Page 1

1998

November 2000

On-line version of 1967

Users Manual

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507, http://www.watlow.com

Series V4

General Purpose

1/4 DIN Temperature Controller

Page 2

2 Watlow Series V4

Overview

The V4 1/4 DIN panel mount controller is a general purpose industrial PID temperature controller.The V4

provides a reliable cost-effective solution for most temperature control applications.Thermocouple, RTD,

and Current and Voltage sensors are supported. Dual outputs can be configured to support heating and

cooling.The secondary output can also be configured as an alarm.

V4 features include: a NEMA 4X front panel seal, a 3-year warranty, meets European CE requirements and

has a 4 inch deep case with removable connectors for wiring convenience.

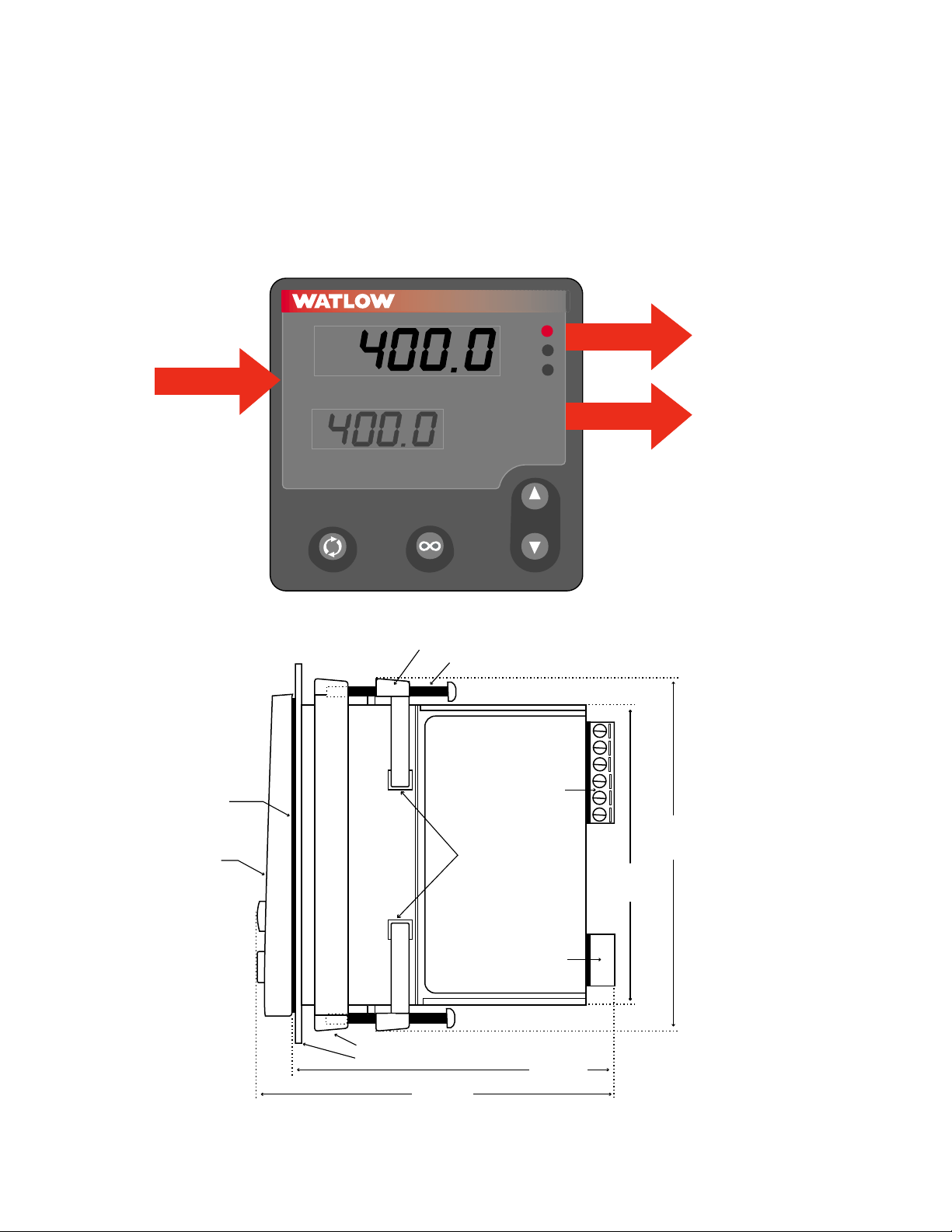

Figure 2a — Series V4 inputs and outputs.

Figure 2b - Controller dimensions.

Dual Control Output -

Single Input Type J, K, T, N or

S Thermocouple,

RTD or Process

V4

1

2

%

PID or ON/OFF, User Selectable

Output 1 Heat or Cool

Output 2 Heat, Cool,

Alarm or None

Mounting Brackets

External

Gasket

Front

Bezel

Mounting Collar

Customer's Front Panel

4.25"

(107.9mm)

M3 Mounting Screw

Terminal

Block

Mounting Slots

Terminal

Block

3.83"

(97.18mm)

4.21"

(106.83mm)

3.58"

(91.03mm)

Page 3

Watlow Series V4 3

Installation and Removal

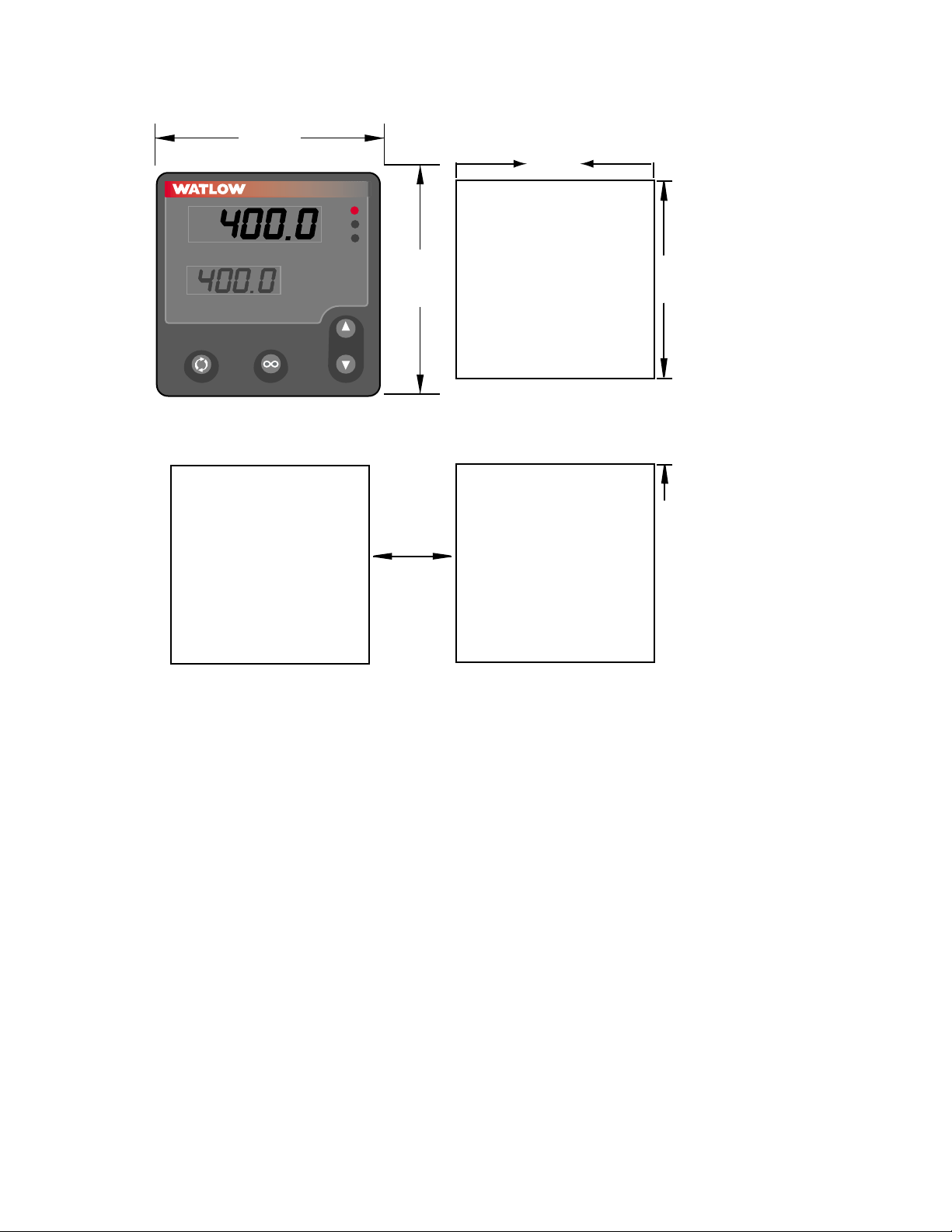

Figure 3 - Series V4 multiple panel cutout dimensions.

NOTE: Measurements between panel cutouts are the minimum recommended.

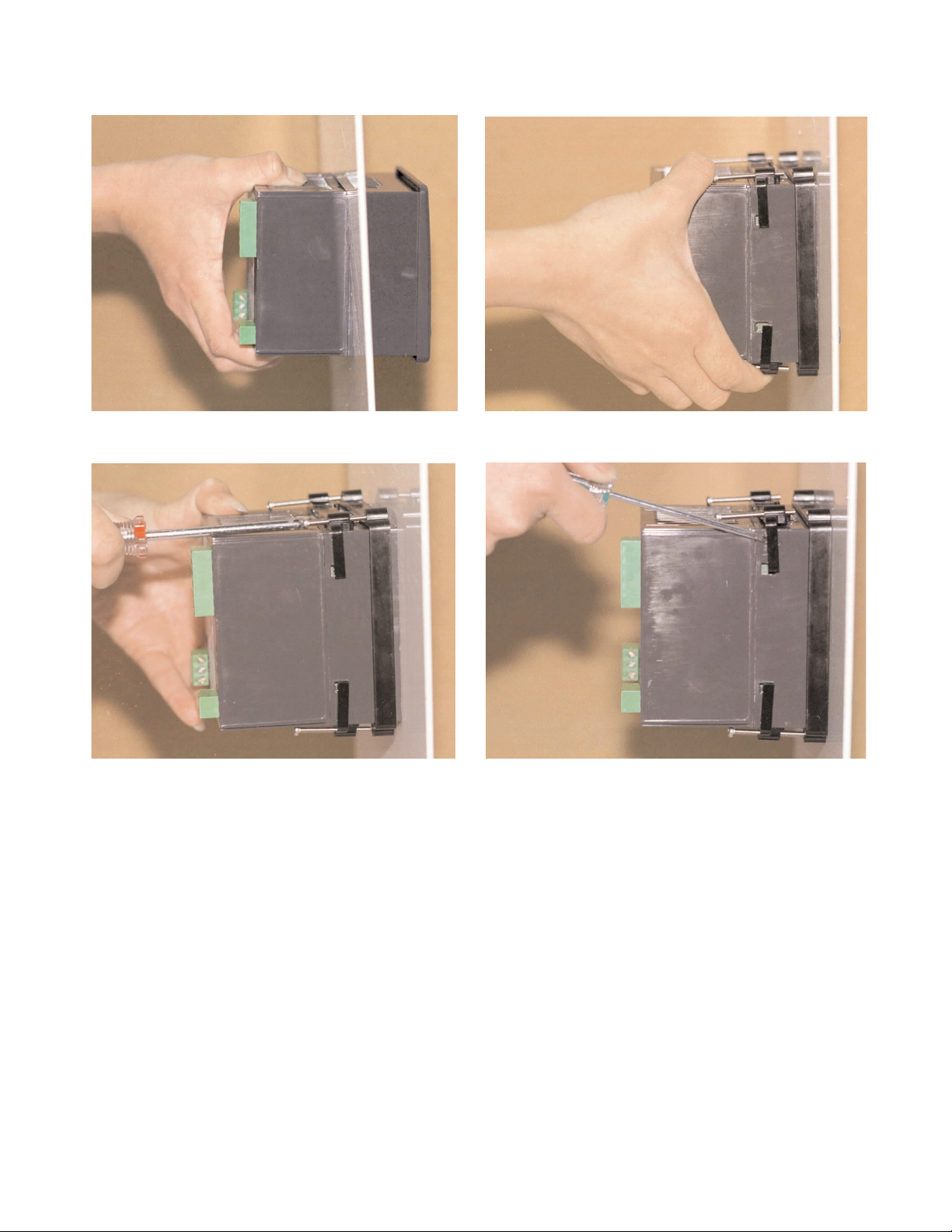

Installing the Series V4 Controller

Installing and mounting requires access to the back panel.

1. Make the panel cutout using the panel cutout dimensions as shown in Figure 4.

2. Make sure the rounded side of the external case gasket is facing the panel surface.

3. Check to see that the gasket is not twisted, and is seated within the case bezel flush with the panel.

4. Slightly compress the top and bottom side of the V4 Case while pulling the controller into the panel

cutout (Figure 5a). Slide the mounting collar over the back of the controller.The tabs on the collar

must line up with the mounting ridges on the case for secure installation. The tab holes are facing

the back of the controller.

5. Adjust the mounting bracket screws enough to allow for the mounting collar and panel thickness.

Snap the upper and lower mounting brackets on the case of the controller (Figure 5 b). Make sure

all the grips are well engaged on the mounting slots of the controller. (The four screw heads are facing the back of the controller.)

6. Make sure the case is seated properly.Tighten the installation screws firmly against the mounting

collar to secure the unit (Figure 5c). To ensure NEMA 4X seal, there should be no space

between the bezel and panel. Over tightening the screws will distort the case and make it difficult to remove or replace the controller.

V4

1

2

%

Panel Cutout

Panel

Thickness

0.375"

9.5 mm)

3.62"

(92mm)

3.62"

(92mm)

0.85"

(20mm)

minimum

0.85"

(20mm)

minimum

3.93"

(99.82mm)

Page 4

Watlow Series V4 4

Installation and Removal (continued)

Figure 4a - Slightly compress the case while Figure 4b - Snap the top and bottom mounting

pulling the controller into the panel cutout. bracket into the slots.

Figure 4c - Tighten screw to secure the controller. Figure 4d - Remove the controller using a flat

screwdriver.

NOTE: Be careful not to over-tighten the screws. This may cause the mounting cover to fail. Over-tightening occurs when the front bezel is touching the customer’s front panel.

Removing the Series V4 Controller

1. Loosen the upper and lower mounting bracket screws.

2. Use a flat screw driver to unsnap the four grips on the opposite side of upper and lower mounting

brackets. Push the brackets back and forth gently until they can be pulled off easily.

3. Remove controller from the panel.

Page 5

Watlow Series V4 5

Wiring the Series V4

Power Wiring

High Voltage

100 to 240VÅ (ac), nominal (85 to 264 actual) V4TH - _ _ _ _ - _ _ _ _

Low Voltage

14 to 24V‡ (ac/dc) V4TL - _ _ _ _ - _ _ _ _

Figure 5 - Power wiring.

Sensor Installation Guidelines

We suggest you mount the sensor at a location in your process or system where

it reads an average temperature. Put the sensor as near as possible to the

material or space you want to control. Air flow past this sensor should be moderate. The sensor should be thermally insulated from the sensor mounting.

ç

WARNING:

To avoid damage to

property and equipment and/or injury or

loss of life, use

National Electric

Code (NEC) standard

wiring practices to

install and operate

this unit. Failure to

do so could result in

injury and/or death,

or such damage.

NOTE:

Taking the unit out of

the case is not a normal operating condition and should only

be done by a qualified maintenance

installation technician. Power to the

case should be disconnected before

removing or

installing the controller into its case.

∫

WARNING:

The case terminals

may still carry live

voltage when the

unit is removed.

∫

WARNING:

Irreversible damage

will occur if high

voltage is applied to

the low voltage unit.

L1 L2

18

OFF

1 2

4

5

6

17

16

15

14

13

8

7

fuse

8

7

Page 6

6 Watlow Series V4

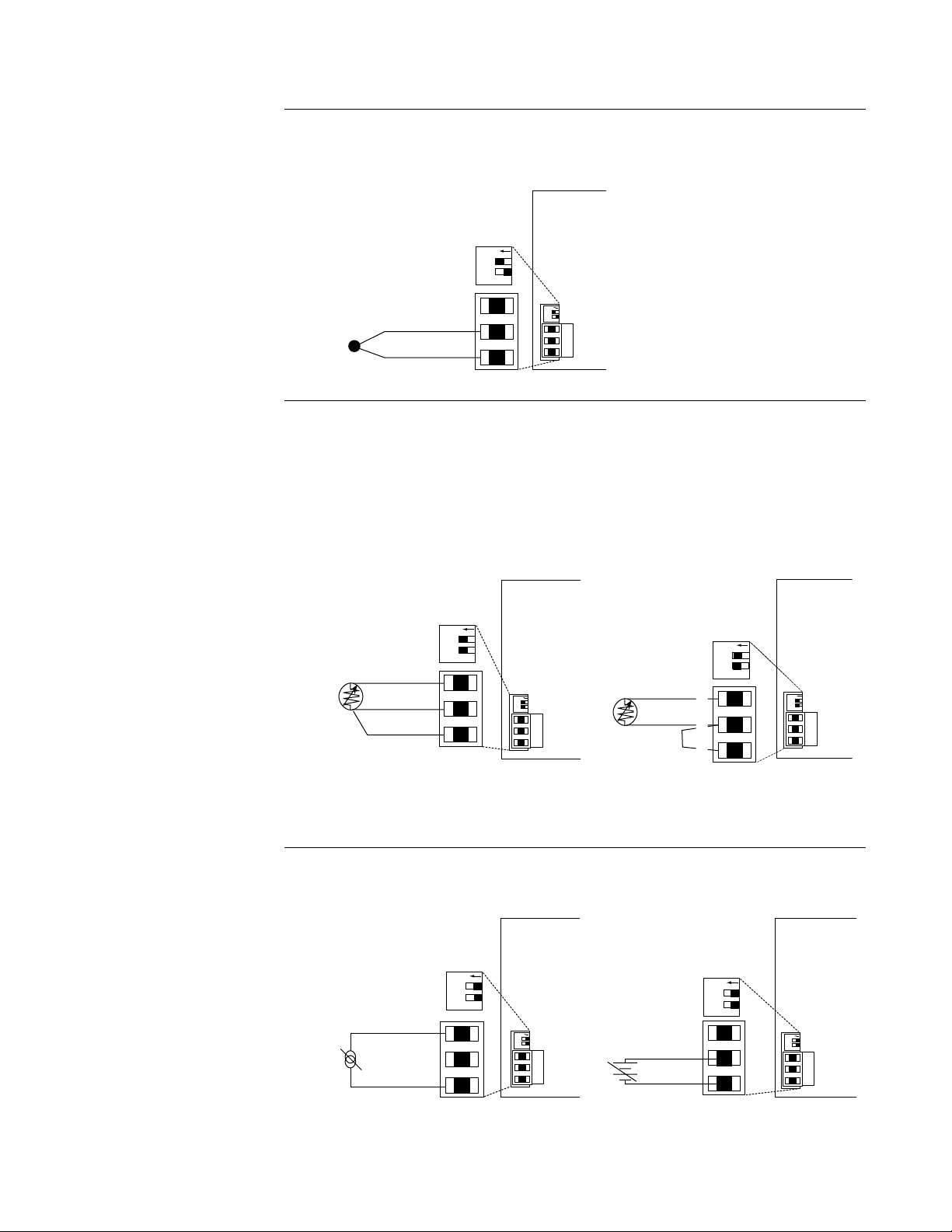

Input Wiring

Figure 6a – Thermocouple

Extension wire for thermocouples must be of the same alloy as the thermocouple itself to limit errors.

Figure 6b – RTD (2- or 3-Wire) 100Ω Platinum

There could be a +2°F input error for every 1Ω of lead length resistance

when using a 2-wire RTD. That resistance,when added to the RTD element

resistance, will result in erroneous input to the instrument. To overcome

this problem, use a 3-wire RTD sensor,which compensates for lead length

resistance. When extension wire is used for a 3-wire RTD,all wires must

have the same electrical resistance (i.e. same gauge, same length, multiplestranded or solid, same metal.

Figure 6c – Process,4-20mA Figure 6d – Process,0-5VÎ (dc)

Input impedance: 5Ω Input impedance: 10kΩ

NOTE:

Successful installation requires five

steps:

• Choose the controller’s hardware

configuration and

model number;

• Choose a sensor;

• Install the con-

troller;

• Wire the controller

and

• Configure the controller.

ç

WARNING:

To avoid damage to

property and equipment and/or injury or

loss of life, use

National Electric

Code (NEC) standard

wiring practices to

install and operate

this unit. Failure to

do so could result in

injury and/or death,

or such damage.

NOTE: When an

external device with a

non-isolated circuit

common is connected to the 4-20mA or

dc output, you must

use an isolated or

ungrounded thermocouple.

ç

CAUTION: Process

input does not have

sensor break protection. Outputs can

remain full on.

DIP Switch

Orientation

1: OFF

2: ON

+

T/C

-

DIP Switch

Orientation

1: OFF

2: OFF

S1

4

S2

5

S3

6

5

6

RTD

OFF

1 2

3-wire

RTD

OFF

1 2

TC

OFF

1 2

DIP Switch

Orientation

4

5

6

DIP Switch

Orientation

1: OFF

RTD

OFF

1 2

2: OFF

S1

S2

S3

4

5

6

OFF

1 2

DIP Switch

Orientation

4

5

6

OFF

1 2

DIP Switch

Orientation

4

5

6

2-wire RTD

Jumper Terminals 5 & 6

(customer supplied)

DIP Switch

Orientation

1: ON

2: ON

I

dc

- 4

+ 6

PROC

OFF

1 2

DIP Switch

Orientation

PROC

OFF

1 2

1: ON

2: ON

OFF

1 2

DIP Switch

Orientation

4

5

6

V

dc

+

5

6

-

OFF

1 2

DIP Switch

Orientation

4

5

6

Page 7

Watlow Series V4

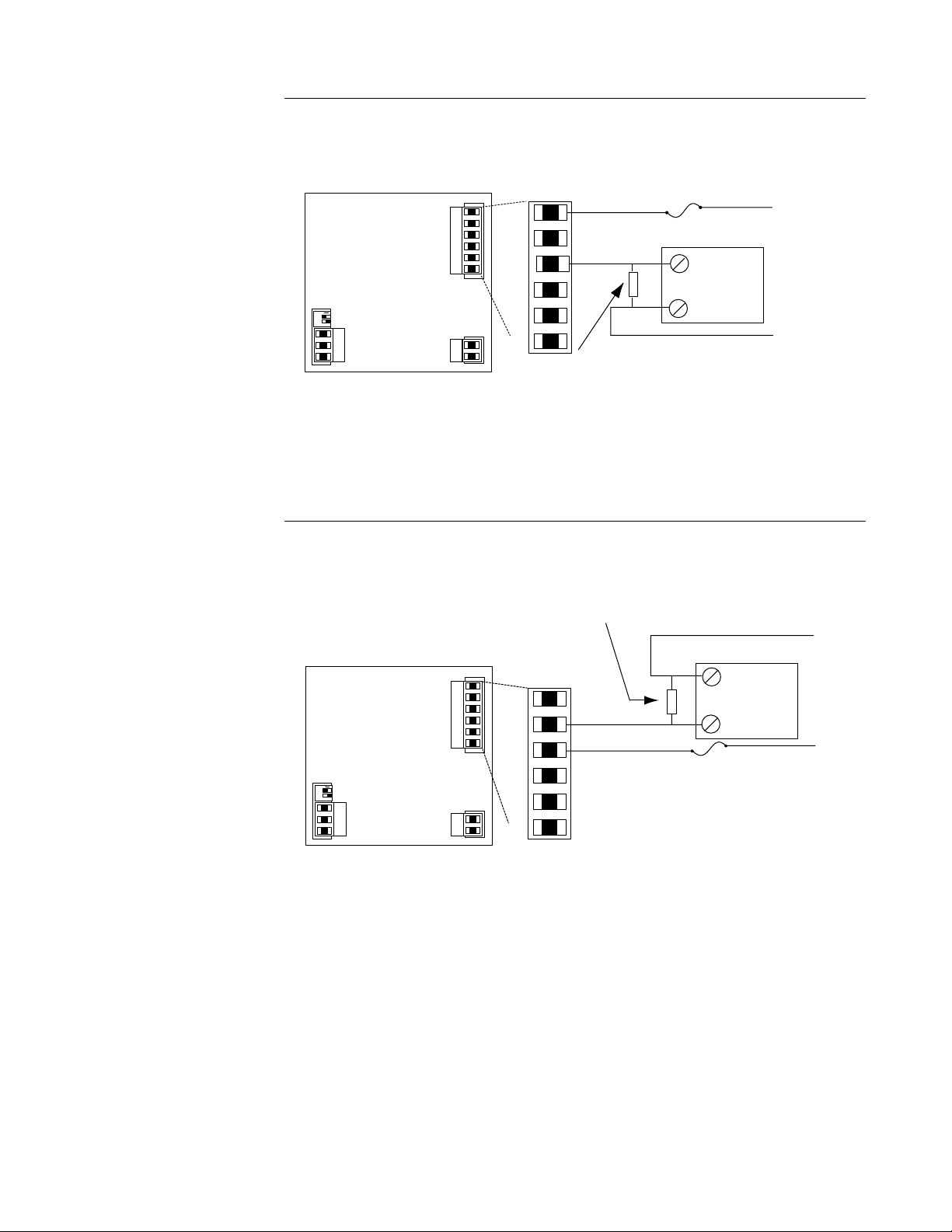

Output 1 Wiring

Figure 7a – Mechanical Relay

Without Contact Suppression

V4T _ - D _ _ _ - _ _ _ _

Form C, rated at 8A @ 125V~ (ac) or 5A @ 240V~ (ac)

Minimum load current: 100mA @ 5VÎ (dc)

Figure 7b – Solid State Relay

Without Contact Suppression

V4T _ - K _ _ _ - _ _ _ _

0.5 amps (AC loads only)

ç

WARNING:

To avoid damage to

property and equipment and/or injury or

loss of life, use

National Electric

Code (NEC) standard

wiring practices to

install and operate

this unit. Failure to do

so could result in

injury and/or death,

or such damage.

NOTE:

Switching inductive

loads (relay coils,

solenoids, etc.) with

the mechanical relay,

switched dc or solidstate relay output

options requires use

of an R.C. suppressor.

Watlow carries the

R.C. suppressor

Quencharc brand

name, which is a

trademark of ITW

Pakron. Watlow Part

No. 0804-0147-0000.

18

18

17

16

17

15

14

16

13

15

OFF

1 2

4

5

6

14

8

13

7

COM

NC

NO

Customer Supplied

Quencharc

Customer Supplied

Quencharc

18

17

18

16

15

17

14

13

16

OFF

1 2

4

5

6

15

14

8

7

13

SS1

SS1

Fuse

L1

External

Load

L2

L2

External

Load

L1

Fuse

Page 8

8 Watlow Series V4

Output 1 Wiring

Figure 8a – Switched DC, Open Collector

V4T _ - C _ _ _ - _ _ _ _

Figure 8b – 4-20mA Process

V4T _ - F _ _ _ - _ _ _ _

Maximum load impedance: 800Ω

NOTE:

When an external

device with a nonisolated circuit common is connected to

the 4-20mA or dc output, you must use an

isolated or ungrounded thermocouple.

OFF

1 2

4

5

6

V+

unregulated

V—

Internal Circuitry

18

17

18

16

15

17

14

13

16

+

External

-

Load

15

14

8

13

7

18

16

OFF

1 2

4

5

6

18

18

17

16

17

15

14

16

13

+

External

-

Load

15

14

8

13

7

Page 9

Watlow Series V4 9

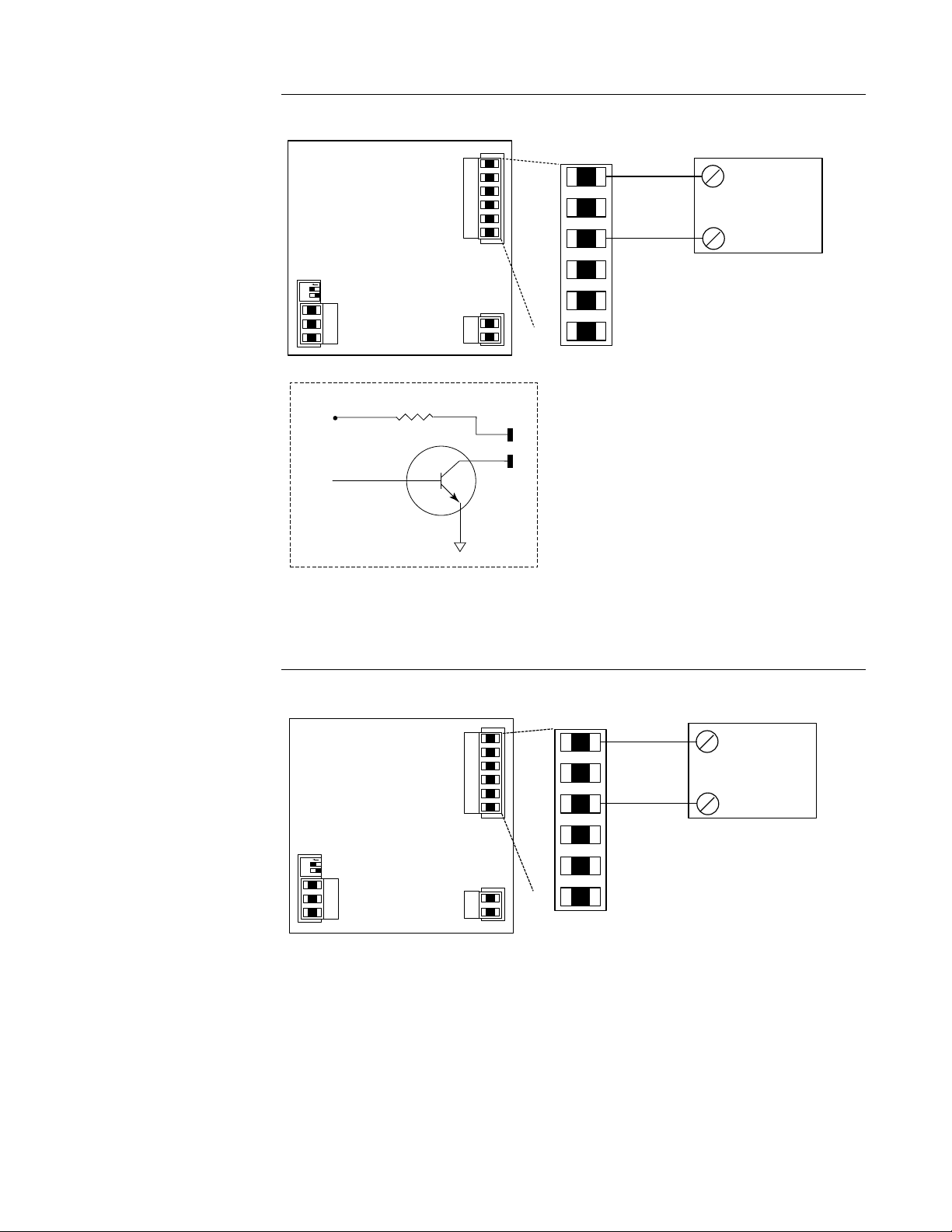

Output 2 Wiring

Figure 9a – Mechanical Relay Without Contact Suppression

V4T _ - _ D _ _ - _ _ _ _

Form C, rated at 8A @ 125V~ (ac) or 5A @ 240V~ (ac). Minimum load current: 100mA @ 5VÎ (dc)

Figure 9b – Solid State Relay Without Contact Suppression

V4T _ - _ K _ _ - _ _ _ _

0.5 amps (AC loads only)

Figure 93 – Switched DC, Open Collector

V4T _ - _ C _ _ - _ _ _ _

18

18

17

17

16

15

16

14

13

15

8

7

14

13

Customer

OFF

1 2

4

5

6

COM

NC

NO

Supplied

Quencharc

Fuse

L1

External

Load

L2

18

18

17

16

15

17

14

13

16

OFF

1 2

4

5

6

15

14

8

13

7

Customer Supplied

Quencharc

SS2

SS2

18

18

17

16

17

15

14

16

13

15

OFF

1 2

1 2

4

5

6

14

8

13

7

+

-

L2

External

Load

L1

Fuse

External

Load

V+

unregulated

V—

15

13

Internal Circuitry

Page 10

Watlow Series V4 10

Wiring Example

Figure 10 - System wiring example.

ç

WARNING:

To avoid damage to

property and equipment and/or injury or

loss of life, use

National Electric

Code (NEC) standard

wiring practices to

install and operate

this unit. Failure to do

so could result in

injury and/or death,

or such damage.

L1

120V~(ac)

L2

Earth Ground

fuse

fuse

coil

high limit

mechanical

contactor

fuses

V4TH-CAAA-AARR

TC

OFF

1 2

4

5 (+)

5

6

6 (-)

120V~ (ac)

L1

1

Temperature

Controller

DIP Switch

Orientation

18

18

17

16

15

16

14

13

8

8

7

7

7 (-)

6 (+)

T1 T2

Heater

DIN-a-mite

DA1C-1624-C000

process sensor limit sensor

L1 L2

Series V4

V4TH - CAAA - AARR

Temperature Controller

(+)

TC+

(-)

TC-

DC+1

94AA-1DK1-00RG

Limit

5 (+)

6 (-)

TC

OFF

1 2

4

5

6

Controller

DIP Switch

Orientation

L2L1

18

18

17

16

16

15

14

13

8

8

7

7

L2

2

DC-1

1 CR-1

1

L1

1

TC+

TC-

COM1

1

(-)(+)

L1 L2

T1

T2

Heater

Series 94

94AA-1DK1-00RG

Limit Controller

DIN-a-mite

DA1C-1624-C000

L2

NO1

NC1

1CR

2

2

2

Page 11

Watlow Series V4 11

Keys and Displays

Upper Display: Indicates

the process value, actual

temperature, operating

parameter values or an open

sensor. When powering up,

the Process display will be

blank for five seconds.

• To set to blank, set [`dsP]

to [`SEt] in the Setup

Menu.

Lower Display: Indicates

set point, output value,

parameters for data in the

upper display, or error and

alarm codes.

• To set to blank, set

[`dsP] to [`Pro] in the

Setup Menu.

Advance Key: Press to

advance through the

Operations, Setup, and

Calibration Menus. In the

Auto mode, new data is

self-entering in five

seconds.

Infinity/Home Key:

• Press once to clear

any latched alarms.

Also disables

deviation alarm

output if silencing is

enabled.

• Press again within

five seconds to

change from Auto to

Manual or vice versa.

While in Manual

mode, percent power

is in the lower display

sensor error.

Output 1 Indicator Light: Lit

when Output 1 is energized.

Output 2 Indicator Light: Lit

when Output 2 is active. This

output can be configured as a

control or alarm output.

V4

1

2

%

% Percent Power Indicator Light:

• Lit: the controller is in Manual

operation. Press the ˆInfinity key

twice to enter Automatic operation.

• Blinking: press the ˆInfinity key to

toggle between Auto and Manual.

Returns to its previous state and stops

blinking if the ˆInfinity key is not

pressed within five seconds.

Up-arrow and Down-arrow Keys:

Increases or decreases the value of

the displayed parameter.

• Press lightly to increase or

decrease the value by one.

• Press and hold down to increase

or decrease the displayed value at a

rapid rate. New data will self-enter

in five seconds, or can be entered by

pressing the Advance Key.

• Press both simultaneously for

three seconds to enter the Setup

Menu. The [`LOC] parameter

appears.

• Continue pressing both keys to

enter the Calibration Menu.

Page 12

Watlow Series V4 12

Setting up the Series V4 is a simple process. First set the DIP switches to match

your input type. Refer to the orientation on the back of the controller to select the

[``In] Input value. Next, configure the Series V4's features to your application

in the Setup Menu, then enter values in the Operating Menu. Both tasks use the

‰Advance key to move through the menus and the Up-arrow/Down-arrow keys to

select data.

Before entering information in the Setup Menu, set the [`dFL] parameter. If

[``SI] is selected, °C, proportional band in % of span, derivative and integral are

the defaults.If [``US] is selected,°F,proportional band in degrees,reset and rate

are the defaults. Changing the [`dFL] prompt will set parameters to their

factory default. Document all current parameter settings first. See the calibration section in the Appendix to change this parameter.

Entering the Setup Menu

The Operation Menu will appear as the default menu of the Series V4.The

Setup Menu displays the parameters that configure the Series V4's features to

your application.

Enter the Setup Menu by pressing the ¿Up-arrow and ¯Down-arrow keys simultaneously for 3 seconds.The lower display shows the [`LOC] Lock parameter, and the upper display shows its current level. All keys are inactive until you

release both keys.You can reach the Lock parameter from anywhere.

Use the ‰Advance key to move through the menus and the ¿Up-arrow and

¯Down-arrow keys to select data. You will not see all parameters in this menu,

depending on the controller's configuration and model number. After stepping

through the menu it returns to the set point parameter under the Operation

Menu. If no keys are pressed for approximately 60 seconds, the controller

returns to the default display, Process over Set Point.

93

93

∫

WARNING:

Remove power from the

controller before removing the chassis from the

case or changing the DIP

switches. Removing the

controller from the chassis is not a normal operating condition and

should only be done by a

qualified technician.

How to Set Up the Series V4

Figure 12a Entering the Setup Menu.

Figure 12b The Setup Menu.

NOTE:

While in the Setup

Menu, all outputs are off.

[`LOC] Lock

[``In] Input

[`dEC] Decimal*

[`C_F] Celsius - Fahrenheit*

[``rL] Range Low

[``rH] Range High

[`Ot1] Output 1

[`HSC] Hysteresis Control

[`Ot2] Output 2

[`HSA] Hysteresis Alarm*

[`LAT] Latching*

[`SIL] Silencing*

[`rtd] RTD*

[`rP`] Ramping

[`rT`] Rate*

[`P`L] Power Limiting*

[`dSP] Display

* Parameter may not always appear.

‰

Setup Menu

Page 13

Watlow Series V4 13

At the top of the Setup Menu the Series V4 displays the user level of operation in

the upper display and the [`LOC] parameter in the lower display .

Press the ‰Advance key and the value of the next parameter appears in the

upper display, and the parameter appears in the lower display.

Lock: Selects the level of operator lock-out as defined below.

Range: 0 to 4 Default: 0

[```0]: All operating parameters may be viewed or changed. Manual operation

is permitted. When in manual operation, percent power is adjustable.

Bumpless transfer to manual mode will occur on sensor break.

[```1] The set point, process value and alarm settings are the only visible

parameters, set point is adjustable in this level. Manual operation and autotune are permitted. When in manual operation, percent power is adjustable.

Bumpless transfer to manual mode will occur on sensor break.

[```2] The set point, process value and alarm settings are the only visible

parameters, set point is adjustable in this level. Manual operation is permit-

ted. When in manual operation, percent power is adjustable. Bumpless transfer

to manual mode will occur on sensor break.

[```3] The set point and process value are the only visible parameters, set

point is adjustable in this level. Manual operation is not permitted. Bumpless

transfer is defeated and outputs are disabled on sensor break.

[```4] The set point and process value are the only visible parameters, set

point is not adjustable in this level of lock-out. Manual operation is not permitted. Bumpless transfer is defeated and outputs are disabled on sensor

break.

Input: Selects the sensor input type. The internal DIP switch must also match

the {`In} parameter. See DIP switch orientation, and see input type temperature ranges in the following chart.

Range: [```J], [```H] (K), [```t], [```n], [```S], [`rtd], [`r†d],

[`0-5], [`420] Default: J

Decimal: Selects the location of the decimal point for all process-related data.

This parameter only appears if the [``In] parameter is set to 0-5 or 420. Make

sure the internal DIP switch matches the [``In] parameter.

Range: 0, 0.0, 0.00 Default: 0

Celsius — Fahrenheit: Selects the units of temperature measurement for the

control. This parameter only appears if the [``In] parameter is set to a thermocouple or RTD input. The default is dependent on the [`dFL] parameter located

in the Calibration Menu. Refer to the Appendix.

Range: [```C] or [```F]

If [`dFL] is set to [``SI]: Default: [```C]

If [`dFL] is set to [``US]: Default: [```F]

Range Low: Selects the low limit of the set point. Also used to scale the low

end of the process input. 0.0VÎ (dc) and 4mA represent [``rL] Range Low for a

process input. The process input is linearly scaled between [``rL] and [``rH].

See the model number and specification in the Appendix for range values,or

refer to the following table.

Range: Sensor range low to [``rh] Range High

Default: Low limit of sensor type for a thermocouple or RTD. -500 for a process

input.

Setup Parameters

{``In}

{`dEC}

{`C-F}

ç

CAUTION:

A process input does not

have sensor break protection

or bumpless transfer.

NOTE:

Shaded parameters may not

appear, depending on the

controller’s configuration

and model number.

ç

CAUTION:

Changing [``In] sets all

parameters to factory

defaults. Document all settings before changing this

parameter.

NOTE:

Set the [`LOC] parameter

value as the final step in

programming the Series V4

controller to prevent locking

yourself out of the Operation

and Setup Menu during ini-

tial programming.

[`LOC}

{``rL}

Page 14

Watlow Series V4 14

{`HSC}

{`Ot1}

{`Ot2}

{`HSA}

{``rh}

{`LAt}

{`SIL}

{`rtd}

{``rt}

{`rP`}

Range High: Selects the high limit of the operating range. Also used to scale the

high end of the process input. 5.0VÎ (dc) and 20mA represent Range High [``rh]

for a process input. The process input is linearly scaled between [``rL] and

[``rH]. See the model number and specification information in the Appendix for

your range values, or refer to the following table.

Range: Sensor range high to [``rL]

Default: High limit of sensor type for a thermocouple or RTD. 9999 for process input.

Output 1: Selects the action for the primary output in response to the difference

between set point and process variable. Select [``ht] (heat) for reverse acting or

select [``CL] (cool) for direct acting.

Range: [``ht], [``CL] Default: [``ht]

Hysteresis-Control: Selects the switching hysteresis for Output 1 and 2 when you

select 0 (on-off) under the [`Pb1] parameter and [`Ot2] is set to [`Con].

Range: 1 to 55, 0.1 to 5.5, 0.01 to 0.55°C/1 to 99, 0.1 to 9.9, 0.01 to 0.99°F

Default: 2, 0.2, 0.02°C/3, 0.3, 0.03°F

Output 2: Selects the output action for the secondary output.

Range:

[`Con] Control mode opposite Output 1 (heat or cool)

[`PrA] Process alarm with alarm message displayed

[``Pr] Process alarm with no alarm message displayed

[`dEA] Deviation alarm with alarm message displayed

[``dE] Deviation alarm with no alarm message displayed

[``no] None

Default: [`Con]

Hysteresis - Alarm: Selects the switching hysteresis for Output 2 when [`Ot2] is

an alarm. Appears only if [`Ot2] is not set to [`Con] or [``no]. See the Operation

Menu for [`Pb1].

Range: 1 to 5555, 0.1 to 555.5, 0.01 to 55.5°C/1 to 9999, 0.1 to 999.9, 0.01 to 99.99°F

Default: 2, 0.2, 0.02°C/3, 0.3, 0.03°F

Latching: Selects whether the alarm is latching or non-latching. Latching alarms

must be cleared by pressing the ˆInfinity key before the alarm output will reset.

Selecting non-latching will automatically reset the alarm output when the condition

clears.Appears only if [`Ot2] is not set to [`Con] or [``no].

Range: [`LAt] or [`nLA] Default: [`nLA]

Silencing: Selects alarm silencing (inhibit) for the alarm. Appears only when

[`Ot2] is set to [`dEA] or [``dE]. For more information see Chapter 5.

Range: [``On] or [`OFF] Default: [`OFF]

RTD: Selects the RTD calibration curve for RTD inputs.Will not appear unless

[``In] is set to [`rtd] or [`r†d]. [`JIS] is 0.003916Ω/Ω°C, [`Din] is

0.003850Ω/Ω°C.

Range: [`din] or [`JIS] Default: [`din]

Ramping: Choose [`Str], and the set point ramps at the selected rate in °/hr. from

the process (actual) temperature to the set point, when power is applied to the controller (start up). It will not ramp with a set point change. [`On] is the same as

[`Str], but ramps with a set point change. It ramps from the previous set point to a

new one at the selected ramp rate. Select [`OFF] for no ramping action. When

ramping, the lower display alternately flashes [``rP]. The set point displayed is the

desired end set point. The ramping set point is not shown. Entering the Setup Menu

or manual operation disables the outputs and ramp. Once you exit either one, the

Series V4 controls to the last entered set point.

Range: [`Str], [``On], [`OFF] Default: [`OFF]

Rate: Selects the ramping rate in degrees per hour.Will not appear if [``rP] is set

to [`OFF].

Range: 0 to 9999 Default: 100°/hr.

Page 15

Watlow Series V4 15

Power Limiting: The power limiting function in % power for heat only. Power

Limiting will function if [`pb1] is set to [```0].

Range: Dependent on output type. 0 to100 Default: 100

Display: Selects which displays are active or viewable. Five seconds after selected,

the appropriate display goes blank. Press ‰Advance, ¿Up-arrow or ¯Down-arrow

to override this feature and cause the current value to be displayed for 5 seconds.

Range: [`nor] Normal displays Default: [`nor]

[`SEt] Set Point - lower display only

[`Pro] Process - upper display only

Setup Menu

Parameter Value Range Factory Default Appears If:

[`LOC]

**

[```0], [```1], [```2], [```3], [```4] 0

[``In] [```J], [```H], [```t], [```n], [```J] DIP switch selectable.

[```S], [`rtd], [`r†d], [`0-5], [`420]

[`dEC] 0, 0.0, 0.00 0 [``In] is set to [`0-5]

or [`420]

[`C_F] [```C] or [```F] Dependent on [`dFL] [``In] is set to [```J],

[```H], [```t], [```n],

[```S], [`rtd], or [`r†d]

[``rL] [``rL] to [``rh] Input dependent.

[``rh] [``rh] to [``rL] Input dependent.

[`Ot1] [``ht] or [``CL] [``ht]

[`HSC] 1 - 99, 0.1 - 9.9, 0.01 - 0.99°F 3, 0.3, 0.03°F

1 to 55, 0.1 to 5.5, 0.01 to 0.55°C 2, 0.2, 0.02°C

[`Ot2] [`Con] = Control [`Con]

[`PrA] = Process Alarm

[``Pr] = Process with no alarm message

[`dEA] = Deviation alarm

[``dE] = Deviation with no alarm message

[``no] = None

[`HSA] 1 - 9999, 0.1 - 999.9, 0.01 - 99.99°F 3, 0.3, 0.03°F [`Ot2] is not set to [`Con]

1 - 5555, 0.1 - 555.5, 0.01 - 55.55°C 2, 0.2, 0.02°C or [``no]

[`LAt] [`LAt] or [`nLA] [`nLA] [`Ot2] is not set to [`Con]

or [``no]

[`SIL] [``On] or [`OFF] [`OFF] [`Ot2] is set to [`dEA] or

[``dE]

[`rtd] [`JIS] or [`din] [`din] [``In] is set to [`rtd] or

[`r†d]

[`rP`] [`Str] is set to Ramping on power up [`OFF]

[``on] is set to Ramping to set point always

[`OFF] is set to None

[`rt`] 0 to 9999 100°/hr [``rP] is not set to [`OFF]

[`P`L] 0 to 100 100

[`dsP] [`nor] = normal [`nor]

[`SEt] = Set Point (lower only)

[`Pro] = Process (upper only)

**LOC Functions

[```0]

: All operating parameters may be viewed or changed. Manual operation is permitted. Bumpless transfer to manual

mode will occur on sensor break.

[```1]

: The set point, actual, and alarm settings are only visible parameters, set point is adjustable in this level. Manual

operation and auto-tune are permitted. Bumpless transfer to manual mode will occur on sensor break.

[```2]

: The set point, actual, and alarm settings are the only visible parameters, set point is adjustable in this level. Manual

operation is permitted. Bumpless transfer to manual mode will occur on sensor break.

[```3]

: The set point and actual are the only visible parameters, set point is adjustable in this level. Manual operation is not

permitted. Bumpless transfer is defeated and outputs are disabled on sensor break.

[```4]

: The set point and actual are the only visible parameters, set point is not adjustable in this level. Manual operation is

not permitted. Bumpless transfer is defeated and outputs are disabled on sensor break.

Input Type Sensor Range Low Sensor Range High

[```J] 0°C/32°F 750°C/1382°F

[```H] -200°C/-328°F 1250°C/2282°F

[```t] -200°C/-328°F 350°C/662°F

[```n] 0°C/32°F 1250°C/2282°F

[```S] 0°C/32°F 1450°C/2642°F

[`rtd] (1°) -200°C/-328°F 700°C/1292°F

[`r†d] (0.1°) -128.8°C/-199.9°F 537.7°C/999.9°F

[`420] 4mA/-999 units 20mA/9999 units

[`0-5] 0VÎ (dc)/-999 units 5VÎ (dc)/9999 units

Table 15a Input Ranges.

{`dSP}

Table 15b Setup Menu Prompts

and Descriptions.

[`P`L]

Page 16

Watlow Series V4 16

Operation Parameters

Set Point: Sets the operating set point for Output 1. Represents the process value the

system tries to achieve for Output 1. "SP" does not appear on the lower display. The

control set point value is displayed and can be incremented or decremented without

pressing the ‰Advance key.The lower display may be blank if [`dSP] is set to

[`Pro]. In a ramping mode, the lower display alternately flashes the desired end set

point and [``rP].

Proportional Band 1 and 2: A proportional band, expressed in degrees or % of

span, within which a proportioning function is active for Output 1 or 2. When

[`Pb1] is set to 0, the unit functions as an on-off control on Output 1 and 2. [`Pb2]

will not appear if [`Pb1] is set to 0 or [`Ot2] is not set to [`Con]. The switching

differential is determined by the [`HSC] parameter.

Range if [`dFL] is set to [``US]: [`Pb1]: 0 to 555°C/0 to 999°F/0 to 999 Units; 0.0

to 5.5°C/0.0 to 9.9°F/0.0 to 9.9 units, [`Pb2]: The same as [`Pb1] except lower limit

is 1 or 0.1. Defaults: [`Pb1] is set to 2.5°C/25°F [`Pb2] is set to 25

Range if [`dFL] is set to [``SI]: 0 to 999.9% of span

Defaults: [`Pb1] is set to 3.0% [`Pb2] is set to 3.0%

Reset /Integral 1 and 2: An integral control action for Output 1 or 2 that auto-

matically eliminates offset, or "droop," between set point and actual process temperature. [`rE1]/[`It1]: Will not appear if [`Pb1] is set to 0. [`rE2]/[`It2]:

Appears if [`Pb1] is not set to 0 and [`Ot2] is set to [`Con]. Either reset [``rE]

or integral [``It] will appear depending on how the [`dFL] parameter is set in the

Calibration Menu. See the Appendix.

Range if [`dFL] is set to [``US]: 0 to 9.99 repeats/minute Default: 0.00

Range if [`dFL] is set to [``SI]: 00.1 to 9.99 minutes per repeat Default: 0.00

Rate/Derivative 1 and 2: The rate (derivative) function for Output 1 or Output 2.

Eliminates overshoot on startup, or after the set point changes. [`rA1]/[`dE1]:

Will not appear if [`Pb1] is set to 0. [`rA2]/[`dE2]: Appears if [`Pb1] is not set to

0 and [`Ot2] is set to [`Con]. Either rate [``rA] or derivative [``dE] appears depending on how [`dFL] is set in the Calibration Menu.

Range if [`dFL] is set to [``US] or [``SI]: 0 to 9.99 minutes Default: 0.0

Cycle Time 1 and 2: Time for a controller to complete one time-proportioned cycle

for Output 1 or Output 2; expressed in seconds. [`Ct1]: Will not appear if [`Pb1] is

set to 0, or Output 1 is 4-20mA. [`Ct2]: Will not appear if [`Pb1] is set to 0 or

[`Ot2] is not set to [`Con].

NOTE:

Shaded parameters

may not appear,

depending on the

controller’s configuration and model

number.

[``SP}

NOTE:

The upper display

will always return to

the process value

after 1 minute without key strokes.

{`rE1}

{`It1}

{`rE2}

{`It2}

{`Ct1}

{`Ct2}

{`rA1}

{`dE1}

{`rA2}

{`dE2}

{`Pb1}

{`Pb2}

[``93] Control Set Point

[`Pb1] Proportional Band 1

[`rE1] Reset 1*

[`It1] Integral 1*

[`rA1] Rate 1*

[`dE1] Derivative 1*

[`Ct1] Cycle Time 1*

[`ALO] Alarm Low*

[`AHI] Alarm High*

[`Pb2] Proportional Band 2*

[`rE2] Reset 2*

[`It2] Integral 2*

[`rA2] Rate 2*

[`dE2] Derivative 2*

[`Ct2] Cycle Time 2*

[`CAL] Calibration Offset

[`AUt] Autotune

‰

Operation Menu

* Parameter may not always appear.

Operation Menu

Figure 16 The Operation Menu.

Page 17

Watlow Series V4 17

If a mechanical relay or contactor is switching power to the load, a longer

cycle time may be desirable to minimize wear on the mechanical components. Typical life of a mechanical relay is 100,000 cycles.

Range: 0.1 to 999.9 seconds Default: 5.0 seconds

Alarm Low: Represents the low process alarm or low deviation alarm. This param-

eter will not appear if [`Ot2] is set to no or [`Con].

Range if [`Ot2] is set to [`dEA] or [``dE]: -999 to 0 Default: -999

Range if [`Ot2] is set to [`PrA] or [``Pr]: [``rL] to [`AHI] Default: [``rL]

Alarm High: Represents the high process alarm or high deviation alarm. This

parameter will not appear if [`Ot2] is set to [``no] or [`Con].

Range if [`Ot2] is set to [`dEA] or [``dE]: 0 to 999 Default: 999

Range if [`Ot2] is set to [`PrA] or [``Pr]: [`ALO] to [``rH] Default: [``rH]

Calibration Offset: Adds or subtracts degrees from the input signal.

Range: -100°C to 100°C/-180°F to 180°F/-180 units to 180 units; or

-10.0°C to 10.0°C/-18.0°F to 18.0°F Default: 0

Autotune: Initiates an autotune.

Range: 0 is set to off, 1 is set to slow, 2 is set to medium, 3 is set to fast

Default: 0

Table 17 Operation Menu

Prompts and

Descriptions.

{`ALO}

Operation Menu Parameters

Document your Series V4 Operation Parameters.

{`AHI}

{`AUt}

{`CAL}

Parameter Value Range Factory Default

[`Pb1] If [`dFL] is set to [``US]:

0 - 999°F/0 - 555°C/0 - 999 Units 25°F

0 - 99.9°F/0 - 55.5°C/0 - 99.9 Units 2.5°F

0 is set to ON/OFF control. [`HSC] is set to switch diff.

If [`dFL] is set to [``SI]: 0.0 to 999.9% of span 3%

[`rE1] 0.00 to 9.99 repeats/minute 0.00 repeats/minute

0.00 = No Reset. Won't appear if [`Pb1] is set to 0

or [`dFL] is set to [``SI].

[`It1] 0.0 - 99.9 minutes/rpt. 0.00 = No Integral. 00.0 minutes/repeat

Won't appear if [`Pb1] is set to 0 or [`dFL] is set to [``US].

[`rA1] 0.00 to 9.99 minutes 0.00 minutes

0.00 = No Rate. Will not appear if [`Pb1] is set to 0

or [`dFL] is set to [``SI].

[`dE1] 0.00 - 9.99 minutes. 0.00 = No Derivative. 0.00 minutes

Won't appear if [`Pb1] is set to 0 or [`dFL] is set to [``US].

[`Ct1] 0.1 to 999.9 5.0 seconds

Won't appear if [`Pb1] = 0, or [`420].

[`Pb2] Same as [`Pb1]. [`Pb2] lower limit = 1, 0.1, 0.01

[`rE2] Same range as [`rE1].

[`It2] Same range as [`It1].

[`rA2] Same range as [`rA1].

[`dE2] Same range as [`dE1].

[`Ct2] Same range as [`Ct1].

[`ALO]

Deviation [``dE] -999 to 0 -999

Process [``Pr] [``rL] to [`AHI] [``rL]

Will not appear if [`Ot2] is set to [``no] or [`Con].

[`AHI]

Deviation [``dE] 0 to 999 999

Process [``Pr] [`ALO] to [``rH] [``rH]

Will not appear if [`Ot2] is set to [``no] or [`Con].

[`CAL] ±180°F/±100°C/±180 Units 0

[`AUt] 0-3 0

Page 18

18 Watlow Series V4

Troubleshooting Alarms and Errors

Indication Probable Cause(s) Corrective Action

Error Code Messages ([----] in the upper display indicates a Series V4 error; error code number is visible in

bottom display)

• Sensor input generated a value lower than allowable

signal range, or A/D circuitry malfunctioned. Enter a

valid input. Make sure

[``In]

parameter (Setup

Menu) matches your sensor and DIP switches are set

accordingly.

• Microprocessor is faulty; consult factory.

• Unless power interruption occurred while controller

was storing data, nonvolatile memory is bad; consult

factory.

• A/D circuit is underrange. Check sensor; if functioning properly, consult factory. Make sure

[``In]

parameter (Setup Menu) matches your sensor and

DIP switches are set accordingly.

• A/D circuit is overrange. Check sensor; if functioning

properly, consult factory. Make sure

[``In]

parameter (Setup Menu) matches your sensor and DIP

switches are set accordingly.

• Sensor underrange error (applies

only to RTD units)

• Configuration error.

• Non-volatile checksum error.

• A/D underflow error.

• A/D overflow error.

• [----] [`Er2]

• [----] [`Er4]

• [----] [`Er5]

• [----] [`Er6]

• [----] [`Er7]

• Check the alarm logic for compatibility with system

peripherals and annunciators.

• Check the power limit setting

• Check the operation mode.

• Check the alarm output function.

• Check the °C or °F setting.

• Check the calibration offset value; set it to a lower

level.

• Alarm may be latched.

• Alarm set points may be incorrect..

• Alarm hysteresis may be incorrect.

• Input may be in error condition.

• Alarm won’t

occur.

• Configure output as an alarm.

• Check alarm set points.

• To clear the alarm, correct the alarm condition; check

to see if the alarm is latched.

• Check the alarm sides setting.

• Check the alarm type setting.

• Alarm output may be off.

• Alarm set points may be incorrect.

• Alarm may be silenced.

• Alarm sides may be incorrect.

• Controller may be in diagnostics

mode.

• Alarm won’t

occur.

Alarms

• Check switches, fuses, breakers, interlocks, limits,

connectors, etc. for energized condition and proper

connection.

• Measure power upstream for required level. Check part

number for input power required.

• Check wire size.

• Check for bad connections.

• Power to unit may be off.

• Fuse may be blown.

• Breaker may be tripped.

• Safety interlock door switch, etc.

may be activated.

• Separate system limit control

may be latched.

• Wiring may be open.

• Input Power may be incorrect.

• No power.

Power

Page 19

Watlow Series V4 19

Calibration

Before attempting to calibrate, make sure you read through

the procedures carefully and have the proper equipment

called for in each procedure. Make sure the DIP switches

are in the proper position for the input type.

Entering the Calibration Menu

In the Calibration Menu, various input signals must be supplied for the controller to go through its auto calibration. The Calibration Menu can only be

entered from the [`LOC] Lock parameter in the Setup Menu. Press the ¿Up-

arrow/¯Down-arrow keys simultaneously for 3 seconds (± 1 second). The [`CAL]

parameter appears in the lower display with "no" in the upper display.

Any inadvertent change in the displayed data, when pressing the ¿Up-

arrow/¯Down-arrow keys, is ignored. Calibration values won't be retained unless

you are in the manual mode. Press the ¿Up-arrow or ¯Down-arrow key to change

the upper display to [`YES] Press ‰Advance to enter the calibration sequence.

Upon entering the calibration menu, the upper display window indicates [`CAL].

It continues to indicate [`CAL] (with the exception of calibration of the 4-20mA

output) while the operator walks through the entire calibration parameter list.

While calibrating the 4-20mA output, the upper display contains a numeric

value to be slewed up or down until the output value is correct. The controller

uses the lower display to prompt the user as to what the input should be.

With the [`dFL] parameter,select either [``US] parameters which include displaying °F, rate, reset, and proportional band in degrees or units. Or select

[``SI] (System International) and the displayed parameters are °C, integral,

derivative, and proportional band in % of span.

Once the information has been properly established and maintained for at least

5 to 10 seconds, the ‰Advance key may then be used to display the next prompt.

After the final input is established, press the ‰Advance key twice to return the

controller to the configuration menu at the top of the parameter list.

Figure 19 Entering the

Calibration Menu.

NOTE:

While in the Calibration

Menu, the controller output(s) go off and the

alarm output (if present)

is on.

NOTE:

Calibration values will

not be retained unless

you are in the MANUAL

mode. Do not enter the

MANUAL mode until you

are at the correct input

parameters.

V4

1

2

%

V4

1

2

%

The [`rSt] parameter restores the factory calibration values to the Series V4. If

you calibrate your control incorrectly, you have the option to default to the original values. Once you leave the [`CAL] menu, the values are entered.

1. Press the ¿Up-arrow/¯Down-arrow keys simultaneously for three seconds.

The LOC parameter appears in the lower display. Continue holding the

¿Up-arrow/¯Down-arrow keys until the lower display reads [`CAL].

2. Press the ¿Up-arrow key until [`YES] appears in the upper display.

3. ‰Advance through the calibration menu until [`rSt] appears in the lower

display.

4. Press the ¿Up-arrow key until [`YES] appears in the upper display.

5. Press the ‰Advance key and the V4 advances to test the displays.

6. To conclude, wait 60 seconds or press the ‰Advance key to reach the next

prompt or to exit from the CAL menu.

This procedure is used only to restore calibration, it is not meant to clear values.

Restoring Factory Calibration

Page 20

20 Watlow Series V4

Calibration Menu

[`)00] Input 0.00mV for low input.

[`5)0]

Input 50.00mV for high input.

[``tC]

Connect a Type "J" ambient compensator with inputs shorted.

[`440] Set the low resistance to 44.01Ω.

[`225] Set the high resitance to 255.42Ω.

[`)00]

Set the voltage source to 0.000 volts.

[`%00] Set the voltage source to 5.000 volts.

[`$00] Set the cursource to 4.00mA

[`2)0] Set the current source to 20.00mA

[`4A0] Enter 4-20mA output calibration value for 4mA

[`2A0] Enter 4-20mA output calibration value for 20mA

[`rSt] Restores factory calibration values.

[`dSP] Test display.

[`dFL] Select US (rate, reset, proportional band in degrees or units, °F) or

SI (integral, derivative, proportional band in % of span, °C)

Calibration Menu

[``NO]

[`CAL]

[`YES]

[`CAL]

‰

‰

‰

Figure 20 Calibration Parameters.

NOTE:

Before calibration on an

installed controller,

make sure all data and

parameters are documented.

Equipment Required

• Type "J" Reference Compensator with reference junction at 32°F/0°C, or Type "J"

Thermocouple Calibrator set at 32°F/0°C.

• Precision millivolt source, 0-50mV min. range, 0.01mV resolution

Setup And Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals.

2. Connect the millivolt source to Terminal 6 Negative and Terminal 5 Positive on the

Series V4 terminal block. Use regular 20 - 24 gauge wire. Make sure the DIP switch is

set for thermocouple input.

3. Apply power to the controller and allow it to warm up for 15 minutes. After warm-up

put the controller in the Calibration Menu. Select [`YES].

4. Press the ˆInfinity key twice to enter the manual mode. The controller is calibrating

when % indicator light is on. Make sure the controller is in manual mode only when

you are in the correct parameters.

5. At the 0.00 prompt, enter 0.00mV from the millivolt source to the control. Allow at

least 10 seconds to stabilize. Press the

‰Advance key.

6. At the 50.0 prompt, enter 50.00mV from the millivolt source to the Series V4.Allow at

least 10 seconds to stabilize. Press the ‰Advance key.

7. At the [``tC] prompt, disconnect the millivolt source, and connect the reference compensator or thermocouple calibrator to Terminal 6 Negative, and Terminal 5 Positive

on the Series V4 terminal block. If using a compensator, turn on and short the input

wires. If using "J" calibrator, set to simulate 32°F/0°C.Allow 10 seconds for the control

to stabilize. The controller will leave the [`CAL] mode if one minute passes between

key activations. Press the ˆInfinity key twice to exit the manual mode. To conclude the

thermocouple calibration, advance the

‰Advance key to the next prompt or exit the

[`CAL] menu.

Thermocouple Field Calibration Procedure

Page 21

Watlow Series V4 21

Equipment Required

• Precision dc voltage source 0-5 volt minimum range with 0.001 volt resolution.

Setup and Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals on the V4.

2. Connect the voltage/current source to Terminal 5 (+) and 6 (-) on the Series V4 terminal block. Use regular 20 - 24 gauge wire. Make sure the DIP switch is set for process

input.

3. Apply power to the controller and allow it to warm up for 15 minutes. After warm-up

put the controller in the [`CAL] menu. See Figure A.3. Select [`YES]. Press the

‰Advance key until 0.00 is displayed.

4. Press ˆInfinity twice to enter the manual mode. The controller is calibrating when

the % indicator light is on. Make sure the controller is in the manual mode only when

you are in the correct parameters.

5. At the 0.00 parameter, set the voltage source to 0.000 volts. Allow at least 10 seconds

to stabilize. Press the

‰Advance key.

6. At the 5.00 parameter, set the voltage source to 5.000VÎ (dc). Allow at least 10 seconds to stabilize. The controller leaves the [`CAL] mode if 1 minute passes between

key activations. Press ˆInfinity twice to exit the manual mode. To conclude the 0-5

volt calibration, press the

‰Advance key to the next prompt or exit the [`CAL] menu.

NOTE:

Before calibration on an

installed controller,

make sure all data and

parameters are documented.

0-5 Volt Input Field Calibration Procedure

NOTE:

When the % indicator

light is on, the controller

is automatically calibrating. Your sequence is

VERY important. Always

move to the next parameter before changing the

calibration equipment.

Equipment Required

• 1KΩ precision decade resistance box with 0.01Ω resolution.

Setup And Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals.

2. Connect the decade resistance box to Terminal 4, 5 and 6 on the terminal block. Use

regular 20 - 24 gauge wire of the same length and type. Make sure the DIP switch is

set for RTD input.

3. Apply power to the controller and allow it to warm up for 15 minutes. After warm-up

put the controller in the [`CAL] menu. Select [`YES]. Press the ‰Advance key until

the 440 prompt is displayed.

4. Press the ˆInfinity key twice to enter the manual mode. The controller is calibrating

when the % indicator light is on. Make sure the controller is in manual mode only

when you are in the correct parameters.

5. At the 440 prompt, set the decade resistance box to 44.01. Allow at least 10 seconds to

stabilize. Press the ‰Advance key.

6. At the 255 prompt, set the decade resistance box to 255.42. Allow at least 10 seconds to

stabilize. Press the ˆInfinity key twice to exit the manual mode. The controller will

leave the [`CAL] mode if one minute passes between key activations.To conclude the

RTD calibration, press the ‰Advance key to the next prompt or exit the [`CAL] menu.

RTD Field Calibration Procedure

Page 22

22 Watlow Series V4

NOTE:

When the % indicator

light is on, the controller

is automatically calibrating. Your sequence is

VERY important. Always

move to the next parameter before changing the

calibration equipment.

4-20mA Input Field Calibration Procedure

Equipment Required:

• Precision current source 0-20mA minimum range with 0.01mA resolution.

Setup and Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals on the V4.

2. Connect the current source to Terminal 4 (-) and 6 (+) on the Series V4 terminal block.

Use regular 20 - 24 gauge wire. Make sure the DIP switch is set for process input, see.

3. Apply power to the controller and allow it to warm up for 15 minutes. After warm-up

put the controller in the [`CAL] menu. Select YES. Press the

‰Advance key until 4 is

displayed.

4. Press ˆInfinity twice to enter the manual mode. The controller is calibrating when the

% indicator light is on. Make sure the controller is in the manual mode only when you

are in the correct parameters.

5. At the 4.00 parameter, set the current source to 4.00mA. Allow at least 10 seconds to

stabilize. Press the

‰Advance key.

6. At the 20.0 parameter, set the current source to 20.00mA. Allow at least 10 seconds to

stabilize. The controller leaves the [`CAL] mode if 1 minute passes between key activations. Press ˆInfinity twice to exit the manual mode. To conclude, press the ‰Advance

key to the next prompt or exit the [`CAL] menu.

4-20mA Output Field Calibration Procedure

Equipment Required:

• 300Ω, 1/2 watt 10% resistor.

• 4 - 1/2 digit Digital Multimeter.

Setup And Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals of the V4. Set the multimeter to measure current.

2. Connect the multimeter in series with the 300Ω resistor to Terminal 18 Positive and 16

Negative on the Series V4 terminal block. Use regular 20 - 24 gauge wire.

3. Apply power to the controller and allow it to warm up for 15 minutes. After warm-up

put the controller in the [`CAL] menu. Select YES. Press the ‰Advance key until the

4A0 prompt is displayed.

4. Press the ˆInfinity key twice to enter the manual mode. The controller is calibrating

when the % indicator light is on.

5. At the [`4A0] prompt, the multimeter should read approximately 4mA. Allow at least

10 seconds to stabilize.

6. Use the ¿Up-arrow/¯Down-arrow keys (reverse acting) to adjust the reading on the

multimeter for 3.85mA ± 0.10mA. Press the ‰Advance key.

7. At the [`2A0] prompt, the multimeter should read approximately 20mA. Allow at least

10 seconds to stabilize. The controller will leave the [`CAL] mode if one minute passes

between key activations except for 4-20mA units.

8. Use the ¿UP/¯DOWN keys (reverse acting) to adjust the reading on the multimeter

for 20.15mA ±0.10mA.

9. To conclude the 4-20mA output calibration, advance the ‰Advance key to the next

prompt or exit the [`CAL] menu.

NOTE:

Before calibration on an

installed controller,

make sure all data and

parameters are documented.

Page 23

Watlow Series V4 23

Specifications (1968)

Control Mode

• Microprocessor-based, user selectable control

modes

• Single process input, dual output

• 2.5Hz input sampling rate

• 1Hz display update rate

• Ramp to set point: 0 to 9999 degrees or units per

hour

• Heat and cool auto-tune operator interface

Operator Interface

• Sealed membrane front panel

• Dual, four-digit red or green displays

• ‰Advance, ¿Up-arrow, ¯Down-arrow, and

ˆInfinity keys

• User selectable screen display

Accuracy

• Calibration accuracy and sensor conformity: ±0.1%

of span, ±1°C @ 77°F ± 5°F (25°C ± 3°C) ambient

and rated line voltage

• Accuracy span: 1000°F (540°C) minimum

• Temperature stability: ±0.2°F/°F (±0.2°C/°C) rise in

ambient maximum

Sensors/Inputs

• Thermocouple, grounded or ungrounded sensors

• RTD 2- or 3-wire, platinum, 100Ω @ 0°C calibration

to DIN curve (0.00385Ω/Ω/°C) or JIS curve

(0.003916Ω/Ω/°C); user selectable

• Process, 4-20mA @ 5Ω, or 0-5VÎ (dc) @ 10kΩ

input impedance

• Sensor break protection de-energizes control output

to protect system or selectable bumpless transfer to

manual operation

• °F or °C or process units display, user selectable

Input Range

Specified temperature ranges represent the

controller’s operational span.

• Thermocouple

Type J 32 to 1382°F or 0 to 750°C

Type K -328 to 2282°F or -200 to 1250°C

Type N 32 to 2282°F or 0 to 1250°C

Type S 32 to 2642°F or 0 to 1450°C

Type T -328 to 662°F or -200 to 350°C

• RTD Resolution (DIN or JIS)

1° -328 to 1292°F or -200 to 700°C

0.1° -199.9 to 999.9°F or -128.8 to 537.7°C

• Process

4-20mA @ 5Ω or -999 to 9999 units

0-5V (dc) @ 10kΩ or -999 to 9999 units

Output 1 (Heating or Cooling)

• Electromechanical relay1. Form C, rated at 8A @

125V~ (ac) or 5A @ 240V~ (ac) or 5A @ 30VÎ (dc),

max. at resistive load, without contact suppression.

Max. switching current is 10A, max. switching power

is 2500VA, and max. switching voltage is 277V~

(ac) or 110VÎ (dc).

• Switched dc signal provides a non-isolated minimum

turn on voltage of 3VÎ (dc) into a minimum 500Ω

load; maximum on voltage not greater than 12VÎ

(dc) into an infinite load.

• 4-20mA reverse or direct acting, non-isolated 0 to

800Ω load.

• Solid-state relay3, Form A, 0.5A @ 24V~ (ac) min.,

264V~ (ac) max., opto-isolated burst fire switched,

without contact suppression. Off-state output

impedance is 31MΩ.

Output 2 (Heat, Cool or Alarm)

• Electromechanical relay1. Form C, rated at 8A @

125V~ (ac) or 5A @ 240V~ (ac) or 5A @ 30VÎ (dc),

max. at resistive load, without contact suppression.

Max. switching current is 10A, max. switching power

is 2500VA, and max. switching voltage is 277V~

(ac) or 110VÎ (dc).

• Switched dc signal provides a non-isolated minimum

turn on voltage of 3VÎ (dc) into a minimum 500Ω

load; maximum on voltage not greater than 12VÎ

(dc) into an infinite load.

• Solid-state relay3, Form A, 0.5A @ 24V~ (ac) min.,

264V~ (ac) max., opto-isolated burst fire switched,

without contact suppression. Off-state output

impedance is 31MΩ.

• Alarm output can be latching or non-latching, and

process or deviation with separate high and low

values. Alarm silencing (inhibit) on power up (for

deviation alarms only).

Output Configurations

• Output 1

User selectable as: on/off: P, PI, PD, PID, heat or cool

action

• Adjustable switching differential: 1 to 99°F (1 to

55°C)

• Proportional band: 0 (off) or 1 to 999°F (0 to 555°C)

or 0.0 to 999.9 units

Integral: 0 (off) or 0.1 to 99.9 minutes per repeat

Reset: 0 (off) or 0.01 to 9.99 repeats per minute

Rate/derivative: 0 (off) or 0.01 to 9.99 minutes

Cycle time: 0.1 to 999.9 seconds

• Output 2

User selectable as: Control with action opposite that of

Output 1 (heating or cooling)

• Process or deviation alarm with flashing alarm

message

• Process or deviation alarm without alarm message

• Alarm with separate high and low set points

• Hysteresis: 1 to 9999° or units switching differential

Line Voltage/Power

• 100-240V~ (ac), -15%, +10%; (85-264V~ [ac])

50/60Hz, ±5%

• 14-24Vı (ac/dc), +10%, -15%; (12-26Vı [ac/dc])

50/60Hz, ±5%

• Fused internally (factory replaceable only) Slo-Blo®

type (time-lag):

1A, 250V for high voltage versions

2A, 250V for low voltage versions

• Maximum power consumption: 12VA (100 to 240V~

[ac]), 7VA (12 to 24Vı [ac/dc])

• Data retention upon power failure via non-volatile

memory

Page 24

Watlow Series V4 24

Operating Environment

• 32 to 149°F (0 to 65°C)

• 0 to 90% RH, non-condensing

Storage Temperature

• -40° to 185°F (-40° to 85°C)

Terminals

• Touch-safe, plugable terminal blocks

• 22 to 12 AWG

Controller Weight

• 0.68 lb (310g)

Shipping Weight

• 0.75 lb (0.34 kg)

Dimensions

• 1⁄4 DIN size and NEMA 4X2front panel make the

Series V4 easy to apply and maintain in a wide

variety of applications. Unique mounting brackets,

gasket and collar make installation a snap.

Overall Height: 4.3 inches (109 mm)

Width: 4.3 inches (109 mm)

Depth: 4.0 inches (101 mm)

Depth Behind Panel Surface:

3.875 inches (98.4 mm)

Agency Approvals

• UL, C-UL, CE, NEMA 4X

• CE 89/336/EEC (EN 50082-2, EN 50081-2 )

• CE 73/23/EEC (EN61010-1, EN 60730-1 and

EN 60730-2-9 )

1

Electromechanical relays warranted for 100,000

closures only. Solid-state switching devices

recommended for applications requiring fast cycle

times or extended service life.

2

To effect NEMA 4X rating requires a minimum

mounting panel thickness of 0.06inch (1.5 mm) and

surface finish not rougher than 0.000032 inch

(0.000812 mm).

3

Switching inductive loads (relay coils, etc.) requires

using an RC suppressor.

Note: These specifications are subject to change

without prior notice.

Ordering Information

(1466)

V 4 T _ - _ _ A A- A A _ _

Series V4

Temperature controller, single analog input,

single control output, dual 4-digit displays

Power Supply

H = 100-240V~(ac)

L = 14-24Vı(ac/dc)

Output 1

C = Switched dc output, non-isolated

D = Electromechanical relay, Form C, max. switching current

8A (refer to specifications), without contact suppression

1,3

F = Process, 4-20mAÎ(dc), non-isolated

K = Solid state relay, Form A, 0.5A,

without contact suppression

3

Output 2

A = None

C = Switched dc output, non-isolated

D = Electromechanical relay, Form C, max. switching current

8A (refer to specifications), without contact suppression

1,3

K = Solid state relay, Form A, 0.5A,

without contact suppression

3

Display Options

Upper/Lower

RR = Red/Red display

RG = Red/Green display

GR = Green/Red display

GG = Green/Green display

XX = Custom Overlays

Page 25

Watlow Series V4 25

Declaration of Conformity

Series V4

WATLOW SINGAPORE PTE LTD

Asia Controls

55, Ayer Rajah Crescent, #03-23

Ayer Rajah Industrial Estate

Singapore 139949

Declares that the following product: English

Designation: Series V4

Model Number(s): V4T(H or L)-(C D F or K) (A C D or K) AA-AA (Any two letters or

numbers)

Classification: Control, Installation Category II, Pollution Degree II

Rated Voltage: 100 to 240V~ (ac) or 24Vı (ac/dc)

Rated Frequency: 50/60 Hz.

Rated Power Consumption: 12VA maximum

Meets the essential requirements of the following European Union Directive(s) using the relevant section(s) of the normalized standards and related documents shown:

89/336/EEC Electromagnetic Compatibility Directive

EN 50082-2: 1995 EMC Generic immunity standard, Part 2, Industrial environment

EN 61000-4-2: 1995 Electrostatic discharge

EN 61000-4-4: 1995 Electrical fast transients

ENV 50140: 1994 Radiated immunity

ENV 50141: 1994 Conducted immunity

ENV 50204: 1995 Cellular phone

EN 50081-2: 1994 EMC Generic emission standard, Part 2: Industrial environment

EN 55011: 1991 Limits and methods of measurement of radio disturbance characteristics

of industrial, scientific and medical radio-frequency equipment (Class A)

EN 61000-3-2: 1995 Limits for harmonic current emissions

EN 61000-3-2: 1995 Limitations of voltage fluctuations and flicker

72/23/EEC Low-Voltage Directive

EN 61010-1: 1993 Safety requirements for electrical equipment for measurement,

control, and laboratory use, Part 1: Generic requirements

W

ATSON NG SAI HIONG SINGAPORE

Name of Authorized Representative Place of issue

General Manager December, 1998

Title of Authorized Representative Date of Issue

Signature of Authorized Representative

(1469)

Page 26

Watlow Series V4 26

NOTE:

Details of a “Note”

appear here in the

narrow margin on the

outside of each page.

CAUTION:

Details of a “Caution”

appear here in the

narrow margin on the

outside of each page.

WARNING:

Details of a

“Warning” appear

here in the narrow

margin on the outside

of each page.

Quality and

Mission

Statement:

Watlow Controls will be the

world’s best supplier of

industrial temperature

control products, services,

and systems by exceeding

our customers’,

employees’, and

shareholders’

expectations.

Safety Information

We use note, caution and warning symbols throughout this book to draw your

attention to important operational and safety information.

A “NOTE” marks a short message in the margin to alert you to an important

detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and performance. Be especially careful to read and follow all cautions that apply to your application.

A “WARNING”safety alert appears with information that is important for protecting you, others and equipment from damage. Pay very close attention to all

warnings that apply to your application.

The safety alert symbol,

ç

, (an exclamation point in a triangle) precedes a gener-

al CAUTION or WARNING statement.

The electrical hazard symbol,

Ó

, (a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, see the Troubleshooting Table and review all of your configuration information to verify that

your selections are consistent with your application: inputs; outputs; alarms; limits; etc. If the problem persists after checking the above, you can get technical

support by dialing 507/494-5656, 7 a.m. to 7 p.m. Central Standard Time. An

applications engineer will discuss your application with you.

Please have the following information available when calling:

• Complete model number • All configuration information

• User’s Manual • Diagnostic menu readings

Your Feedback

Your comments or suggestions on this manual are welcome. Please send them to:

Technical Writer, Watlow Controls,1241 Bundy Boulevard, P.O. Box 5580,

Winona, MN 55987-5580. The Series V4 User’s Manual is copyrighted by Watlow

Winona, Inc., © July 2000, with all rights reserved.

How to Reach Us

• Phone: (507) 454-5300.

• Fax:(507) 452-4507.

• For technical support,ask for an Applications Engineer.

• To place an order, ask for Customer Service.

• To discuss a custom option, ask for a Series V4 Product Manager.

Warranty

The Watlow Series V4 is warranted to be free of defects in material and workmanship for 36 months after delivery to the first purchaser for use, providing

that the units have not been misapplied. Since Watlow has no control over their

use, and sometimes misuse, we cannot guarantee against failure. Watlow's obligations hereunder, at Watlow's option, are limited to replacement, repair or

refund of purchase price, and parts which upon examination prove to be defective within the warranty period specified. This warranty does not apply to damage resulting from transportation, alteration, misuse, or abuse.

Returns

• Call or fax Customer Service for a Return Material Authorization (RMA)

number before returning a controller.

• Put the RMA number on the shipping label, and also on a written description

of the problem.

• A restocking charge of 20% of the net price is charged for all standard units

returned to stock.

Loading...

Loading...