Page 1

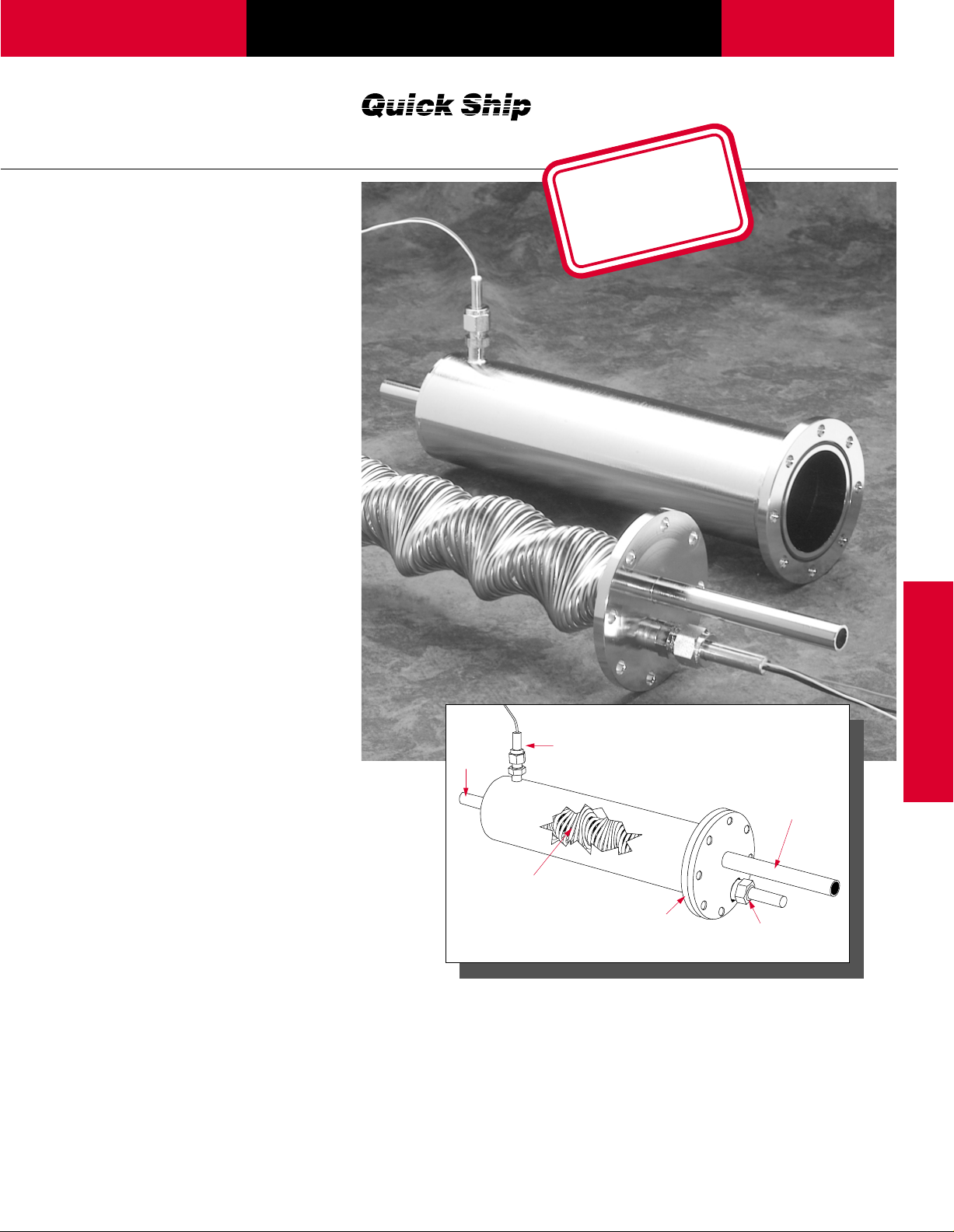

Cable Heaters

NEW

PRODUCT

STARFLOW

Circulation Heater

Throughout many steps in the

semiconductor manufacturing

process, Watlow cable circulation

heaters help to improve process time

and operating efficiency. Using

clean, hot gases reduces wafer

drying time. Flameless dry heat

efficiently solders and desolders

electronic circuits and boards.

Heated gas streams quickly dry and

cure circuit boards without using a

large baking oven, saving precious

floor space. Watlow’s STARFLOW

circulation heater is specifically

designed to meet the requirements of

these applications.

The STARFLOW circulation heater is

engineered to heat a flowing gas

stream up to temperatures of 1400°F

(760°C). The 316L stainless steel

chamber houses a small diameter

sheathed element, which allows for

quick response to both heat up and

cool down cycles. Watlow’s

starwound coiled cable heater

provides extremely efficient and

reliable heating by maximizing the

contact area of the gas or fluid with

the element.

Because the element is sheathed, the

unit can operate in gas streams that

require a clean environment as well

as atmospheres that contain contaminants and moisture. This provides

superior performance compared to

units with internally exposed or open

element wires.

Features and Benefits

• Small diameter heater allows for

quick response times.

• Internal star wound heater

element provides fast, efficient

heating.

• Sheathed element can run in

clean or impure streams.

• Flexibility in configurations allows

for adaptablity to any process.

• 316L stainless steel construction

is rugged and corrosion resistant.

W A T L O W

• One to three day

shipment.

Process

Outlet

Tube

Cable

Circulation

Heater

• Electropolishing available on all

wetted surfaces to reduce

particulate contamination.

• Thermocouple Type J or K

options provide precise control

and high limit safety.

• Replaceable thermocouple and

heating element reduces

replacement costs.

Thermocouple

Fitting

O-Ring Groove

• Shipment from stock reduces

downtime.

Applications

• Semiconductor processing

• Curing and drying

• Electronics

• Heat shrinking

• Thermal forming/sealing

Cable Heaters

Inlet Tube

Heater Adaptor

Exit

69

Page 2

Cable Heaters

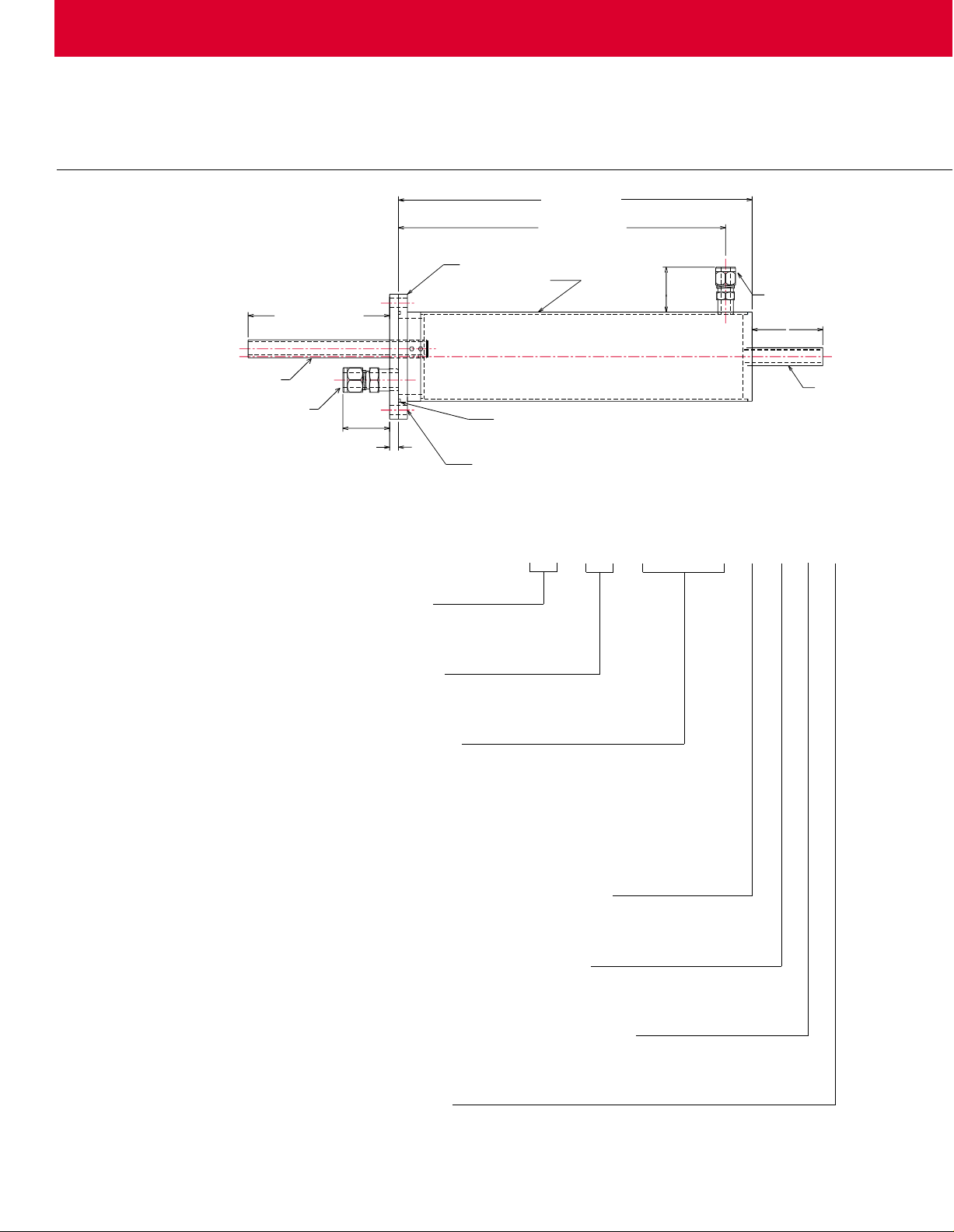

10.00'' (254 mm)

9.25'' (234.95 mm)

Process T/C Fitting

2.00'' (50.80 mm)

Outlet Tube

O-Ring Groove

ø3.00'' (76.20 mm) B.C.

(8) :

1

/4-20 Threads

4.00'' (101.60 mm)

1.32'' Ref.

(33.63 mm)

Heater Adapter Exit

Inlet Tube

0.25''

(6.35 mm)

ø.3.50''

(88.90 mm)

ø.2.50''

(63.50 mm)

1.26'' Ref.

(32.51 mm)

STARFLOW

Circulation Heater

Ordering Information

123456 7891011121314

CH

3-4. Type of Inlet

ET =1⁄4" (6.35 mm) O.D. tube

JT =1⁄2" (12.7 mm) O.D. tube

F.O.B.: St. Louis, Missouri

———— ————————

Availability

Consult a Watlow sales engineer or

the St. Louis facility for availablity of

custom manufactured products.

Aflas®is a registered trademark of the

Asahi Glass Co., Ltd.

Viton®and Teflon®are registered trademarks

of E.I. du Pont de Nemours & Company.

70

5-6. Type of Outlet

ET =1⁄4" (6.35 mm) O.D. tube

JT =1⁄2" (12.7 mm) O.D. tube

7-10. Heater Wattage

0375 = 120V 375W

0500 = 120V 500W

0750 = 120V 750W

1500 = 240V 1500W

2000 = 240V 2000W

3000 = 240V 3000W

11. Internal Thermocouple Calibration (Heater)

J = Type J

K = Type K

12. Surface Finish of Assembly and Heater

X = Unfinished

E = Electropolished

13. Process Thermocouple Calibration (Assembly)

J = Type J

K = Type K

14. O-Ring Material

A = Viton®(500°F/260°C)

F = Aflas®(446°F/230°C)

T = Teflon

®

encapsulated Viton®(392°F/200°C)

Loading...

Loading...