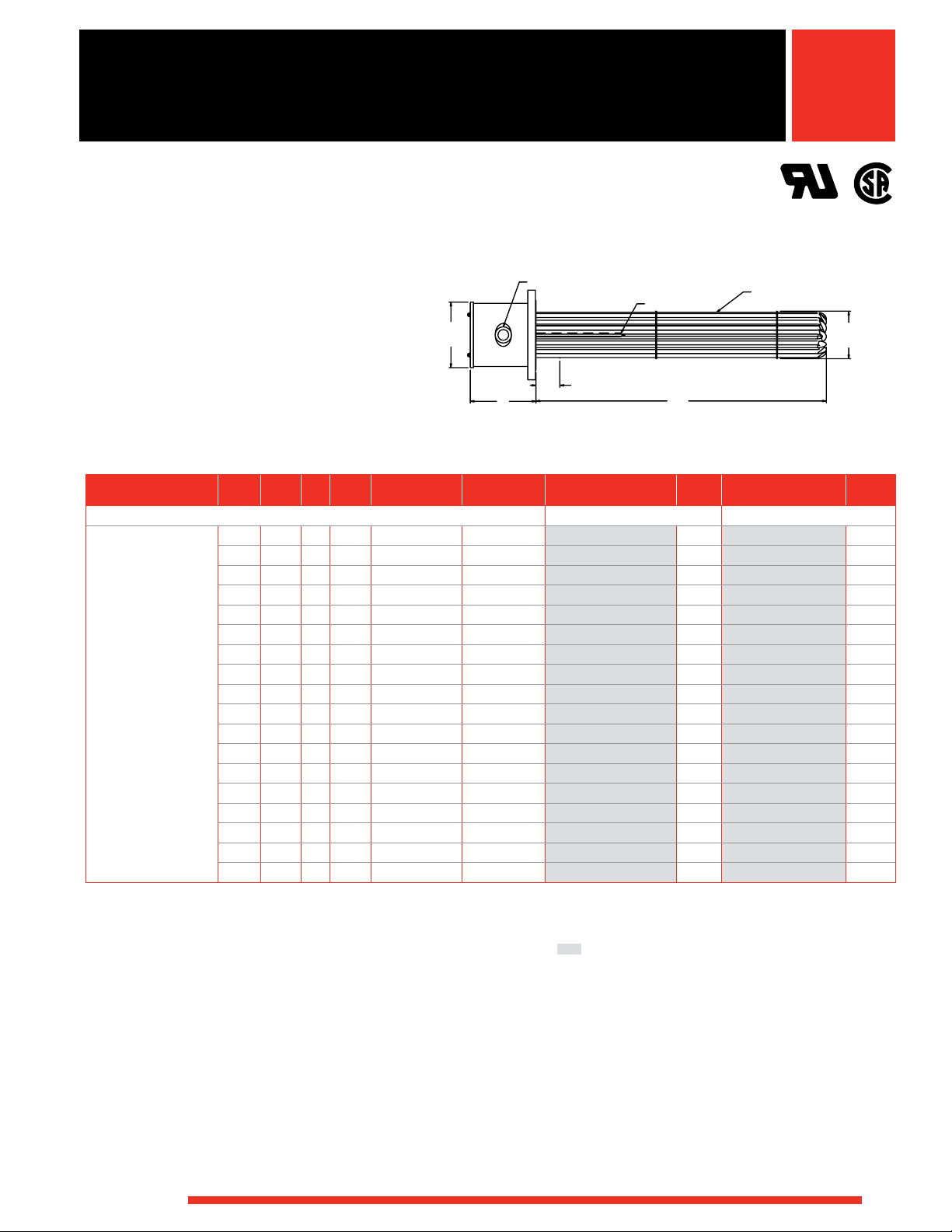

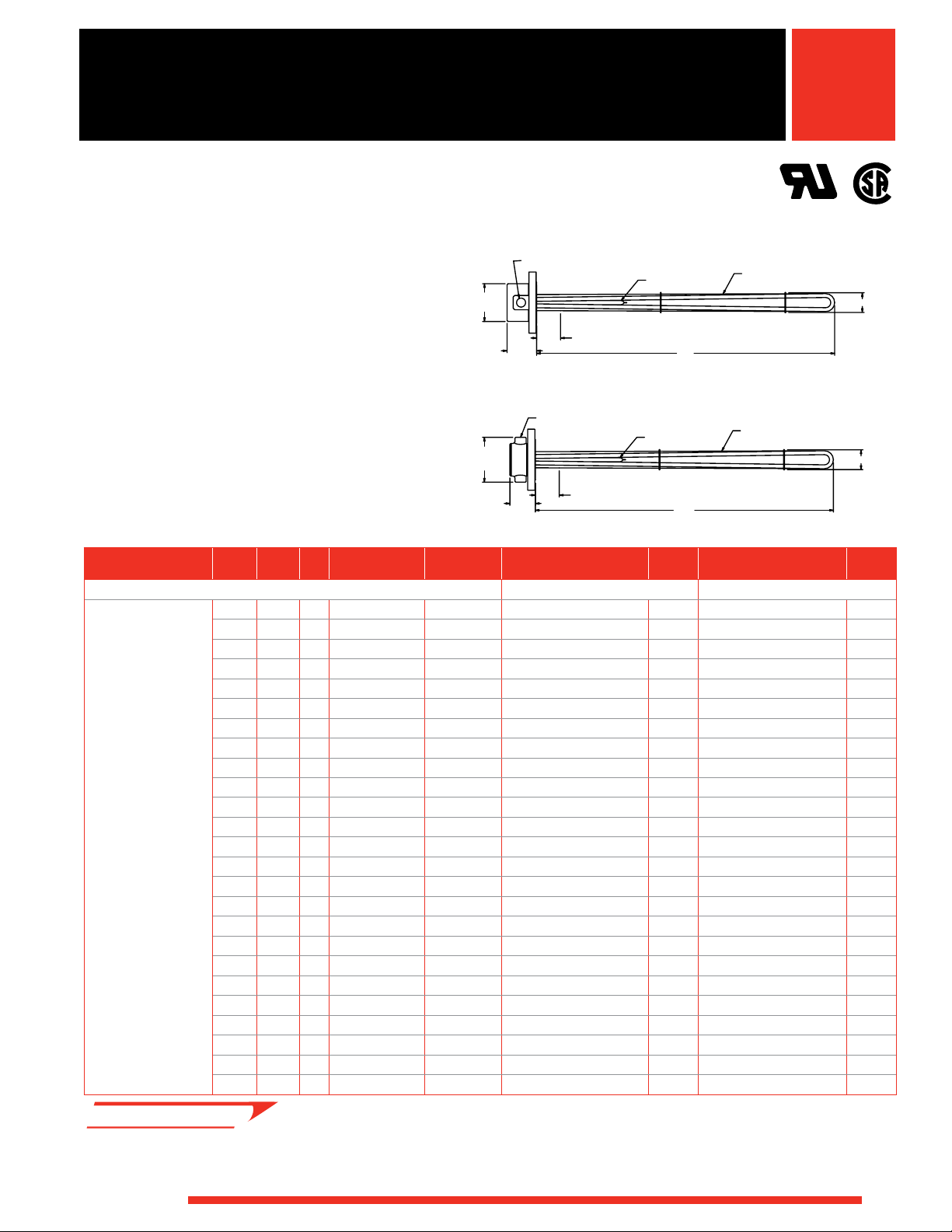

Application: Clean Water

• 3 inch - 150 lb ANSI flange.

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

• Single circuit

Description Volts kW Ph

• M - Manufacturing lead times

2

60 W/in

Steel Flange

3-Alloy 800

Elements

(9.3 W/cm2)

120 6.0 1 15

240 6.0 3 15

480 6.0 1 15

480 6.0 3 151/2 (394) 22 (10) FMN715J5S RS FMN715J5W RS

120 9.0 1 211/2 (546) 25 (12) FMN721J10S RS FMN721J10W RS

240 9.0 3 21

480 9.0 1 21

480 9.0 3 21

240 12.0 3 27 (686) 27 (13) FMN727A3S RS FMN727A3W RS

480 12.0 1 27 (686) 27 (13) FMN727A11S RS FMN727A11W RS

480 12.0 3 27 (686) 27 (13) FMN727A5S RS FMN727A5W RS

240 15.0 3 32

480 15.0 1 32

480 15.0 3 32

240 18.0 3 38 (965) 30 (14) FMN738A3S RS FMN738A3W RS

480 18.0 1 38 (965) 30 (14) FMN738A11S RS FMN738A11W RS

480 18.0 3 38 (965) 30 (14) FMN738A5S RS FMN738A5W RS

480 25.0 1 51 (1295) 34 (16) FMN751A11S RS FMN751A11W RS

480 25.0 3 51 (1295) 34 (16) FMN751A5S RS FMN751A5W RS

480 30.0 1 60

480 30.0 3 60

• RS - Next day shipment

up to 5 pieces

General Purpose

45⁄8 in.

(117.5 mm)

35⁄8 in. Dia.

(92.1 mm)

¾ in. NPT Knockout

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

0.475 in. (12.1 mm)

Dia. Element

Moisture Resistant

(2)

“B” Dim.

in. (mm)

53⁄8 in.

(136.5 mm)

1⁄8 in. Dia.

3

(79.4 mm)

Ship Wt.

lbs (kg)

¾ in. NPT Hubs

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

Part

Number Del.

0.475 in. (12.1 mm)

Dia. Element

Part

Number Del.

General Purpose Enclosure Moisture-Resistant Enclosure

1

/2 (394) 22 (10) FMN715J10S RS FMN715J10W RS

1

/2 (394) 22 (10) FMN715J3S RS FMN715J3W RS

1

/2 (394) 22 (10) FMN715J11S RS FMN715J11W RS

1

/2 (546) 25 (12) FMN721J3S RS FMN721J3W RS

1

/2 (546) 25 (12) FMN721J11S RS FMN721J11W RS

1

/2 (546) 25 (12) FMN721J5S RS FMN721J5W RS

1

/2 (826) 28 (13) FMN732J3S RS FMN732J3W RS

1

/2 (826) 28 (13) FMN732J11S RS FMN732J11W RS

1

/2 (826) 28 (13) FMN732J5S RS FMN732J5W RS

1

/2 (1537) 36 (17) FMN760J11S M FMN760J11W RS

1

/2 (1537) 36 (17) FMN760J5S M FMN760J5W RS

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

2¾ in. O.D.

(70 mm)

2¾ in. O.D.

(70 mm)

244

WATLOW

®

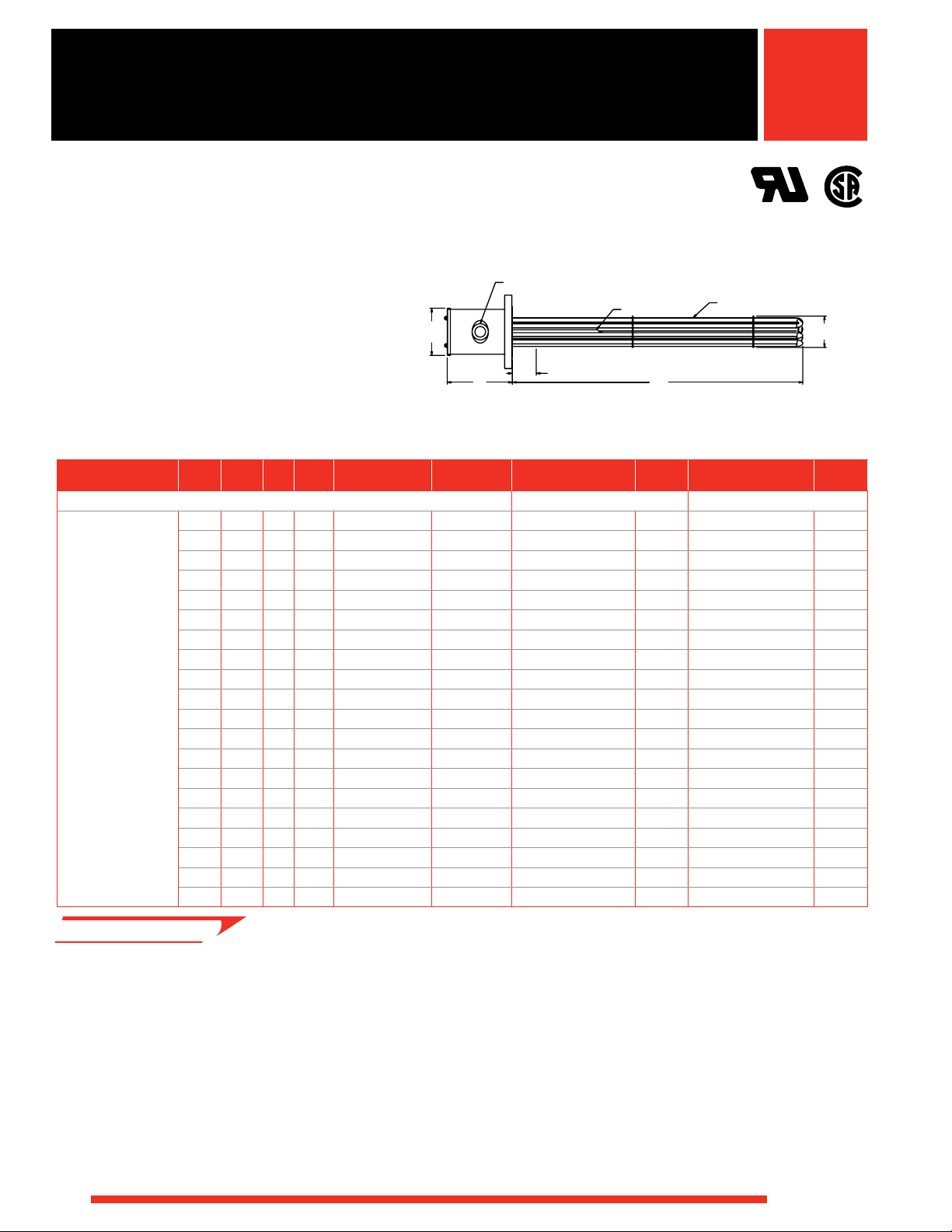

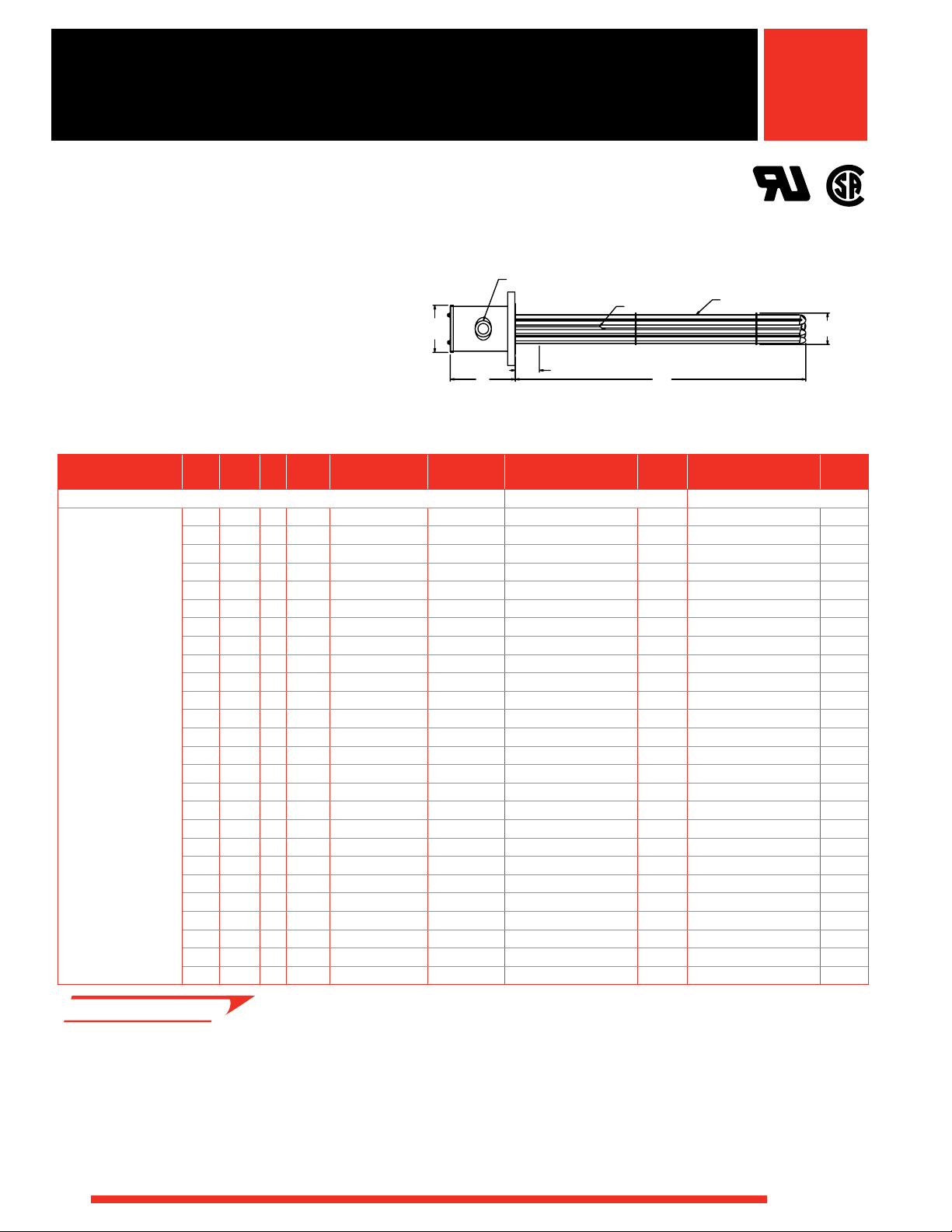

Page 9

Immersion Heaters

4"-150# FLANGE

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

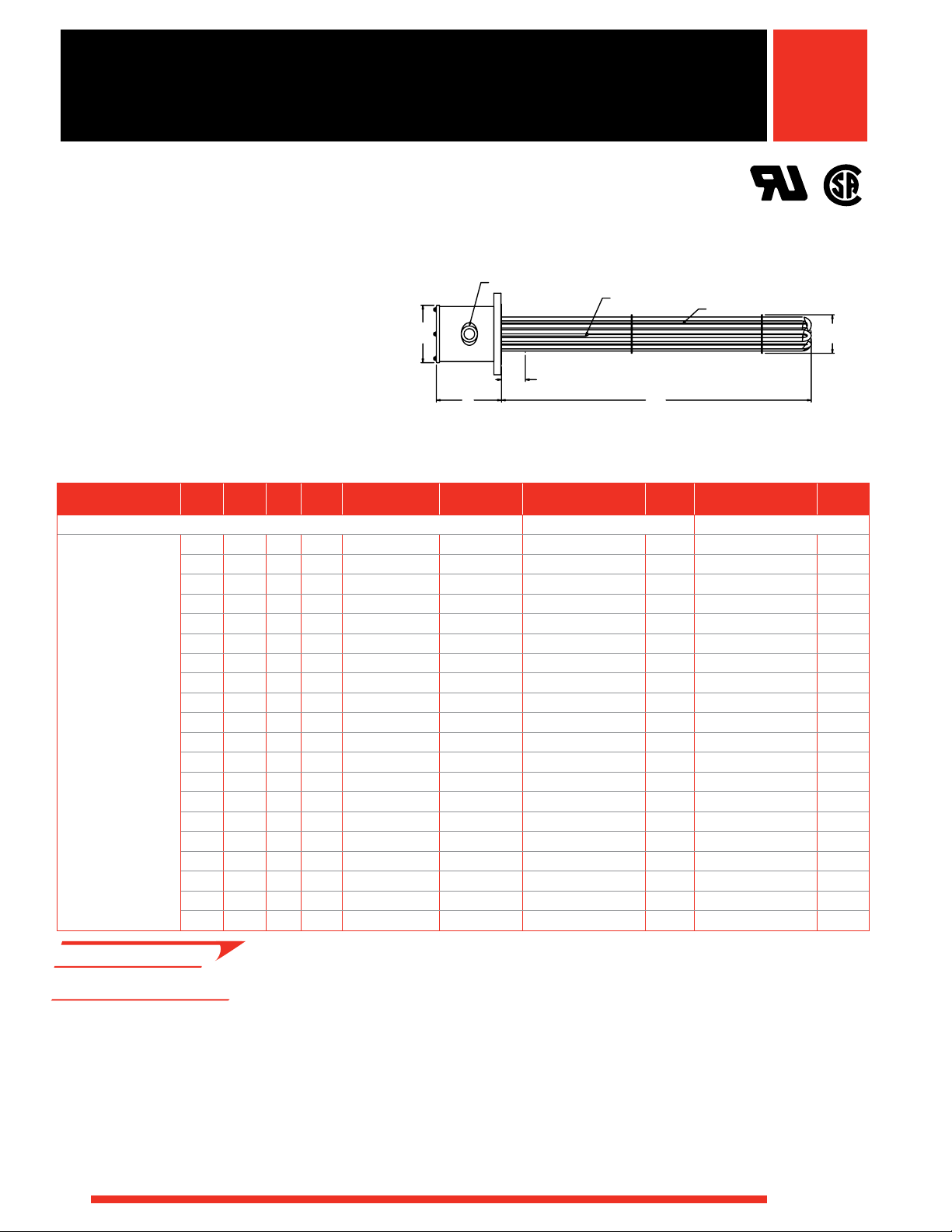

Application: Clean Water

• 4 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

Steel Flange

6-Alloy 800

Elements

(9.3 W/cm2)

• RS - Next day shipment

up to 5 pieces

• M - Manufacturing lead times

240 12.0 1 2 15

240 12.0 3 1 15

480 12.0 1 1 15

480 12.0 3 1 15

240 18.0 1 2 21

240 18.0 3 1 21

480 18.0 1 1 21

480 18.0 3 1 21

240 24.0 1 2 27 (686) 36 (17) FON727A10S RS FON727A10W RS

240 24.0 3 2 27 (686) 36 (17) FON727A3S RS FON727A3W RS

480 24.0 1 1 27 (686) 36 (17) FON727A11S RS FON727A11W RS

480 24.0 3 1 27 (686) 36 (17) FON727A5S RS FON727A5W RS

240 30.0 3 2 32

480 30.0 1 2 32

480 30.0 3 1 32

240 36.0 3 2 38 (965) 43 (20) FON738A3S RS FON738A3W RS

480 36.0 1 2 38 (965) 43 (20) FON738A11S RS FON738A11W RS

480 36.0 3 1 38 (965) 43 (20) FON738A5S RS FON738A5W RS

480 50.0 3 2 51 (1295) 48 (22) FON751A5S RS FON751A5W RS

480 60.0 3 2 60

General Purpose and

Moisture Resistant

0.475 in. (12.1 mm) Dia. Element

5

½

in.

(140 mm)

8 in.

(203 mm)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (394) 31 (14) FON715J10S RS FON715J10W RS

1

/2 (394) 31 (14) FON715J3S RS FON715J3W RS

1

/2 (394) 31 (14) FON715J11S RS FON715J11W RS

1

/2 (394) 31 (14) FON715J5S RS FON715J5W RS

1

/2 (546) 34 (16) FON721J10S RS FON721J10W RS

1

/2 (546) 34 (16) FON721J3S RS FON721J3W RS

1

/2 (546) 34 (16) FON721J11S RS FON721J11W RS

1

/2 (546) 34 (16) FON721J5S RS FON721J5W RS

1

/2 (826) 39 (18) FON732J3S RS FON732J3W RS

1

/2 (826) 39 (18) FON732J11S RS FON732J11W RS

1

/2 (826) 39 (18) FON732J5S RS FON732J5W RS

1

/2 (1537) 52 (24) FON760J5S M FON760J5W M

Ship Wt.

lbs (kg)

General Purpose Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

Part

Number Del.

Moisture-Resistant Enclosure

3

7⁄8 in. O.D.

(98.4 mm)

WATLOW

®

245

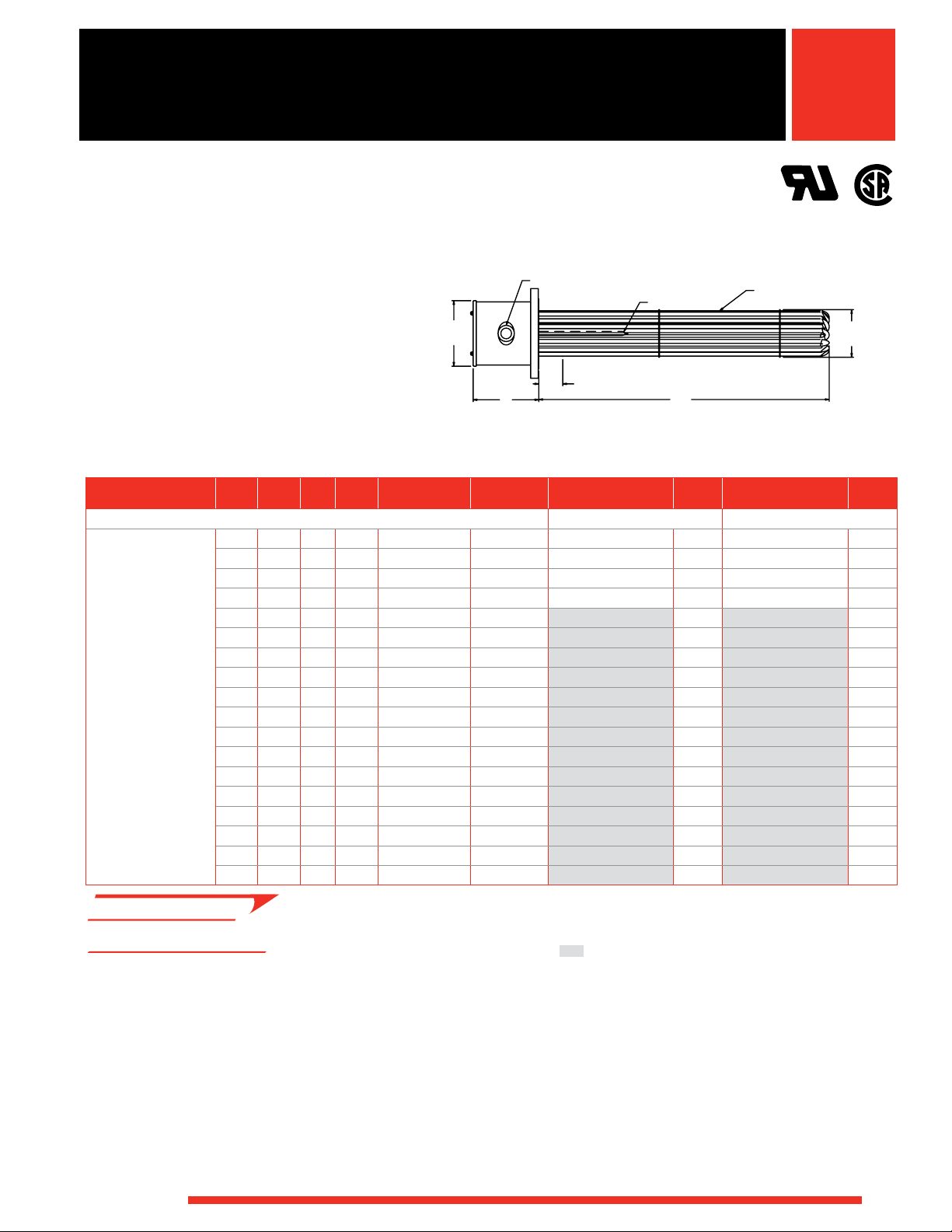

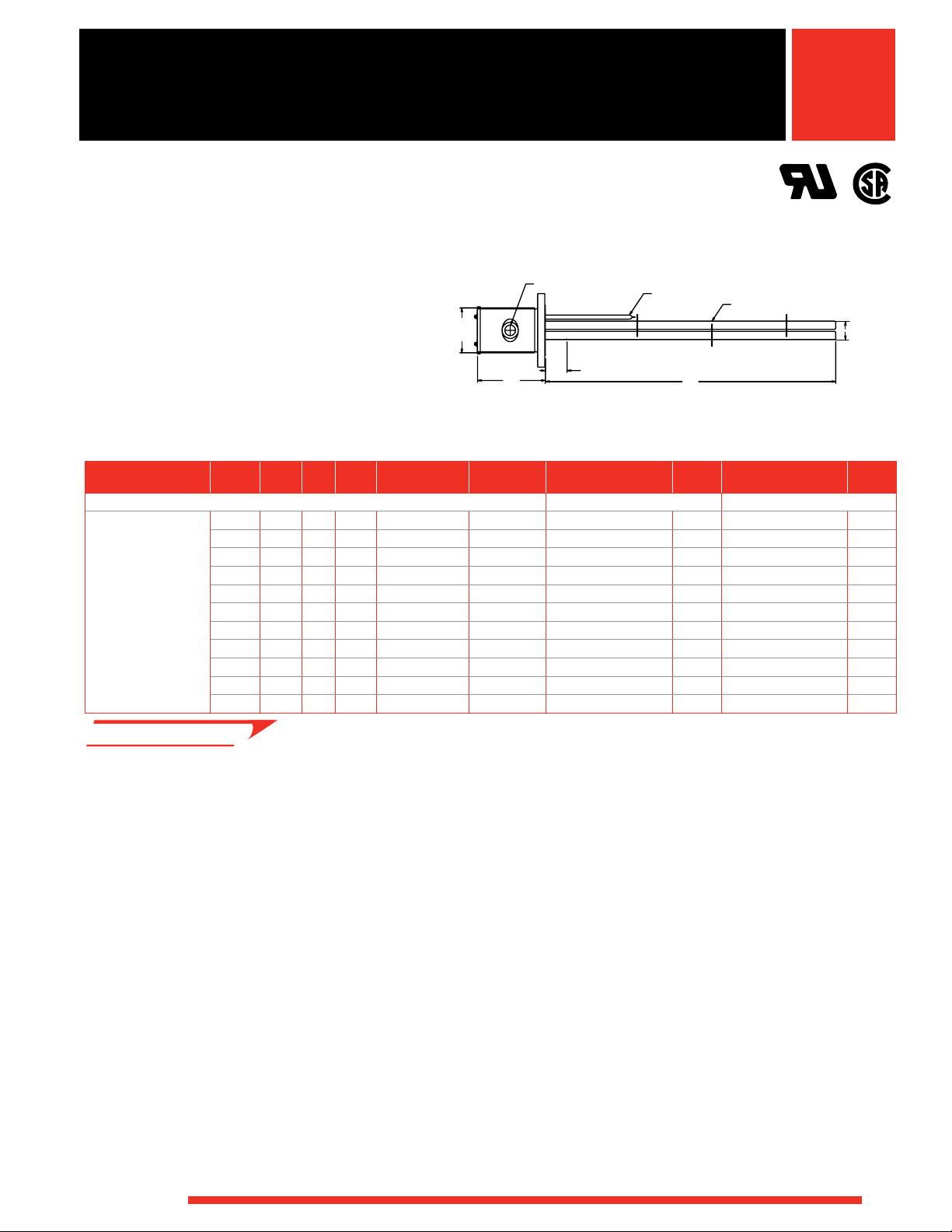

Page 10

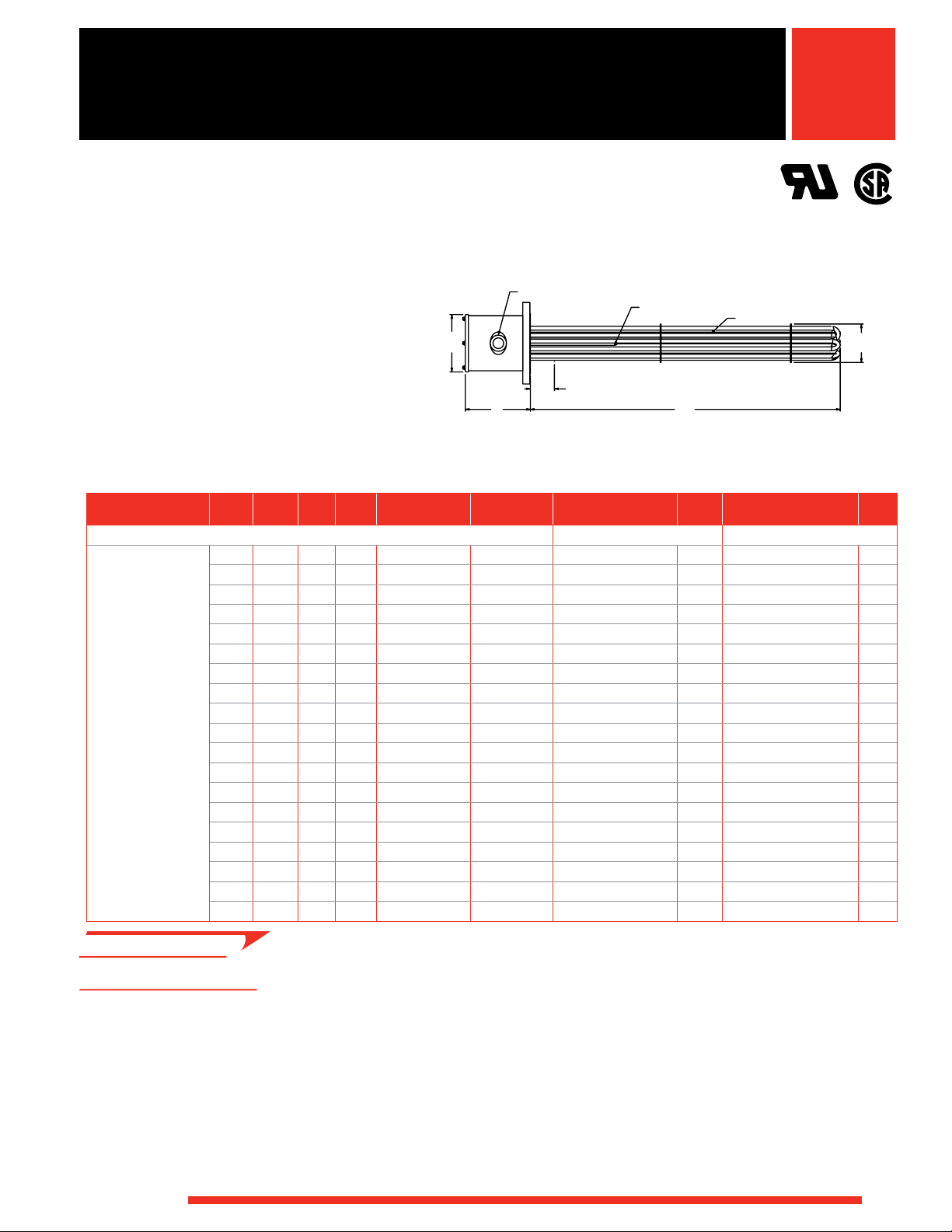

Immersion Heaters

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Clean Water

• 5 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph# Circ.

60 W/in2

Steel Flange

6-Alloy 800

Elements

(9.3 W/cm2)

240 12.0 1 2 15

240 12.0 3 1 15

480 12.0 1 1 15

480 12.0 3 1 15

240 18.0 1 2 21

240 18.0 3 1 21

480 18.0 1 1 21

480 18.0 3 1 21

240 24.0 1 3 27 (686) 40 (19) FNN727A10S RS FNN727A10W RS

240 24.0 3 2 27 (686) 40 (19) FNN727A3S RS FNN727A3W RS

480 24.0 1 3 27 (686) 40 (19) FNN727A11S RS FNN727A11W RS

480 24.0 3 1 27 (686) 40 (19) FNN727A5S RS FNN727A5W RS

240 30.0 3 2 32

480 30.0 1 2 32

480 30.0 3 1 32

240 36.0 3 2 38 (965) 47 (22) FNN738A3S RS FNN738A3W RS

480 36.0 1 2 38 (965) 47 (22) FNN738A11S RS FNN738A11W RS

480 36.0 3 1 38 (965) 47 (22) FNN738A5S RS FNN738A5W RS

480 50.0 3 2 51 (1295) 52 (24) FNN751A5S RS FNN751A5W RS

480 60.0 3 2 60

General Purpose and

Moisture Resistant

7 in.

(178 mm)

8 in. O.D.

(203 mm)

①

4 in. (102 mm) Cold (Ref.)

Thermowell

“B”

0.475 in. (12.1 mm) Dia. Element

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (394) 35 (16) FNN715J10S RS FNN715J10W RS

1

/2 (394) 35 (16) FNN715J3S RS FNN715J3W RS

1

/2 (394) 35 (16) FNN715J11S RS FNN715J11W RS

1

/2 (394) 35 (16) FNN715J5S RS FNN715J5W RS

1

/2 (546) 38 (18) FNN721J10S RS FNN721J10W RS

1

/2 (546) 38 (18) FNN721J3S RS FNN721J3W RS

1

/2 (546) 38 (18) FNN721J11S RS FNN721J11W RS

1

/2 (546) 38 (18) FNN721J5S RS FNN721J5W RS

1

/2 (826) 43 (20) FNN732J3S RS FNN732J3W RS

1

/2 (826) 43 (20) FNN732J11S RS FNN732J11W RS

1

/2 (826) 43 (20) FNN732J5S RS FNN732J5W RS

1

/2 (1537) 56 (26) FNN760J5S M FNN760J5W M

Ship Wt.

lbs (kg)

Part

Number Del.

General Purpose Enclosure

Part

Number

Moisture-Resistant Enclosure

4¾ in. O.D.

(121 mm)

Del.

• RS - Next day shipment

up to 5 pieces

• M - Manufacturing lead times

246

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

WATLOW

®

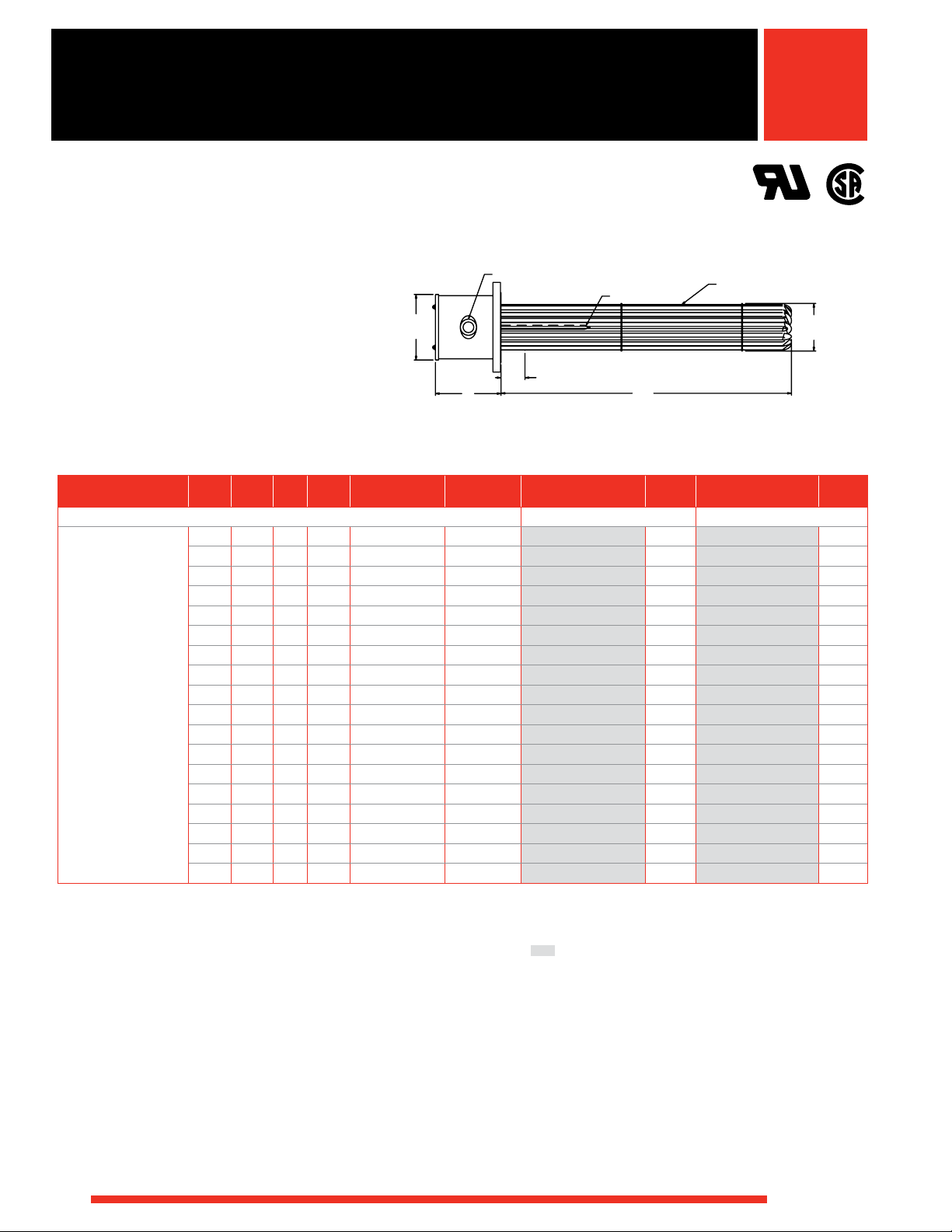

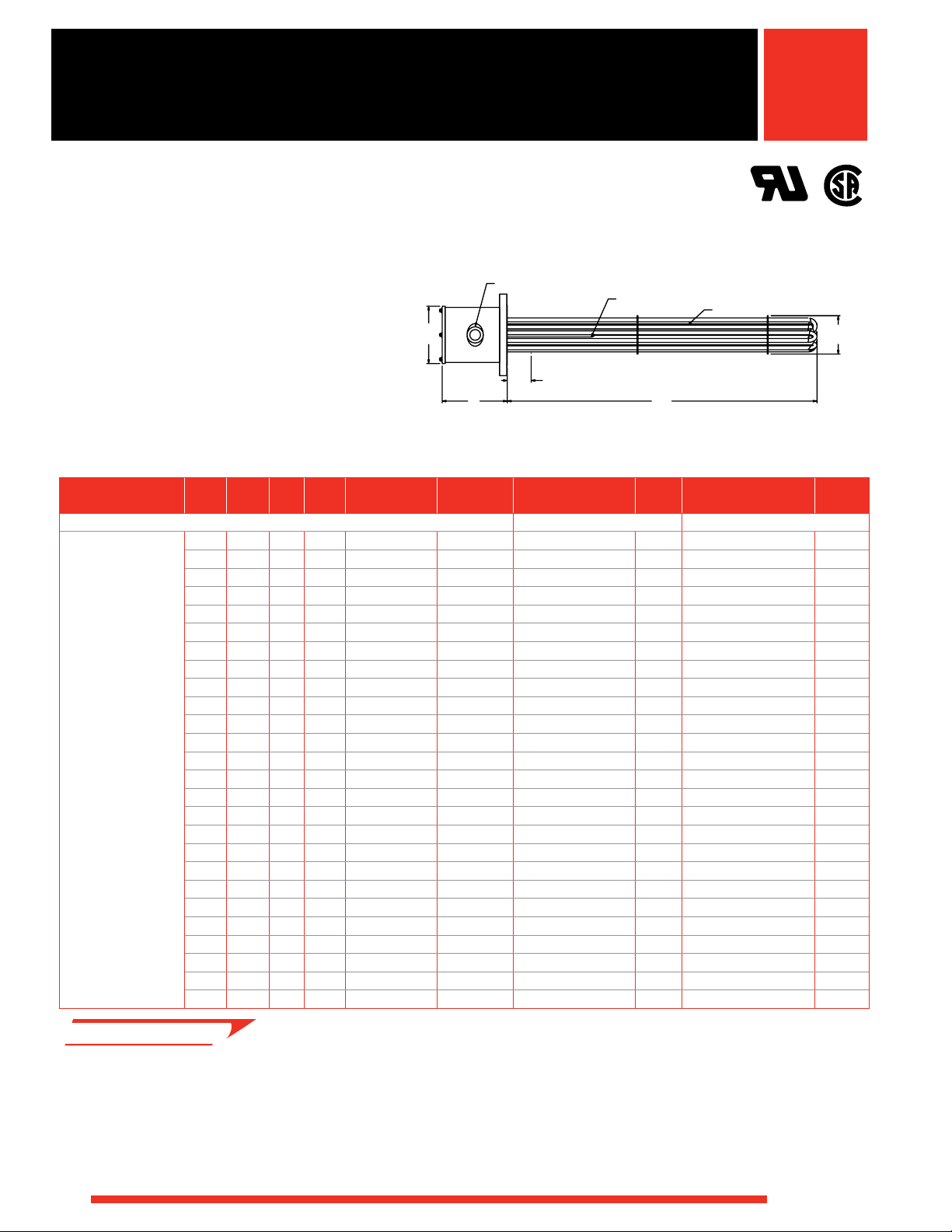

Page 11

Immersion Heaters

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Clean Water

• 5 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

Steel Flange

9-Alloy 800

Elements

(9.3 W/cm2)

• RS - Next day shipment

up to 5 pieces

• M - Manufacturing lead times

240 18.0 1 3 15

240 18.0 3 1 15

480 18.0 1 1 15

480 18.0 3 1 15

240 27.0 1 3 21

240 27.0 3 3 21

480 27.0 1 3 21

480 27.0 3 1 21

240 36.0 3 3 27 (686) 45 (21) FNN727A3XS RS FNN727A3XW RS

480 36.0 1 3 27 (686) 45 (21) FNN727A11XS RS FNN727A11XW RS

480 36.0 3 1 27 (686) 45 (21) FNN727A5XS RS FNN727A5XW RS

240 45.0 3 3 32

480 45.0 1 3 32

480 45.0 3 3 32

240 54.0 3 3 38 (965) 53 (24) FNN738A3XS RS FNN738A3XW RS

480 54.0 1 3 38 (965) 53 (24) FNN738A11XS RS FNN738A11XW RS

480 54.0 3 3 38 (965) 53 (24) FNN738A5XS RS FNN738A5XW RS

480 75.0 3 3 51 (1295) 60 (28) FNN751A5XS RS FNN751A5XW RS

480 90.0 3 3 60

General Purpose and

Moisture Resistant

7 in.

(178 mm)

8 in. O.D.

(203 mm)

①

4 in. (102 mm) Cold (Ref.)

Thermowell

“B”

0.475 in. (12.1 mm) Dia. Element

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (394) 38 (18) FNN715J10XS RS FNN715J10XW RS

1

/2 (394) 38 (18) FNN715J3XS RS FNN715J3XW RS

1

/2 (394) 38 (18) FNN715J11XS RS FNN715J11XW RS

1

/2 (394) 38 (18) FNN715J5XS RS FNN715J5XW RS

1

/2 (546) 42 (19) FNN721J10XS RS FNN721J10XW RS

1

/2 (546) 42 (19) FNN721J3XS RS FNN721J3XW RS

1

/2 (546) 42 (19) FNN721J11XS RS FNN721J11XW RS

1

/2 (546) 42 (19) FNN721J5XS RS FNN721J5XW RS

1

/2 (826) 48 (22) FNN732J3XS RS FNN732J3XW RS

1

/2 (826) 48 (22) FNN732J11XS RS FNN732J11XW RS

1

/2 (826) 48 (22) FNN732J5XS RS FNN732J5XW RS

1

/2 (1537) 66 (30) FNN760J5XS M FNN760J5XW M

Ship Wt.

lbs (kg)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

General Purpose Enclosure

Part

Number

Moisture-Resistant Enclosure

4¾ in. O.D.

(121 mm)

Del.

WATLOW

®

247

Page 12

Immersion Heaters

4¾ in. O.D.

(121 mm)

Thermowell

1 in. (25 mm)

FIREBAR Element

4 in. (102 mm) Cold (Ref.)

“B”

8 in. O.D.

(203 mm)

7 in.

(178 mm)

0.475 in. (12.1 mm) Dia. Element

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Application: Clean Water

• 6 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

Steel Flange

12-Alloy 800

Elements

(9.3 W/cm2)

• RS - Next day shipment

up to 2 pieces

• M - Manufacturing lead times

240 24.0 1 3 15

240 24.0 3 2 15

480 24.0 1 2 15

480 24.0 3 1 15

240 36.0 1 4 21

240 36.0 3 2 21

480 36.0 1 2 21

480 36.0 3 1 21

240 48.0 3 4 26

480 48.0 1 3 26

480 48.0 3 2 26

240 60.0 3 4 32

480 60.0 1 3 32

480 60.0 3 2 32

240 72.0 3 4 37

480 72.0 3 2 37

480 100.0 3 4 50

480 120.0 3 4 60

“B” Dim.

in. (mm)

3

3

3

3

3

3

3

3

7

7

7

3

3

3

7

7

7

3

General Purpose and

Moisture Resistant

8 in.

(203 mm)

(203 mm)

① The number and size of the conduit opening will comply with the

/8 (390.5) 73 (33) FPN715G10S RS FPN715G10W RS

/8 (390.5) 73 (33) FPN715G3S RS FPN715G3W RS

/8 (390.5) 73 (33) FPN715G11S RS FPN715G11W RS

/8 (390.5) 73 (33) FPN715G5S RS FPN715G5W RS

/8 (542.9) 78 (36) FPN721G10S M FPN721G10W M

/8 (542.9) 78 (36) FPN721G3S M FPN721G3W M

/8 (542.9) 78 (36) FPN721G11S M FPN721G11W M

/8 (542.9) 78 (36) FPN721G5S M FPN721G5W M

/8 (682.6) 81 (37) FPN726R3S M FPN726R3W M

/8 (682.6) 81 (37) FPN726R11S M FPN726R11W M

/8 (682.6) 81 (37) FPN726R5S M FPN726R5W M

/8 (822.3) 85 (39) FPN732G3S M FPN732G3W M

/8 (822.3) 85 (39) FPN732G11S M FPN732G11W M

/8 (822.3) 85 (39) FPN732G5S M FPN732G5W M

/8 (962.0) 92 (42) FPN737R3S M FPN737R3W M

/8 (962.0) 92 (42) FPN737R5S M FPN737R5W M

/8 (1292.2) 100 (45) FPN750R5S M FPN750R5W M

/8 (1533.5) 110 (50) FPN760G5S M FPN760G5W M

8 in.

①

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

0.475 in. (12.1 mm) Dia. Element

National Electrical Code® standards.

Ship Wt.

lbs (kg)

General Purpose Enclosure

Part

Number Del.

Part

Number

Moisture-Resistant Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Truck Shipment only

7⁄8 in. O.D.

5

(149.2 mm)

®

Del.

248

WATLOW

®

Page 13

Immersion Heaters

4¾ in. O.D.

(121 mm)

Thermowell

1 in. (25 mm)

FIREBAR Element

4 in. (102 mm) Cold (Ref.)

“B”

8 in. O.D.

(203 mm)

7 in.

(178 mm)

0.475 in. (12.1 mm) Dia. Element

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Application: Clean Water

• 6 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

Steel Flange

15-Alloy 800

Elements

(9.3 W/cm

2

)

• M - Manufacturing lead times

240 30.0 1 3 15

240 30.0 3 5 15

480 30.0 1 3 15

480 30.0 3 1 15

240 45.0 1 5 21

240 45.0 3 5 21

480 45.0 1 3 21

480 45.0 3 5 21

240 60.0 3 5 26

480 60.0 1 3 26

480 60.0 3 5 26

240 75.0 3 5 32

480 75.0 1 5 32

480 75.0 3 5 32

240 90.0 3 5 37

480 90.0 3 5 37

480 125.0 3 5 50

480 150.0 3 5 60

(203 mm)

“B” Dim.

in. (mm)

3

/8 (390.5) 76 (35) FPN715G10XS M FPN715G10XW M

3

/8 (390.5) 76 (35) FPN715G3XS M FPN715G3XW M

3

/8 (390.5) 76 (35) FPN715G11XS M FPN715G11XW M

3

/8 (390.5) 76 (35) FPN715G5XS M FPN715G5XW M

3

/8 (542.9) 82 (38) FPN721G10XS M FPN721G10XW M

3

/8 (542.9) 82 (38) FPN721G3XS M FPN721G3XW M

3

/8 (542.9) 82 (38) FPN721G11XS M FPN721G11XW M

3

/8 (542.9) 82 (38) FPN721G5XS M FPN721G5XW M

7

/8 (682.6) 85 (39) FPN726R3XS M FPN726R3XW M

7

/8 (682.6) 85 (39) FPN726R11XS M FPN726R11XW M

7

/8 (682.6) 85 (39) FPN726R5XS M FPN726R5XW M

3

/8 (822.3) 90 (41) FPN732G3XS M FPN732G3XW M

3

/8 (822.3) 90 (41) FPN732G11XS M FPN732G11XW M

3

/8 (822.3) 90 (41) FPN732G5XS M FPN732G5XW M

7

/8 (962.0) 98 (45) FPN737R3XS M FPN737R3XW M

7

/8 (962.0) 98 (45) FPN737R5XS M FPN737R5XW M

7

/8 (1292.2) 108 (49) FPN750R5XS M FPN750R5XW M

3

/8 (1533.5) 120 (55) FPN760G5XS M FPN760G5XW M

General Purpose and

Moisture Resistant

8 in.

8 in.

(203 mm)

①

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

0.475 in. (12.1 mm) Dia. Element

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

Ship Wt.

lbs (kg)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

General Purpose Enclosure

Truck Shipment only

Part

Number

Moisture-Resistant Enclosure

7⁄8 in. O.D.

5

(149.2 mm)

Del.

®

WATLOW

®

249

Page 14

WATLOW

®

Immersion Heaters

4"-150# FLANGE

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Deionized or

Demineralized Water

• 4 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

316 SS Flange

6-316 SS Elements

(9.3 W/cm2)

Passivated

• RS - Next day shipment

up to 5 pieces

240 12.0 1 2 16 (406) 31 (14) FOR716A10S RS FOR716A10W RS

240 12.0 3 1 16 (406) 31 (14) FOR716A3S RS FOR716A3W RS

480 12.0 1 1 16 (406) 31 (14) FOR716A11S RS FOR716A11W RS

480 12.0 3 1 16 (406) 31 (14) FOR716A5S RS FOR716A5W RS

240 18.0 1 2 22 (559) 34 (16) FOR722A10S RS FOR722A10W RS

240 18.0 3 1 22 (559) 34 (16) FOR722A3S RS FOR722A3W RS

480 18.0 1 1 22 (559) 34 (16) FOR722A11S RS FOR722A11W RS

480 18.0 3 1 22 (559) 34 (16) FOR722A5S RS FOR722A5W RS

240 24.0 1 2 27

240 24.0 3 2 27

480 24.0 1 1 27

480 24.0 3 1 27

240 30.0 3 2 33 (838) 39 (18) FOR733A3S RS FOR733A3W RS

480 30.0 1 2 33 (838) 39 (18) FOR733A11S RS FOR733A11W RS

480 30.0 3 1 33 (838) 39 (18) FOR733A5S RS FOR733A5W RS

240 36.0 3 2 38

480 36.0 1 2 38

480 36.0 3 1 38

480 50.0 3 2 51

480 60.0 3 2 61 (1549) 52 (24) FOR761A5S RS FOR761A5W RS

General Purpose and

Moisture Resistant

①

0.475 in. (12.1 mm) Dia. Element

5

½ in.

(140 mm)

8 in.

(203 mm)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (699) 36 (17) FOR727J10S RS FOR727J10W RS

1

/2 (699) 36 (17) FOR727J3S RS FOR727J3W RS

1

/2 (699) 36 (17) FOR727J11S RS FOR727J11W RS

1

/2 (699) 36 (17) FOR727J5S RS FOR727J5W RS

1

/2 (978) 43 (20) FOR738J3S RS FOR738J3W RS

1

/2 (978) 43 (20) FOR738J11S RS FOR738J11W RS

1

/2 (978) 43 (20) FOR738J5S RS FOR738J5W RS

1

/2 (1308) 48 (22) FOR751J5S RS FOR751J5W RS

Ship Wt.

lbs (kg)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

General Purpose Enclosure

Part

Number Del.

Moisture-Resistant Enclosure

3

7⁄8 in. O.D.

(98.4 mm)

250

Page 15

WATLOW

®

Immersion Heaters

4¾ in. O.D.

(121 mm)

Thermowell

1 in. (25 mm)

FIREBAR Element

4 in. (102 mm) Cold (Ref.)

“B”

8 in. O.D.

(203 mm)

7 in.

(178 mm)

0.475 in. (12.1 mm) Dia. Element

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Deionized or

Demineralized Water

• 6 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

316 SS Flange

12-316 SS Elements

(9.3 W/cm2)

(Passivated)

• RS - Next day shipment

up to 2 pieces

• M - Manufacturing lead times

240 24.0 1 3 15

240 24.0 3 2 15

480 24.0 1 2 15

480 24.0 3 1 15

240 36.0 1 4 21

240 36.0 3 2 21

480 36.0 1 2 21

480 36.0 3 1 21

240 48.0 3 4 27

480 48.0 1 3 27

480 48.0 3 2 27

240 60.0 3 4 32

480 60.0 1 3 32

480 60.0 3 2 32

240 72.0 3 4 38

480 72.0 3 2 38

480 100.0 3 4 51

480 120.0 3 4 60

General Purpose and

Moisture Resistant

8 in.

(203 mm)

① The number and size of the conduit opening will comply with the

“B” Dim.

in. (mm)

3

/4 (400) 73 (33) FPR715N10S RS FPR715N10W RS

3

/4 (400) 73 (33) FPR715N3S RS FPR715N3W RS

3

/4 (400) 73 (33) FPR715N11S RS FPR715N11W RS

3

/4 (400) 73 (33) FPR715N5S RS FPR715N5W RS

3

/4 (552) 78 (36) FPR721N10S M FPR721N10W M

3

/4 (552) 78 (36) FPR721N3S M FPR721N3W M

3

/4 (552) 78 (36) FPR721N11S M FPR721N11W M

3

/4 (552) 78 (36) FPR721N5S M FPR721N5W M

1

/4 (692) 81 (37) FPR727E3S M FPR727E3W M

1

/4 (692) 81 (37) FPR727E11S M FPR727E11W M

1

/4 (692) 81 (37) FPR727E5S M FPR727E5W M

3

/4 (832) 85 (39) FPR732N3S M FPR732N3W M

3

/4 (832) 85 (39) FPR732N11S M FPR732N11W M

3

/4 (832) 85 (39) FPR732N5S M FPR732N5W M

1

/4 (972) 92 (42) FPR738E3S M FPR738E3W M

1

/4 (972) 92 (42) FPR738E5S M FPR738E5W M

1

/4 (1302) 100 (45) FPR751E5S M FPR751E5W M

3

/4 (1543) 110 (50) FPR760N5S M FPR760N5W M

8 in.

(203 mm)

①

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

0.475 in. (12.1 mm) Dia. Element

National Electrical Code® standards.

Ship Wt.

lbs (kg)

Part

Number Del.

General Purpose Enclosure

Part

Number

Moisture-Resistant Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Truck Shipment only

7⁄8 in. O.D.

5

(149.2 mm)

Del.

251

Page 16

WATLOW

®

Immersion Heaters

4¾ in. O.D.

(121 mm)

Thermowell

1 in. (25 mm)

FIREBAR Element

4 in. (102 mm) Cold (Ref.)

“B”

8 in. O.D.

(203 mm)

7 in.

(178 mm)

0.475 in. (12.1 mm) Dia. Element

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Deionized or

Demineralized Water

• 6 inch - 150 lb ANSI flange

• WATROD element

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

60 W/in2

316 SS Flange

15-316 SS Elements

(9.3 W/cm2)

(Passivated)

• M - Manufacturing lead times

240 30.0 1 3 15

240 30.0 3 5 15

480 30.0 1 3 15

480 30.0 3 1 15

240 45.0 1 5 21

240 45.0 3 5 21

480 45.0 1 3 21

480 45.0 3 5 21

240 60.0 3 5 27

480 60.0 1 3 27

480 60.0 3 5 27

240 75.0 3 5 32

480 75.0 1 5 32

480 75.0 3 5 32

240 90.0 3 5 38

480 90.0 3 5 38

480 125.0 3 5 51

480 150.0 3 5 60

General Purpose and

Moisture Resistant

8 in.

(203 mm)

8 in.

(203 mm)

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

3

/4 (400) 76 (35) FPR715N10XS M FPR715N10XW M

3

/4 (400) 76 (35) FPR715N3XS M FPR715N3XW M

3

/4 (400) 76 (35) FPR715N11XS M FPR715N11XW M

3

/4 (400) 76 (35) FPR715N5XS M FPR715N5XW M

3

/4 (552) 82 (38) FPR721N10XS M FPR721N10XW M

3

/4 (552) 82 (38) FPR721N3XS M FPR721N3XW M

3

/4 (552) 82 (38) FPR721N11XS M FPR721N11XW M

3

/4 (552) 82 (38) FPR721N5XS M FPR721N5XW M

1

/4 (692) 85 (39) FPR727E3XS M FPR727E3XW M

1

/4 (692) 85 (39) FPR727E11XS M FPR727E11XW M

1

/4 (692) 85 (39) FPR727E5XS M FPR727E5XW M

3

/4 (832) 90 (41) FPR732N3XS M FPR732N3XW M

3

/4 (832) 90 (41) FPR732N11XS M FPR732N11XW M

3

/4 (832) 90 (41) FPR732N5XS M FPR732N5XW M

1

/4 (972) 98 (45) FPR738E3XS M FPR738E3XW M

1

/4 (972) 98 (45) FPR738E5XS M FPR738E5XW M

1

/4 (1302) 108 (49) FPR751E5XS M FPR751E5XW M

3

/4 (1543) 120 (55) FPR760N5XS M FPR760N5XW M

Ship Wt.

lbs (kg)

①

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

Part

Number Del.

General Purpose Enclosure

0.475 in. (12.1 mm) Dia. Element

7⁄8 in. O.D.

5

(149.2 mm)

Part

Number

Moisture-Resistant Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Truck Shipment only

Del.

252

Page 17

WATLOW

®

Immersion Heaters

2¾ in. O.D.

(70 mm)

¾ in. NPT Knockout

Thermowell

0.475 in. (12.1 mm)

Dia. Element

4 in. (102 mm) Cold (Ref.)

45⁄8 in.

(117.5 mm)

35⁄8 in. Dia.

(92.1 mm)

“B”

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Application: Process Water

• 3 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

• Single circuit

Description Volts kW Ph

48 W/in2 6

Steel Flange

3-Alloy 800

Elements

(7.5 W/cm2)

• RS - Next day shipment

up to 5 pieces

240 4.5 1 13

240 4.5 3 13

480 4.5 1 13

480 4.5 3 13

240 6.0 1 18 (457) 23 (11) FMN718A10S RS FMN718A10W RS

240 6.0 3 18 (457) 23 (11) FMN718A3S RS FMN718A3W RS

480 6.0 1 18 (457) 23 (11) FMN718A11S RS FMN718A11W RS

480 6.0 3 18 (457) 23 (11) FMN718A5S RS FMN718A5W RS

240 7.5 1 20

240 7.5 3 20

480 7.5 1 20

480 7.5 3 20

240 9.0 1 25

240 9.0 3 25

480 9.0 1 25

480 9.0 3 25

240 12.0 3 33 (838) 28 (13) FMN733A3S RS FMN733A3W RS

480 12.0 1 33 (838) 28 (13) FMN733A11S RS FMN733A11W RS

480 12.0 3 33 (838) 28 (13) FMN733A5S RS FMN733A5W RS

240 15.0 3 40

480 15.0 1 40

480 15.0 3 40

240 18.0 3 48 (1219) 32 (15) FMN748A3S RS FMN748A3W RS

480 18.0 1 48 (1219) 32 (15) FMN748A11S RS FMN748A11W RS

480 18.0 3 48 (1219) 32 (15) FMN748A5S RS FMN748A5W RS

“B” Dim.

in. (mm)

1

/2 (343) 22 (10) FMN713J10S RS FMN713J10W RS

1

/2 (343) 22 (10) FMN713J3S RS FMN713J3W RS

1

/2 (343) 22 (10) FMN713J11S RS FMN713J11W RS

1

/2 (343) 22 (10) FMN713J5S RS FMN713J5W RS

1

/2 (521) 25 (12) FMN720J10S RS FMN720J10W RS

1

/2 (521) 25 (12) FMN720J3S RS FMN720J3W RS

1

/2 (521) 25 (12) FMN720J11S RS FMN720J11W RS

1

/2 (521) 25 (12) FMN720J5S RS FMN720J5W RS

1

/2 (648) 27 (13) FMN725J10S RS FMN725J10W RS

1

/2 (648) 27 (13) FMN725J3S RS FMN725J3W RS

1

/2 (648) 27 (13) FMN725J11S RS FMN725J11W RS

1

/2 (648) 27 (13) FMN725J5S RS FMN725J5W RS

1

/2 (1029) 30 (14) FMN740J3S RS FMN740J3W RS

1

/2 (1029) 30 (14) FMN740J11S RS FMN740J11W RS

1

/2 (1029) 30 (14) FMN740J5S RS FMN740J5W RS

General Purpose

45⁄8 in.

(117.5 mm)

35⁄8 in. Dia.

(92.1 mm)

Moisture Resistant

53⁄8 in.

(136.5 mm)

1⁄8 in. Dia.

3

(79.4 mm)

Ship Wt.

lbs (kg)

¾ in. NPT Knockout

Thermowell

4 in. (102 mm) Cold (Ref.)

(2)

¾ in. NPT Hubs

Thermowell

4 in. (102 mm) Cold (Ref.)

Part

Number Del.

General Purpose Enclosure

“B”

“B”

0.475 in. (12.1 mm)

Dia. Element

2¾ in. O.D.

(70 mm)

0.475 in. (12.1 mm)

Dia. Element

2¾ in. O.D.

(70 mm)

Part

Number Del.

Moisture-Resistant Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

6 Can be rewired wye to produce

1

/3 of the original kW and

watt density (3-phase only)

®

253

Page 18

WATLOW

®

Immersion Heaters

4"-150# FLANGE

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 4 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

48 W/in2 6

Steel Flange

6-Alloy 800

Elements

(7.5 W/cm2)

• RS - Next day shipment

up to 5 pieces

240 9.0 1 1 13

240 9.0 3 1 131/2 (343) 29 (14) FON713J3S RS FON713J3W RS

480 9.0 1 1 13

480 9.0 3 1 13

240 12.0 1 2 18 (457) 32 (15) FON718A10S RS FON718A10W RS

240 12.0 3 1 18 (457) 32 (15) FON718A3S RS FON718A3W RS

480 12.0 1 1 18 (457) 32 (15) FON718A11S RS FON718A11W RS

480 12.0 3 1 18 (457) 32 (15) FON718A5S RS FON718A5W RS

240 15.0 1 2 201/2 (521) 34 (16) FON720J10S RS FON720J10W RS

240 15.0 3 1 201/2 (521) 34 (16) FON720J3S RS FON720J3W RS

480 15.0 1 1 201/2 (521) 34 (16) FON720J11S RS FON720J11W RS

480 15.0 3 1 201/2 (521) 34 (16) FON720J5S RS FON720J5W RS

240 18.0 1 2 25

240 18.0 3 1 25

480 18.0 1 1 251/2 (648) 36 (17) FON725J11S RS FON725J11W RS

480 18.0 3 1 251/2 (648) 36 (17) FON725J5S RS FON725J5W RS

240 24.0 1 2 33 (838) 39 (18) FON733A10S RS FON733A10W RS

240 24.0 3 2 33 (838) 39 (18) FON733A3S RS FON733A3W RS

480 24.0 1 1 33 (838) 39 (18) FON733A11S RS FON733A11W RS

480 24.0 3 1 33 (838) 39 (18) FON733A5S RS FON733A5W RS

240 30.0 3 2 401/2 (1029) 43 (20) FON740J3S RS FON740J3W RS

480 30.0 1 2 401/2 (1029) 43 (20) FON740J11S RS FON740J11W RS

480 30.0 3 1 40

240 36.0 3 2 48 (1219) 48 (22) FON748A3S RS FON748A3W RS

480 36.0 1 2 48 (1219) 48 (22) FON748A11S RS FON748A11W RS

480 36.0 3 1 48 (1219) 48 (22) FON748A5S RS FON748A5W RS

General Purpose and

Moisture Resistant

①

0.475 in. (12.1 mm) Dia. Element

5

½

in.

(140 mm)

8 in.

(203 mm)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (343) 29 (14) FON713J10S RS FON713J10W RS

1

/2 (343) 29 (14) FON713J11S RS FON713J11W RS

1

/2 (343) 29 (14) FON713J5S RS FON713J5W RS

1

/2 (648) 36 (17) FON725J10S RS FON725J10W RS

1

/2 (648) 36 (17) FON725J3S RS FON725J3W RS

1

/2 (1029) 43 (20) FON740J5S RS FON740J5W RS

Ship Wt.

lbs (kg)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

6 Can be rewired wye to produce

watt density (3-phase only)

Part

Number Del.

General Purpose Enclosure

Part

Number

Moisture-Resistant Enclosure

1

/3 of the original kW and

3

7⁄8 in. O.D.

(98.4 mm)

Del.

254

Page 19

WATLOW

®

Immersion Heaters

Thermowell

5

½ in.

4 in. (102 mm) Cold (Ref.)

3

7⁄8 in. O.D.

(98.4 mm)

“B”

8 in.

(203 mm)

0.475 in. (12.1 mm) Dia. Element

①

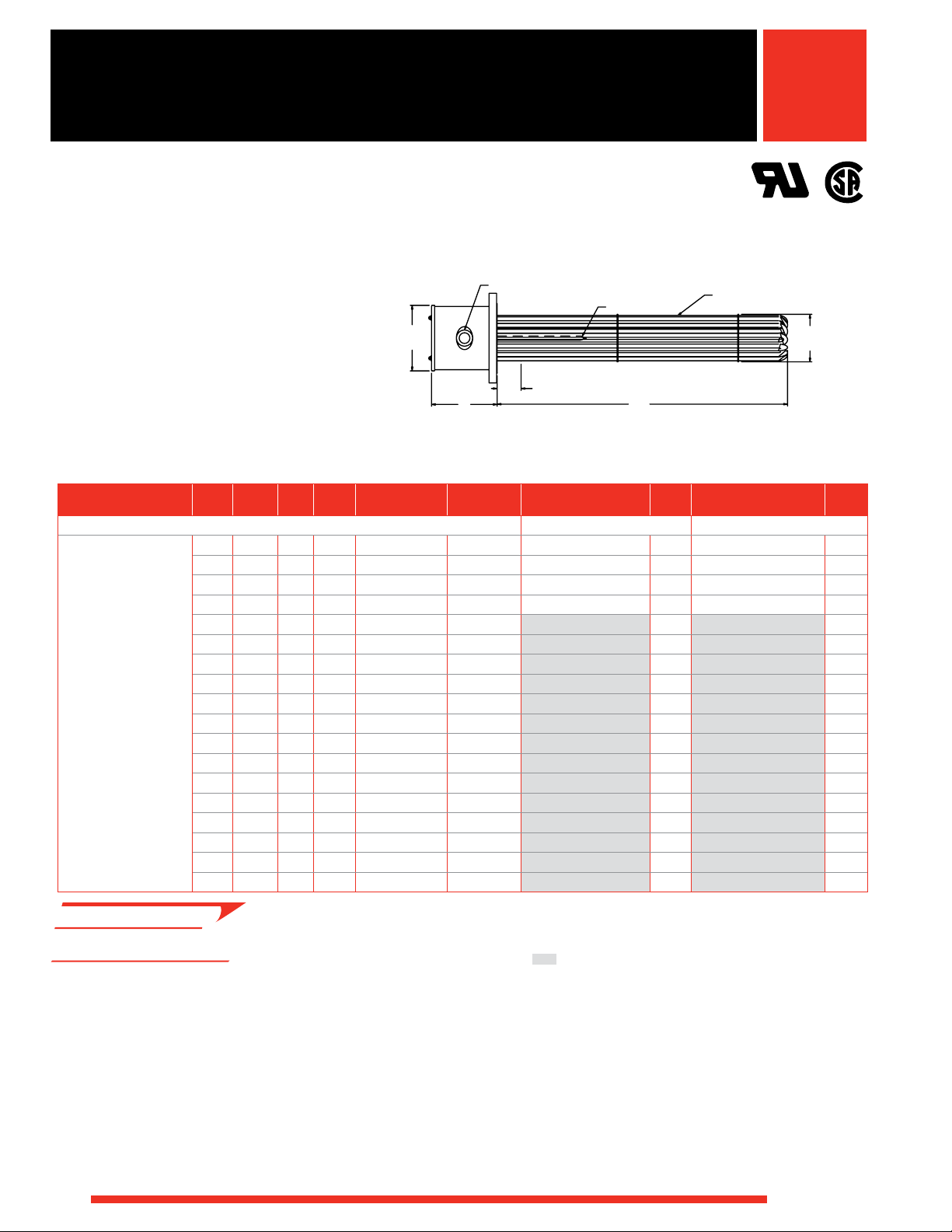

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Application: Process Water

• 4 inch - 150 lb ANSI flange

• FIREBAR elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

45 W/in2

304 SS Flange

6-Alloy 800

Elements

(7 W/cm2)

• RS - Next day shipment

up to 5 pieces

240 12.0 3 1 13

240 15.0 3 1 16 (406.0) 35 (16) FONF16A27S RS FONF16A27W RS

240 18.0 3 1 18

240 24.0 3 2 22

480 24.0 3 1 227/8 (581.0) 41 (19) FONF22R28S RS FONF22R28W RS

240 30.0 3 2 277/8 (708.0) 44 (20) FONF27R27S RS FONF27R27W RS

480 30.0 3 1 277/8 (708.0) 44 (20) FONF27R28S RS FONF27R28W RS

240 36.0 3 2 32

480 36.0 3 1 32

480 48.0 3 2 423/8 (1076.3) 50 (23) FONF42G28S RS FONF42G28W RS

480 60.0 3 2 517/8 (1317.6) 54 (25) FONF51R28S RS FONF51R28W RS

“B” Dim.

in. (mm)

3

/8 (339.7) 32 (15) FONF13G27S RS FONF13G27W RS

3

/8 (466.7) 38 (17) FONF18G27S RS FONF18G27W RS

7

/8 (581.0) 41 (19) FONF22R27S RS FONF22R27W RS

7

/8 (835.0) 46 (21) FONF32R27S RS FONF32R27W RS

7

/8 (835.0) 46 (21) FONF32R28S RS FONF32R28W RS

General Purpose and

Moisture Resistant

5½ in.

(140 mm)

(212.7 mm)

① The number and size of the conduit opening will comply with the

National Electrical Code

Ship Wt.

lbs (kg)

①

4 in. (102 mm) Cold (Ref.)

83⁄8 in.

Part

Number Del.

General Purpose Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Thermowell

®

standards.

1 in. (25 mm)

FIREBAR Element

“B”

Part

Number

Moisture-Resistant Enclosure

®

37⁄8 in. O.D.

(98.4 mm)

Del.

255

Page 20

WATLOW

®

Immersion Heaters

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 5 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

2

48 W/in

Steel Flange

6-Alloy 800

Elements

(7.5 W/cm2)

• RS - Next day shipment

up to 5 pieces

240 9.0 1 1 13

240 9.0 3 1 131/2 (343) 33 (15) FNN713J3S RS FNN713J3W RS

480 9.0 1 1 131/2 (343) 33 (15) FNN713J11S RS FNN713J11W RS

480 9.0 3 1 131/2 (343) 33 (15) FNN713J5S RS FNN713J5W RS

240 12.0 1 2 18 (457) 36 (17) FNN718A10S RS FNN718A10W RS

240 12.0 3 1 18 (457) 36 (17) FNN718A3S RS FNN718A3W RS

480 12.0 1 1 18 (457) 36 (17) FNN718A11S RS FNN718A11W RS

480 12.0 3 1 18 (457) 36 (17) FNN718A5S RS FNN718A5W RS

240 15.0 1 2 201/2 (521) 38 (18) FNN720J10S RS FNN720J10W RS

240 15.0 3 1 201/2 (521) 38 (18) FNN720J3S RS FNN720J3W RS

480 15.0 1 1 201/2 (521) 38 (18) FNN720J11S RS FNN720J11W RS

480 15.0 3 1 201/2 (521) 38 (18) FNN720J5S RS FNN720J5W RS

240 18.0 1 2 251/2 (648) 40 (19) FNN725J10S RS FNN725J10W RS

240 18.0 3 1 251/2 (648) 40 (19) FNN725J3S RS FNN725J3W RS

480 18.0 1 1 251/2 (648) 40 (19) FNN725J11S RS FNN725J11W RS

480 18.0 3 1 251/2 (648) 40 (19) FNN725J5S RS FNN725J5W RS

240 24.0 1 3 33 (838) 43 (20) FNN733A10S RS FNN733A10W RS

240 24.0 3 2 33 (838) 43 (20) FNN733A3S RS FNN733A3W RS

480 24.0 1 1 33 (838) 43 (20) FNN733A11S RS FNN733A11W RS

480 24.0 3 1 33 (838) 43 (20) FNN733A5S RS FNN733A5W RS

240 30.0 3 2 401/2 (1029) 47 (22) FNN740J3S RS FNN740J3W RS

480 30.0 1 2 401/2 (1029) 47 (22) FNN740J11S RS FNN740J11W RS

480 30.0 3 1 401/2 (1029) 47 (22) FNN740J5S RS FNN740J5W RS

240 36.0 3 2 48 (1219) 52 (24) FNN748A3S RS FNN748A3W RS

480 36.0 1 2 48 (1219) 52 (24) FNN748A11S RS FNN748A11W RS

480 36.0 3 1 48 (1219) 52 (24) FNN748A5S RS FNN748A5W RS

General Purpose and

Moisture Resistant

7 in.

(178 mm)

8 in. O.D.

(203 mm)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

0.475 in. (12.1 mm) Dia. Element

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (343) 33 (15) FNN713J10S RS FNN713J10W RS

Ship Wt.

lbs (kg)

General Purpose Enclosure Moisture-Resistant Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

Part

Number Del.

4¾ in. O.D.

(121 mm)

256

Page 21

WATLOW

®

Immersion Heaters

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 5 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

48 W/in2

Steel Flange

9-Alloy 800

Elements

(7.5 W/cm2)

• RS - Next day shipment

up to 5 pieces

240 14.0 1 3 13

240 14.0 3 1 13

480 14.0 1 1 13

480 14.0 3 1 13

240 18.0 1 3 18 (457) 39 (18) FNN718A10XS RS FNN718A10XW RS

240 18.0 3 1 18 (457) 39 (18) FNN718A3XS RS FNN718A3XW RS

480 18.0 1 1 18 (457) 39 (18) FNN718A11XS RS FNN718A11XW RS

480 18.0 3 1 18 (457) 39 (18) FNN718A5XS RS FNN718A5XW RS

240 23.0 1 3 20

240 23.0 3 3 20

480 23.0 1 1 20

480 23.0 3 1 20

240 27.0 1 3 25

240 27.0 3 3 25

480 27.0 1 3 25

480 27.0 3 1 25

240 36.0 3 3 33 (838) 48 (22) FNN733A3XS RS FNN733A3XW RS

480 36.0 1 3 33 (838) 48 (22) FNN733A11XS RS FNN733A11XW RS

480 36.0 3 1 33 (838) 48 (22) FNN733A5XS RS FNN733A5XW RS

240 45.0 3 3 40

480 45.0 1 3 40

480 45.0 3 3 40

240 54.0 3 3 48 (1219) 60 (28) FNN748A3XS RS FNN748A3XW RS

480 54.0 1 3 48 (1219) 60 (28) FNN748A11XS RS FNN748A11XW RS

480 54.0 3 3 48 (1219) 60 (28) FNN748A5XS RS FNN748A5XW RS

General Purpose and

Moisture Resistant

7 in.

(178 mm)

8 in. O.D.

(203 mm)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

0.475 in. (12.1 mm) Dia. Element

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

1

/2 (343) 35 (16) FNN713J10XS RS FNN713J10XW RS

1

/2 (343) 35 (16) FNN713J3XS RS FNN713J3XW RS

1

/2 (343) 35 (16) FNN713J11XS RS FNN713J11XW RS

1

/2 (343) 35 (16) FNN713J5XS RS FNN713J5XW RS

1

/2 (521) 42 (19) FNN720J10XS RS FNN720J10XW RS

1

/2 (521) 42 (19) FNN720J3XS RS FNN720J3XW RS

1

/2 (521) 42 (19) FNN720J11XS RS FNN720J11XW RS

1

/2 (521) 42 (19) FNN720J5XS RS FNN720J5XW RS

1

/2 (648) 45 (21) FNN725J10XS RS FNN725J10XW RS

1

/2 (648) 45 (21) FNN725J3XS RS FNN725J3XW RS

1

/2 (648) 45 (21) FNN725J11XS RS FNN725J11XW RS

1

/2 (648) 45 (21) FNN725J5XS RS FNN725J5XW RS

1

/2 (1029) 53 (24) FNN740J3XS RS FNN740J3XW RS

1

/2 (1029) 53 (24) FNN740J11XS RS FNN740J11XW RS

1

/2 (1029) 53 (24) FNN740J5XS RS FNN740J5XW RS

Ship Wt.

lbs (kg)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

General Purpose Enclosure

Part

Number

Moisture-Resistant Enclosure

4¾ in. O.D.

(121 mm)

Del.

257

Page 22

WATLOW

®

Immersion Heaters

4¾ in. O.D.

(121 mm)

Thermowell

1 in. (25 mm)

FIREBAR Element

4 in. (102 mm) Cold (Ref.)

“B”

8 in. O.D.

(203 mm)

7 in.

(178 mm)

0.475 in. (12.1 mm) Dia. Element

①

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 6 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

48 W/in2

Steel Flange

12-Alloy 800

Elements

(7.5 W/cm2)

• RS - Next day shipment

up to 2 pieces

• M - Manufacturing lead times

240 18.0 1 2 13

240 18.0 3 1 13

480 18.0 1 1 13

480 18.0 3 1 13

240 24.0 1 3 17

240 24.0 3 2 17

480 24.0 1 2 17

480 24.0 3 1 17

240 30.0 1 3 20

240 30.0 3 2 20

480 30.0 1 2 20

480 30.0 3 1 20

240 36.0 1 4 25

240 36.0 3 2 25

480 36.0 1 2 25

480 36.0 3 1 25

240 48.0 3 4 32

480 48.0 1 3 32

480 48.0 3 2 32

240 60.0 3 4 40

480 60.0 1 3 40

480 60.0 3 2 40

240 72.0 3 4 47

480 72.0 3 2 47

General Purpose and

Moisture Resistant

8 in.

(203 mm)

8 in.

(203 mm)

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

3

/8 (339.7) 73 (33) FPN713G10S RS FPN713G10W RS

3

/8 (339.7) 73 (33) FPN713G3S RS FPN713G3W RS

3

/8 (339.7) 73 (33) FPN713G11S RS FPN713G11W RS

3

/8 (339.7) 73 (33) FPN713G5S RS FPN713G5W RS

7

/8 (454.0) 75 (34) FPN717R10S M FPN717R10W M

7

/8 (454.0) 75 (34) FPN717R3S M FPN717R3W M

7

/8 (454.0) 75 (34) FPN717R11S M FPN717R11W M

7

/8 (454.0) 75 (34) FPN717R5S M FPN717R5W M

3

/8 (517.5) 78 (36) FPN720G10S M FPN720G10W M

3

/8 (517.5) 78 (36) FPN720G3S M FPN720G3W M

3

/8 (517.5) 78 (36) FPN720G11S M FPN720G11W M

3

/8 (517.5) 78 (36) FPN720G5S M FPN720G5W M

3

/8 (644.5) 81 (37) FPN725G10S M FPN725G10W M

3

/8 (644.5) 81 (37) FPN725G3S M FPN725G3W M

3

/8 (644.5) 81 (37) FPN725G11S M FPN725G11W M

3

/8 (644.5) 81 (37) FPN725G5S M FPN725G5W M

7

/8 (835.0) 85 (39) FPN732R3S M FPN732R3W M

7

/8 (835.0) 85 (39) FPN732R11S M FPN732R11W M

7

/8 (835.0) 85 (39) FPN732R5S M FPN732R5W M

3

/8 (1025.5) 92 (42) FPN740G3S M FPN740G3W M

3

/8 (1025.5) 92 (42) FPN740G11S M FPN740G11W M

3

/8 (1025.5) 92 (42) FPN740G5S M FPN740G5W M

7

/8 (1216.0) 100 (46) FPN747R3S M FPN747R3W M

7

/8 (1216.0) 100 (46) FPN747R5S M FPN747R5W M

Ship Wt.

lbs (kg)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

Part

Number Del.

General Purpose Enclosure

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

0.475 in. (12.1 mm) Dia. Element

7⁄8 in. O.D.

5

(149.2 mm)

Part

Number

Del.

Moisture-Resistant Enclosure

Truck Shipment only

258

Page 23

WATLOW

®

Immersion Heaters

4¾ in. O.D.

(121 mm)

Thermowell

1 in. (25 mm)

FIREBAR Element

4 in. (102 mm) Cold (Ref.)

“B”

8 in. O.D.

(203 mm)

7 in.

(178 mm)

0.475 in. (12.1 mm) Dia. Element

①

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 6 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

48 W/in2

Steel Flange

15-Alloy 800

Elements

(7.5 W/cm2)

• M - Manufacturing lead times

240 23.0 1 3 13

240 23.0 3 5 13

480 23.0 1 1 13

480 23.0 3 1 13

240 30.0 1 3 17

240 30.0 3 5 17

480 30.0 1 3 17

480 30.0 3 1 17

240 38.0 1 5 20

240 38.0 3 5 20

480 38.0 1 3 20

480 38.0 3 1 20

240 45.0 1 5 25

240 45.0 3 5 25

480 45.0 1 3 25

480 45.0 3 5 25

240 60.0 3 5 32

480 60.0 1 3 32

480 60.0 3 5 32

240 75.0 3 5 40

480 75.0 1 5 40

480 75.0 3 5 40

240 90.0 3 5 47

480 90.0 3 5 47

General Purpose and

Moisture Resistant

8 in.

(203 mm)

① The number and size of the conduit opening will comply with the

“B” Dim.

in. (mm)

3

/8 (339.7) 76 (35)

3

/8 (339.7) 76 (35)

3

/8 (339.7) 76 (35)

3

/8 (339.7) 76 (35)

7

/8 (441.3) 78 (36)

7

/8 (441.3) 78 (36)

7

/8 (441.3) 78 (36)

7

/8 (441.3) 78 (36)

3

/8 (517.5) 82 (38)

3

/8 (517.5) 82 (38)

3

/8 (517.5) 82 (38)

3

/8 (517.5) 82 (38)

3

/8 (644.5) 85 (39)

3

/8 (644.5) 85 (39)

3

/8 (644.5) 85 (39)

3

/8 (644.5) 85 (39)

7

/8 (835.0) 90 (41)

7

/8 (835.0) 90 (41)

7

/8 (835.0) 90 (41)

3

3

3

7

7

/8 (1025.5) 98 (45)

/8 (1025.5) 98 (45)

/8 (1025.5) 98 (45)

/8 (1216.0) 108 (49)

/8 (1216.0) 108 (49)

0.475 in. (12.1 mm) Dia. Element

8 in.

(203 mm)

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

National Electrical Code® standards.

Ship Wt.

lbs (kg)

FPN713G10XS

FPN713G3XS

FPN713G11XS

FPN713G5XS

FPN717R10XS

FPN717R3XS

FPN717R11XS

FPN717R5XS

FPN720G10XS

FPN720G3XS

FPN720G11XS

FPN720G5XS

FPN725G10XS

FPN725G3XS

FPN725G11XS

FPN725G5XS

FPN732R3XS

FPN732R11XS

FPN732R5XS

FPN740G3XS

FPN740G11XS

FPN740G5XS

FPN747R3XS

FPN747R5XS

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

Part

Number Del.

General Purpose Enclosure

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

Part

Number Del.

Moisture-Resistant Enclosure

FPN713G10XW

FPN713G3XW

FPN713G11XW

FPN713G5XW

FPN717R10XW

FPN717R3XW

FPN717R11XW

FPN717R5XW

FPN720G10XW

FPN720G3XW

FPN720G11XW

FPN720G5XW

FPN725G10XW

FPN725G3XW

FPN725G11XW

FPN725G5XW

FPN732R3XW

FPN732R11XW

FPN732R5XW

FPN740G3XW

FPN740G11XW

FPN740G5XW

FPN747R3XW

FPN747R5XW

• For ANSI flange dimensions, reference chart on page 241

Truck Shipment only

7⁄8 in. O.D.

5

(149.2 mm)

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

259

Page 24

WATLOW

®

Immersion Heaters

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 6 inch - 150 lb ANSI flange

• FIREBAR elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

45 W/in2

304 SS Flange

15-Alloy 800

Elements

(7 W/cm2)

• M - Manufacturing lead times

240 30.0 3 5 133/8 (339.7) 78 (36) FPNF13G27S M FPNF13G27W M

240 37.5 3 5 16 (406.0) 81 (37) FPNF16A27S M FPNF16A27W M

240 45.0 3 5 18

240 60.0 3 5 22

480 60.0 3 5 22

240 75.0 3 5 27

480 75.0 3 5 27

240 90.0 3 5 32

480 90.0 3 5 32

480 120.0 3 5 42

480 150.0 3 5 51

General Purpose and

Moisture Resistant

8 in.

(203 mm)

3⁄8 in.

8

(212.7 mm)

①

4 in. (102 mm) Cold (Ref.)

Thermowell

“B”

1 in. (25 mm) FIREBAR Element

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

“B” Dim.

in. (mm)

3

/8 (466.7) 84 (38) FPNF18G27S M FPNF18G27W M

7

/8 (581.0) 87 (40) FPNF22R27S M FPNF22R27W M

7

/8 (581.0) 87 (40) FPNF22R28S M FPNF22R28W M

7

/8 (708.0) 91 (42) FPNF27R27S M FPNF27R27W M

7

/8 (708.0) 91 (42) FPNF27R28S M FPNF27R28W M

7

/8 (835.0) 95 (43) FPNF32R27S M FPNF32R27W M

7

/8 (835.0) 95 (43) FPNF32R28S M FPNF32R28W M

3

/8 (1076.3) 106 (48) FPNF42G28S M FPNF42G28W M

7

/8 (1317.6) 116 (53) FPNF51R28S M FPNF51R28W M

Ship Wt.

lbs (kg)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

General Purpose Enclosure

Truck Shipment only

Part

Number

Moisture-Resistant Enclosure

57⁄8 in. O.D.

(149.2 mm)

Del.

260

Page 25

WATLOW

®

Immersion Heaters

Thermowell

4 in. (102 mm) Cold (Ref.)

“B”

8

3⁄8 in.

(212.7 mm)

8 in.

(203 mm)

1 in. (25 mm) FIREBAR Element

①

①

57⁄8 in. O.D.

(149.2 mm)

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

®

Application: Process Water

• 8 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

Description Volts kW Ph#Circ.

48 W/in2

Steel Flange

18-Alloy 800

Elements

(7.5 W/cm2)

2

48 W/in

Steel Flange

24-Alloy 800

Elements

(7.5 W/cm2)

• M - Manufacturing lead times

240 50.0 3 3 25

480 50.0 1 3 253/4 (654.0) 121 (55) FRN725N11S M FRN725N11W M

480 50.0 3 2 25

240 75.0 3 6 35

480 75.0 3 2 353/4 (908.0) 130 (59) FRN735N5S M FRN735N5W M

240 100.0 3 6 441/4 (1124.0) 132 (60) FRN744E3S M FRN744E3W M

480 100.0 3 3 441/4 (1124.0) 132 (60) FRN744E5S M FRN744E5W M

240 125.0 3 6

480 125.0 3 6

480 150.0 3 6

480 175.0 3 6 733/16 (1859.0) 151 (69) FRN773D5S M FRN773D5W M

480 200.0 3 6 8211/16

240 67.0 3 4 26

480 67.0 1 3 26

480 67.0 3 2 263/16 (665.2) 129 (59) FRN726D5XS M FRN726D5XW M

240 100.0 3 8 363/16 (919.2) 142 (65) FRN736D3XS M FRN736D3XW M

480 100.0 3 4 363/16 (919.2) 142 (65) FRN736D5XS M FRN736D5XW M

240 133.0 3 8 4411/16

480 133.0 3 4 4411/16

240 167.0 3 8 5411/16

480 167.0 3 8 5411/16

480 200.0 3 8 6311/16

480 233.0 3 8 73

480 267.0 3 8 82

“B” Dim.

in. (mm)

3

/4 (654.0) 121 (55) FRN725N3S M FRN725N3W M

3

/4 (654.0) 121 (55) FRN725N5S M FRN725N5W M

3

/4 (908.0) 130 (59) FRN735N3S M FRN735N3W M

5411/16 (1389.1)

5411/16 (1389.1)

6311/16 (1617.6)

(2100.3) 157 (72) FRN782M5S M FRN782M5W M

3

/16 (665.2) 129 (59) FRN726D3XS M FRN726D3XW M

3

/16 (665.2) 129 (59) FRN726D11XS M FRN726D11XW M

(1135.1) 147 (67) FRN744M3XS M FRN744M3XW M

(1135.1) 147 (67) FRN744M5XS M FRN744M5XW M

(1389.1) 158 (72) FRN754M3XS M FRN754M3XW M

(1389.1) 158 (72) FRN754M5XS M FRN754M5XW M

(1617.6) 166 (76) FRN763M5XS M FRN763M5XW M

3

/16

(1859.0) 175 (80) FRN773D5XS M FRN773D5XW M

11

/16

(2100.3) 184 (84) FRN782M5XS M FRN782M5XW M

General Purpose and

Moisture Resistant

0.475 in. (12.1 mm) Dia. Element

10 in.

(254 mm)

6 in. (152 mm) Cold (Ref.)

3⁄16 in.

8

(208 mm)

“B”

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

Ship Wt.

lbs (kg)

140 (64) FRN754M3S M FRN754M3W M

140 (64) FRN754M5S M FRN754M5W M

145 (66) FRN763M5S M FRN763M5W M

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Part

Number Del.

General Purpose Enclosure

Truck Shipment only

Part

Number Del.

Moisture-Resistant Enclosure

¾ in. O.D.

7

(197 mm)

261

Page 26

WATLOW

®

Immersion Heaters

6 in. (152 mm) Cold (Ref.)

“B”

13

½ in.

(343 mm)

8

3⁄8 in.

(212.7 mm)

10

3⁄8 in. O.D.

(263.5 mm)

0.475 in. (12.1 mm) Dia. Element

①

6 in. (152 mm) Cold (Ref.)

9

¼ in. O.D.

(235 mm)

8

¼ in.

(210 mm)

“B”

11

5⁄8

in.

(295.3 mm)

0.475 in. (12.1 mm) Dia. Element

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Application: Process Water

• 10 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

① The number and size of the conduit opening

will comply with the National Electrical Code®

standards.

Description Volts kW Ph#Circ.

48 W/in2

Steel Flange

27-Alloy 800

Elements

(7.5 W/cm

2

)

Application: Process Water

• 12 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

① The number and size of the conduit opening

48 W/in2

Steel Flange

36-Alloy 800

Elements

(7.5 W/cm2)

• M - Manufacturing lead times

will comply with the National Electrical Code®

standards.

Description Volts kW Ph#Circ.

480 190.0 3 9 54

480 262.0 3 9 73

480 250.0 3 6 54

480 350.0 3 12 73

“B” Dim.

in. (mm)

3

/4 (1391) 240 (109) FSN754N5S M FSN754N5W M

1

/4 (1861) 260 (118) FSN773E5S M FSN773E5W M

“B” Dim.

in. (mm)

5

/8 (1387.5) 280 (127) FTN754L5S M FTN754L5W M

1

/8 (1857.4) 291 (132) FTN773C5S M FTN773C5W M

General Purpose

11

5⁄8 in.

(295.3 mm)

(210 mm)

Moisture Resistant

¾ in.

13

(349 mm)

(229 mm)

Ship Wt.

lbs (kg)

General Purpose

13

½ in.

(343 mm)

(212.7 mm)

Moisture Resistant

in.

7⁄8

15

(403.2 mm)

(229 mm)

Ship Wt.

lbs (kg)

①

0.475 in. (12.1 mm) Dia. Element

9

8

¼ in.

6 in. (152 mm) Cold (Ref.)

“B”

①

0.475 in. (12.1 mm) Dia. Element

¼ in. O.D.

9

(235 mm)

6 in. (152 mm) Cold (Ref.)

9 in.

Part

Number Del.

General Purpose Enclosure

“B”

Part

Number

Moisture-Resistant Enclosure

①

0.475 in. (12.1 mm) Dia. Element

10

(263.5 mm)

6 in. (152 mm) Cold (Ref.)

8

9 in.

3⁄8 in.

①

6 in. (152 mm) Cold (Ref.)

Part

Number Del.

General Purpose Enclosure

“B”

0.475 in. (12.1 mm) Dia. Element

“B”

Part

Number

Moisture-Resistant Enclosure

103⁄8 in. O.D.

(263.5 mm)

Notes: • All flange bundles are designed to fit the inside diameter

of the equivalent standard schedule pipe

• For ANSI flange dimensions, reference chart on page 241

Truck Shipment only

¼ in. O.D.

(235 mm)

Del.

3⁄8 in. O.D.

Del.

®

262

Page 27

WATLOW

®

Immersion Heaters

6 in. (152 mm) Cold (Ref.)

“B”

15

1⁄8

in.

(384.2 mm)

12¼ in. O.D.

(311 mm)

8

½ in.

(216 mm)

0.475 in. (12.1 mm) Dia. Element

①

①

®

WATROD and FIREBAR ANSI Flange

Immersion Heaters

Application: Process Water

• 14 inch - 150 lb ANSI flange

• WATROD elements

• Without thermostat

• General purpose or

moisture-resistant enclosures

General Purpose

1⁄8

in.

15

(384.2 mm)

Moisture Resistant

17

¼ in.

(438 mm)

① The number and size of the conduit opening will comply with the

National Electrical Code® standards.

½ in.

8

(216 mm)