Page 1

Watlow’s New

WATCONNECT®

Control Panels are

Quickly Configured

for Standard Two-Week

Delivery

SPECIFICATION SHEET

WATCONNECT®

Watlow® is now offering WATCONNECT® standard control

panels that are quickly configured to your specific application

requirements and delivered within two weeks. WATCONNECT

panels integrate Watlow’s high-quality heater, sensor,

temperature controller and power controller products for a

complete thermal solution. Normally, competitive custom

panels require significantly longer lead times. The broad

range of standard features allow customers to quickly

configure panels that usually would be considered custom

for delivery within two weeks.

Watlow’s customers will be impressed with the speed and

ease of specifying, selecting, pricing, ordering and delivery.

WATCONNECT panels are flexible and scalable; there are

thousands of configurable, pre-engineered panel solutions

available.

Features and Benefits

Full documentation provided for all WATCONNECT control

panels at the time of quotation

• Eliminates lengthy approval process and phone calls

Watlow’s F4T process controllers provide data logging

and Ethernet

• Provides real time and historical data management of

process parameters

Range of standard input / output (I/O) options

• Provide the user with a higher level of monitoring

and control, assuring an efficient and safe operation

(See Communcations Interface Chart on page 4.)

WATCONNECT enclosure easily mounts to wall or frame

• Decreases installation time

Bottom, right and top power entries

• Provides multiple options for accessing and making

connections to the inside of the panel

IP-20 finger-safe construction

• Decreases chance of electrical shock for service and

maintenance personnel

Fast acting fuses

• Protects sensitive solid state components from

damaging currents

Available illuminated E-Stop

• Allows quick emergency shut down

Variety of cooling options

• Suited for a wide range of environmental conditions

Carbon steel and stainless steel enclosure materials

available

• Offers materials that are most economical for the

user’s application

Supports a wide variety of sensor inputs including ASTM

thermocouple types J, K and T, 3 wire 100 ohm RTD and

4 to 20mA process input

• Provides the customer a variety of process signals to ensure

compatibility with field equipment

For more information on WATCONNECT go to www.watlow.com/watconnect

Powered by Possibility

To be automatically connected to the nearest

North American Technical Sales Oce:

1-800-WATLOW2 • www.watlow.com

inquiry@watlow.com

©2017 Watlow Electric Manufacturing Company all rights reserved.

International Technical Sales Offices:

China +86 21 3532 8532

France +33 1 41 32 79 70

Germany +49 7253 9400 0

India +91 40 6661 2700

Italy +39 02 4588841

Japan +81 3 3518 6630

Korea +82 2 2169 2600

Mexico +52 442 256 2200

Singapore +65 6773 9488

Spain +34 91 675 1292

Taiwan +886 7 288 5168

UK +44 115 964 0777

HOU-WATC-0417

Page 2

WATCONNECT Standard Control Panels Include:

• UL®/cUL® listed control panels for installation in indoor/outdoor

and non-hazardous/hazardous locations

• Wall or frame mount enclosures with hinged door, sized to

accommodate one to four branch circuits and top, side or

bottom power entry

• Limited access and increased safety through the use of tool

operated, ¼ turn, mechanical latches that secure the hinged

door to the enclosure

• Molded case circuit breaker disconnect with through-door

interlocked handle and lock out/tag out functionality (provides

enhanced safety)

• Fused branch circuit protection ensures protection of system

load and panel components

• DIN-A-MITE® C series solid state SCR power switching

controller(s) with zero cross output firing and touch-safe

terminals provide outstanding reliability

• Through wall heat sink(s) reduces ambient temperatures within

the enclosure

• Independent high temperature limit control(s) ensures safety

and protection of the equipment being controlled

• Safety mechanical contactor(s) removes power to system load

in the event of a high limit and/or safety situation

• Process controllers come pre-programmed for the configured

options and operation, reducing overall set-up time

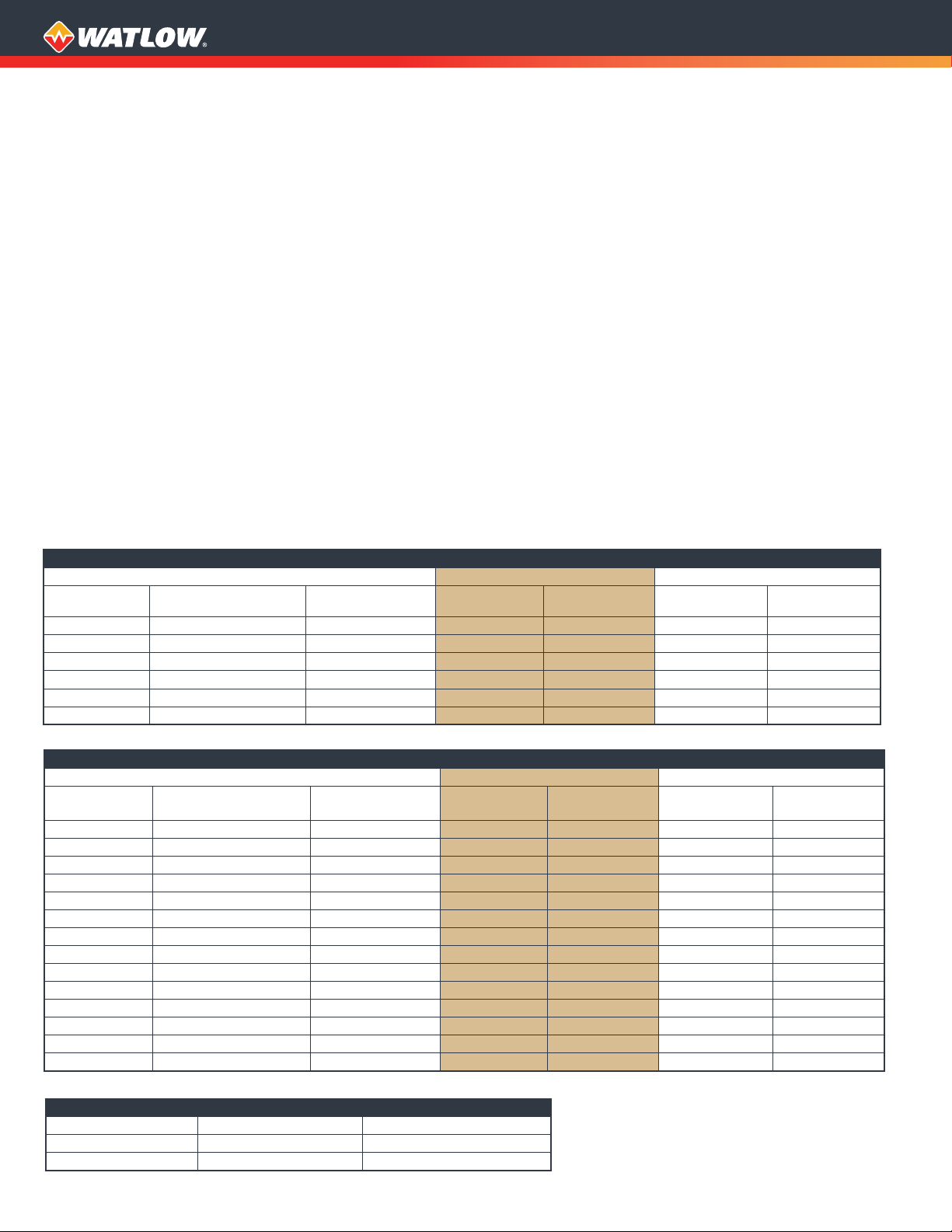

Cooling Requirements Charts

SERIES C2 (Small Non-Hazardous)

Panel Configuration Ambient Temperatures Cooling Requirements

Total Number of

Branch Circuits

1 24A (load <= 24A) Carbon steel -18°C 40°C None None

1 24A (load <= 24A) SS -18°C 35°C None No F4T

1 48A (load <= 48A) Carbon steel -18°C 30°C None No F4T

1 48A (load <= 48A) Carbon steel or SS -10°C 40°C Fans/shrouds None

2 24A (load <= 48A) Carbon steel or SS -10°C 40°C Fans/shrouds None

2 48A (load <= 96A) Carbon steel or SS -10°C 40°C Fans/shrouds None

*FLA = Full Load Amps/Branch Circuit, Total Load = (# Branch Circuits) x (Full Load Amps/Branch Circuit)

Total Number of

Branch Circuits

1 24A (load <= 24A) SS -18°C 35°C None No F4T

1 24A (load <= 24A) SS -10°C 40°C Fans/shrouds No F4T

1 24A (load <= 24A) Carbon steel -18°C 40°C None None

1 48A (load <= 48A) Carbon steel -18°C 30°C None No F4T

1 48A (load <= 48A) Carbon steel or SS -10°C 40°C Fans/shrouds None

2 24A (load <= 48A) Carbon steel -18°C 30°C None No F4T

2 24A (load <= 48A) Carbon steel or SS -10°C 40°C Fans/shrouds None

2 48A (load <= 96A) Carbon steel or SS -10°C 40°C Fans/shrouds None

3 24A (load <= 72A) Carbon steel or SS -10°C 40°C Fans/shrouds None

3 48A (load <= 144A) Carbon steel or SS -10°C 40°C Fans/shrouds None

4 24A (load <= 96A) Carbon steel or SS -10°C 40°C Fans/shrouds None

4 48A (load <= 192A) Carbon steel or SS -10°C 35°C Fans/shrouds None

4 48A (load <= 192A) Carbon steel or SS -10°C 40°C Fans/shrouds No F4T

4 48A (load <= 168A) Carbon steel or SS -10°C 40°C Fans/shrouds None

*FLA = Full Load Amps/Branch Circuit, Total Load = (# Branch Circuits) x (Full Load Amps/Branch Circuit)

Air Required SERIES C3 (Small) SERIES C5 (Medium)

PSIG 80-120* 100-120*

SCFM 25-30 40-80

*Available air ow and pressure to the panel must be sucient to maintain stated SCFM.

FLA/Branch Circuit

(Total Load)*

Panel Configuration Ambient Temperatures Cooling Requirements

FLA/Branch Circuit

(Total Load)*

SERIES C3 and C5 (Hazardous Area) Panels

Enclosure Material

SERIES C4 (Medium Non-Hazardous)

Enclosure Material

• Operator interface features:

• Illuminated control power on/off switch (one per panel) for

increased visibility of control status (status determination at

a glance)

• Illuminated heater on/off switch(s) (one for each control

loop) for increased visibility of heater power status (status

determination at a glance)

• Illuminated heater high temperature light with momentary

push to reset (allows reset of all limit controls without the

necessity of opening the enclosure door)

• Watlow process temperature control coupled with the

DIN-A-MITE power switching controller provide superior

thermal performance through tight process temperature

control

• Z-type purge system with environmental window and

temperature regulation on hazardous location panels

• Remote inputs/outputs based on process controller selection

• Field upgradable (most options)

Agency Approvals

• Preconfigured and certified to UL® Standard 508A for

non-hazardous locations

• Non-hazardous panels certified to one or more of the following:

• Type 4, 4X, 1, 12 and IP65

• Hazardous location panels certified for UL® Listed installation,

investigated to NFPA 496: 2008 and UL®698A and cUL® Listed,

investigated to NFPA 496: 208 and CAN/CSA 22.2

Min. Ambient

Operating Temp.

Min. Ambient

Operating Temp.

Max. Ambient

Operating Temp.

Operating Temp.

2

Max. Ambient

Cooling Needs Restrictions

Cooling Needs Restrictions

Page 3

Configuration Options

Control

Panel

Size

Small

SERIES

C2

C3

Hazardous

Location

NonHazardous

Hazardous

Class 1,

Div. 2,

Groups

B/C/D or

Class 1,

Zone 2,

Groups IIA/

IIB/IIC

Total # of

Control

Loops or

Zones

1 1

1 2

2 2

1 1

1 2

2 2

Total # of

Branch

Circuits

in Panel

Voltage

Supply

240V, 480V

or 600V

3-phase,

50/60Hz

4 wire

(3 power,

1 ground)

240V, 480V

or 600V

3-phase,

50/60Hz

4 wire

(3 power,

1 ground)

(external

120V single

phase

necessary for

purge

operation)

Total #

(Type) of

Process

Controllers

Up to 2

(EZ-ZONE®

PM6 or PM4,

F4T)

Up to 2

(EZ-ZONE PM6

or PM4, F4T)

Total

Process +

Limit

Controllers Notes and Restrictions

Up to 4

(1 process

w/up to

3 limits) or

(2 process

w/1 limit

each)

Up to 4

(1 process

w/up to

3 limits) or

(2 process

w/1 limit

each)

1. Shorted SCR not available

2. See process controller and

communications interface charts

for available features

1. Shorted SCR not available

2. See process controller and

communications interface charts

for available features

Medium

C4

C5

NonHazardous

Hazardous

Class 1,

Div. 2,

Groups

B/C/D or

Class 1,

Zone 2,

Groups

IIA/IIB/IIC

1 1

1 2

1 3

1 4

2 2

2 4

1 1 240V, 480V

1 2

1 3

1 4

2 2

2 4

240V, 480V

or 600V

3-phase,

50/60Hz

4 wire

(3 power,

1 ground)

or 600V

3-phase,

50/60Hz

4 wire

(3 power,

1 ground)

(external

120V single

phase

necessary

for purge

operation)

Up to 2

(EZ-ZONE

PM4, F4T)

Up to 2

(EZ-ZONE

PM4, F4T)

Up to 8

(up to

2 process +

up to 3 limits

for each

control loop/

zone

Up to 8

(up to

2 process +

up to 3 limits

for each

control loop/

zone

See process controller and

communications interface charts for

available features

See process controller and

communications interface charts for

available features

WATCONNECT®, DIN-A-MITE® and EZ-ZONE® are registered trademarks of

Watlow Electric Manufacturing Company.

UL® and cUL® are registered trademarks of Underwriter’s Laboratories, Inc.

3

Page 4

Process Controller Chart

Available Process Controllers

Small

(C2 or C3 SERIES)

Available Options/Features EZ-ZONE

PM6

Integrated Limit X X X X X

Single Sensor or Outlet Control X X X X X

Cascade Process Control X X Integrated limit not available with cascade or dierential

Dierential Process Control X X Integrated limit not available with cascade or dierential

Shorted SCR Detection X

Remote I/O (See Communications

Interface Chart)

Local Ethernet Connectivity X X RJ45 Ethernet jack on door standard on all F4Ts

Remote Copper Ethernet

Connectivity

Remote Copper/Fiber Ethernet

Connectivity

Total Number of Controllers Needed = Total

EZ-ZONE

PM4 F4T

X X X X On EZ-ZONE PM4 - Remote set point feature (within

X X Via optional Ethernet switch mounted within enclosure

X X Via optional Ethernet switch mounted within enclosure

Number of Control Loops or Zones

Medium

(C4 or C5

SERIES)

EZ-ZONE

PM4 F4T

Notes/Restrictions

process control options

process control options

Remote I/O) not available with integrated limit

Communications Interface Chart - Standard Features by Controller Type Chart

Per Control Loop/

Function

Remote I/O: Dig In - Remote Shutdown Per loop/zone Std. Std.

Remote I/O: Dig Out - Heater Hi Limit Status Per loop/zone Std. Std.

Remote I/O: Dig Out - Heater Enabled Status Per loop/zone Std. Std.

Remote I/O: Analog Out - Process Temp Retransmit

Remote I/O: Analog In - Remote Set Point Per loop/zone Std.* Std.

Remote I/O: Dig Out - Common Alarm System Std. Std.

Remote I/O: Dig Out - Purge Loss System Std. Std.

Front RJ45 Ethernet Jack System Std.

Data Logging System (per controller) Std.

Standard Copper Remote Ethernet Connection System Available option

Fiber Remote Ethernet Connection System Available option

* Note: Remote SP not available with integrated limit.

Zone or System

Per loop/zone Std. Std.

EZ-ZONE PM6

Process Controller

EZ-ZONE PM4

Process Controller

F4T Process

Controller

4

Page 5

Dimensional Drawings

A

REVISIONS

ZONE

REV.

DESCRIPTION

1

PRELIMINARY RELEASE

2/24/2017

8

7

6

5

4

3

2

1

2.17 in.

(55 mm)

19.69 in.

(500 mm)

2.17 in.

(55 mm)

18.11 in.

(460 mm)

10.24 in.

(260 mm)

19.69 in.

(500 mm)

18.11 in.

(460 mm)

24.56 in.

(624 mm)

22.05 in.

(560 mm)

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

1

PRELIMINARY RELEASE

2/24/2017

JJACKSON

D

C

6

5

4

3

2

1

10.24 in.

(260 mm)

19.69 in.

(500 mm)

18.11 in.

(460 mm)

24.56 in.

(624 mm)

22.05 in.

(560 mm)

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

1

PRELIMINARY RELEASE

2/24/2017

JJACKSON

D

C

4

3

2

1

19.69 in.

(500 mm)

18.11 in.

(460 mm)

24.56 in.

(624 mm)

22.05 in.

(560 mm)

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

1

PRELIMINARY RELEASE

2/24/2017

JJACKSON

D

C

3

2

1

REVISIONS

ZONE

REV.

DESCRIPTION

2

PRELIMINARY RELEASE

8

7

6

5

4

3

2

A

3.97 in.

(101 mm)

19.69 in.

(500 mm)

2.87 in.

(73 mm)

13.70 in.

(348 mm)

3.66 in.

(93 mm)

18.11 in.

(460 mm)

Ø 0.39 in.

(10 mm)

T YP.

21.06 in.

(535 mm)

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

2

PRELIMINARY RELEASE

2/23/2017

JJACKSON

D

C

4

3

2

1

B

A

3.66 in.

(93 mm)

18.11 in.

(460 mm)

24.81 in.

(630 mm)

22.05 in.

(560 mm)

Ø 0.39 in.

(10 mm)

T YP.

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

2

PRELIMINARY RELEASE

2/23/2017

JJACKSON

D

C

6

5

4

3

2

1

B

A

13.70 in.

(348 mm)

3.66 in.

(93 mm)

18.11 in.

(460 mm)

24.81 in.

(630 mm)

22.05 in.

(560 mm)

Ø 0.39 in.

(10 mm)

T YP.

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

2

PRELIMINARY RELEASE

2/23/2017

JJACKSON

D

C

3

2

1

B

C2 SERIES, Small, Non-Hazardous Location

C3 SERIES, Small, Hazardous Location

23.62 in.

(600 mm)

1.25 in.

(31 mm)

T YP.

2.17 in.

(55 mm)

Left Side View

9.78 in.

(248 mm)

19.69 in.

(500 mm)

18.11 in.

(460 mm)

10.24 in.

(260 mm)

Right Side View

2.17 in.

(55 mm)

23.62 in.

(600 mm)

1.25 in.

(32 mm)

T YP.

10.24 in.

(260 mm)

Left Side View

3.45 in.

(88 mm)

19.69 in.

(500 mm)

13.70 in.

(348 mm)

Right Side View

2.87 in.

(73 mm)

22.05 in.

(560 mm)

21.06 in.

(535 mm)

24.81 in.

(630 mm)

22.05 in.

(560 mm)

24.56 in.

(624 mm)

3.97 in.

(101 mm)

3.66 in.

(93 mm)

A

18.11 in.

(460 mm)

Front View

A

Front View

19.69 in.

(500 mm)

18.11 in.

(460 mm)

Rear View

Ø 0.39 in.

(10 mm)

T YP.

Rear View

5

Page 6

Dimensional Drawings

SCR1

SCR2

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3 PRELIMINARY RELEASE

3/23/2017

JJACKSON

D

C

8

7

6

5

4

3

2

1

B

2.29 in.

(58 mm)

23.62 in.

(600 mm)

2.25 in.

(57 mm)

Air

Outlet

Port

Air

Inlet

Port

12.39 in.

(315 mm)

21.34 in.

(542 mm)

31.10 in.

(790 mm)

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3 PRELIMINARY RELEASE

3/23/2017

JJACKSON

D

C

4

3

2

1

B

21.34 in.

(542 mm)

31.10 in.

(790 mm)

SCR1

SCR2

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3

PRELIMINARY RELEASE

3/23/2017

JJACKSON

D

C

6

5

4

3

2

1

B

12.39 in.

(315 mm)

21.34 in.

(542 mm)

31.10 in.

(790 mm)

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3

PRELIMINARY RELEASE

3/23/2017

JJACKSON

D

C

3

2

1

B

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3

PRELIMINARY RELEASE

3/27/2017

JJACKSON

D

C

8

7

6

5

4

3

2

1

B

2.87 in.

(73 mm)

23.62 in.

(600 mm)

2.87 in.

(73 mm)

27.36 in.

(695 mm)

3.97 in.

(101 mm)

12.39 in.

(315 mm)

21.34 in.

(542 mm)

4.02 in.

(102 mm)

31.10 in.

(790 mm)

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3

PRELIMINARY RELEASE

3/27/2017

JJACKSON

D

C

4

3

2

1

B

21.34 in.

(542 mm)

4.02 in.

(102 mm)

31.10 in.

(790 mm)

A

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3

PRELIMINARY RELEASE

3/27/2017

JJACKSON

D

C

6

5

4

3

2

1

B

12.39 in.

(315 mm)

21.34 in.

(542 mm)

4.02 in.

(102 mm)

31.10 in.

(790 mm)

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

3

PRELIMINARY RELEASE

3/27/2017

JJACKSON

D

C

3

2

1

B

C4 SERIES, Medium, Non-Hazardous Location C5 SERIES, Medium, Hazardous Location

11.75 in.

(298 mm)

10.96 in.

(278 mm)

2.29 in.

(58 mm)

12.39 in.

(315 mm)

11.75 in.

(298 mm)

11 in.

(278 mm)

3.45 in.

(88 mm)

12.39 in.

(315 mm)

(760 mm)

1.25 in.

(32 mm)

29.92 in.

2.29 in.

(58 mm)

Outlet

SCR3

Left Side View

Air

Port

SCR4

23.62 in.

(600 mm)

SCR2

SCR1

Right Side View

2.25 in.

(57 mm)

1.06 in.

(27 mm)

29.92 in.

(760 mm)

Left Side View

2.87 in.

(73 mm)

23.62 in.

(600 mm)

Right Side View

2.87 in.

(73 mm)

27.36 in.

(695 mm)

3.97 in.

(101 mm)

4.02 in.

(102 mm)

A

Front View

21.34 in.

(542 mm)

Air

Inlet

Port

Front View

21.34 in.

(542 mm)

A

31.10 in.

(790 mm)

Rear View

6

Rear View

31.10 in.

(790 mm)

Loading...

Loading...