Page 1

TLM-8

User’s Guide

Features and Description

The TLM-8 is a multi-zone temperature limit switch.

For thermal system safety, the TLM-8 can satisfy the

requirement for independent temperature monitoring.

The TLM-8’s alarm outputs interface with visual and

audible alarm devices, or they can initiate safe shutdown of equipment.

The TLM-8 has the following features:

• Multi-channel temperature monitoring

• Latching alarms

• Isolated sensor inputs

• Support for various thermocouples, RTDs, and

thermostats

• Diagnostic test mode

• Open-sensor fail-safe

• Compact and easy to install

• LED indicator lights

Up to eight temperature zones may be monitored. If

any temperature exceeds a trip point, the TLM-8 generates an alarm output. The alarm output may be used

for safety shutdown or annunciation. Alarm outputs

remain active until two conditions are met in sequence:

the temperature drops below the trip point and alarms

are acknowledged. Built-in indicator lights show power

and alarm states.

The TLM-8 accepts up to eight thermocouple, RTD or

thermostatic switch temperature sensors. There are

two global alarm relay outputs. The TLM-8 is also

available with eight channel-alarm relays in addition

to the two global relay outputs. If all temperatures are

below the trip point, the TLM-8’s relay outputs are

closed. When alarms activate, the relay contacts open.

1241 Bundy Blvd., Winona, MN 55987

E-mail: wintechsupport@watlow.com

Watlow Controls

Customer Service

Phone: 1-800-414-4299

Fax: 1-800-445-8992

Technical Support

Phone: (507) 494-5656

Fax: (507) 452-4507

Relays that open on alarm are consistent with fail safe

designs and practices. Alarms are acknowledged with

an optically isolated, digital input. Another isolated

digital input is used for testing, by simulating alarms

on all channels.

4FOTPS*OQVUT

0QUJPOBM/0

5-.

545"$,*OQVUT

1PXFS

TLM-8 System Diagram

5IFSNBM-JNJU.POJUPS

$IBOOFM3FMBZ0VUQVUT

/0(MPCBM3FMBZ0VUQVUT

)FBUFS1PXFS

*OUFSMPDLT"MBSN

"OVODJBUJPO

1-$FUD

Warranty

The TLM-8 is manufactured by ISO 9001-registered

processes and is backed by a three-year warranty to

the first purchaser for use, providing that the units

have not been misapplied. Since Watlow has no control

over their use, and sometimes misuse, we cannot guarantee against failure. Watlow’s obligations hereunder,

at Watlow’s option, are limited to replacement, repair,

or refund of purchase price, and parts which upon

examination prove to be defective within the warranty

period specified. This warranty does not apply to damage resulting from transportation, alteration, misuse or

abuse. The purchaser must use Watlow parts to maintain all listed ratings.

Part No. 0600-2150-2000 Rev. D

Revised: October 2007

© 2004, 2007 Watlow Electric and Manufacturing Company. All

rights reserved.

WATLOW TLM-8 User’s Guide 1

Page 2

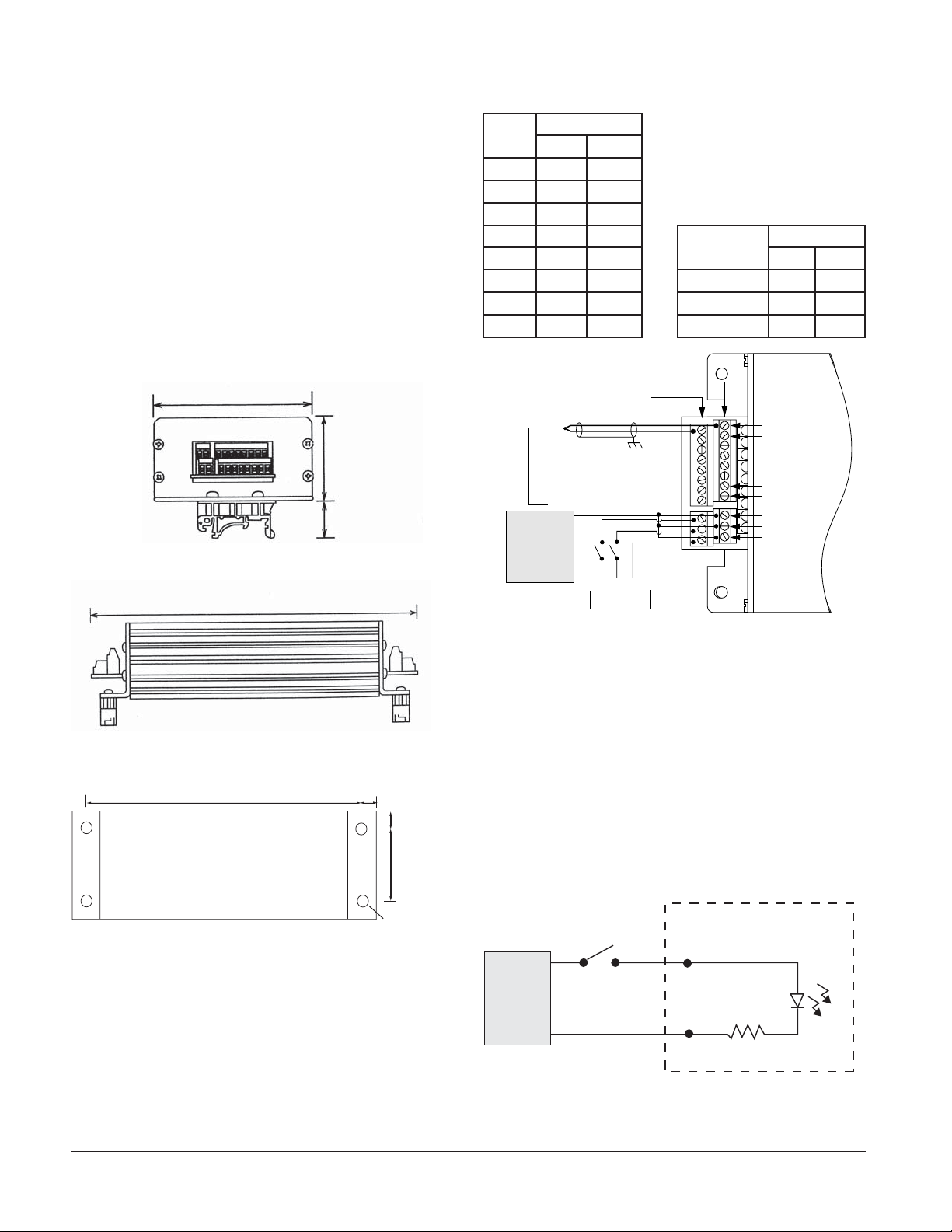

Mounting the TLM-8

SENSOR

J6

1 2

3

4

5

6

7

8

TST-

V-

J5

ACK-

The TLM-8 mounts directly to a panel or on a DIN rail

depending on the mounting style ordered.

DIN Rail Mounting

The TLM-8 simply snaps onto a standard 35 mm DIN

rail. Place the hook side of the mounting mechanisms

over one of the DIN rail edges and snap the assembly

over the other edge.

DIN Rail Removal

Remove the TLM-8 from the DIN rail by placing a flat

blade screw driver through the slot in the end plate,

hook the blade into the snap latch and pry the snap

latch away from the DIN rail edge. Repeat for the other

side.

92 mm (3.61 in)

48 mm

(1.87 in)

20 mm

(0.75 in)

End View

Wiring Recommendations

TB5 Sensor Inputs

Sensor

Input

1 12

2 34

3 56

4 7 8

5 9 10

6 11 12

7 13 14

8 15 16

Sensor

Inputs

DC Power

Terminals

+-

Positive Terminals

Negative Terminals

+

Isolated

supply

_

TB6 Power and Digital

Inputs

Function

Test

Acknowledge

Power

Terminals

+-

12

34

56

Channel 1

Channel 2

.

.

.

.

Channel 7

Channel 8

TST

ACK

Powe r

236 mm (9.30 in)

Side View

NN

NNJO

Mounting Hole Dimensions

Panel Mounting

The four mounting holes will accommodate up to 3.8

mm (#6) screws or bolts.

JO

NN

JO

NN

JO

NN

JO

Test and

Acknowledge Circuits

Input Wiring

DC Power Supply

The TLM-8 accepts 12 to 24VÎ (dc) power input from a

class 2 power supply.

Test Input

The test input, TST, is a level-triggered digital input. It

is activated after the input signal is applied for at least

1 second (filter). The input signal may be generated by

a contact closure or controller output. The input accepts

a 5 to 30VÎ (dc) signal. The circuit contains a resistor

and optical isolator.

6TFS4VQQMJFE

$POUBDU

%$

1PXFS

4VQQMZ

@

Test Input

5-.*OUFSOBM$JSDVJU

545

545m

2 WATLOW TLM-8 User’s Guide

Page 3

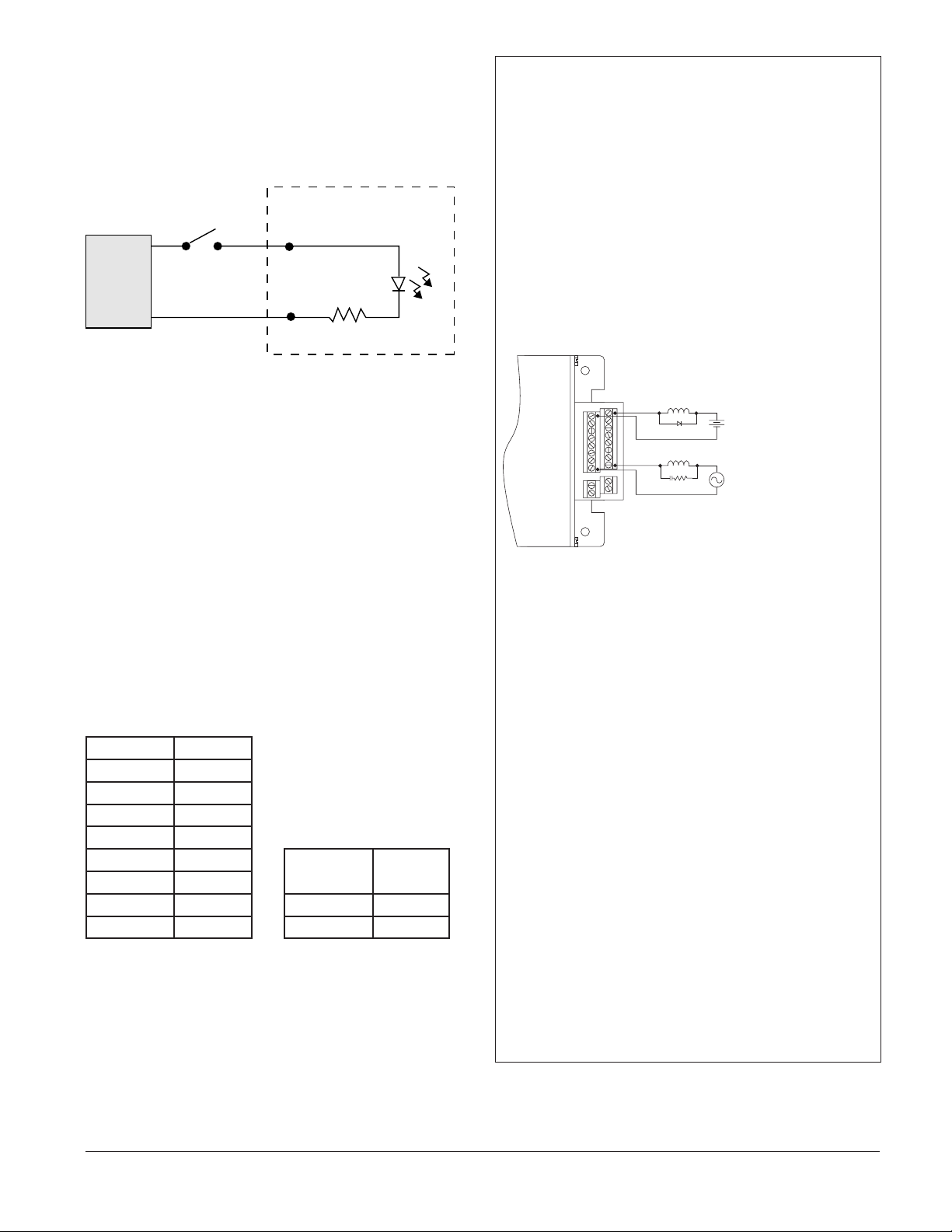

Acknowledge Input

J1

CH1CH2

CH3

CH4CH5CH6CH7 CH8 NOG1 NOG2

J2

OUTPUTS

The acknowledge input, ACK is an edge-triggered digital input. The input accepts a 5 to 30V

The circuit contains a resistor and optical isolator. If

you are using a push button to generate the input signal, momentary contacts are recommended because the

input is edge-triggered.

DC

Powe r

Supply

User Supplied

Contact

+

_

TLM-8 Internal Circuit

ACK+

ACK–

Î (dc) signal.

Ó

WARNING:

You must connect the thermocouple to the input terminal

blocks correctly. If the inputs are reversed, the sensor

may be unable to generate an alarm. This could result

in a fire or other accident leading to loss of property or

lives.

Ó

CAUTION:

To protect the alarm relay contacts when connected to an

inductive load, use catch diodes for dc loads and snubbers on ac or dc loads. For dc applications select a diode

with a reverse breakdown voltage 10 times the applied

voltage and forward load current.

Acknowledge Input

Thermocouple and RTD Inputs

Be sure to use the type of sensor that matches your

TLM-8; the input type is noted on the label.

Thermostatic Switch Inputs

When using thermostatic switch (thermostat) inputs,

TLM-8 trip points can be set externally. The TLM-8

should be configured for thermostatic switches. Use

normally-closed thermostats that open at or above the

trip point.

Unused Inputs

If a sensor input is not used, short the positive and

negative input terminals.

TB1 Channel Relay Outputs

Relay Output Terminals

1 1, 2

2 3, 4

3 5, 6

4 7, 8

5 9, 10

6 11, 12

7 13, 14 1 1, 2

8 15, 16 2 3, 4

TB2 Global Relay Outputs

Global Alarm

Output

Terminals

Load

Back EMF Clamp

Load

Back EMF Clamp

Wiring Recommendations for relay outputs

Ó

CAUTION:

To minimize the power dissipated by the internal circuits

and ensure temperature accuracy, apply voltage to the

ACK and TST inputs only when intending to test the TLM-8

or acknowledge alarms. At other times the applied signal

should be 0VÎ (dc).

NOTE: To avoid interference with sensor readings, separate sensor and power wiring.

NOTE: This device is designed for indoor use only.

NOTE: Use only copper conductors for power and signals

other than thermocouples.

NOTE: Previous versions of the TLM-8 recommended

earth grounding the unit’s case, but the current version

does not require the case to be earth grounded.

NOTE: Alarm outputs and indicators are latched until the

condition is corrected and the alarm is acknowledged, as

long as the TLM-8 remains powered. If power is cycled to

the unit, it will evaluate the limits again.

WATLOW TLM-8 User’s Guide 3

Page 4

Using the TLM-8

SENSOR

J6

1 2

3

4

5

6

7

8

TST-

V-

J5

ACK-

Sensor Types

Sensor types for the TLM-8 are factory configured; the

type of sensor for your TLM-8 is marked on the label.

Trip Points

Your TLM-8 has been factory configured with trip

points per your specification. Accuracy of a trip point

is ± 5% for TLM-8s with model numbers starting with

“TLME.” For example, 5% of a 200°C trip point is 10°.

So a 200°C trip point would trigger between 190 and

210°C.

Reading Trip Points

The trip points for TLM-8s with model numbers starting with “TLME” are encoded in the part number. To

determine trip points from a part number, see the section, TLM-8 Part Numbers. The trip points for TLM-8s

with model numbers starting with “TLMC” are listed

on the label.

Alarms and Acknowledgment

When the TLM-8 is powered and there is no alarm,

the alarm relay contacts are held closed. When a channel’s temperature exceeds the trip point or the sensor

fails, that channel’s indicator light is illuminated and

the global alarm relay contacts open.

When the TLM-8 is configured with the eight, optional

channel alarm relays and a channel’s temperature

exceeds its trip point, both the global alarm relay and

the corresponding channel alarm relay open.

All alarms are acknowledged with the ACK input. An

external device provides the logic signal to the ACK

input. The ACK input activates on the trailing edge of

the input signal. The input must be high for at least

20 milliseconds; when the input signal transitions to

low, alarms are acknowledged. Allow up to 3.5 seconds

after acknowledging the alarms for the relays to close.

Acknowledging alarms before the temperature drops

below the trip point or before a failed sensor is

repaired will have no effect. Wait until the temperature drops below the trip point before acknowledging

alarms. When the alarms are successfully acknowledged, the alarm indicator lights turn off and the

alarm relay contacts close.

Reading the Indicator Lights

The alarm status of each channel is indicated by the

red indicator lights adjacent to the sensor input terminal block. A channel indicator light turns on when

the associated channel goes into alarm. If the TLM-8

is configured with channel relays, this indicator light

reflects the status of the associated channel relay. The

indicator light will remain on until the acknowledge

input, ACK, is activated after the temperature drops

below the trip point.

The green power light indicates the TLM-8 has power.

Indicator

Lights

Channel 1

Channel 2

.

.

.

.

.

Channel 7

Channel 8

Powe r

Alarm Status Indicator Lights

Testing the Outputs

The TLM-8 TST digital input allows users to simulate

excessive temperature on all channels. An external

device — switch or controller — provides the logic signal to the test, TST, input. All channels go into alarm

which can be easily verified by the channel indicator

lights. Use the following procedure to test the TLM-8:

1. Activate the TST input for at least 1 second. All

alarms and indicator lights should activate.

2. Deactivate the TST input.

3. Activate the ACK input for at least 20 milliseconds.

4. Deactivate the ACK input. All alarms should deactivate within 3.5 seconds.

Changing Trip Points

To change a trip point on the TLM-8, obtain an RMA

number from your supplier and return the TLM-8 for

adjustment.

Maintenance

Over-temperature conditions may not occur regularly.

To test the TLM-8’s outputs, use the procedure in the

section “Testing the Outputs” to force the TLM-8 to

simulate alarm conditions on all channels.

To test trip point values and other system components,

use a thermocouple calibrator or other appropriate

means to simulate a sensor input above the trip point.

4 WATLOW TLM-8 User’s Guide

Page 5

Application Example

In the following example, a TLM-8 monitors temperatures and provides independent safety shutdown, alarm

annunciation and acknowledgment. A multi-loop controller, CLS200 or MLS300, is used for primary control.

The TLM-8 has its own set of thermocouples to monitor

temperatures independent of the controller. If a temperature exceeds a trip point configured in the TLM8, then power to the heater is turned off by a TLM-8

controlled relay, and the System OK indicator light is

turned off. After the temperature drops and the cause

of the alarm has been corrected, an operator acknowledges the alarm. The primary controller resumes control of the loop(s).

relay contacts

Relay

(normally open)

heater

thermocouples

TST

ACK

Solid-state

AC

Example Schematic

CLS/MLS Multi-Loop

Temperature Controller

TLM-8 Thermal

Limit Monitor

+

-

DC Power

Supply

DC Power

Supply

System OK

indicator light

relay

coil

Declaration of Conformity

Series TLM-8

Watlow Winona, Inc.

1241 Bundy Blvd.

Winona, MN 55987 USA

Declares that the following product:

Designation: Series TLM-8

Model Numbers: TLM (C, E or P)(0 – 6)(0 or 1)(0 – 9)(additional letters or numbers indicating setpoint tempera-

Classification: Temperature control, Installation Category II, Pollution degree 2

Rated Voltage and Power:

Meets the essential requirements of the following European Union Directives by using the relevant standards show below to indicate

compliance.

EN 61326 1997 A1:1998

EN 61000-4-2 1995 A2, 2001 Electrostatic Discharge Immunity

EN 61000-4-3 2002 Radiated Field Immunity

EN 61000-4-4 2004 Electrical Fast-Transient / Burst Immunity

EN 61000-4-5* 1995 A2, 2001 Surge Immunity

EN 61000-4-6 1996 A3, 2005 Conducted Immunity

EN 61000-4-11* 2004 Voltage Dips, Short Interruptions and Voltage Variations Immunity

EN 61000-3-2* 2001 ED.2. Harmonic Current Emissions

EN 61000-3-3* 1995 A2:2002 Voltage Fluctuations and Flicker

EN 61010-1 2001 Safety Requirements of electrical equipment for measurement, control and laboratory use.

Raymond D. Feller III Winona, Minnesota, USA

Name of Authorized Representative Place of Issue

General Manager August 2007

Title of Authorized Representative

Signature of Authorized Representative

Declaration of Conformity

tures.

Î (dc) 400 mA maximum

Control 12 to 24 V

Note: Use of external CE approved ELV (UL Class 2) power supply required.*

2004/108/EC Electromagnetic Compatibility Directive

Electrical equipment for measurement, control and laboratory use – EMC

requirements (Industrial Immunity, Class B Emissions).

A2:2002

A3:2004

73/23/EEC Low-Voltage Directive

Part 1: General requirements

2002/96/EC WEEE Directive Equipment Requires Recycling

Date of Issue

NOTE: Relay contacts are illustrated in the unpowered or

alarmed state.

WATLOW TLM-8 User’s Guide 5

Page 6

Specifications

Analog Inputs

Sensor input channels: 8

Sensor Types and Trip Point Ranges:

• 2-Wire 100 Ω Platinum RTD DIN curve (385): -100 to

850°C (-148 to 1,562°F)

• E Thermocouple: 100 to 801°C (212 to 1,474°F)

• K Thermocouple: 100 to 1,205°C (212 to 2,201°F)

• S Thermocouple: 500 to 1,711°C (932 to 3,112°F)

• J Thermocouple: 100 to 754°C (212 to 1,389°F)

• R Thermocouple: 500 to 1,720°C (932 to 3,128°F)

• T Thermocouple: 100 to 384°C (212 to 723°F)

• Thermostatic switch

At actual temperatures of -100°C (-148°F) or less, nuisance

alarms may occur.

Accuracy for trip points above 100°C (212°F):

• For part numbers starting with “TLME,” ± 5% of trip

point.

• For part numbers starting with “TLMC,” see below.

Sensor (s) Trip Point Accuracy

J, K, E, T, RTD ±0.5% of trip point and

S, R ±0.5% of trip point and

Repeatability: better than 5°C (9°F) or accuracy for trip

point, whichever is less.

Input filter: 1 second (minimum time the over-temperature

condition exists before the output responds)

Isolation:

• Common Mode: ± 10V

(Input to analog common)

• Input-to-Input: ± 10V

• Input-to-Frame Ground: ± 500V

Ambient: 15 to 35ºC

(59 to 95ºF)

±2ºC (3.2ºF)

±3ºC (5.4ºF)

Å (ac) or VÎ (dc)

Å (ac) or VÎ (dc)

ACK Input

Function: alarm acknowledge

Type: digital input

Activation: edge triggered (on to off transition)

Filter: 20 milliseconds

Maximum time to reset relays: 3.5 seconds

Maximum time signal should be held high: 5 seconds

Isolation: optical

Voltage and current: 5 to 30VÎ (dc); 2 mA @ 5VÎ (dc); 19

mA @ 30VÎ (dc)

Impedance: 1.5 kΩ

Trip Point Accuracy

Ambient: 0 to 60ºC

(32 to 140ºF)

±0.5% of trip point and

±4ºC (7.2ºF)

±0.5% of trip point and

±5ºC (9ºF)

Å (ac) or VÎ (dc)

TST Input

Function: test

Type: digital input

Activation: level triggered (signal high)

Filter: must be active for 1 second for valid simulation

Maximum time signal should be held high: 5 seconds

Isolation: optical

Voltage and current: 5 to 30VÎ (dc); 2 mA @ 5VÎ (dc); 19

mA @ 30VÎ (dc)

Impedance: 1.5 kΩ

Electromechanical Alarm Relays

Contact arrangement: open in power-off condition

Contact action: latch open in alarm condition

Maximum contact rating: 1 A @ 30VÎ (dc)

Indicator Lights

Alarm status: 8 red

Power: 1 green

Dimensions

Length: 236 mm (9.30 in.)

Width: 92 mm (3.61 in.)

Depth: 48 mm (1.87 in.)

DIN rail mount: add 20 mm (0.75 in.) to depth

Power Requirements

Nominal voltage: 12 to 24VÎ (dc)

Absolute voltage: 10 to 27V

Power: 3.2 watts

Requires: Class 2 power supply

Î (dc)

Terminal Blocks

Type: Removable

Torque: 0.33 to 0.35 Nm (2.9 to 3.1 in-lbs.)

Wire Gauge: 26 to 18 AWG

Environmental

Operating ambient temperature: 0 to 60°C (32 to 140°F)

Storage ambient temperature: -20 to 100°C (-4 to 212°F)

Relative humidity: 0 to 95%, non condensing

Agency Approvals / Compliance

UL, cUL Listed (File No. E185611)

• Process Control Equipment UL 61010

• Process Control Equipment C22.2 #61010-1

FM

• Temperature Limit Switches – Non Indicating Class 3545

• Temperature Supervisory Switch Class 3545

CE

• Low Voltage Directive (LVD) 73/23/EEC

• Electromagnetic Compatibility Directive (EMC) 2004/108/

EC

6 WATLOW TLM-8 User’s Guide

Page 7

TLM-8 Part Numbers

Use the tables to determine the characteristics of your

TLM-8 based on its part number.

Standard TLM-8 Part Number

T L M E __ __ __ __ __ __ __ __ __ __ __

Sensor Type

0 RTD or Thermostat

1 Type E Thermocouple

2 Type J Thermocouple

3 Type K Thermocouple

4 Type R Thermocouple

5 Type S Thermocouple

6 Type T Thermocouple

Alarm Relays

0 Global relays only

1 Global and 8-channel alarm relays

Mounting

0 Panel

1 DIN Rail

Trip Point (Channels 1 through 8)

(See Trip Point table below.)

Trip Points

Custom TLM-8 Part Number

T L M C – __ __ __ 0 - 0 _ _ _

Sensor Type

0 RTD or Thermostat

1 Type E Thermocouple

2 Type J Thermocouple

3 Type K Thermocouple

4 Type R Thermocouple

5 Type S Thermocouple

6 Type T Thermocouple

Alarm Relays

0 Global relays only

1 Global and 8-channel alarm relays

Mounting

0 Panel

1 DIN Rail

Custom Code

3-digit code assigned by factory (See label on unit for trip-point values.)

RTD E Thermocouple J Thermocouple K Thermocouple R Thermocouple S Thermocouple T Thermocouple

Temperature

Unused Input A Unused Input A Unused Input A Unused Input A Unused Input A Unused Input A Unused Input A

103°C (217°F) B 101°C (214°F) B 100°C (212°F) B 100°C (212°F) B

121°C (250°F) C 202°C (396°F) C 152°C (307°F) C 150°C (302°F) C

151°C (304°F) D 302°C (576°F) D 202°C (396°F) D 200°C (392°F) D

215°C (419°F) E 403°C (756°F) E 251°C (484°F) E 252°C (486°F) E

324°C (615°F) F 502°C (936°F) F 302°C (576°F) F 303°C (577°F) F

404°C (759°F) G 600°C (1,112°F) G 350°C (662°F) G 353°C (667°F) G

478°C (892°F) H 702°C (1,296°F) H 402°C (756°F) H 401°C (754°F) H

584°C (1,083°F) I 801°C (1,474°F) I 450°C (842°F) I 455°C (851°F) I

708°C (1,306°F) J 502°C (936°F) J 504°C (939°F) J

824°C (1,515°F) K 554°C (1,027°F) K 556°C (1,033°F) K

Thermostat K 600°C (1,112°F) L 603°C (1,117°F) L

Trip

Point

Temperature

Trip

Point

Temperature

653°C (1,207°F)

704°C (1,299°F)

754°C (1,389°F)

Trip

Point

651°C (1,204°F)

M

701°C (1,294°F)

N

753°C (1,387°F)

O

807°C (1,485°F)

851°C (1,564°F)

907°C (1,665°F)

952°C (1,746°F)

998°C (1,828°F)

1,057°C (1,935°F)

1,101°C (2,014°F)

1,157°C (2,115°F

1,205°C (2,201°F)

Temperature

Trip

Point

M

N

O

P

Q

R

S

T

U

V

W

X

Temperature

501°C (934°F)

602°C (1,116°F)

708°C (1,306°F)

800°C (1,472°F)

903°C (1,657°F)

999°C (1,830°F)

1,100°C (2,012°F)

1,206°C (2,203°F)

1,306°C (2,383°F)

1,410°C (2,570°F)

1,497°C (2,727°F)

1,593°C (2,899°F)

1,720°C (3,128°F)

Trip

Point

B

C

D

E

F

G

H

I

J

K

L

M

N

Temperature

506°C (943°F)

601°C (1,114°F)

700°C (1,292°F)

810°C (1,490°F)

902°C (1,656°F)

1,005°C (1,841°F)

1,110°C (2,030°F)

1,210°C (2,210°F)

1,313°C (2,395°F)

1,404°C (2,559°F)

1,500°C (2,732°F)

1,600°C (2,912°F)

1,711°C (3,112°F)

Trip

Point

B

C

D

E

F

G

H

I

J

K

L

M

N

Temperature

100°C (212°F)

202°C (396°F)

291°C (556°F)

384°C (723°F)

Trip

Point

B

C

D

E

WATLOW TLM-8 User’s Guide 7

Page 8

How to Reach Us

Corporate Headquarters

Watlow Electric Manufacturing Company

12001 Lackland Road

St. Louis, MO 63146

Sales: 1-800-WATLOW2

Manufacturing Support: 1-800-4WATLOW

Email: info@watlow.com

Website: www.watlow.com

From outside the USA and Canada:

Tel: +1 (314) 878-4600

Fax: +1 (314) 878-6814

Latin America

Watlow de México S.A. de C.V.

Av. Fundición No. 5

Col. Parques Industriales

Querétaro, Qro. CP-76130

Mexico

Tel: +52 442 217-6235

Fax: +52 442 217-6403

Europe

Watlow France SARL

Immeuble Somag

16, Rue Ampère

95307 Cergy-Pontoise CEDEX

France

Tel: + 33 (0)1 30 73 24 25

Fax: + 33 (0)1 30 73 28 75

Email: info@watlow.fr

Website: www.watlow.fr

Watlow GmbH

Postfach 11 65, Lauchwasenstr. 1

D-76709 Kronau

Germany

Tel: +49 (0) 7253 9400-0

Fax: +49 (0) 7253 9400-900

Email: info@watlow.de

Website: www.watlow.de

Watlow Italy S.r.l.

Viale Italia 52/54

20094 Corsico MI

Italy

Tel: +39 024588841

Fax: +39 0245869954

Email: italyinfo@watlow.com

Website: www.watlow.it

Asia and Pacific

Watlow Singapore Pte Ltd.

16 Ayer Rajah Crescent,

#06-03/04,

Singapore 139965

Tel: +65 6773 9488 Fax: +65 6778 0323

Email: info@watlow.com.sg Website:www.watlow.com.sg

Watlow Australia Pty., Ltd.

4/57 Sharps Road

Tullamarine, VIC 3043

Australia

Tel: +61 3 9335 6449

Fax: +61 3 9330 3566

Website: www.watlow.com

瓦特隆电子科技(上海)有限公司

(销售办事处)

上海市浦东新区张江工业园区碧波路115号572弄22棟 *

201203

邮编:

86 21 5080-0902 传真: 86 21 5080-0906

电话:

电子邮箱:

Watlow Electric Manufacturing (Shanghai) Company

115-22#, 572nd Lane, Bibo Road, Zhangjiang High-Tech Park,

Shanghai, PRC 201203

People’s Republic of China

Tel: +86 21 5080-0902 Fax: +86 21 5080-0906

Email: info@watlow.cn Website: www.watlow.cn

ワトロー・ジャパン株式会社

〒101-0047 東京都千代田区内神田1-14-4

四国ビル別館9階

Tel: 03-3518-6630 Fax: 03-3518-6632

Email: infoj@watlow.com Website: www.watlow.co.jp

Watlow Japan Ltd.

1-14-4 Uchikanda, Chiyoda-Ku

Tokyo 101-0047

Japan

Tel: +81-3-3518-6630 Fax: +81-3-3518-6632

Email: infoj@watlow.com Website: www.watlow.co.jp

Revised: September 20, 2007

info@watlow.cn Website: www.watlow.cn

Watlow Ibérica, S.L.U.

CME - Avda. de la Vía Láctea, s/n. Oficina 24

28830 - San Fernando de Henares Madrid

Spain

Tel: +34.91.675.1292

Fax: +34.91.648.7380

Email: info@watlow.es

Website: www.watlow.es

Watlow

Storgatan 24

302 43 Halmstad

Sweden

Tel: + 46 (0)35 27 11 66

Fax: +46 (0)35 27 11 67

Email: info@watlow.se

Website: www.watlow.se

Watlow UK Ltd.

Linby Industrial Estate

Linby, Nottingham, NG15 8AA

United Kingdom

Telephone: (0) 115 964 0777

Fax: (0) 115 964 0071

Email: info@watlow.co.uk

Website: www.watlow.co.uk

From outside The United Kingdom:

Tel: +44 115 964 0777

Fax: +44 115 964 0071

Watlow Korea Co., Ltd.

#1406, E&C Dream Tower, 46, Yangpyeongdong-3ga

Yeongdeungpo-gu, Seoul 150-103

Republic of Korea

Tel: +82 (2) 2628-5770 Fax: +82 (2) 2628-5771

Website: www.watlow.co.kr

Watlow Malaysia Sdn Bhd

No. 14-3 Jalan 2/114

Kuchai Business Centre

Jalan Kuchai Lama

58200 Kuala Lumpur

Malaysia

Tel: +60 3 7980 7741 Fax: +60 3 7980 7739

瓦特龍電機股份有限公司

80143 高雄市前金區七賢二路189號 10樓之一

07-2885168 傳真: 07-2885568

電話:

Watlow Electric Taiwan Corporation

10F-1 No.189 Chi-Shen 2nd Road Kaohsiung 80143

Taiwan

Tel: +886-7-2885168 Fax: +886-7-2885568

Your Authorized Watlow Distributor

Loading...

Loading...