Watlow WATROD Application Guide

W A T L O W

Tubular and

Process Assemblies

Elements and Assemblies

Watlow tubular elements and

assemblies are primarily used for

direct immersion in water, oils,

viscous materials, solvents, process

solutions and molten materials as

well as air and gases.

Additionally, round and flat surface

tubular elements (WATROD and

FIREBAR®heaters respectively) can

be used for surface heating.

WATROD and FIREBAR heating

elements may be purchased

separately, or fabricated into

process heating assemblies,

including:

• Screw plug

• Flange

• Circulation

• Booster

• Engine Preheater

• Over-the-Side

• Vertical Loop

• Drum

• Duct

Both elements and assemblies are

available from stock. They can be

configured with a variety of watt and

volt ratings, terminations, sheath

materials and mounting options to

satisfy the most demanding

applications.

If our stock products do not meet

your application needs, Watlow can

custom engineer the optimum

heater.

Performance Capabilities

• Sheath temperatures up to

1800°F (983°C)

• Assembly wattages to 2.2

megawatts

• Process assembly ratings up to

1000 psi (70 kg/cm2)

• Watt densities up to 120 W/in

(18.6 W/cm2)

2

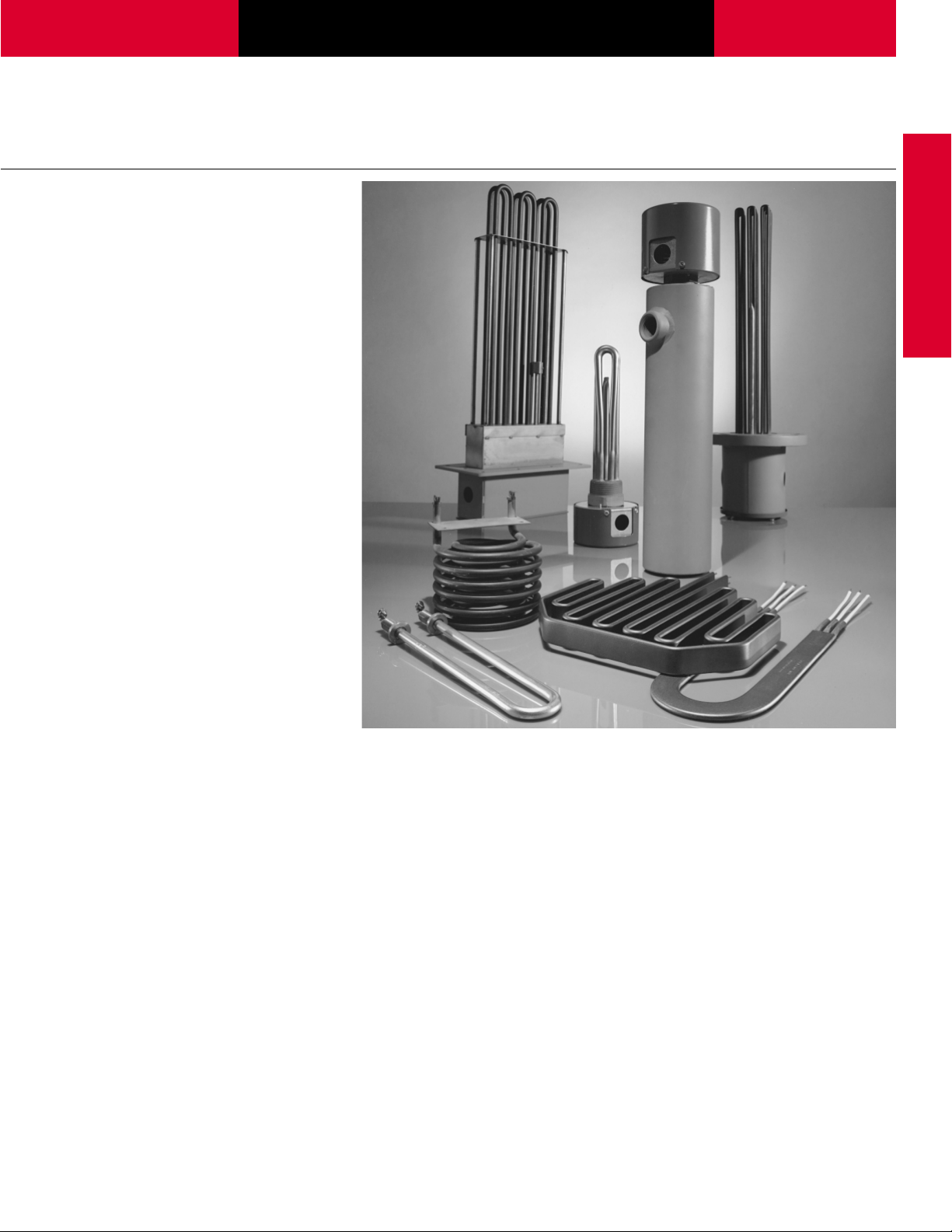

Assemblies, left to right:WATROD duct,WATROD screw plug, circulation and FIREBAR flange heater.

WATROD and FIREBAR elements are in front.

• Enhanced performance beyond

Features and Benefits

• 36 standard bend formations

• FIREBAR flat surface geometry

these specifications available

from Watlow Process Systems.

enable designing the heating

element around available space

to maximize heating efficiency.

enhances heat transfer in both

immersion and air applications,

and surface heating, too.

Increased surface area per linear

inch allows heaters to run cooler

in viscous materials.

➀

Tubular Elements & Assy.

• Wattages from 95 watts to 2.2

megawatts (on individual

elements and assemblies

respectively) make tubular

heaters one of the most versatile

electric heating sources

available.

Applications

• Liquids

• Air

• Gases

• Molten materials

• Contact surface heating

• Radiant surface heating

➀ Watlow Process Systems can design

thermal systems to meet specific

performance criteria. Contact your Watlow

representative for details.

261

Tubular and

Process Assemblies

Elements and Assemblies

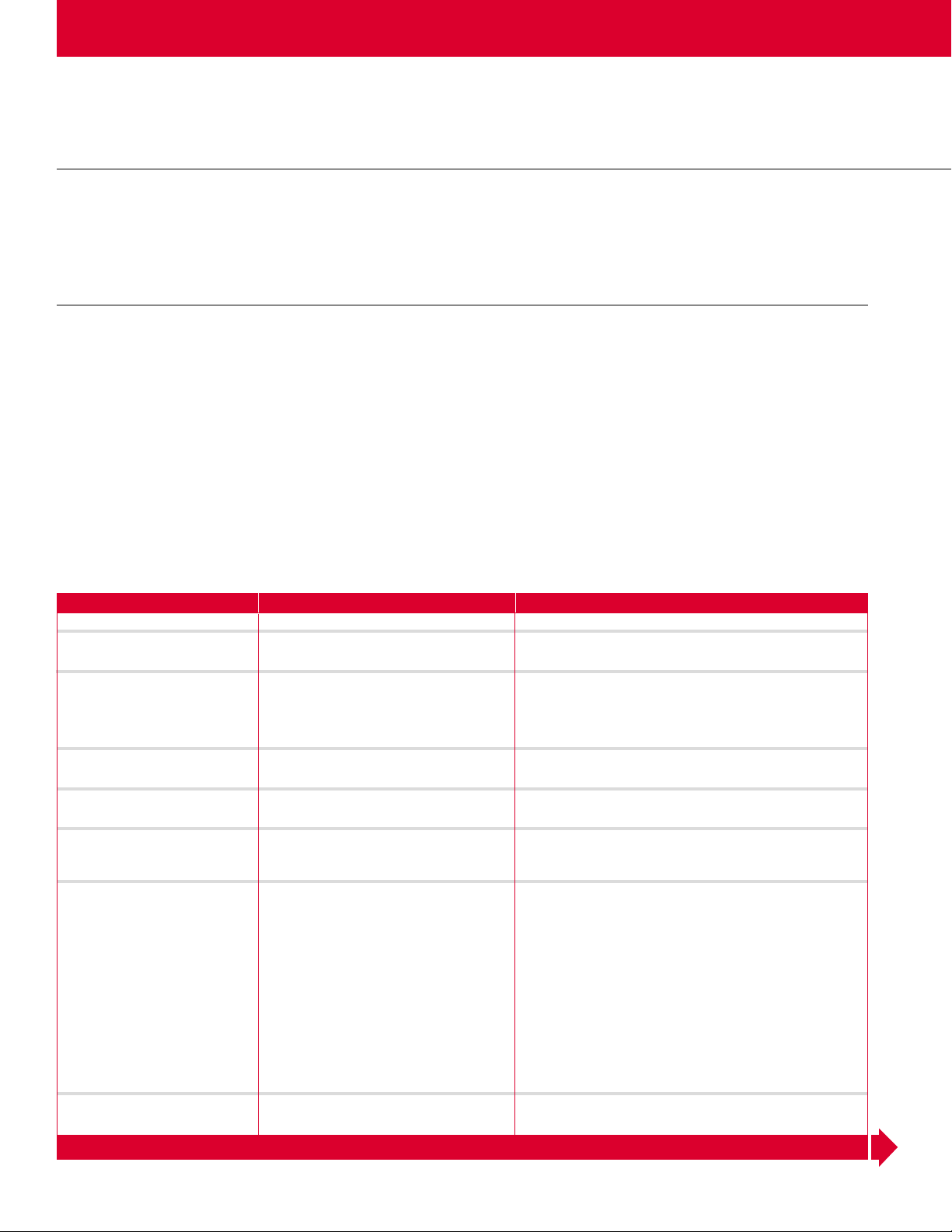

The following two charts will help

you select an appropriate heater

based on your application and watt

density restrictions. These charts

are application driven. The total

wattage required by your application

should be known before selecting a

specific heater type(s) from the

stock tables. If your required

wattage is not known, please

consult your Watlow representative.

Once the heater type has been

identified, turn to the appropriate

product section for information on

the element or assembly.

Element and Assembly

Selection Guide

To identify the tubular heater type

best suited to your application,

consult the Element and Assembly

Selection Guide.

In most cases Watlow recommends

using single tubular heating

elements for low kilowatt

applications.

Assemblies are better suited for

large kilowatt applications to heat

liquids, air or gases.

When selecting a heater according

to watt density, be sure to consider

the following:

• Liquid viscosity at start up and at

process temperature

• Operating temperature

• Chemical composition

Under the “Heating Method”

column in the Element and

Assembly Selection Guide locate

the method that applies to your

application to find the

recommended “Heater Type.”

After identifying the heater type(s)

suitable for your application, refer to

the Supplemental Applications Chart

for further application data. This

chart will assist you in selecting the

appropriate watt density and sheath

material for your specific

application. It also presents the

performance characteristics for both

WATROD and FIREBAR elements.

Element and Assembly Selection Guide

Application Heating Method Heater Type

Liquids:

Acids Direct immersion (circulating/non-circulating) FIREBAR, WATROD, Screw Plug, Flange, Over-the-Side,

Vertical Loop, and Pipe Insert

Caustic Soda Direct immersion (circulating/non-circulating) WATROD, Screw Plug, Square Flange, Flange,

12% Concentrate Over-the-Side, Vertical Loop, Circulation, and Pipe Insert

10% Concentrate

75% Concentrate

Degreasing Solutions Direct immersion (circulating/non-circulating) FIREBAR, WATROD, Screw Plug, Square Flange, Flange,

Over-the-Side, and Pipe Insert

Electroplating Direct immersion (circulating/non-circulating) FIREBAR, WATROD, Screw Plug, Square Flange, Flange,

Over-the-Side, Drum, Vertical Loop and Pipe Insert

Ethylene Glycol Direct immersion (circulating/non-circulating) FIREBAR, WATROD, Screw Plug, Flange, Over-the-Side,

50% Concentrate Circulation, Booster, and Engine Preheater

100% Concentrate

Oils Direct immersion (circulating/non-circulating) FIREBAR, WATROD, Screw Plug, Square Flange,

Asphalt Flange, Over-the-Side, Drum, Vertical Loop, Circulation,

Fuel Oils Booster, and Pipe Insert

Light Grades 1 & 2

Medium Grades 4 & 5

Heavy Grade 6 & Bunker C

Heat Transfer

Lubricating

SAE 10, 20, 30

SAE 40, 50

API STD 614

Vegetable (Cooking)

Paraffin or Wax Direct immersion (circulating/non-circulating) FIREBAR, WATROD, Screw Plug, Square Flange, Flange,

Over-the-Side, Drum, and Pipe Insert

CONTINUED

262

W A T L O W

Tubular and

Process Assemblies

Elements and Assemblies

Element and Assembly Selection Guide

Application Heating Method Heater Type

Water

Clean Direct immersion (circulating/non-circulating) FIREBAR (non-process water only)

Deionized WATROD, Screw Plug, Screw Plug with Control Assembly,

Demineralized Square Flange, Flange, Over-the-Side, Drum, Vertical Loop,

Potable Circulation, Booster, Engine Preheater and Pipe Insert

Process

Air: Direct (forced or natural convection) FIREBAR, WATROD, FINBAR, WATROD Enclosure Heater,

Screw Plug, Flange, Circulation, and Duct

Gas: Direct (forced) FIREBAR, WATROD, Screw Plug, Flange, and Circulation

Hydrocarbons, Nitrogen, Oxygen

Ozone, Steam

Molten Materials:

Aluminum Indirect (radiant) WATROD

Lead Direct (non-circulating) FIREBAR and WATROD

Salt Direct (non-circulating) FIREBAR and WATROD

Solder Direct (non-circulating) FIREBAR and WATROD

Surface Heating:

Dies, Griddles, Molds, Platens Direct FIREBAR and WATROD

Tubular Elements & Assy.

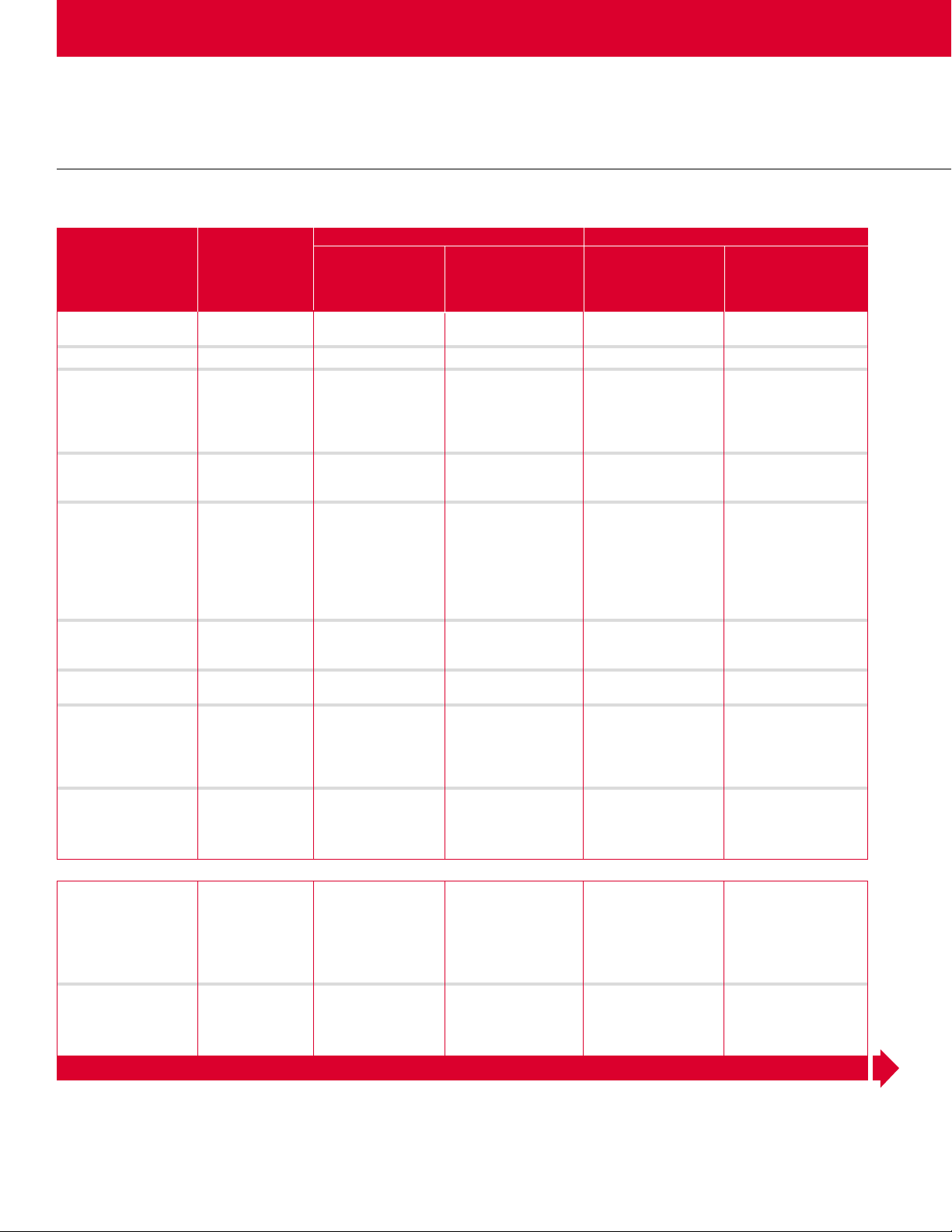

Supplemental Applications Chart

This Supplemental Applications

Chart is provided in addition to the

Element and Assembly Selection

Guide. This chart will help you

select watt density and sheath

materials for either WATROD or

FIREBAR heating elements

according to the specific media

being heated.

For example, if you’re heating

vegetable oil, either WATROD or

FIREBAR elements at 30 and 40

watts per square inch respectively

(4.6 and 6.2 W/cm2) with 304

stainless steel sheath can be used.

Supplemental Applications Chart

WATROD Element FIREBAR Element

Maximum Maximum Maximum

Operating Watt Watt

Heated Material Temperature Density Sheath Material Density Sheath Material

°F (°C) W/in2(W/cm2) W/in

Acid Solutions (Mild)

Acetic 180 (82) 40 (6.2) 316 Stainless Steel 40 (6.2) Incoloy®800

Boric (30% max.) 257 (125) 40 (6.2) Titanium 40 (6.2) 304 Stainless Steel

Carbonic 180 (82) 40 (6.2) Inconel®600 40 (6.2) 304 Stainless Steel

Chromic 180 (82) 40 (6.2) Titanium N/A N/A N/A

Citric 180 (82) 23 (3.6) Incoloy

Fatty Acids 150 (65) 20 (3.1) 316 Stainless Steel 30 (4.6) Incoloy®800

Lactic 122 (50) 10 (1.6) 316 Stainless Steel N/A N/A N/A

Levulinic 180 (82) 40 (6.2) Inconel®600 40 (6.2) 304 Stainless Steel

Malic 122 (50) 10 (1.6) 316 Stainless Steel 16 (2.5) Incoloy®800

Nitric (30% max.) 167 (75) 20 (3.1) 316 Stainless Steel 30 (4.6) Incoloy®800

Phenol—2-4

Disulfonic 180 (82) 40 (6.2) 316 Stainless Steel 40 (6.2) Incoloy®800

Phosphoric 180 (82) 23 (3.6) Incoloy

Phosphoric (Aerated) 180 (82) 23 (3.6) 304 Stainless Steel 30 (4.6) 304 Stainless Steel

®

®

2

(W/cm2)

30 (4.6) Incoloy®800

30 (4.6) Incoloy®800

CONTINUED

Incoloy®and Inconel®are registered trademarks of Special Metals Corporation.

263

Tubular and

Process Assemblies

Elements and Assemblies

Supplemental Applications Chart

WATROD Element FIREBAR Element

Maximum Maximum Maximum

Operating Watt Watt

Heated Material Temperature Density Sheath Material Density Sheath Material

°F (°C) W/in2(W/cm2) W/in

Proponic (10% max.) 180 (82) 40 (6.2) Copper 40 (6.2) 304 Stainless Steel

Tannic 167/180 (75/82) 23/40 (3.6/6.2) Steel/304 S.Steel 40 (6.2) 304 Stainless Steel

Tartaric 180 (82) 40 (6.2) 316 Stainless Steel 40 (6.2) Incoloy®800

Acetaldehyde 180 (82) 10 (1.6) Copper 16 (2.4) Incoloy®800

Acetone 130 (54) 10 (1.6) 304 Stainless Steel 16 (2.4) 304 Stainless Steel

Air ➀➀➀➀Incoloy

®

Alcyl Alcohol 200 (93) 10 (1.6) Copper 16 (2.4) Incoloy®800

Alkaline Solutions 212 (100) 40 (6.2) Steel 48 (7.4) 304 Stainless Steel

Aluminum Acetate 122 (50) 10 (1.6) 316 Stainless Steel 16 (2.5) Incoloy

Aluminum Potassium

Sulfate 212 (100) 40 (6.2) Copper N/A N/A N/A

Ammonia Gas ➀➀➀➀Steel ➀➀304 Stainless Steel

Ammonium Acetate 167 (75) 23 (3.6) Incoloy

Amyl Acetate 240 (115) 23 (3.6) Incoloy

®

®

Amyl Alcohol 212 (100) 20 (3.1) 304 Stainless Steel 30 (4.6) 304 Stainless Steel

Aniline 350 (176) 23 (3.6) 304 Stainless Steel 30 (4.6) 304 Stainless Steel

Asphalt 200-500 (93-260) 4-10 (0.6 - 1.6) Steel 6-12 (0.9 - 1.8) 304 Stainless Steel

Barium Hydroxide 212 (100) 40 (6.2) 316 Stainless Steel 40 (6.2) Incoloy®800

Benzene, liquid 150 (65) 10 (1.6) Copper 16 (2.5) 304 Stainless Steel

Butyl Acetate 225 (107) 10 (1.6) 316 Stainless Steel 16 (2.5) Incoloy®800

Calcium Bisulfate 400 (204) 20 (3.1) 316 Stainless Steel N/A N/A N/A

Calcium Chloride 200 (93) 5-8 (0.8 - 1.2) Inconel®600 N/A N/A N/A

Carbon Monoxide — — ➀➀ Incoloy

Carbon Tetrachloride 160 (71) 23 (3.6) Incoloy

®

®

Caustic Soda:

2% 210 (98) 48 (7.4) Incoloy

10% Concentrate 210 (98) 23 (3.6) Incoloy

75% 180 (82) 23 (3.6) Incoloy

Citric Juices 185 (85) 23 (3.6) Incoloy

®

®

®

®

Degreasing Solution 275 (135) 23 (3.6) Steel 30 (4.6) 304 Stainless Steel

Dextrose 212 (100) 20 (3.1) 304 Stainless Steel 30 (4.6) 304 Stainless Steel

Dyes & Pigments 212 (100) 23 (3.6) 304 Stainless Steel 30 (4.6) 304 Stainless Steel

Electroplating Baths:

Cadmium 180 (82) 40 (6.2) 304 Stainless Steel 40 (6.2) 304 Stainless Steel

Copper 180 (82) 40 (6.2) 316 Stainless Steel N/A N/A N/A

Dilute Cyanide 180 (82) 40 (6.2) 316 Stainless Steel N/A N/A N/A

Rochelle Cyanide 180 (82) 40 (6.2) 316 Stainless Steel N/A N/A N/A

Sodium Cyanide 180 (82) 40 (6.2) 316 Stainless Steel N/A N/A N/A

Potassium Cyanide 180 (82) 40 (6.2) 316 Stainless Steel 40 (6.2) 304 Stainless Steel

Ethylene Glycol 300 (148) 30 (4.6) Steel 40 (6.2) 304 Stainless Steel

Formaldehyde 180 (82) 10 (1.6) 304 Stainless Steel 16 (2.5) 304 Stainless Steel

®

Gas 300 (148) 2-5 (0.3 - 0.8) Steel ➀➀304 Stainless Steel

Freon

Gasoline 300 (148) 23 (3.6) Steel 30 (4.6) 304 Stainless Steel

2

(W/cm2)

➀➀Incoloy®800

®

800

30 (4.6) Incoloy®800

30 (4.6) Incoloy®800

➀➀Incoloy

30 (4.6) Incoloy

®

®

— — Consult factory

— — Consult factory

— — Consult factory

30 (4.6) Incoloy

®

CONTINUED

➀ Consult your Watlow representative.

Freon®is a registered trademark of

E.I. du Pont de Nemours and Company.

264

Loading...

Loading...