Page 1

W A T L O W

Clamping Bars

Zinc Steel

Inner Sheath

Aluminized

Steel Outside

Diameter

Sheath

Resistance

Ribbon

Mica Insulation

Post Terminals

Side Folds

to the Inside

Diameter

Band Heaters

THINBAND®Mica

Barrel and Nozzle

The THINBAND®heater is Watlow’s

patented redesign of the mica band.

THINBAND heaters deliver fast and

install easily, keeping costs down

and machines running.

Performance Capabilities

• Sheath temperatures to 480°C

(900°F)

• Watt densities to 55 W/in

(8.5 W/cm2)

2

Same day shipment on more than 1000 variations

•

f THINBAND heaters.

o

Band Heaters

Features and Benefits

Flexible, one-piece design

• Makes installation easier on

plastic pr

ocessing equipment

because it can open to full

diameter of the barrel without

internal damage to the heater

• Installs on a barrel without

removing other band heaters

already in place

Same day shipment on more than

1,000 variations available because

of Watlow’s Lead Adapter (LA)

manufacturing method

• Reduces inventories and costly

downtimes

Only one set of leads or terminals

• Cumbersome, two-piece

replacement band heaters with

straps require two sets

Quick clamp

• Opens to fit over barrels and

snaps in place with one easy flip

of its latching lever

• No need to remove other heaters

Permanently attached clamping

bars

No folds on the outside of the

heater

Contamination r

•

esistance

Applications

• Extruders

• Blown film dies

• Injection molding machines

• Other cylinder heating

applications

1

Page 2

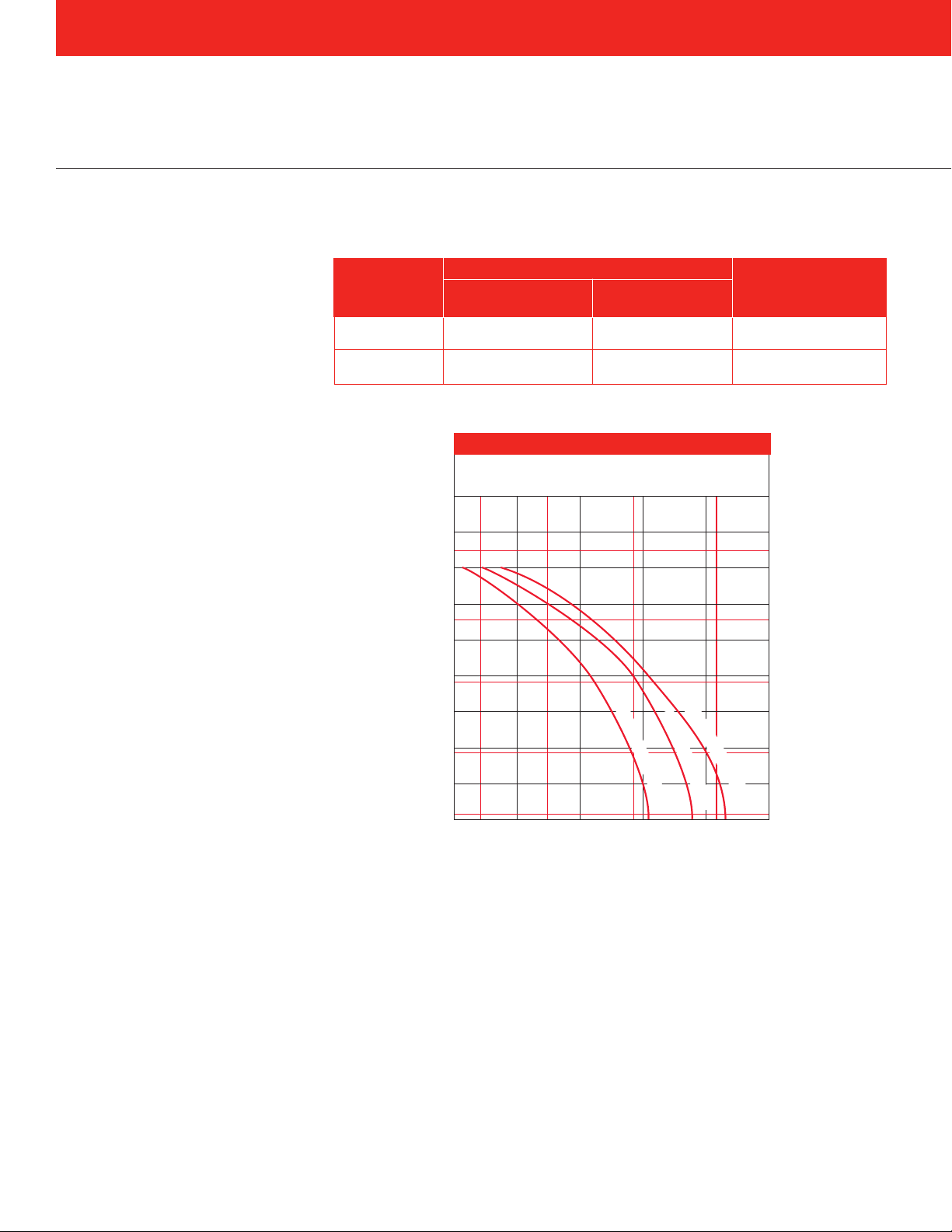

20 30 40 50

Watt Density—W/in

2

700

500

300

800

900

1000

1100

600

400

200

10 60

500

400

300

200

2

4 68

100

Cylinder Temperature—°F

Cylinder Temperature—°C

Watt Density—W/cm

2

10 in. (254 mm) Dia.

3 in. (76.2 mm) Dia.

1

1

/

2

in. (38.1 mm) Dia.

Band Heaters

THINBAND Mica

Barrel and Nozzle

Applications and

Technical Data

Operating Factors

Use as low a watt density rating as your

application permits. A close match of

the heat supplied to the actual requirements will reduce temperature

overshoot, reduce cycling and increase

the life of any band heater you use.

Calculate the

for your heater using:

Heated Area x Maximum

Watt Density

Calculate the heated area of your band

heater by subtracting the no-heat area

from the total area in contact with the

cylinder (3.14 x I.D. x width). Subtract

the no-heat area at the terminals (from

table) and any additional no-heat area

caused by holes, slots or oversize gaps.

Determine the maximum watt density of

your heater from the Maximum

Allowable Watt Density graph. The

curves are based on narrow heaters

mounted on a smooth, steel cylinder.

Apply the necessary correction factors:

• For heaters 2

five inches wide (127 mm), multiply

watt density by 0.8.

• For high expansion cylinders

(aluminum or brass), reduce the watt

density by 3 W/in

• For heaters 21⁄4 inches to five inches

(57 mm to 127 mm) wide installed

on a high expansion cylinder,

educe watt density by a total of

r

3 W/in2(0.46 W/cm2) only.

• For regular cylinder surfaces other

than smooth, machined fi

reduce watt density by 3 W/in

(0.46 W/cm2).

For heaters that will be insulated

•

or enclosed, contact Watlow for

specific watt densities.

For units gr

•

(355 mm) diameter, consult the

THINBAND Recommended

Clamping Options graph.

• For units used in vertical

applications, consult factory for

application assistance.

2

safe maximum wattage

1

⁄4 inches (57 mm) to

2

(0.46 W/cm2).

nish,

2

eater than 14 inches

No-Heat Area for THINBAND Barrel (All Terminations)

Heater Size No-Heat Area

Heater

Type in. (mm) in. (mm) in. (mm)

One Piece Less than 21⁄2 (63.5) Up to 7 (177.8) 11⁄4 (31.75) x width

Two Piece 5 (127) or more More than 3 (76.2) 2

Diameter Width

MMaaxxiimmuumm AAlllloowwaabbllee WWaatttt DDeennssiittyy

Standard Gap 3⁄8 in.

1

⁄2 (63.5) x width

Page 3

W A T L O W

Band Heaters

THINBAND Mica

Barrel and Nozzle

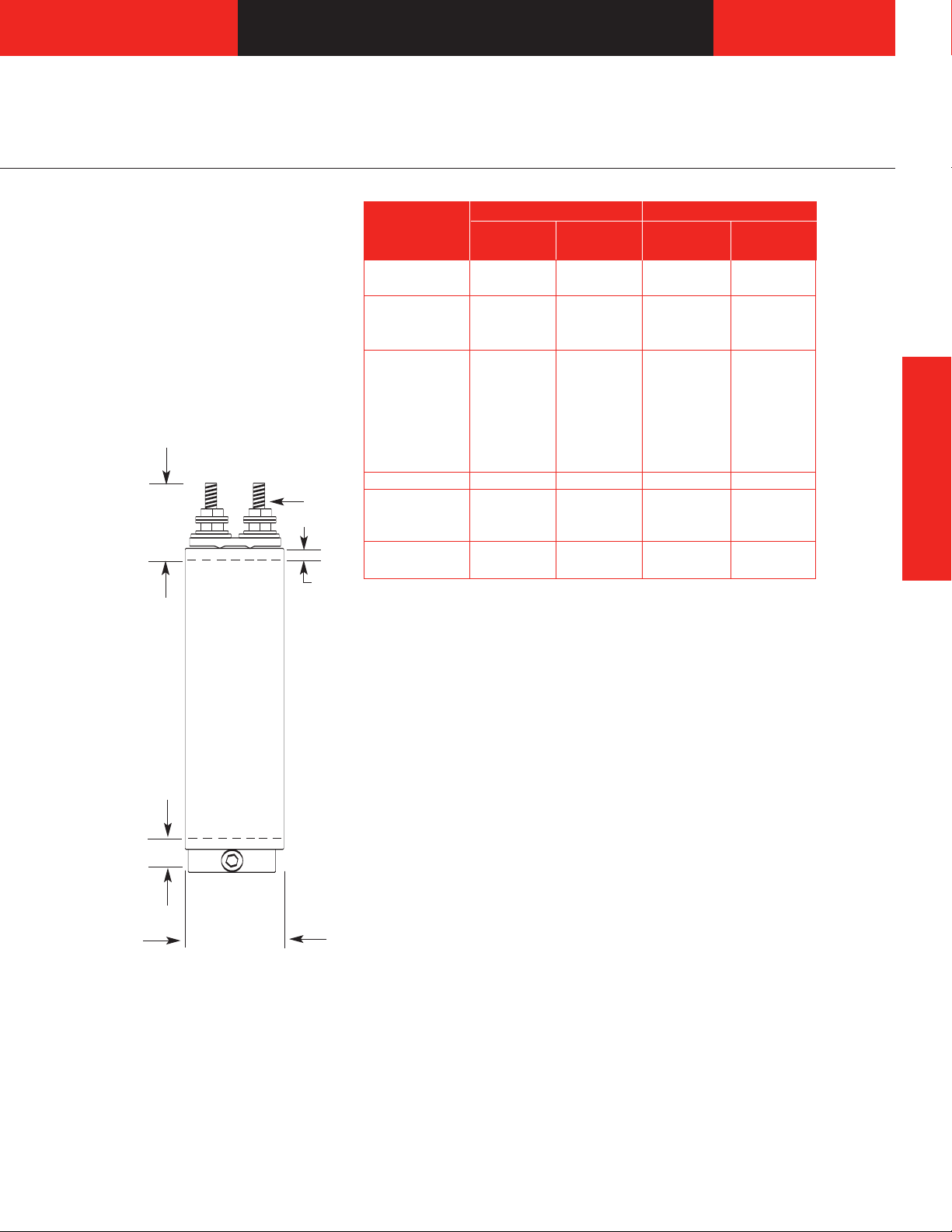

Physical Limitations of

Lead Variations

Check the table to be certain the

variations and lead arrangements

you order are available on the

heater size you require. If you need

to exceed any limitations, please

contact a Watlow representative.

THINBAND Barrel

11⁄4 in.

(32 mm)

Minimum

21⁄2 in. (63 mm)

Maximum

141⁄2 in. (368 mm) 1pc.

29 in. (736 mm) 2 pc.

10-24

thread

0.156 in.

(3.9 mm)

Physical Limitations of Lead Variations

Diameter Width

Heater Type Min. Max. Min. Max.

in. (mm) in. (mm) in. (mm) in. (mm)

1 pc. const. 1 (25.4) 141⁄2 (368.3) 11⁄2 (38.1) 7 (177.8)

2 pc. const. 5 (127) 29 (736.6) 1

Nozzle

Type A 1 (25.4) 4 (101.6) 1 (25.4) 6 (152.4)

Type L 1 (25.4) 4 (101.6) 1 (25.4) 6 (152.4)

Barrel

Type T 21⁄2 (63.5) 11⁄2 (38.1) 7 (177.8)

ype H 2

T

Type F, FR 2

Type E 2

Type C, BR 2

Type K, KR 21⁄2 (63.5) 11⁄2 (38.1) 7 (177.8)

Terminal Box 31⁄2 (88.9) 11⁄2 (38.1) 7 (177.8)

European Plug

1 pc. vertical 2

1 pc. horizontal 2

Welded Barrel Nuts

1 pc. 21⁄2 (63.5) 141⁄2 (368.3) 11⁄2 (38.1) 7 (177.8)

Note: Some combinations of maximums and minimums cannot occur on the

same heater. Check the table to be certain the variations and lead arrangements

you order are available on the heater size you require. If you need to exceed

any limitations, please contact your Watlow representative.

Standard gap is 3⁄8 inch (9.53 mm) between clamp bars.

1

63.5) 1

⁄2 (

1

⁄2 (63.5) 11⁄2 (38.1) 7 (177.8)

1

⁄2 (63.5) 11⁄2 (38.1) 7 (177.8)

1

⁄2 (63.5) 11⁄2 (38.1) 7 (177.8)

1

⁄2 (63.5) 141⁄2 (368.3) 11⁄2 (38.1) 7 (177.8)

1

⁄2 (63.5) 141⁄2 (368.3) 11⁄2 (38.1) 7 (177.8)

1

⁄2 (38.1) 7 (177.8)

1

38.1) 7 (177.8)

⁄2 (

Band Heaters

9

⁄16 in.

(14 mm)

Minimum 11⁄2 in. (38 mm)

Maximum 7 in. (177 mm)

3

Page 4

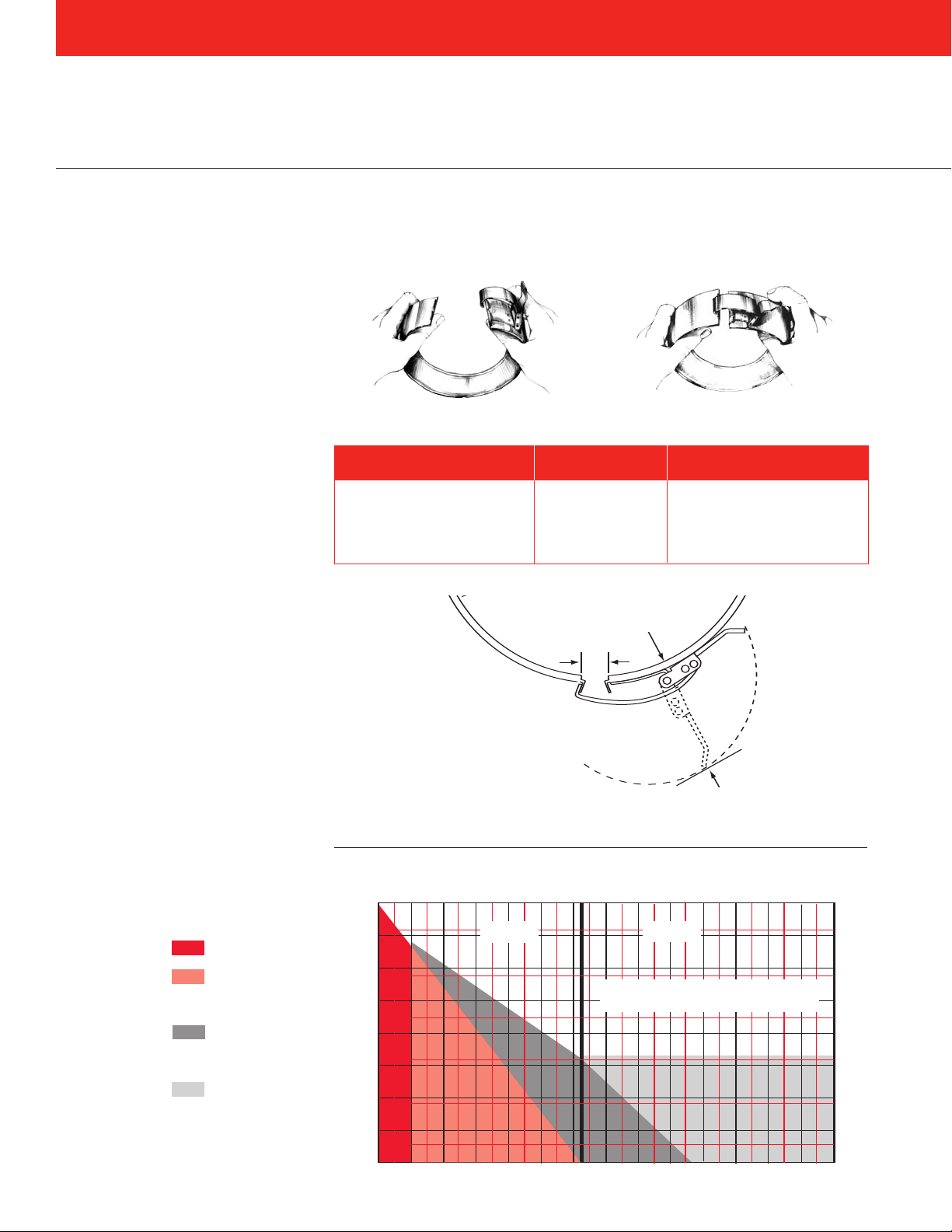

Band Heaters

Coil Spring

For 2 piece only:

Clamp bar at other gap

50

40

30

20

10

2 468102 12 14 16 18 20

22 24

26 28

Watt Density (W/in

2

)

Diameter (inches)

Clamp Bars

QUICK CLAMP

For 2 piece:

Clamp bar at other gap

Clamp Bars

Or QUICK CLAMP

above 4 in. (101.6 mm) diameter

2 Piece

Diameter (millimeters)

76 127 178 229 279 330 381 432 483 533 584 635 686 737

Watt Density (W/cm

2

)

2

3

4

5

6

7

1 Piece

Above Recommended Watt Density

Consult Engineering

DD

1

/

2

"

(12.7 mm)

21/8"

(54 mm)

THINBAND Mica

Barrel and Nozzle

Barrel Heater

QUICK CLAMP Option

With QUICK CLAMP, the THINBAND

heater can be secured tightly in

place in a matter of seconds. The

spring-loaded clamp secures the

heater tightly around the barrel with

an easy flip of the lever.

Features and Benefi

• THINBAND with QUICK CLAMP

fits over barrels and snaps in

place with easy flip of its latching

lever.

• Hot change-outs are completed

in seconds.

• Spring tensioned clamp keeps

the THINBAND heater tight

against barrel—will not loosen

over time.

ts

QUICK CLAMP eliminates tools, loose parts and hassle

THINBAND opens up to fit over

•

barrel. There is no need to

remove other heaters.

One easy flip of the latching lever

•

and QUICK CLAMP shuts,

completing installation.

Clearance Dimensions

Width Range Number of Distance Between Clamps

in. (mm) QUICK CLAMPS in. (mm)

11⁄2 (38.1) to 211⁄16 (69.3) 1 NA

3

⁄4 (69.9) to 311⁄16 (94.8) 2 11⁄2 (12.7)

2

33⁄4 (69.9) to 411⁄16 (120.1) 2 1 (25.4)

43⁄4 (120.6) to 511⁄16 (145.5) 3 11⁄2 (12.7)

53⁄4 (146.1) to 711⁄16 (145.5) 3 1 (25.4)

• Ideal for vertical applications.

• Available on selected stock

and made-to-order THINBAND

barrel heaters—minimum 4 inch

(100 mm) diameter, 1

(38 mm) width.

• Standard gap is 1⁄2 inch.

Recommended

Clamping Options

THINBAND Barrel Pr

1

⁄2 inch

oducts

Notes: Widths four inches (101.6 mm) and

over add two inches (50.8 mm) to diameter

then reference chart clamp selection.

4

Page 5

W A T L O W

0.75 in.

(19 mm)

5.8 in. (147 mm)

0

.563 in.

(14 mm)

T

ig Welded

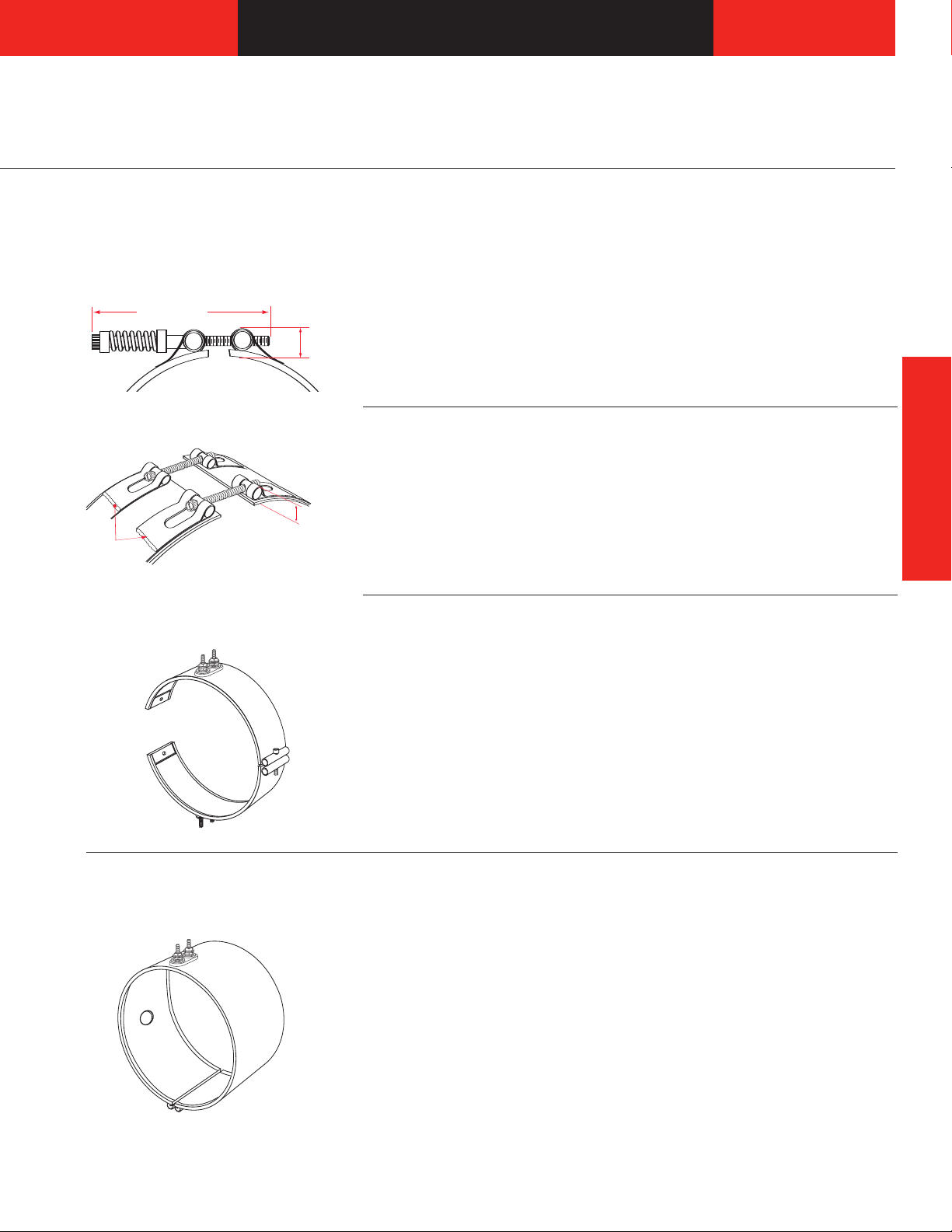

Band Heaters

THINBAND Mica

Barrel and Nozzle

Barrel Heater

Clamping Variations

Tig Welded Barrel Nuts with Spring Loaded Clamping

Non-Stock Option

Tig welded barrel nuts with spring

loaded clamping are used during

start-up to maintain a tight heater

fit on large barrels. Stainless steel

top metal is required.

Tig Welded Barrel Nuts

An ideal way to provide access

for instrumentation is to specify an

oversized gap between the heater

ends. If the THINBAND clamp bar

screw interferes with the positioning

of the instrumentation device,

Clamping Pads

Clamping pads are used when an

obstruction would prevent a

standard full circumferential heater

from fitting completely around a

machine barrel. The clamping pads

Refer to the THINBAND Recom-

mended Clamping Options graph.

This option is mandatory on vertical

applications. To order, specify

spring loaded clamping.

tig welded barrel nuts are recommended. Stainless steel top metal is

required. Maximum gap is one inch

(25 mm) Specify

tig welded barrel

nuts and gap dimension when

ordering.

have a hole to allow easy fastening

to the machine barrel.

Dimensional

drawing required or customer

supplied sample heater when

ordering.

Band Heaters

Variations

Non-Stoc

k Option

Holes

An economical way to provide

access for instrumentation is to

specify an oversized gap between

the heater ends. A hole in the sheath

should be specified only when all the

cylinder surface adjacent to the hole

must be heated. When required,

one hole may be provided in

nearly any location as long as

there is at least one inch (25 mm)

between the hole and one side of

the heater

to two inches (51 mm) diameter

. Standard hole sizes up

.

Consult factory for limitations. For

oper hole location, a

pr

dimensional

drawing or custom supplied

sample heater is required.

5

Page 6

Band Heaters

1

3

/

4

in.

(45 mm)

1

3

/

8

in.

(35 mm)

1

7

/

8

in.

(48 mm)

2

3

/

8

in.

(60 mm)

2

7

/

8

in.

(73 mm)

THINBAND Mica

Barrel and Nozzle

Barrel Heater Variations

Continued

Stock LA Option

Stock Option

Non-Stock Option

Stock Option

Two-Piece Band Heaters

Two-piece construction is available

on heaters five inches (127 mm) or

greater in diameter. Heaters

1

⁄2 inches (38 mm) wide and greater

1

with post terminals have the two

terminals side-by-side.

Note: When ordering two-piece

band heaters, specify the volts and

watts per half. On two-piece units

with leads, you must also specify the

per half may be wired in series to a

480V

Å(ac) power supply. In this

case the band heater lead wire

insulation must be rated for

Å(ac). Available from stock by

480V

combining two one-piece heaters to

create a large diameter. Terminations

will be 90 degrees from each gap.

QUICK CLAMP must be supplied at

one gap when ordering.

power supply voltage. Example:

a two-piece band that is 240VÅ(ac)

High Temperature “Quick Disconnect” European Style Plugs

They provide the simplest and

safest way to apply power to band

heaters. The combination of high

temperature male and female quick

disconnect plug assemblies

eliminates all live exposed terminals

and electrical wiring that can be a

potential hazard to employees or

machine. Maximum 15 amps at

240VÅ(ac), maximum 240 volts.

When ordering, specify vertical or

horizontal European plug.

Vertical

Stock Option

Code # N6027AF049

6

Right Angle

Horizontal

Stock Option

Code # N6027ZZ028

Straight

emperature “Quick Disconnect” European Style Female Adapters

T

High

Available as an accessory item that

must be used in conjunction with

Specify code number N6027AF049

or N6027ZZ028 and quantity.

high temperature “quick disconnect”

European style plugs.

Page 7

W A T L O W

1

13

/

1

6

in.

(46 mm)

1

7

/

1

6

in.

(37 mm)

3

1

/

2

in. for 3

1

/

2

-5

15

/

16

in. I.D.

4 in. for 6-29 in. I.D.

WAT

L

OW

1

1

/

4

in.

(32 mm)

1

1

/

2

in.

(38 mm)

Band Heaters

THINBAND Mica

Barrel and Nozzle

Barrel Heater Variations

Continued

Stock Option

Metallic Terminal Box

Available on heaters of 31⁄2 inches

(88 mm) diameter or larger.

Terminal boxes are attached to the

heater to cover the terminals for an

added safety feature. Conduit may

be attached to the box through

7

⁄8 inch (22 mm) diameter holes in

the ends of the box. Terminal box

is available on one or two-piece

stock THINBAND heaters. When

ordering, specify

terminal box.

Band Heaters

Stock Option

Terminations

Stock LA Option

Code # Z-4919

Ceramic Terminal Covers

A convenient and economic way to

insulate post terminals. Sized for

standard length posts. 10-24 screw

thread size. These are supplied as

Metric Clamp Bars and Screws

Metric hardware is available on

made-to-order THINBAND heaters

with post terminals and clamp

bars. The post terminal thread size

ype T

T

Post ter

minals pr

ovide a quick

connection with ring or fork

connectors, or buss strips.

eaded 10-24 studs or optional

Thr

metric (M5X.8) are provided with

double nuts and washers. Post

minals have a thr

ter

9

⁄16 inch (14 mm) and require 11⁄4

eaded length of

inches (32 mm) clearance from the

cylinder. Maximum amperage for

post ter

minals is 35 amps and they

can withstand up to 45 in-lbs

(61.0 Newton-Meter) of tor

eased tor

incr

que is possible

que. The

an accessory item and shipped

separately. Specify code number

Z-4919 and quantity.

is M5X.8. The screw for the clamp

bar will be M6X1.0 socket head

cap screw. When ordering, specify

metric hardware required.

due to the unique add-on lead cap

design, which makes the cap a

separate entity fr

of

means

all

om the heater. This

the torque carrying

capability is maintained within the

cap design, allowing the ter

e to be torqued to a specific

dwar

har

minal

setting and tested prior to connection

to the heater.

The welded electrical connection to

the heater is superior to crimped or

staked connections which can

loosen and oxidize during operation.

T

o or

, specify

der

T

ype

.

T

7

Page 8

Band Heaters

THINBAND Mica

Barrel and Nozzle

Barrel Heater Terminations

Continued

Heaters rated at less than 250

volts use UL®approved lead

insulation for operations to 250˚C

(482˚F) as standard. Lead

®

insulation UL

tion to 450˚C (850˚F) may be

required in high temperature

applications where the leads are

shrouded or enclosed with the

heater. All heaters rated at more

than 250V

rated for opera-

Å(ac) use this wire.

Type K

Stock LA Option

Flexible lead wires exit vertically

from the heater. These leads can be

bent adjacent to the heater for a

quick and easy connection. To order,

specify

Type C

Stock LA Option

Type K and length.

ype KR

T

tock LA Option

S

Same specifications as Type K

except lead wires exit at right angle.

To order, specify Type KR and

length.

Type BR

Stock LA Option

Two fiberglass lead wires exit a

single tightly woven metal braid for

good abrasion protection, lead

flexibility and wiring convenience.

Leads are two inches (51 mm)

der,

longer than the braid. T

specify Type C and length.

ype F

T

Stock LA Option

Loose fiberglass sleeving encloses

berglass leads for additional

two fi

insulation pr

temperatur

esent. Leads ar

pr

(51 mm) longer than the sleeving. T

der, specify

or

otection wher

e or minor abrasion is

ype F

T

o or

e high

e two inches

and length.

Same specifications as Type C

except lead wires exit at right angle.

To order, specify

length.

ype FR

T

Stock LA Option

Same specifications as Type F

except lead wires exit at right angle.

To order, specify Type FR and

length.

o

Type BR and

8

Page 9

W A T L O W

0.38 in.

(

10 mm)

0

.30 in.

(8 mm)

1 in. - 4 in. Diameter

(25 mm - 102 mm)

7

/16 in. (12 mm)

1

/2 in.

(13 mm)

3

/32 in.

(3 mm)

8-32 x 1

5

/16 in. (34 mm)

long S.H.C.S.

Band Heaters

THINBAND Mica

Barrel and Nozzle

Barrel Heater Terminations

Continued

Type E

Stock LA Option

Loose metal braid encloses two

fiberglass leads for good abrasion

protection, lead flexibility and wiring

convenience. Leads are two inches

(51 mm) longer than the braid. To

order, specify Type E and length.

Ground Wire or Terminal Stud

Uninsulated 18 gauge ground wire

is available on all lead types

except post terminals and Type C

leads. A 10-24 ground terminal

Type H

Stock LA Option

A stainless steel, flexible conduit

encloses the leads for superior

mechanical protection where lead

abrasion is a particular problem.

Leads are two inches (51 mm)

longer than the conduit. To order,

specify

Type H and length.

stud has a threaded length of 1

inch (17 mm). To order, specify

uninsulated ground wire or

terminal stud.

Band Heaters

1

⁄16

THINBAND Nozzle Heater

Terminations

• One to four inch diameter

• One to six inches wide

Type L

Stock Option

Flexible lead wires with fiberglass

sleeves exit the nozzle heater on

both sides of the gap. The heater

sheath encloses the ends for

protection against contamination.

To order, specify Type L.

Type A

Stock Option

Especially designed for nozzle

heaters, there is a galvanized metal

braid over the fiberglass insulated

leads, which provides strength and

protection. The heater ends are

enclosed to protect against melted

plastic and contaminants. This

arrangement permits one inch (25

mm) and wider nozzle heaters to be

placed flush against a flange.

Available on

nozzle sizes only. To order, specify

Type A.

9

Page 10

Band Heaters

THINBAND Mica

Barrel and Nozzle

How to Utilize Watlow's

Universal THINBAND Barrel

Stock Program

Various diameters and widths of

Watlow's unique patented flexible

THINBAND barrel heaters are

available with LA termination's for

shipment faster than any in the

market because of Watlow's unique

stocking program.

atlow stocks THINBAND barrel

W

heaters ranging in diameters from

hree to nine inches (76.2 to

t

228.6 mm) in

increments and widths in 1

1

⁄4 inch (6.35 mm)

1

⁄2 inch

(38.1 mm), two inch and three inch

(50.8 and 76.2 mm). Watlow can

combine these sizes, creating a

two-piece assembly ranging from

nine to 18 inches (228.6 to 457.2

mm) in diameter, and any

combination between three and

18 inches (76.2 and 457.2 mm) as a

two-piece assembly. This versatility

should satisfy almost any

requirements whether millimeter or

inch size barrels.

Regarding possible slight wattage

differences from your original heater

to your THINBAND replacement you

must keep in mind that about 80

percent of the wattage is required to

bring the barrel up to temperature.

The 20 percent remaining is used to

offset radiation and convection heat

losses. So, if you have a 550 watt

heater there is no harm in using a

500 or 600 watt stock THINBAND

barrel heater.

There are three approaches to

receive a THINBAND combination

from stock. To illustrate, let’s

examine a customer who needs a

10 inch (254 mm) diameter heater

but neither the size or width needed

is in stock.

Solutions:

#1) Take two five-inch (127 mm)

diameter heaters and curve to a

10 inch (254 mm) diameter.

Please note that a QUICK CLAMP

has to be added to the order for

the heater to fit. This heater is

offered next day delivery.

#2) Take two THINBAND heaters as

noted in #1 but mix each diameter.

For example, one four-inch (101.6

mm) and one six-inch (152.4 mm)

3

diameter or a 4

⁄4 (120.6 mm)

diameter with a 51⁄4 (133.3 mm)

diameter equal 10 inches (254

mm). Again you need a QUICK

CLAMP. This heater is also offered

next day delivery.

#3) Take two THINBANDs as in #1 or

1

#2 but subtract a

⁄4 inch (6.35

mm) to the diameter and supply

without the QUICK CLAMP for

same day delivery. For example

for a 10 inch (254 mm) diameter,

any combination of 93⁄4 inch (248

mm) should be supplied to fit the

10 inch (254 mm) diameter

requirement. The reason you have

to reduce your selection size by a

1

⁄4 inch (6.35 mm) is to ensure a

gap when tightening the clamp

bars otherwise you will run out of

gap and the bars will touch befor

you can tighten the heater

completely to the barrel. This is

only necessary when QUICK

CLAMP is not included.

e

Installation Procedures

Install heaters over a clean

1.

surface.

After installing the unit, begin to

2.

. The

tighten the clamp scr

clamping screw is

11⁄4 inch, allen head cap scr

Begin tightening the clamp bars.

If the clamp bars appear not to

have seated, tap the clamp bars

with a small hammer to insur

bars are well seated in the angle

med by the 60 degree bent tab

for

and the heater

.

10

ew

1

⁄4 inch-20 x

ew.

e the

3.If the bar has multiple screws,

nately tighten the scr

alter

ews as

you would the lug nuts on a car

wheel to insure even loading.

4.

or

T

que all scr

ews to

approximately 8 ft-lbs.

ake a soft rubber mallet and tap

T

5.

gently around the circumference

of the heater while tightening the

ews. This will ensur

scr

e the heater

fit to the barrel is maximized

without any air gaps.

6.When installing terminal lugs,

que the top nuts to 30 in.-lbs.

tor

The bottom nut should not be

touched as it is factory torqued to

45 in.-lbs. at assembly.

7.Retighten the heater after the

heater has operated for a shor

time. Always make adjustments

when the heater and cylinder are

cold.

t

Page 11

Band Heaters

THINBAND Mica

Barrel and Nozzle

Stock Product List

Watt 1 pc. Approx.

I.D. Width Density or Terminals, Leads and Net. Wt. Code Former

n. (mm) in. (mm) Volts WattsW/in

i

1 (25.4) 1 (25.4) 120 100 44 (6.8) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1A1 B1A1AN1

1 (25.4) 240 100 44 (6.8) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1A2 B1A1AN2

1 (25.4) 120 125 55 ①(8.5) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1A3 B1A1AN3

1 (25.4) 240 125 55 ①(8.5) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1A4 B1A1AN4

11⁄2 (38.1) 240 150 44 (6.8) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1J2 B1A1JN2

11⁄2 (38.1) 120 200 59 ①(9.1) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1J3 B1A1JN3

11⁄2 (38.1) 240 200 59 ①(9.1) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1A1J4 B1A1JN4

11⁄4 (31.8)

13⁄8 (34.9) 1 (25.4) 120 140 41 (6.4) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1G1A1 B1G1AN1

11⁄2 (38.1) 17⁄8 (22.2) 240 100 31 (4.8) 1 Mica Band–Type A or L 0.2 0.09 Stock B1JORN1 –

11⁄2 (38.1) 2 (50.8) 240 300 39 (6.0) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1J2A1 B1J2AN1

13⁄4 (44.5) 11⁄2 (38.1) 240 150 22 (3.4) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1N1J1 B1N1JN1

5

⁄8 (15.9)

1

11⁄4 (31.8) 120 125 33 (5.1) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1E1E1 B1E1EN1

11⁄4 (31.8) 240 125 33 (5.1) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1E1E2 B1E1EN2

11⁄4 (31.8) 240 250 67 ①(10.4) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1E1E3 B1E1EN4

3 (76.2) 240 250 27 (4.2) 1 THINBAND–Type A or L 0.5 0.22 Stock STB1E3A2 B1E3AN2

3 (76.2) 240 300 33 (5.1) 1 THINBAND–Type A or L 0.5 0.22 Stock STB1E3A3 B1E3AN3

2 (50.8) 240 300 51 ①(7.9) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1G2A1 B1G2AK1

1 (25.4) 120 100 26 (4.0) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1J1A1 B1J1AN1

1 (25.4) 240 100 26 (4.0) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1J1A2 B1J1AN2

1 (25.4) 120 150 39 (6.0) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1J1A3 B1J1AN3

1 (25.4) 240 150 39 (6.0) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1J1A4 B1J1AN4

1 (25.4) 120 200 52 ①(8.0) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1J1A5 B1J1AN5

1 (25.4) 240 200 52 ①(8.0) 1 THINBAND–Type A or L 0.2 0.09 Stock STB1J1A6 B1J1AN6

11⁄4 (31.8) 240

11⁄2 (38.1)

11⁄2 (38.1) 120 250 43 (6.6) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1J1J3 B1J1JN3

11⁄2 (38.1) 240 250 43 (6.6) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1J1J4 B1J1JN4

11⁄2 (38.1) 120 275 48 ①(7.4) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1J1J5 B1J1JN5

11⁄2 (38.1) 240 275 48 ①(7.4) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1J1J6 B1J1JN6

11⁄2 (38.1) 240 300 52 ①(8.0) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1J1J7 B1J1JN7

11⁄2 (38.1) 240 200 43 (6.7) 1

21⁄2 (63.5) 240 400 42 (6.5) 1 THINBAND–Type A or L 0.5 0.23 Stock STB1J2J1 –

21⁄2 (63.5) 240 400 43 (6.7) 1

(76.2)

3

3 (76.2) 240 500 43 (6.7) 1 THINBAND–Type A or L 0.6 0.27 Stock STB1J3A2 B1J3AN2

3 (76.2) 240 800 69 a(10.7) 1 THINBAND–Type A or L 0.6 0.27 Stock STB1J3A3 B1J3AN3

4 (101.6) 240 600 39 (6.0) 1 THINBAND–Type A or L 0.6 0.27 Stock STB1J4A1 –

11⁄2 (38.1) 120 200 29 (4.5) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1N1J2 B1N1JN2

11⁄2 (38.1)

120 100 54

250 52

200

240

240 350 30 (4.6) 1 THINBAND–Type A or L 0.6 0.27 Stock

250

240

2

2

35

36

W/cm

(

①

①

pc. Special Features lbs (kg) Avail. No. Code No.

)

2

(8.4)

(8.0) 1

(5.4) 1 THINBAND–Type A or L 0.3 0.14 Stock

(5.6)

1 Mica Band–12 in. Type A 0.2 0.09 Stock

THINBAND–Type A or L 0.2 0.09 Stock

Mica Band–36 in. Black Glass 90° from Gap

Mica Band–36 in. Type C 90° from Gap

THINBAND–Type A or L 0.3 0.14 Stock

1

0.3 0.14 Stock B1J1JX1 –

0.5 0.23 Stock B1J2JC1 –

B1EOLA1

STB1J1E1 B1J1EN1

STB1J1J2

STB1J3A1

STB1N1J6

–

B1J1JN2

B1J3AN1

B1N1JN6

CCOONNTTIINNUUEEDD

a Watt density is above Watlow recommendations at some common molding temperatures.

16

Page 12

W A T L O W

W A T L O W

.O.B.: St. Louis, Missouri

Band Heaters

F

THINBAND Mica

Barrel and Nozzle

Stock Product List (Con’t)

Watt 1 pc. Approx.

I.D. Width Density or Terminals, Leads and Net. Wt. Code Former

in. (mm) in. (mm) Volts Watts

13⁄4 (44.5) 11⁄2 (38.1) 120 300 43 (6.7) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1N1J7 B1N1JN7

11⁄2 (38.1) 240 300 43 (6.7) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1N1J8 B1N1JN8

11⁄2 (38.1) 240 300 44 (6.8) 1

17⁄8 (47.6) 1 (25.4) 240 140 28 (4.3) 1 THINBAND–Type A or L 0.3 0.14 Stock STB1R1A1 B1R1AL1

2 (50.8) 11⁄2 (38.1) 120 300 42 (6.5) 1

11⁄2 (38.1) 240 300 42 (6.5) 1

21⁄8 (54.0) 1 (25.4) 120 200 34 (5.3) 1 THINBAND–Type A or L 0.3 0.14 Stock STB2C1A1 B2C1AN1

2 (52.8) 240 200 17 (2.6) 1 THINBAND–Type A or L 0.3 0.14 Stock STB2C2A1 B2C2AN1

21⁄4 (57.2) 17⁄8 (22.2) 120 215 43 (6.7) 1 Mica Band–Type A or L 0.3 0.14 Stock B2E0RN1 –

1 (25.4) 240 250 45 a(7.0) 1

2 (50.8) 240 525 47 a(7.3) 1

21⁄2 (63.5) 240 500 38 (5.9) 1

2 3⁄8 (60.3) 1 (25.4) 240 250 42 (6.5) 1

1 (25.4) 240 275 46 a(7.1) 1

21⁄2 (63.5) 1 (25.4) 240 300 47 a(7.3) 1

11⁄2 (38.1) 240 200 19 (2.9) 1 THINBAND–Type A or L 0.3 0.14 Stock STB2J1J1 B2J1JN1

11⁄2 (38.1) 120 300 31 (4.8) 1

11⁄2 (38.1) 240 300 31 (4.8) 1

11⁄2 (38.1) 120 350 37 (5.7) 1

11⁄2 (38.1) 240 350 37 (5.7) 1

23⁄8 (60.3) 240 550 39 (6.0) 1

27⁄8 (73.0) 240 650 38 (5.9) 1

21⁄2 (63.5) 4 (101.6) 240 850 32 (5.0) 1

5 (127.0) 240 1150 35 (5.4) 1

8 (203.2) 240 1800 33 (5.1) 1

23⁄4 (69.9) 11⁄2 (38.1) 240 400 34 (5.3) 1 THINBAND–Type A or L 0.4 0.18 Stock STB2N1J1 B2N1JN1

3 (76.2) 1 (25.4) 240 200 23 (3.6) 1 THINBAND–Type A or L 0.4 0.18 Stock STB3A1A2 B3A1AN1

1 (25.4) 240 250 29 (4.5) 1 THINBAND–Type A or L 0.4 0.18 Stock STB3A1A3 B3A1AN2

1 (25.4) 240 300 35 (5.4) 1 THINBAND–Type A or L 0.4 0.18 Stock STB3A1A4 B3A1AN3

1 (25.4) 240 300 38 (5.9) 1

1 (25.4) 240 350 44 (6.8) 1

(25.4)

1

11⁄2 (38.1)

11⁄2 (38.1) 240 400 32 (5.0) 1

11⁄2 (38.1) 240 450 36 (5.6) 1

11⁄2 (38.1) 120 500 40 (6.2) 1

11⁄2 (38.1) 240 500 40 (6.2) 1

(50.8)

2

(50.8)

2

21⁄2 (63.5) 240 650 33 (5.1) 1

(76.2) 240 750 30 (4.7) 1

3

240 400 50

120

240

240

600

500

600

W/in2(W/cm2)

a

(7.7)

a

47

(7.3)

(4.6) 1

30

(5.6)

36

2 pc. Special Features lbs (kg) Avail. No. Code No.

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

Mica Band–36 in. Type K w/sleeving

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

Mica Band–Post–T/C Hole at Gap

Mica Band–Post Terminals Only w/Strap

Mica Band–Post Terminals Only w/Strap

1

Mica Band–Post T

THINBAND–T

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

minals Only w/Strap

er

ype A or L

0.3 0.14 Stock B1N1JP5 –

0.3 0.14 Stock B2A1JP1 –

0.3 0.14 Stock B2A1JP2 –

0.3 0.14 Stock B2E1AP2 –

0.6 0.27 Stock B2E2AP1 –

0.6 0.27 Stock B2E2JK1 –

0.3 0.14 Stock B2G1AP2 –

0.3 0.14 Stock B2G1AP3 –

0.3 0.14 Stock B2J1AP2 –

0.4 0.18 Stock STB2J1J8 B2J1JP1

0.4 0.18 Stock STB2J1J9 B2J1JP2

0.4 0.18 Stock STB2J1J10 B2J1JP3

0.4 0.18 Stock STB2J1J11 B2J1JP4

0.6 0.27 Stock STB2J2G1 B2J2GP1

0.7 0.32 Stock STB2J2R1 B2J2RP1

1.0 0.45 Stock STB2J4A2 B2J4AP1

1.2 0.54 Stock STB2J5A3 B2J5AP1

2.0 0.91 Stock B2J8AP1 –

0.4 0.18 Stock B3A1AP1 –

0.4 0.18 Stock B3A1AP2 –

Stock

0.18

0.4

0.5 0.23 Stock

0.5 0.23 Stock STB3A1J1

0.5 0.23 Stock STB3A1J2 B3A1JP2

0.5 0.23 Stock STB3A1J3 B3A1JP3

0.5 0.23 Stock STB3A1J4 B3A1JP4

Stock

0.36

0.8

Stock

0.36

0.8

0.8 0.36 Stock STB3A2J7 B3A2JP1

0.46 Stock

1.0

B3A1AP4

STB3A1J6

STB3A2A1

STB3A2A2

STB3A3A18

–

B3A1JN2

B3A1JP1/C1

B3A2AP1

B3A2AP2

–

CCOONNTTIINNUUEEDD

Band Heaters

b

b

b

b

a Watt density is above Watlow recommendations at some common molding temperatures.

b Mica Band-Post-thermocouple hole at gap, THINBAND replacement does not include thermocouple hole at gap.

17

Page 13

Band Heaters

THINBAND Mica

Barrel and Nozzle

Stock Product List (Con’t)

Watt 1 pc. Approx.

I.D. Width Density or Terminals, Leads and Net. Wt. Code Former

in. (mm) in. (mm) Volts Watts

31⁄4 (82.6) 11⁄2 (38.1) 240 400 29 (4.5) 1

2 (50.8) 240 500 27 (4.2) 1

31⁄2 (88.9) 1 (25.4) 120 300 32 (5.0) 1 Mica Band–36 in. Type C 0.5 0.23 Stock B3J1AC1 –

11⁄2 (38.1) 120 400 27 (4.2) 1

11⁄2 (38.1) 240 500 33 (5.1) 1

2 (50.8) 240 650 33 (5.1) 1

21⁄2 (63.5) 240 750 30 (4.6) 1

3 (76.2) 240 750 25 (3.9) 1

33⁄4 (95. 3) 1 (25.4) 240 350 34 (5.3) 1

11⁄2 (38.1) 240 700 43 a(6.7) 1

2 (50.8) 240 600 28 (4.4) 1

21⁄2 (63.5) 240 850 33 (5.1) 1

3 (76.2) 240 900 28 (4.4) 1

4 (101.6) 1 (25.4) 240 625 55 a(8.5) 1

11⁄2 (38.1) 240 550 32 (5.0) 1

11⁄2 (38.1) 240 750 43 (6.5) 1

11⁄2 (38.1) 240 650 37 (5.7) 1

2 (50.8) 240 550 24 (3.7) 1

2 (50.8) 240 800 35 (5.4) 1

3 (76.2) 240 1000 29 (4.5) 1

41⁄4 (107.9) 11⁄2 (38.1) 240 550 30 (4.7) 1

2 (50.8) 240 700 28 (4.4) 1

3 (76.2) 240 900 24 (3.7) 1

41⁄2 (114.3) 1

43⁄4(120.7) 11⁄2 (38.1) 240 600 29 (4.5) 1

47⁄8 (123.8)

att density is above W

a W

b Mica Band-Post-ther

(25.4) 240 350 28 (4.3) 1

11⁄2 (38.1) 240 650 33 (5.1) 1

11⁄2 (38.1) 240 400 20 (3.1) 1

2 (50.8) 240 500 19 (2.9) 1

21⁄2 (63.5)

3 (76.2) 240 1200 30 (4.7) 1

11⁄2 (38.1) 480 600 29 (4.5) 1

11⁄2 (38.1) 240 650 31 (4.8) 1

(50.8)

2

(50.8)

2

3 (76.2) 240 1100 26 (4.1) 1

3 (76.2) 480 1100 26 (4.1) 1

1

1

⁄2 (38.1)

2 (50.8) 240 650 23 (3.6) 1

2 (50.8) 240 760 27 (4.2) 1

2 (50.8) 480 760 27 (4.2) 1

240

240

480

240

atlow r

mocouple hole at gap, THINBAND r

W/in2(W/cm2)

1000

800 29 (4.5) 1

800

900 42 (6.5) 1

ecommendations at some common molding temperatur

35 (5.4) 1

29

2 pc. Special Features lbs (kg) Avail. No. Code No.

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

Mica Band–Post Terminals Only w/Strap

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

Mica Band–Post Terminals Only w/Strap

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

minals Only w/Strap

(4.5)

Mica Band–Post Ter

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

eplacement does not include ther

0.5 0.23 Stock STB3E1J1 B3E1JP1

0.7 0.33 Stock STB3E2A41 –

0.5 0.23 Stock STB3J1J1 B3J1JP1

0.5 0.23 Stock STB3J1J2

0.7 0.32 Stock STB3J2A1 B3J2AP1

0.8 0.36 Stock STB3J2J1 B3J2JP1

1.1 0.54 Stock STB3J3A31 –

0.5 0.23 Stock B3N1AP1 –

0.6 0.27 Stock STB3N1J1 B3N1JP1

0.8 0.38 Stock STB3N2A17 –

1.0 0.45 Stock STB3N2J1 B3N2JP1

1.2 0.58 Stock STB3N3A5 –

0.7 0.32 Stock B4A1AP1 –

0.6 0.27 Stock STB4A1J1

0.6 0.27 Stock STB4A1J2 B4A1JP4

0.6 0.27 Stock STB4A1J3 B4A1JP3

0.8 0.36 Stock STB4A2A1 B4A2AP1

0.8 0.36 Stock STB4A2A2 B4A2AP2

1.2 0.58 Stock STB4A3A31 –

0.7 0.32 Stock STB4E1J13 –

0.8 0.36 Stock STB4E2A20 –

1.2 0.58 Stock STB4E3A9 –

0.6 0.27

0.7 0.32 Stock STB4J1J1

0.7 0.32 Stock STB4J1J2 B4J1JP1

0.9 0.41 Stock STB4J2A1 B4J2AP1

0.45

1.0

1.2 0.58 Stock STB4J3A26 –

0.7 0.32 Stock STB4N1J1 –

0.7 0.32 Stock STB4N1J2 –

0.7 0.32 Stock STB4N1J3 B4N1JP2

0.41

0.9

0.41

0.9

1.4 0.64 Stock STB4N3A12 –

1.4 0.64 Stock STB4N3A13 –

0.32

0.7

0.9 0.41 Stock STB4R2A1 B4R2AP1

0.9 0.41 Stock STB4R2A2 –

0.9 0.41 Stock STB4R2A3 –

es.

mocouple hole at gap.

Stock

Stock

Stock

Stock

Stock

B3J1JP3/P2

B4A1JP1/2

B4J1AP1 –

B4J1JP2/3

STB4J2J1

STB4N2A11

STB4N2A12

STB4R1J1

B4J2JC1

B4R1JP1

CCOONNTTIINNUUEEDD

–

–

18

Page 14

W A T L O W

W A T L O W

Band Heaters

THINBAND Mica

Barrel and Nozzle

Stock Product List (Con’t)

Watt 1 pc. Approx.

I.D. Width Density or Terminals, Leads and Net. Wt. Code Former

n. (mm) in. (mm) Volts WattsW/in

i

5 (127.0) 11⁄2 (38.1) 240 700 32 (5.0) 1

11⁄2 (38.1) 240 900 41 (6.4) 1

2 (50.8) 240 900 30 (4.65) 1

2 (50.8) 480 900 30 (4.65) 1

3 (76.2) 240 850 20 (3.1) 1

31⁄4 (82.6) 240 1250 26 (4.0) 1

1

51⁄8 (130.2)

51⁄4 (133.4) 1 (25.4) 240 500 33 (5.1) 1

51⁄2 (139.7) 11⁄2 (38.1) 240 800 33 (5.1) 1

53⁄4 (146.0) 11⁄2 (38.1) 240 750 29 (4.47) 1

6 (152.4) 11⁄2 (38.1) 240 600 22 (3.4) 1

61⁄4 (158.8) 2 (50.8) 240 1000 27 (4.2) 1

65⁄16 (160.3)

a

Watt density is above Watlow recommendations at some common molding temperatures.

1

⁄2 (38.1)

11⁄2 (38.1) 240 600 26 (4.0) 1

11⁄2 (38.1) 480 600 43 a(6.7) 1

11⁄2 (38.1) 240 1000 43 a(6.7) 1

2 (50.8) 240 1000 33 a(5.1) 1

3 (76.2) 240 1200 26 (4.08) 1

3 (76.2) 480 1200 26 (4.08) 1

11⁄2 (38.1) 240 900 37 (5.7) 1

2 (50.8) 240 1000 30 (4.65) 1

2 (50.8) 480 1000 30 (4.65) 1

3 (76.2) 240 1500 30 (4.65) 1

3 (76.2) 480 1500 30 (4.65) 1

2 (50.8) 240 1000 30 (4.65) 1

3 (76.2) 240 1500 30 (4.65) 1

3 (76.2) 480 1500 30 (4.65) 1

11⁄2 (38.1)

11⁄2 (38.1) 240 1000 37 (5.7) 1

2 (50.8) 240 1000 28 (4.31) 1

(50.8)

2

21⁄2 (38.1) 240 1450 34 (5.3) 1

(76.2) 240/480 1400 27 (4.2) 2 Mica Band–Post (2 on 1) 1.6 0.73 Stock

3

(76.2)

3

3 (76.2) 480 1400 26 (4.0) 1

3 (76.2) 240/480 1500 29 (4.5) 2 Mica Band–Post (2 on 1) 1.8 0.82 Stock B6E3AR1 –

3 (76.2) 240 1500 27 (4.2) 1

3 (76.2) 480 1500 27 (4.2) 1

(76.2)

3

3 (76.2) 480 1250 22 (3.4) 1

240 900 42

240 850 32 (5.0) 1

1000

480

1400

240

1250

240

2

2

W/cm

(

a

(4.31)

28

26 (4.0) 1

22

pc. Special Features lbs (kg) Avail. No. Code No.

)

2

(6.5)

(3.4)

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

Mica Band–72 in. (Type C-180° from 3⁄8" Gap)

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

0.7 0.32 Stock STB5A1J1

0.7 0.32 Stock STB5A1J2 B5A1JP3

0.9 0.41 Stock STB5A2A27 –

0.9 0.41 Stock STB5A2A28 –

1.4 0.64 Stock STB5A3A5 B5A3AP1

1.5 0.68 Stock STB5A3E1 B5A3ER1

0.32 Stock

0.7

0.7 0.32 Stock B5E1AC1 –

0.8 0.36 Stock STB5E1J1 B5E1JP1

0.8 0.36 Stock STB5E1J5 –

0.8 0.36 Stock STB5E1J2 B5E1JP3

0.9 0.41 Stock STB5E2A1 B5E2AP1

1.4 0.64 Stock STB5E3A14 –

1.4 0.64 Stock STB5E3A15 –

0.8 0.36 Stock STB5J1J1

0.8 0.36 Stock STB5J1J2 B5J1JP3

0.9 0.41 Stock STB5J2A23 –

0.9 0.41 Stock STB5J2A24 –

1.6 0.72 Stock STB5J3A19 –

1.6 0.72 Stock STB5J3A20 –

0.9 0.41 Stock STB5N1J17 –

1.0 0.46 Stock STB5N2A5 –

1.8 0.82 Stock STB5N3A8 –

1.8 0.82 Stock STB5N3A9 –

0.9 0.41 Stock STB6A1J1 B6A1JP1

0.41 Stock

0.9

0.9 0.41 Stock STB6A1J3 B6A1JP4

0.8 0.36 Stock STB6A2A36 –

Stock

0.36

0.8

1.5 0.68 Stock STB6A2J3 B6A2JP1

Stock

0.73

1.6

1.6 0.73 Stock STB6A3A2 –

1.0 0.46 Stock STB6E2A5 –

1.8 0.82 Stock STB6E3A1 –

1.8 0.82 Stock STB6E3A2 –

Stock

0.82

1.8

1.8 0.82 Stock STB6F3A2 –

STB5C1J2

STB6A1J2

STB6A2A37

B6A3AR1

STB6A3A1

STB6F3A1

CCOONNTTIINNUUEEDD

B5A1JP1/2

Band Heaters

B5C1JP1

B5J1JP1/2

B6A1JP2/3

–

–

–

–

19

Page 15

Band Heaters

THINBAND Mica

Barrel and Nozzle

Stock Product List (Con’t)

Watt 1 pc. Approx.

I.D. Width Density or Terminals, Leads and Net. Wt. Code Former

in. (mm) in. (mm) Volts Watts

61⁄2 (165.1) 11⁄2 (38.1) 240 900 31 (4.8) 1

11⁄2 (38.1) 240 950 33 (5.1) 1

2 (50.8) 240 1000 26 (3.9) 1

3 (76.2) 240 1400 24 (3.7) 1

3 (76.2) 480 1400 24 (3.7) 1

65⁄8 (168.3) 41⁄2 (114.3) 240 2300 26 (4.0) 1

63⁄4 (171.5) 11⁄2 (38.1) 240 1000 33 (5.1) 1

11⁄2 (38.1) 240 750 25 (3.9) 1

11⁄2 (38.1) 240 1150 38 (5.9) 1

2 (50.8) 240 1300 32 (5.0) 1

3 (76.2) 240 2000 33 (5.1) 1

3 (76.2) 480 2000 33 (5.1) 1

7 (177.8) 11⁄2 (38.1) 240 950 30 (4.6) 1

11⁄2 (38.1) 240 1100 35 (5.4) 1

2 (50.8) 240 1100 26 (4.1) 1

2 (50.8) 480 1100 26 (4.1) 1

3 (76.2) 230/460 1650 28 (4.3) 2 Mica Band–Post (2 on 1) 2.0 0.91 Stock B7A3AR1 –

3 (76.2) 230 1650 26 (4.0) 1

3 (76.2) 460 1650 26 (4.0) 1

71⁄4 (184.1) 11⁄2 (38.1) 240 1000 30 (4.7) 1

2 (50.8) 240 1200 27 (4.2) 1

(50.8) 480 1200 27 (4.2) 1

2

3 (76.2) 240 1800 27 (4.2) 1

3 (76.2) 480 1800 27 (4.2) 1

71⁄2 (190.5) 11⁄2

73⁄4 (196.8) 11⁄2 (38.1) 240 1000 29 (4.5) 1

8 (203.2) 11⁄2 (38.1) 240 950 26 (4.0) 1

att density is above W

a W

(38.1)

11⁄2

(38.1)

(50.8)

2

2 (50.8) 480 1200 27 (4.2) 1

3

(76.2)

3

(76.2)

11⁄2 (38.1) 480 1000 29 (4.5) 1

2 (50.8) 240 1300 28 (4.4) 1

2 (50.8) 480 1300 28 (4.4) 1

(76.2)

3

(76.2)

3

11⁄2 (38.1) 240 1200 33 (5.1) 1

11⁄2 (38.1) 480 1200 33 (5.1) 1

11⁄2 (38.1) 240 1400 39 a(6.0) 1

240 1000 30

240

240

240 1800 27

480

240 2000 29 (4.5) 1

480

ecommendations at some common molding temperatur

atlow r

W/in2(W/cm2)

1200

1200

1800 27

2000

35

27

29 (4.5) 1

2 pc. Special Features lbs (kg) Avail. No. Code No.

(4.6)

(5.4)

(4.2) 1

(4.2)

(4.2)

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

es.

0.9 0.41 Stock STB6J1J1

0.9 0.41 Stock STB6J1J2 B6J1P3

1.2 0.54 Stock STB6J2A1 B6J2AP1

1.8 0.82 Stock STB6J3A13 –

1.8 0.82 Stock STB6J3A14 –

2.8 1.27 Stock STB6L4J1 B6L4JR1

1.0 0.45 Stock STB6N1J1 B6N1JP2

1.0 0.45 Stock STB6N1J2 B6N1JP1

1.0 0.45 Stock STB6N1J3 B6N1JP3

1.3 0.59 Stock STB6N2A1

2.0 0.90 Stock STB6N3A7 –

2.0 0.90 Stock STB6N3A8 –

1.0 0.45 Stock STB7A1J1 B7A1JP1

1.0 0.45 Stock STB7A1J2 B7A1JP2

1.3 0.59 Stock STB7A2A16 –

1.3 0.59 Stock STB7A2A17 –

2.0 0.91 Stock STB7A3A1 –

2.0 0.91 Stock STB7A3A2 –

1.1 0.50 Stock STB7E1J9

1.5 0.65 Stock STB7E2A10

0.65 Stock

1.5

2.2 1.00 Stock STB7E3A3

2.2 1.00 Stock STB7E3A4

1.1 0.50

1.1

2.0

2.0 0.90 Stock STB7J2A14

2.4 1.08

2.4

1.2 0.58 Stock STB7N1J10 –

1.2 0.58 Stock STB7N1J11 –

2.1 0.95 Stock STB7N2A2 –

2.1 0.95 Stock STB7N2A3 –

2.3

2.3

1.1 0.50 Stock STB8A1J1 B8A1JP1

1.1 0.50 Stock STB8A1J2 B8A1JP2

1.1 0.50 Stock STB8A1J3 –

1.1 0.50 Stock STB8A1J4 B8A1JP4

0.50

0.90

1.08

1.10

1.10

Stock

Stock

Stock

Stock

Stock

Stock

Stock

STB7E2A11

STB7J1J1 B7J1JP1

STB7J1J2

STB7J2A13

STB7J3A1

STB7J3A2

STB7N3A22

STB7N3A23

CCOONNTTIINNUUEEDD

B6J1JP1/2

B6N2AP1/2

–

–

–

–

–

B7J1JP2

–

–

–

–

–

–

20

Page 16

W A T L O W

W A T L O W

Band Heaters

THINBAND Mica

Barrel and Nozzle

Stock Product List (Con’t)

Watt 1 pc. Approx.

I.D. Width Density or Terminals, Leads and Net. Wt. Code Former

in. (mm) in. (mm) Volts Watts

8 (203.2) 2 (50.8) 240 1500 30 (4.7) 1

2 (50.8) 480 1500 30 (4.7) 1

3 (76.2) 240/480 2250 33 (5.1) 2 Mica Band–Post (2 on 1) 2.6 1.18 Stock B8A3AR1 –

3 (76.2) 240 2250 31 (4.8) 1

3 (76.2) 480 2250 31 (4.8) 1

81⁄4 (209.6) 2 (50.8) 240 1500 30 (4.7) 1

(50.8) 480 1500 30 (4.7) 1

2

3 (76.2) 240 2000 27 (4.2) 1

3 (76.2) 480 2000 27 (4.2) 1

4 (101.6) 240/480 3000 31 (4.8) 2

4 (101.6) 240 3000 30 (4.6) 1

4 (101.6) 480 3000 30 (4.6) 1

81⁄2 (215.9) 11⁄2 (38.1) 240 1200 31 (4.8) 1

11⁄2 (38.1) 480 1200 30 (4.7) 1

2 (50.8) 240 1600 31 (4.8) 1

2 (50.8) 480 1600 30 (4.7) 1

3 (76.2) 240 2500 32 (5.0) 1 THINBAND-Post Terminals Only 2.4 1.10 Stock STB8J3A14 –

81⁄2 (215.9) 3 (76.2) 480 2500 32 (5.0) 1

83⁄4 (222.3) 11⁄2 (38.1) 240 1200 30 (4.7) 1

11⁄2 (38.1) 480 1200 30 (4.7) 1

2 (50.8) 240 1600 30 (4.7) 1

2 (50.8) 480 1600 30 (4.7) 1

3 (76.2) 240/480 2000 27 (4.2) 2 Mica Band–Post (2 on 1) 2.7 1.22 Stock B8N3AR1 –

3 (76.2) 240 2000 25 (3.9) 1

3 (76.2) 480 2000 25 (3.9) 1

1

(228.6)

9

91⁄2 (244.3) 2 (50.8) 240 1800 32 (5.0) 1

95⁄8 (244.5)

193⁄4 (247.7) 2 (50.8) 240 2000 34 (5.3) 1

10

101⁄4 (260.4) 4 (101.6) 240/480 3000 25 (3.9) 2

11 (279.4) 11⁄2 (38.1) 240 1600 32 (5.0) 1

12 (304.8) 2 (50.8) 240/480 2300 33 (5.1) 2

1

⁄2 (38.1)

11⁄2 (38.1)

11⁄2 (38.1) 480 1500 37 a(5.7) 1

2 (50.8) 240 1800 33 (5.1) 1

(50.8)

2

3 (76.2) 240 2500 30 (4.7) 1 THINBAND-Post Terminals Only 2.6 1.18 Stock STB9A3A18 –

3 (76.2) 480 2500 30 (4.7) 1

3 (76.2) 240 2000 23 (3.6) 1

(76.2)

3

(76.2)

3

3 (76.2) 480 3000 34 (5.3) 1

(254.0) 1

1

⁄2 (38.1)

2 (50.8) 240 2000 30 (4.6) 1

240

240

480 1800 33 (5.1) 1

480

240/480

240 1400 31 (4.8) 1

W/in2(W/cm2)

1300

1500

2000 23 (3.6) 1

3000

32

a

37

37 2

2 pc. Special Features lbs (kg) Avail. No. Code No.

(5.0) 1

(5.7)

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

Mica Band–Post Terminals Only w/Strap

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

1

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

minals Only w/Strap

Mica Band–Post T

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

Mica Band–Post Terminals Only w/Strap

THINBAND–All LA Options, except A or L

THINBAND–All LA Options, except A or L

Mica Band–Post Terminals Only w/Strap

er

1.5 0.65 Stock STB8A2A20 –

1.5 0.65 Stock STB8A2A21 –

2.6 1.18 Stock STB8A3A1 –

2.6 1.18 Stock STB8A3A2 –

2.3 1.10 Stock STB8E2A8 –

1.10 Stock

2.3

2.6 1.25 Stock STB8E3A10 –

2.6 1.25 Stock STB8E3A11 –

3.0 1.36 Stock B8E4AP1 –

3.0 1.36 Stock STB8E4A1 –

3.0 1.36 Stock STB8E4A2 –

1.2 0.55 Stock STB8J1J1 B8JIJP1

1.2 0.55 Stock STB8J1J21 –

1.6 0.73 Stock STB8J2A1 B8J2AP1

1.6 0.73 Stock STB8J2A12 –

2.4 1.10 Stock STB8J3A15 –

1.3 0.61 Stock STB8N1J10 –

1.3 0.61 Stock STB8N1J11 –

1.5 0.68 Stock STB8N2A10 –

1.5 0.68 Stock STB8N2A11 –

2.7 1.22 Stock STB8N3A1 –

2.7 1.22 Stock STB8N3A2 –

Stock

0.59

1.3

Stock

0.59

1.3

1.3 0.59 Stock STB9A1J3 –

1.5 0.68 Stock STB9A2A1 B9A2AP1

Stock

0.68

1.5

2.6 1.18 Stock STB9A3A19 –

1.7 0.77 Stock STB9J2A1 B9J2AP1

2.8 1.27 Stock STB9J3A1 –

Stock

1.27

2.8

Stock

1.22

2.7

2.8 1.27 Stock STB9L3A4 –

1.9 0.86 Stock STB9N2A1 B9N2AP1

0.68 Stock

1.5

3.9 1.77 Stock B10E4AP1 –

1.7 0.77 Stock STB11A1J1

2.1 0.95 Stock STB11A2A1

2.3 1.04 Stock B12A2AP2 –

STB8E2A9

STB9A1J1

STB9A1J2

STB9A2A20

STB9J3A2

B9L3AP2

STB10A1J1

Band Heaters

–

B9A1JP1

B9A1JP2

–

–

–

B10A1JP1

B11A1JP1

B11A2AP1

att density is above W

a W

ecommendations at some common molding temperatures.

atlow r

21

Page 17

Band Heaters

THINBAND Mica

Barrel and Nozzle

How to Order

To order stock THINBAND or

standard mica band, specify:

• Watlow code number

• Termination type(s)

• Lead lengths

• Quantity

Notes:

Post terminals are provided

•

unless otherwise specified.

• On Types A, L and K, 12 inches

(305 mm) in lead length will be

supplied unless otherwise

specified.

• On Types E, C, F and H, 14

inches (356 mm) in lead length

will be supplied unless otherwise

specified.

• On Types A, E, C, F and H, leads

will be two inches (51 mm) longer

than the protective covering

unless otherwise specified.

• All LA termination options will

be 180 degrees from the gap

unless otherwise specified.

• Stock LA termination options

can only be supplied with LA

termination 180 degrees from the

gap.

• For THINBAND heaters higher

than 8.5 amps, consult Watlow.

Availability

• Stock: Same day shipment

• Made-to-Order: If our stock units

do not meet your application

needs, Watlow can manufacture to

your special requirements. Please

consult your sales engineer or

authorized distributor for price and

delivery of made-to-order items.

22

Loading...

Loading...