Watlow SSR-240-10A-DC1, SSR-240-25A-DC1, SSR-240-50A-DC1, SSR-240-10A-AC1, SSR-240-25A-AC1 Specifications

...Page 1

Solid State Relay

Solid State Relay Offers

More For Less: Longer

Heater Life at Lower Cost

®

Watlow

advantages of solid state power controllers, yet at a lower

cost. Watlow’s extensive knowledge in power controller

design has led to the development of a special fast cycle

input card that enables a SSR to operate from a standard

4-20mA instrumentation command signal. Test results

have shown that a zero cross SSR in combination with the

fast cycle card promotes better temperature control and

longer heater life than slow cycle relays. Through a time

proportional cycle rate of one tenth of a second heater life

will be extended.

Both low and high voltage models are available from

24 up to 530VAC. All ac output models include back to back

Silicon Controlled Rectifiers (SCRs) for a more rugged design

than the traditional triac based SSR. The internal design

allows it to handle high currents and the harsh electrical

environments of heavy industry. Watlow also offers a

switched VDC model for dc heating applications.

Watlow can provide all the components necessary

for trouble-free operation. This includes two standard

convenience items: a thermal foil to ensure proper thermal

transfer from the relay to the heat sink and belville washers

that ensure the relay is mounted with sufficient pressure for

good heat transfer. Matched semiconductor fuses and heat

sinks are available to complete the power switching package.

solid state relays (SSR) offer many of the

Features and Benefits

Fast cycle card

• Increases heater life

• Optimizes temperature control

• Allows for higher watt density heaters

Zero cross firing

• Results in minimal electrical noise

Back-to-back SCR design

• Withstands harsh or hostile industrial environments

UL® recognized File #E151484 and #E73741;

CSA certified File #LR700195; VDE 60950

License #40021401, File #1995500 up to 480VAC

• Meets applications requiring agency approval

© 2013 Watlow Electric Manufacturing Company

WIN-SSR-0413

Page 2

Specifications

07

Load Current (Amperes)

Specifications Standard To All SSRs:

Dielectric Strength (Volts) 4000 RMS

Input, DC Control

Voltage range 3-32VDC

Typical input current 3.4 to 20mA

Turn on voltage (max.) 3VDC

Turn off voltage (min.) 1VDC

Input, AC Control

Voltage range 90-280VAC

Typical input current 2mA (typical) @ 120VAC

4mA (typical) @ 240VAC

Turn on voltage (max.) 90VAC

Turn off voltage (min.) 10VAC

AC Output (Max.)

Forward voltage drop 1.5VAC and 2.1VDC

Min. holding current (mA) 50mA

Turn on-off time (ms) up to 10ms (max.)

Frequency range 47 to 63Hz

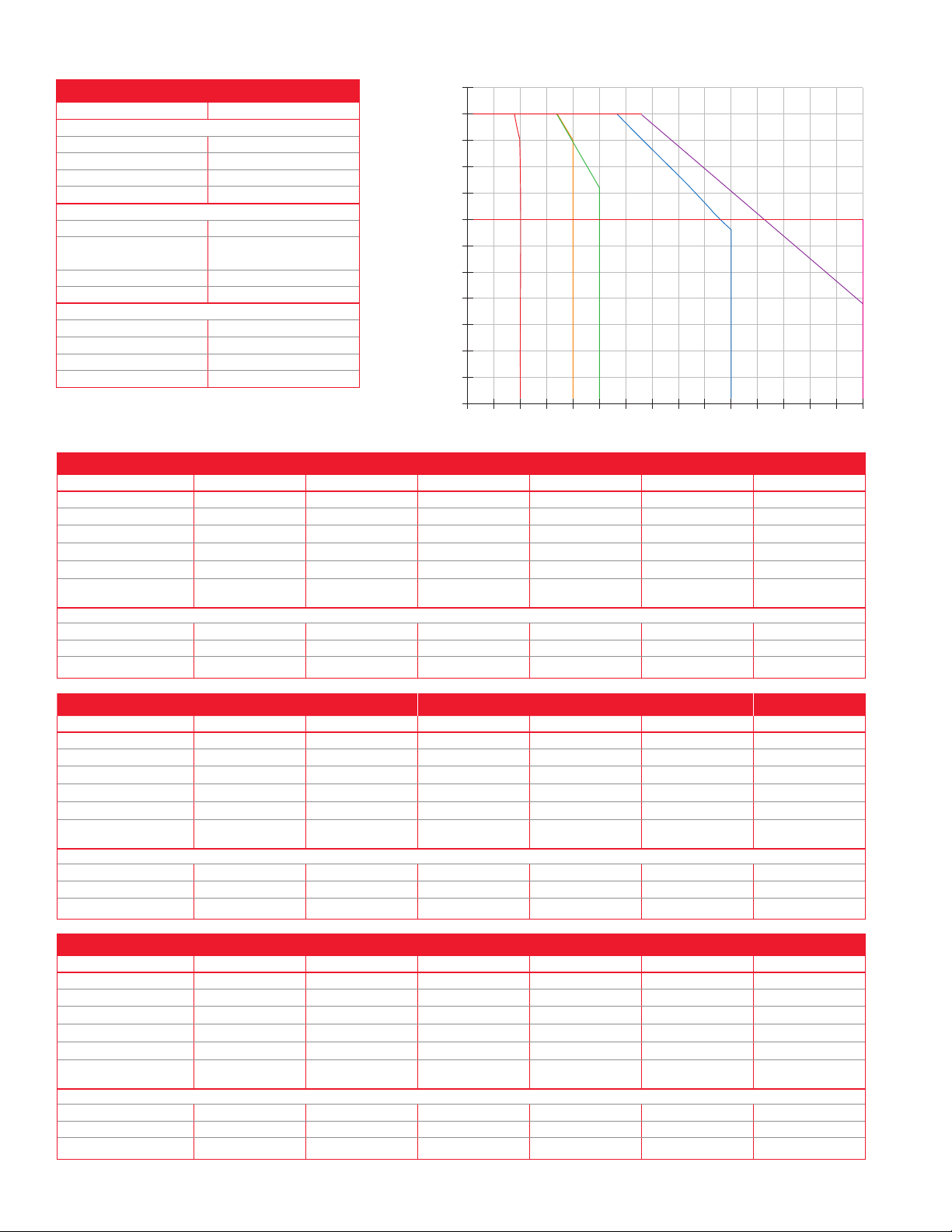

Ambient Temperature Operating Curve

85

80

75

70

65

60

55

50

45

Ambient temperature inside enclosure

3 inches left or right of the heatsink (ºC)

40

35

30

25

SSR-240-10A-XXX and Z100-0815-000A Heatsink

51015202530354045505560657

SSR-XXX-25A-XXX and Z100-0815-000B Heatsink

SSR-100-20A-DC1 and Z100-0815-000B Heatsink

SSR-XXX-75A-XXX and Z100-0815-000C Heatsink

SSR-XXX-50A-XXX and Z100-0815-000C Heatsink

SSR-XXX-75A-XXX and

Z100-0815-XXFC Heatsink

120/240VAC

Model Number

Current output 10A 25A 50A 10A 25A 50A

Nominal voltage 120/240VAC 120/240VAC 120/240VAC 120/240VAC 120/240VAC 120/240VAC

One cycle surge current 120A 250A 625A 120A 250A 625A

2

Max. I

t for fusing 60A2 seconds 260A2 seconds 1,620A2 seconds 60A2 seconds 260A2 seconds 1,620A2 seconds

Thermal resistance 1.48° C/W 1.05° C/W 0.63° C/W 1.48° C/W 1.05° C/W 0.31° C/W

Ambient operating

temperature

Output (Max.)

Voltage range 48-280VAC 48-280VAC 48-280VAC 48-280VAC 48-280VAC 48-280VAC

Over voltage rating 600V (peak) 600V (peak) 600V (peak) 600V (peak) 600V (peak) 600V (peak)

Off state leakage 10mA 10mA 10mA 10mA 10mA 10mA

SSR-240-10A-DC1 SSR-240-25A-DC1 SSR-240-50A-DC1 SSR-240-10A-AC1 SSR-240-25A-AC1 SSR-240-50A-AC1

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

5

120/240VAC Random Fired Models 100VDC

Model Number

Current output 75A 75A 50A 75A 10A 20A

Nominal voltage 120/240VAC 120/240VAC 480VAC 480VAC 120/240VAC 100VDC

One cycle surge current 1000A 1000A 625A 1000A 120A 42A (10ms)

2

Max. I

t for fusing 6000A2 seconds 6000A2 seconds 1,620A2 seconds 6000A2 seconds 60A2 seconds N/A

Thermal resistance 0.31° C/W 0.31° C/W 0.63° C/W 0.31° C/W 1.48° C/W 1.06° C/W

Ambient operating

temperature

Output (Max.)

Voltage range 48-280VAC 48-280VAC 80-530VAC 80-530VAC 48-280VAC 0-100VDC

Over voltage rating 600V (peak) 600V (peak) 1200V (peak) 1200V (peak) 600V (peak) N/A

Off state leakage 10mA 10mA 10mA 10mA 10mA 0.3mA VDC

SSR-240-75A-DC1 SSR-240-75A-AC1

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

SSR-480-50A-

-40 to 176°F

(-40 to 80°C)

RND

SSR-480-75A-

-40 to 176°F

(-40 to 80°C)

RND

SSR-240-10A-

-40 to 176°F

(-40 to 80°C)

RND SSR-100-20A-DC1

-4 to 176°F

(-20 to 80°C)

480 VAC

Model Number

Current output 25A 50A 75A 25A 50A 75A

Nominal voltage 480VAC 480VAC 480VAC 480VAC 480VAC 480VAC

One cycle surge current 250A 625A 1000A 250A 625A 1000A

2

Max. I

t for fusing 260A2 seconds 1,620A2 seconds 6,000A2 seconds 260A2 seconds 1,620A2 seconds 6,000A2 seconds

Thermal resistance 1.02° C/W 0.63° C/W 0.31° C/W 1.02° C/W 0.63° C/W 0.31° C/W

Ambient operating

temperature

Output (Max.)

Voltage range 48-530VAC 48-530VAC 48-530VAC 48-530VAC 48-530VAC 48-530VAC

Over voltage rating 1200V (peak) 1200V (peak) 1200V (peak) 1200V (peak) 1200V (peak) 1200V (peak)

Off state leakage 10mA 10mA 10mA 10mA 10mA 10mA

SSR-480-25A-DC1 SSR-480-50A-DC1 SSR-480-75A-DC1 SSR-480-25A-AC1 SSR-480-50A-AC1 SSR-480-75A-AC1

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

-40 to 176°F

(-40 to 80°C)

Page 3

Heater Life

Temp

Watlow has extensively tested electric heating elements with

a variety of power switching devices. Results prove that the

life of an electric element dramatically increases when the

on-off cycle time that is used to time-proportion the heater

is kept at less than one second. This reduces the thermal

expansion and contraction of the element and improves

heater life as much as 20 times. This very fast cycle time

controls temperature much more accurately and allows the

use of higher watt density heating elements.

Fast Cycle Card

In order to obtain the very rapid cycling time required for

longer heater life, accurate temperature control and higher

watt densities, Watlow has developed a loop-powered

firing card for SSRs. This card operates from a standard

instrumentation signal of 4 to 20mA and controls solid state

relays with a time proportional cycle rate of less than one

second (4VAC cycles on and 4VAC cycles off at 50 percent

power).

Thermal Transfer

A thermal foil is provided with each solid state relay for

mounting on the base of the relay to improve heat transfer.

In addition, two belville washers are supplied to provide

the proper pressure for this transfer of heat. Use two #8-32

screws 0.625 in. (16 mm) long to secure the relay to

the heat sink.

Replacing Contactors or Mercury Displacement Relays (MDRs)

Improvements in heater life and control accuracy can be

achieved with SSRs operated with rapid cycle times as

compared to slower operating electromechanical relays or

even MDRs. When replacing these types of relays with the

SSR, it is important to consider two aspects:

1. Heat

Solid state devices require a small voltage to turn

on, which is consumed as heat (approx. 1.5 volts x

amps = watts). This heat must be removed from the

device and is usually accomplished by mounting the

relay on a heat sink.

2. Failure Mode

Solid state devices should last for many years

when properly protected with voltage snubbers,

mounted on appropriate heat sinks and when fused

with semiconductor fuses against the high currents

caused by electrical shorts. Watlow’s SSRs include

an internal voltage snubber. However, if the unit

fails, the most probable condition will be a short.

Mechanical relays also have a good probability of

failing short. In all cases where uncontrolled full power

can cause damage, it is recommended that a high

limit temperature controller and contactor be used for

protection.

Wiring Diagrams

Single-Phase Fast Cycle Input Card

Control

Input

4-20

mA VDC

Output

L1

L2

Fuse

Shorted SSR Alarm

The most prevalent concern when using solid state relays is

the possibility of a relay failing in a shorted condition. With

this in mind, Watlow has designed a cost effective “Shorted

SSR Alarm”.

The device monitors the output (current through the heater)

and activates a triac (alarm) if there is no command signal

from the temperature controller. The triac can be wired to a

bell, or to a normally closed latching relay to remove power

to the heater.

The shorted SSR alarm is not a substitute for an

agency-approved high-temperature limit device.

Single-Phase Shorted SSR Detector

L1

L2

Temp

Control

Open

Collector

Contactor

Note: Semiconductor power switching devices are not legal

for over temperature limit or safety devices. For limit and

safety devices you must have a positive mechanical break of

all electrically hot legs simultaneously.

Card

+-

DC

SSR

Thermocouple

Solid

State

Relay

D.C.

-+

0 and

5VDC

on-off

Relay

Heater

Transformer

Shorted SSR

Detector

Heater

Mounted

Current

Page 4

F

Dimensions - Heat Sink

E

47.8 mm

C

(1.88 in.)

A

B

Drilled and

Tapped 8-32

D

F

Dimensions - Solid State Relay

4.8 mm

(0.19 in.)

47.63 mm

(1.875 in.)

4.37 mm

(0.172 in.) Dia.

2 Places

3 mm

(0.12 in.)

44.5 mm

(1.75 in.)

28 mm

(1.1 in.)

13.5 mm

(0.53 in.)

25 mm

(1 in.)

8 mm

(0.3 in.)

43 mm

(1.7 in.)

19.6 mm

(0.77 in.)

Thread

57.2 mm

(2.25 in.)

6-32 Thread

23 mm

(0.9 in.)

Case Temp.

8-32

Ref. Point

Heat Sink Dimensions by Part Number

Dimensions

Code Number Descriptor

in. (mm)

Z100-0815-000A 18A N/A 1.8 (46) 3.25 (82.6) 3.7 (94) N/A 1.9 (48)

Z100-0815-000B 35A 1.91 (48.5) 3.2 (81) 3.25 (82.6) 3.7 (94) 1.81 (46) 2.9 (74)

Z100-0815-000C 55A 1.89 (48) 3.2 (81) 5.45 (138.4) 5.89 (149.6) 1.81 (46) 3.6 (91)

Z100-0815-XXFC* 75A 1.89 (48) 3.2 (81) 5.45 (138.4) 7.16 (181.9) 1.81 (46) 3.6 (91)

*Fan cooled

A

B

in. (mm)

C

in. (mm)

D

in. (mm)

E

in. (mm)

F

in. (mm)

Ordering Information

Part Number

①

③

②

⑤④⑥

Voltage

SSR

-

⑤④⑥

100 =

0 to 100VDC (20A model only)

240 =

24 to 240VAC

480 =

24 to 530VAC

⑦

⑧

10 =

10A

20 =

20A (100VDC model only)

25 =

25A

40 =

40A

50 =

50A

75 =

75A

⑩ ⑪ ⑫

DC1 =

AC1 =

RND =

3 to 32VDC (see specifications)

90 to 280VAC

3 to 32VDC (10, 50 and 75A models only)

⑦

⑧

Current

- -

Voltage

Current

Control Voltage

⑨

A

Note: Relay will also include thermal foil, two belville washers and

#8-32 screws for mounting to a heat sink.

⑩ ⑪ ⑫

Control

Voltage

Heat Sinks (sold separately)

Z100-0815-000A =

Z100-0815-000B =

Z100-0815-000C =

Z100-0815-12FC =

Z100-0815-24FC =

18A or 2.2°C/watt

35A or 1.1°C/watt

55A or 0.6°C/watt

75A or 0.16°C/watt (120VAC fan)

75A or 0.16°C/watt (240VAC fan)

Fast Cycle Input Card and Shorted SSR Alarm Card

For direct mounting on zero cross dc input solid state relay.

RPC-5399-42-000 =

RPC-5386-0000 =

Fast cycle input card, 4 to 20mA input

Shorted SSR alarm card

Sub Cycle Fuses - I2T (sold separately)

Recommended and available with holders.

®

Watlow

is a registered trademark of Watlow Electric Manufacturing

Company.

UL® is a registered trademark of Underwriter’s Laboratories, Inc.

To be automatically connected to the nearest North American Technical Sales Office:

1-800-WATLOW2 • www.watlow.com • inquiry@watlow.com

International Technical Sales Offices: Australia, +61 3 9335 6449 • China, +86 21 3532 8532 • France, +33 1 41 32 79 70

Germany, +49 (0) 72 53 / 94 00-0 • India, +91 40 6661 2700 • Italy, +39 024588841 • Japan, +81 3 3518 6630 • Korea, +82 2 2628 5770

Malaysia, +60 3 8076 8745 • Mexico, +52 442 217 6235 • Singapore, +65 6773 9488 • Spain, +34 91 675 12 92

Taiwan, +886 7 288 5168 • United Kingdom, +44 (0) 115 964 0777

Loading...

Loading...